稻秆与圆捆机钢辊间滑动摩擦特性试验

王德福,江志国,李百秋,王国富,蒋亦元

稻秆与圆捆机钢辊间滑动摩擦特性试验

王德福1,2,江志国1,2,李百秋1,2,王国富1,2,蒋亦元1

(1. 东北农业大学工程学院,哈尔滨 150030;2. 农业部生猪养殖设施工程重点实验室,哈尔滨 150030)

针对钢辊式圆捆机秸秆卷捆过程基础研究较少的情况,该文对稻秆与钢辊(由碳素钢冷轧板卷制而成)之间的滑动摩擦特性进行了研究。利用自制的钢辊滑动摩擦系数测试装置,采用L27(313)正交试验方案研究了稻秆含水率、正压应力、钢辊线速度及其之间的交互作用对稻秆与钢辊之间滑动摩擦系数的影响,并通过单因素试验分别获得稻秆含水率、正压应力和钢辊线速度对滑动摩擦系数的影响规律及回归方程。正交试验结果表明:稻秆与钢辊之间的滑动摩擦系数受稻秆含水率、正压应力影响显著,受钢辊线速度影响较显著,且影响因素主次顺序为:稻秆含水率>正压应力>钢辊线速度,而且稻秆含水率与正压应力之间的交互作用对稻秆与钢辊之间的滑动摩擦系数影响显著;单因素试验结果表明:稻秆与钢辊之间的滑动摩擦系数随稻秆含水率的增加而增加,随正压应力的增加而减小,随钢辊线速度的增加而减小;在稻秆含水率为10%~70%、正压应力为1~9 kPa和钢辊线速度为0.2~0.8 m/s时,稻秆与钢辊之间的滑动摩擦系数的变化范围为0.353~0.612。研究结果可为钢辊式圆捆机的研究与设计提供理论依据。

秸秆;农业机械;力学特性;钢辊;滑动摩擦系数

0 引 言

中国稻秆年产量超2亿t[1],作为重要的可再生生物质资源,广泛应用于肥料、饲料、能源、工业原料和食用菌基料等领域[2-4]。但稻秆资源分布零散,结构疏松,体积庞大,收贮运较困难,由于稻秆打捆收获机械化程度较低[7-8],严重制约了稻秆资源的规模化利用。目前用于稻秆收获的打捆机主要为中小型钢辊式圆捆机[9-12],此类机型存在效率低、打捆过程易于发生堵塞等问题,因此,开展其钢辊对稻秆摩擦作用特性等基础研究,促进其创新研发非常必要。

目前,国外对圆捆机的相关基础研究主要由企业进行,因此其对圆捆机卷捆过程摩擦系数等基础性研究报道较少[11-13];国外学者主要进行了苜蓿等牧草的摩擦系数研究,其中Shinners、Joseph等[14-15]分别研究了不同含水率、压力、相对速度和材料类型对苜蓿秸秆滑动摩擦系数、切碎牧草静摩擦系数和滑动摩擦系数的影响;Kakitis等[16]研究了不同滑动速度、压力和表面材料对芦苇等草本生物质切碎秸秆动态摩擦系数的影响;Larsson等[17]研究了不同含水率、压力对芦苇草粉末动态摩擦系数的影响关系,并建立模型分析其影响规律;Phani等[18]研究了在未经处理与蒸汽爆破处理后大麦、油菜、燕麦和小麦粉碎秸秆摩擦系数的变化规律,而其他主要农作物秸秆的相关研究较少。中国对圆捆机的研究以企业进行的经验性设计或仿制为主[19-20],中国学者主要进行了秸秆粉碎后静摩擦角及含水率、接触材料类型对滑动摩擦系数影响的相关研究[21-27],其中李永军等[21]研究了各种粒径陶瓷颗粒和玉米秸秆粉混合物沿斜面和斜管的滑动摩擦系数;隋美丽等[22]分别利用剪切仪和斜面仪研究了玉米秸秆粒度在10~30 mm范围内的内摩擦角和滑动摩擦角的变化规律;田宜水等[23]研究了不同地区不同农作物切碎秸秆的静态堆积角和外摩擦角等理化特性;霍丽丽等[24]研究了6种不同地区玉米秸秆和5种不同种类秸秆细粉的内摩擦角及其与金属、橡胶材料间的最大静摩擦系数;房欣等[25]研究了不同含水率对揉搓粉碎处理后大豆秸秆与不同材料间滑动摩擦系数的影响;卢彩云等[26]研究了不同滑板材料、土壤含水率、秸秆部位和接触角等因素对小麦秸秆和玉米秸秆摩擦系数的影响。综上可知,稻秆与钢辊之间滑动摩擦特性的基础研究很少,亟待开展。

