2016—2017斯图加特大学ICD/ITKE研究展亭

(德)阿希姆·蒙斯 (德)贾恩·尼珀斯

由斯图加特大学的计算设计与施工研究所(ICD)和建筑结构与结构设计研究所(ITKE)联合设计与建造的研究展亭已于近日完成,展亭由玻璃和碳纤维复合材料建造而成。这种新的建造工艺充分利用纤维结构独一无二的功能和特性,由于这些材料质轻且具有较高的抗拉强度,因此可采用一种完全不同的方法进行制造—使用低有效载荷的远程机器,如功能强大精准,但到达范围有限的工业机器人—无人机(UAV)。这种协作理念为实现长跨度光纤复合结构提供了可扩展制造的可能。该研究建立在一系列成功建成的展亭之上,综合了计算设计、工程和制造等学科,并探讨了展亭的空间影响和施工可能性。该项目由学生、研究人员及一个由建筑师、工程师和生物学家组成的跨学科团队设计和建造。

轻型长跨度纤维结构

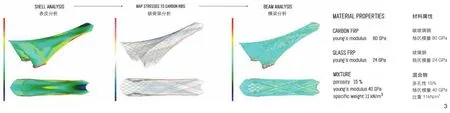

1 具有2个机器人手臂和无人机的多机器制造设备Multi-machine fabrication set up utilizing two robotic arms and an autonomous drone

纤维复合材料在建筑领域中有着巨大的发展潜力。由于其性能特征,纤维复合材料易运用于高度工程化的设计中,如汽车和航空航天工业等领域,但在建筑设计中,该材料的应用潜力仍等待着人们去探索。在建筑规模生产中,材料的自重是较大跨度结构设计的关键,而轻质纤维复合材料有着无与伦比的性能优势,但目前仍缺乏成熟的纤维复合材料制造工艺,难以满足建筑自身和设计行业所需的设计自由度以及系统适应性。传统的制造方法需要全尺寸的表面模具,并且通常为同一部件的序列化生产。ICD和ITKE在前期研究中,已经对纤维复合材料的结构进行了探索,不再需要表面模具或昂贵的样板。这些新颖的制造工艺已被用于建造高度差异化的多层结构、功能集成的建筑系统及大型元件组件,同时这些相对可塑的材料已不再受传统纤维复合材料制造工艺的限制。然而早期的调查显示,建造规模仍受到工业机器人的手臂工作空间限制。2016—2017ICD/ITKE研究展亭的研究目标是提出一个可扩展的制造过程,并通过开发长跨度连续纤维结构的制造工艺来测试未来这项技术在建筑结构应用中的可能性。

2 2种“潜叶虫”蚕及其显微图像,演示可见其体积结构、纤维层次和方向性Two species of leaf miner moths and their microscopic image,illustrating volumetric structure, fiber hierarchy and directionality2-1 “潜叶虫”蚕Lyonetiaprunifoliell, "Apple Leaf Miner" cocoon

2-2 “潜叶虫”蚕Leucopteraerythrinella, Leaf miner cocoon

2-3 展现“潜叶虫”蚕体积结构的显微图像Microscopic image of "Apple Leaf Miner" cocoon,illustrating volumetric structure

2-4 展现“潜叶虫”蚕纤维层次和方向性的显微图像Microscopic image of "Apple Leaf Miner" cocoon,illustrating fiber hierarchy and directionality

过程仿生学调查

该项目的关键点有二:自下而上的平行设计策略,用于长跨度纤维复合结构的自然建造过程的仿生学研究;纤维增强聚合物结构的创新型机器人制造方法的发展。研究期望开发一种更大跨度的纤维缠绕技术,从而将所需的模板最小化,同时充分利用连续纤维的结构性能。为此,项目团队和进化与生态学研究所(Institute of Evolution and Ecology)及图宾根大学古生物学系(The Department for Paleobiology of the University of Tübingen) 进行了合作,对自然轻型结构的功能原理和建造逻辑进行了分析和抽象处理。研究确定了2种潜叶蛾,它们的幼虫会在弯曲叶片的连接点之间吐丝形成“吊床”,这种结构的形态和程序原理极有可能被模拟,从而运用到长跨度纤维的制造中。研究人员从生物学模型中抽象出几个概念用于纤维材料的制造,包括:弯曲活性子结构和无芯缠绕纤维增强件的组合,该组合结构用以产生整体复合缠绕框架;长跨度结构上的纤维取向和层次结构;多级体积纤维铺设工艺,用于生成复杂的三维几何形状。