本文利用自制的钢辊滑动摩擦系数测试装置(钢辊由厚度为1.5 mm的碳素钢冷轧板卷制而成[28]),针对钢辊式圆捆机(其钢辊为主要卷捆部件)卷捆过程中钢辊对稻秆摩擦力的主要影响因素——稻秆含水率、正压应力和钢辊线速度,研究其对稻秆与钢辊之间滑动摩擦特性的影响规律,并分别建立其对应的回归方程,为钢辊式圆捆机的研究与设计提供基础依据。

1 材料与方法

1.1 试验材料

试验材料为哈尔滨市香坊区城高子镇经半喂入式水稻收获机获得的完整稻秆,其含水率为10%,中下部平均直径为4.8 mm,将稻秆压缩为98 mm×18 mm×60 mm的长方体作为试样(密度为120 kg/m3)。试验时将试样在原含水率基础上采用复水法分别调至各所需含水率,计算公式(1)如下

式中W为试验所需的稻秆含水率,%;M为稻秆湿质量,kg;M为稻秆干质量,kg。

1.2 测试装置及原理

采用的测试装置如图1a所示。该测试装置主要包括电机、转矩传感器(AKC-215型,允许转速:≤5 000 r/min,转矩精度:±0.1%)、钢辊(外径160 mm)、S型压应力传感器(YZC-516型,最大量程为30 MPa)和物料盒(固接于机架上,长宽高净尺寸100 mm×20 mm×100 mm)等。其电机通过1台FR-F740-45K-CHT1型变频器(日本三菱公司)调节转速。

另外,采用的仪器设备还有DHG-9420A型电热恒温鼓风干燥箱(上海一恒科学仪器有限公司),BSA3 202S型电子天平(最大量程3 200 g,精度0.01 g,奥多利斯科学仪器有限公司),游标卡尺,TS-5F智能测试仪(测量范围800 N·m,中国航天空气动力技术研究院)和自主研制的拉压力测量仪(数据采集速率:20点/s),其中转矩值和拉压力测试值分别通过数据线传送至电脑实现数据的采集、显示和记录。

如图1b所示为滑动摩擦系数测试装置示意图,物料盒的竖直中心线与钢辊轴线垂直相交,试验时将达到要求含水率的稻秆试样放入方形物料盒中,试样下端面与钢辊外圆表面充分均匀接触,从而保证在试验过程中的不同稻秆含水率、正压应力及钢辊线速度下试样与钢辊外圆表面接触面积均保持相同,缓慢匀速转动丝杠,连接件中的轴承将丝杠的螺旋运动转化为缓冲弹簧、S型压力传感器和压板的上下移动,通过压板对试样上端面施压,获得试样与钢辊之间的接触压力,其中压力传感器用于间接采集试样与钢辊之间的接触压力值,然后通过计算得到试样与钢辊之间的接触正压应力值,电机通过前、后置联轴器依次驱动转矩传感器和钢辊转动,转矩传感器用于采集不同工况下钢辊转动的转矩值,变频器通过控制电机来间接调节钢辊线速度,从而实现不同含水率的稻秆在不同正压应力、不同钢辊线速度下与钢辊之间滑动摩擦系数的测试。

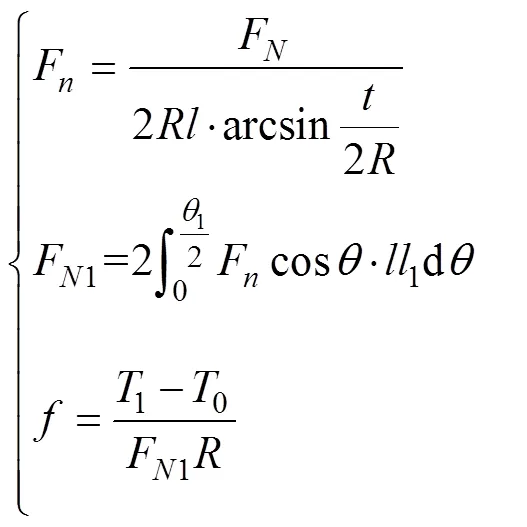

稻秆试样与钢辊表面接触受力分析如图2所示,钢辊外圆半径为,其转动的转矩值为,稻秆试样在沿钢辊周向方向与钢辊外圆表面的接触弧长及其所对的圆心角分别为1和1,稻秆试样对钢辊施加的正压力及其与钢辊之间的滑动摩擦力分别为F和F,该测试装置采用的测试原理用公式表达如下