多机操作的物理网络建造系统

创建一个超出标准设备制造工作空间的长跨度结构,需要一个协作式的安装设备—多个机器人系统可以在这里完成对接和通信,从而进行无缝的纤维铺设过程。纤维可以在多台机器之间传递,以确保材料结构的连续性。制造过程依托范围有限、功能强大而精确的固定式机器与精度有限的移动式远程机器之间的完美配合。在具体的建造过程中,2个固定式工业机器人手臂位于结构的末端,保证了纤维缠绕工作所需的强度和精度,而纤维的传递工作依靠定制的无人机,通过不太精确但可自主远距离传递的纤维运输系统完成。结合无人机和机器人的自由性与适应性,使纤维铺设成为可能,并开发出单独使用机器人或无人机进行材料安排和结构性能探索的创新性方法。

项目开发并使用了自适应的控制和通信系统,使得多个工业机器人和无人机在整个纤维缠绕和铺设过程中相互作用。集成传感器接口使得机器人和无人机能够在制造过程中进行实时调整,以适应环境变化。无人机可自主飞行,不需要人为控制。由于无人机和机器人的作用,纤维的张力得到了有效的适应性控制。同时,利用定位系统在机器人和无人机之间创建了一个数字物理“握手”程序,以完成整个缠绕过程中的纤维传递。一系列自适应行为和集成传感器装置为开发多机操作,并用于大规模纤维复合材料生产的新型物理网络制造工艺奠定了基础。

总体介绍

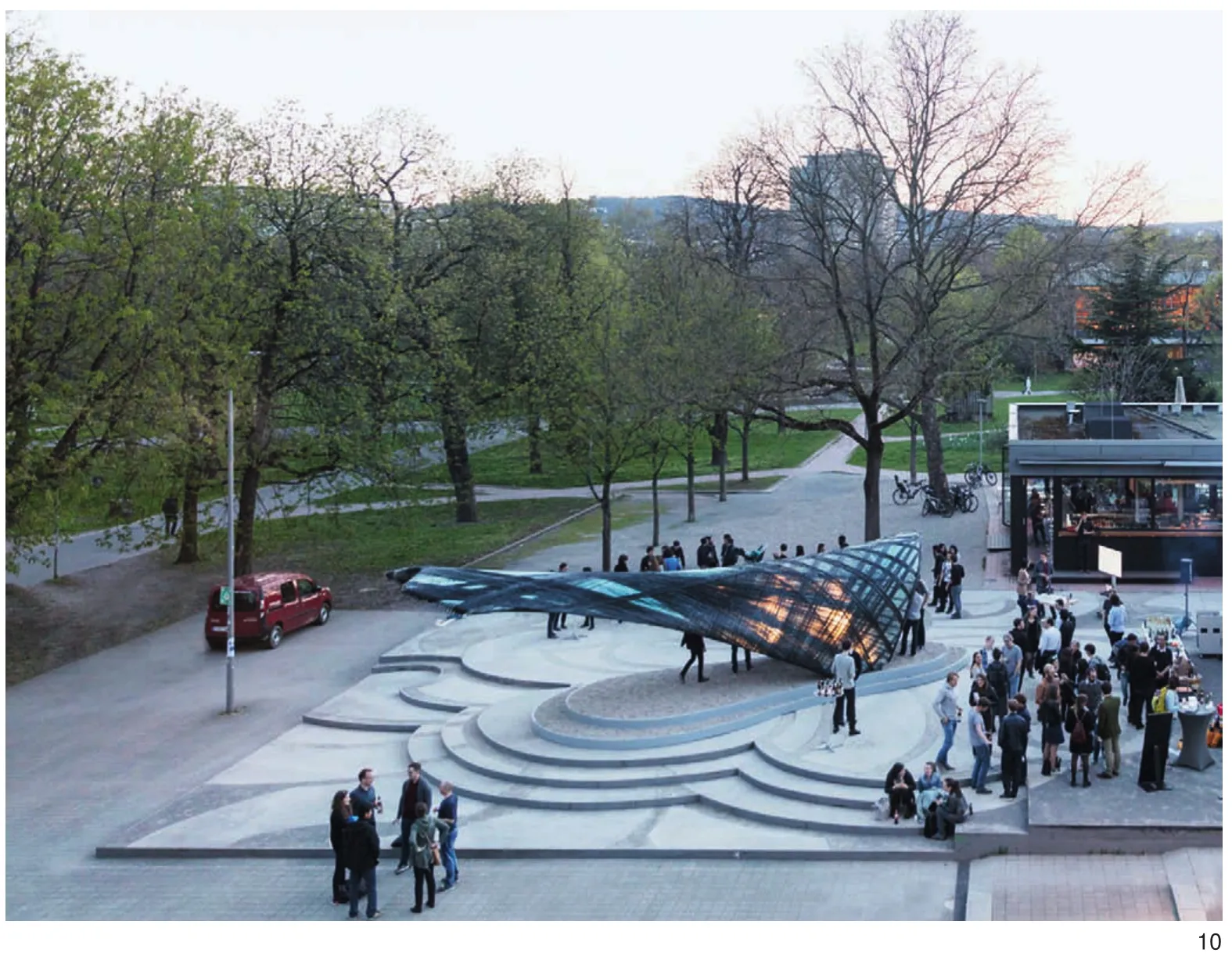

2016—2017ICD/ITKE研究展亭是由184km长的树脂—浸渍玻璃和碳纤维制成的,采用轻质材料系统创建了一个总长度为12m的长跨度悬臂梁,表面积约40m2,重量约1 000kg。由于这个结构是非现场制造的,因此尺寸被限定在可运输范围内。经研究发现,该装置更适合在现场或原位制造,这样便可达到更长的跨度和创造出更大的纤维复合结构。

研究展亭的整体几何结构验证了通过多级体积纤维缠绕法制造结构形态的可能性,该方法通过集成的可活动弯曲复合框架减少了不必要的模板,并通过机器人和自主轻型无人机制造工艺提高了施工的规模和跨度。研究探索了未来的结构构建模式,包括分布式、协作式和自适应性系统。该研究将结构性能、材料特征、建造逻辑、生物原理和建筑设计等方面结合纳入综合计算设计与建构中,深入挖掘了计算设计与施工的潜力。这个典型性展亭向我们证明,可扩展的长跨度纤维复合结构的制造工艺可应用于建筑领域。

3 展亭结构发展过程图Diagram of Research Pavillion structural development process

4显示内应力轨迹的结构模拟图Diagram of structural simulation showing internal stress trajectories

(编辑/张雯娟)

项目团队:计算设计与施工研究所(ICD)—阿希姆·蒙斯教授,建筑结构与结构设计研究所(ITKE)—贾恩·尼珀斯教授

合作方:进化与生态学研究所,飞机设计研究所(IFB)—米登多夫教授、马库斯·布兰德、弗洛里安·格纳丁格教授,工程大地测量研究所(IIGS)—沃尔克·施瓦格教授、奥托·拉克教授,图宾根大学无脊椎动物进化生物学系—奥利弗·贝茨教授,图宾根大学无脊椎动物古生物学系—詹姆斯·纳贝尔西克教授

合作成员:Benjamin Felbrich (德国), Nikolas Früh (德国),Marshall Prado (美国), Daniel Reist (澳大利亚), Sam Saffarian (伊朗), James Solly(英国), Lauren Vasey (美国)

支持单位:大众汽车基金会、GETTYLAB、库卡机器人有限公司、派瑞有限公司、SGL技术有限公司、斯图加特瀚森化工有限公司、埃德旭普林公司、龙特尔有限公司、温德尔钢结构有限公司、徕卡测量系统有限公司、科菲有限公司

研究项目资金:来自2020欧盟地平线研究项目、玛丽亚·斯克沃多夫斯卡·居里赠款协议642877号创新计划、德国研究基金会的合作研究中心CRC141项目和大众基金会的实验资助计划

项目位置:斯图加特,开普勒街11-17号,70174

建成时间:2017年3月

面积:26.5m2

体积:58m3

纤维总长:184km

重量:1 000kg

外形尺寸:12.0m x 2.6m x 3.1m

图片来源:图 1~4 © ICD/ITKE,图 5、8~9、11 © 博格雷夫和赖克特,图6~7、10 © 劳里安·格尼托

翻译:郑黛丹

校对:张希

5 研究展亭实景View of Research Pavilion

The Institute for Computational Design and Construction (ICD) and the Institute of Building Structures and Structural Design (ITKE)at the University of Stuttgart have completed a new research pavilion exploring building-scale fabrication of glass and carbon fibre-reinforced composites. The novel process is based on the unique affordances and characteristics of fibre construction. Because these materials are lightweight and have high tensile strength, a radically different approach to fabrication becomes possible, which combines low-payload yet longrange machines, such as unmanned aerial vehicles(UAV), with strong, precise, yet limited reach,industrial robots. This collaborative concept enables a scalable fabrication setup for long span fibre composite construction. The research builds on a series of successful pavilions, which investigate integrative computational design, engineering and fabrication, and explores their spatial rami fi cations and construction possibilities. The project was designed and fabricated by students and researchers within an interdisciplinary team of architects,engineers and biologists.

Lightweight, Long Span Fibrous Construction

Fibre composite materials have tremendous potential in architectural applications. Due to performative material characteristics, they are readily used in highly engineered applications, such as in the automotive and aerospace industries. The potentials within architecture, however, remain still largely unexplored. Within architectural scale production, where material self-weight is of high concern for larger span structures,lightweight fibre composites provide unparalleled

performance. However, we currently lack adequate fibre composite fabrication processes to produce at this scale without compromising the design freedom and system adaptability required for the architecture and design industries. Traditional methods of fabrication require full-scale surface moulds and often restrict the process to serialized production of identical parts. Previous research at the ICD and ITKE has explored fibre composite construction without the need for surface moulds or costly formwork. These novel manufacturing processes have been utilized to create highly differentiated multi-layered structures, functionally integrated building systems and large element assemblies. They have freed the relatively formable material from the limitations of traditional fibre composite fabrication processes. However, the scale of these early investigations has been limited by the working space of the industrial robotic arms that were utilized. The goal of the ICD/ITKE Research Pavilion 2016-17 is to envision a scalable fabrication process and to test alternative scenarios for architectural application by developing a manufacturing process for long span continuous fi bre structures.

6~8 研究展亭实景View of Research Pavilion

Process Biomimetic Investigation

The focus of the project is a parallel bottomup design strategy for the biomimetic investigation of natural construction processes of long span fi bre composite structures and the development of novel robotic fabrication methods for fibre reinforced polymer structures. The aim was to develop a fibre winding technique over a longer span, which reduces the required formwork to a minimum whilst taking advantage of the structural performance of continuous fi lament. Therefore, functional principles and construction logics of natural lightweight structures were analysed and abstracted in cooperation with the Institute of Evolution and Ecology and the department for Paleobiology of the University of Tübingen. Two species of leaf miner moths, the Lyonetiaclerkellaand the Leucopteraerythrinella,whose larvae spin silk “hammocks” stretching between connection points on a bent leaf, were identified as particularly promising for the transfer of morphological and procedural principles for long span fi brous construction. Several concepts were abstracted from the biological role models and transferred into fabrication and structural concepts, including: the combination of a bending-active substructure and coreless wound fibre reinforcement to create an integrated composite winding frame, fi bre orientation and hierarchy over a long span structure and multistage volumetric fibre laying processes for the generation of complex three dimensional geometries.

Multi-Machine Cyber-Physical Fabrication

Creating a long span structure, beyond the working space of standard industrial fabrication equipment, required a collaborative setup where multiple robotic systems could interface and communicate to create a seamless fibre laying process. A fibre could be passed between multiple machines to ensure a continuous material structure.The concept of the fabrication process is based on the collaboration between strong and precise, yet stationary machines with limited reach and mobile,long-range machines with limited precision. In the speci fi c experimental set-up, two stationary industrial robotic arms with the strength and precision necessary for fibre winding work are placed at the extremities of the structure, while an autonomous, long range but less precise fi bre transportation system is utilized to pass the fibre from one side to the other, in this case a custom-built UAV. Combining the untethered freedom and adaptability of the UAV with the robots,opened up the possibilities for laying fi bres on, around or through a structure, creating the potential for material arrangements and structural performance not feasible with the robot or UAV alone.

10 研究展亭鸟瞰实景Aerial view of Research Pavilion

An adaptive control and communication system was developed to allow multiple industrial robots and a UAV to interact throughout the winding and fibre laying processes. An integrated sensor interface enabled the robots and UAV to adapt their behaviours, in real time, to the changing conditions during fabrication. The UAV could fly and land autonomously without the need of human pilots,the tension of the fibre was actively and adaptively controlled in response to both the UAV and robot behaviours. A localization system was utilized to create a digital and physical “handshake” between the robot and the UAV in order to pass the fi bre back and forth throug·hout the winding process. The series of adaptive behaviours and integrated sensors lay the foundation for developing novel multi-machine,cyber-physical fabrication processes for large scale if bre composite production.

Integrative Demonstrator

The ICD/ITKE Research Pavilion 2016-17 was created by laying a combined total of 184km of resin-impregnated glass and carbon fibre. The lightweight material system was employed to create and test a single long spanning cantilever with an overall length of 12m as an extreme structural scenario. The surface covers an area of about 40m2and weighs roughly 1 000kg. The realized structure was manufactured offsite and thus the size was constrained to fit within an allowable transport volume. However, variations of the setup were found suitable for on-site or in situ fabrication,which could be utilized for much longer span and larger fi bre composite structures.

The pavilion’s overall geometry demonstrates the possibilities for fabricating structural morphologies through multi-stage volumetric fibre winding, reducing unnecessary formwork through an integrated bending-active composite frame, and increasing the possible scale and span of construction through integrating robotic and autonomous lightweight UAV fabrication processes. It explores how future construction scenarios may evolve to included distributed,collaborative and adaptive systems. This research showcases the potential of computational design and construction through the incorporation of structural capacities, material behaviour,fabrication logics, biological principles and architectural design constraints into integrative computational design and construction. The prototypical pavilion is a proof of concept for a scalable fabrication processes of long-span,fibre composite structural elements, suitable for architectural applications.

11 研究展亭夜景灯光效果Evening view of Research Pavilion

Project Team:Institute for Computational Design and Construction (ICD)—Prof. Achim Menges,Institute of Building Structures and Structural Design (ITKE)—Prof. Jan Knippers

In collaboration with:Institute of Evolution and Ecology; Institute of Aircraft Design (IFB)—Prof. Dr. Ing. P. Middendorf, Markus Blandl,Florian Gnädinger; Institute of Engineering Geodesy(IIGS)—Prof. Dr.Ing. habil. Volker Schwieger, Otto Lerke;Department of Evolutionary Biology of Invertebrates,University of Tuebingen—Prof. Oliver Betz; Department of Palaeontology of Invertebrates, University of Tuebingen—Prof. James Nebelsick

Cooperator:Benjamin Felbrich (Germany), Nikolas Früh(Germany), Marshall Prado (USA), Daniel Reist(Austria), Sam Saffarian (Iran), James Solly(UK), Lauren Vasey (USA)

Supported by:Volkswagen Stiftung, GETTYLAB, KukaRoboter GmbH, Peri GmbH, SGL Technologies GmbH,Hexion Stuttgart GmbH, Ed. Züblin AG,Lange Ritter GmbH, StahlbauWendeler GmbH,Leica Geosystems GmbH, KOFI GmbH

Research Project Funds:Researchers on this project have received funding from the European Union's Horizon 2020 research and innovation programme under the Marie Sklodoska-Curie grant agreement No 642877, from the Collaborative Research Centre CRC 141 of the German Research Foundation and from the Volkswagen Stiftung's Experimentfunding programme

Address:Kepler str. 11-17, 70174, Stuttgart

Completion:March 2017

Area:26.5 m2