1. 稻杆试样 2. 钢辊

1. Sample of rice straw 2. Steel-roll

注:为稻秆试样沿钢辊周向方向与钢辊外圆表面接触弧长所对应的稻杆试样宽度,m;为钢辊外圆半径,m;F为稻秆试样对钢辊施加的正压力,N;F为稻秆试样对钢辊在竖直方向上施加的正压应力值,N·m–2;F为稻秆试样与钢辊之间的滑动摩擦力,N;1为稻秆试样在钢辊圆形截平面内与钢辊接触弧长所对应的圆心角,rad;为稻秆试样在钢辊圆形截平面内与钢辊接触弧长所对应圆心角一半内的任意角,rad;为钢辊转动的转矩值,N·m。

Note:is the width of the rice straw sample corresponding to contact arc length between the rice straw sample along the steel-roll in the circumferential direction and the steel-roll outer surface, m;is the outer radius of the steel-roll, m;Fis the positive pressure applied by the rice straw sample to the steel-roll,Fis the positive pressure stress applied to steel-roll by the rice straw sample in the vertical direction, N·m–2; Fis the sliding friction between the rice straw sample and the steel-roll, N;1is the center angle corresponding to the contact arc length of rice straw and steel-roll in the circular cut plane of the steel-roll, rad;is the angle in half of the central angle corresponding to the contact arc length of rice straw and steel-roll in the circular cut plane of the steel-roll, rad;is the torque value of the rotation of the steel-roll, N·m.

图2 稻秆试样与钢辊表面接触受力模型简图

Fig.2 Schematic diagram of force contact model of rice straw and steel-roll surface

式中为稻秆试样沿钢辊周向方向与钢辊外圆表面接触弧长所对应的稻杆试样宽度,m;为稻秆试样沿钢辊轴向与钢辊间的接触长度,m;F为稻秆试样对钢辊在竖直方向上施加的正压应力值,N/m2;为稻秆试样在沿钢辊周向方向与钢辊外圆表面接触弧长所对应的1/2圆心角内的任意角,rad;F1为稻秆试样沿钢辊半径方向对钢辊施加的总的法向力,N;0为钢辊空载时转动的转矩值,N·m;1为稻秆试样对钢辊施加压力时钢辊转动的转矩值,N·m;为稻秆与钢辊之间的滑动摩擦系数。

1.3 试验因素与评价指标

由文献资料及预试验[29-31]分析可知,钢辊式圆捆机在卷捆过程中钢辊对稻秆的滑动摩擦作用直接影响稻秆卷捆效果和效率,而且稻秆与钢辊之间的滑动摩擦系数与稻秆含水率、正压应力及钢辊线速度有关。因此,本文选取稻秆含水率、正压应力和钢辊线速度为试验因素,稻秆与钢辊之间的滑动摩擦系数为评价指标进行试验研究。试验因素具体取值计算如下:

1)稻秆含水率

考虑稻秆不同利用领域对稻秆含水率的要求(如稻秆青贮时要求含水率为65%以上[32])以及不同收获期的稻秆含水率,本试验取稻秆含水率为10%~70%。通过大量预试验,在不同正压应力和钢辊线速度下,对不同含水率的稻秆试样在其试验前后分别进行质量称量,可得试验过程中稻秆含水率始终保持恒定。

2)正压应力

根据前期已进行的研究[33]及钢辊式圆捆机打捆预试验可知,稻秆捆直径为500 mm、长度为750 mm时其质量为27~33 kg(对应含水率为20%~46%),测得打完捆后的草捆分别与打捆室内底部2个钢辊的接触平均弧长为100 mm,接触平均长度为750 mm,此时在卷捆过程中,稻秆由于应力松弛而对钢辊产生的最大压应力为6.37 kPa~7.75 kPa,假设草捆重力全部由打捆室内底部的2个钢辊支撑,因此稻秆对钢辊的最大正压应力为稻秆质量对钢辊产生的最大正压应力和稻秆应力松弛对钢辊产生的正压应力之和。稻秆对钢辊式圆捆机打捆室内底部钢辊的最大压应力的计算公式为

式中为稻秆捆的重力,N;2为稻秆捆在钢辊圆形截平面内与钢辊的接触弧长,m;3为稻秆捆沿钢辊轴向与钢辊的接触长度,m;1为稻秆捆由于应力松弛而对钢辊产生的最大压应力,kPa;max为稻秆捆对钢辊产生总的最大正压应力,kPa。

经由公式(3)分析计算,本试验取稻秆对钢辊的正压应力为1 kPa~9 kPa。

3)钢辊线速度

电机输出轴通过联轴器与钢辊旋转轴相连,因此钢辊转速与电机输出轴的转速相同,钢辊外圆半径为,经计算分析,本试验取钢辊线速度为0.2~0.8 m/s,其中钢辊线速度计算公式为

式中为钢辊外圆线速度,m/s;1为电机额定转速,r/min;1为电机额定频率,Hz;2为电机任意频率,Hz;为电机的减速比。

1.4 试验方法

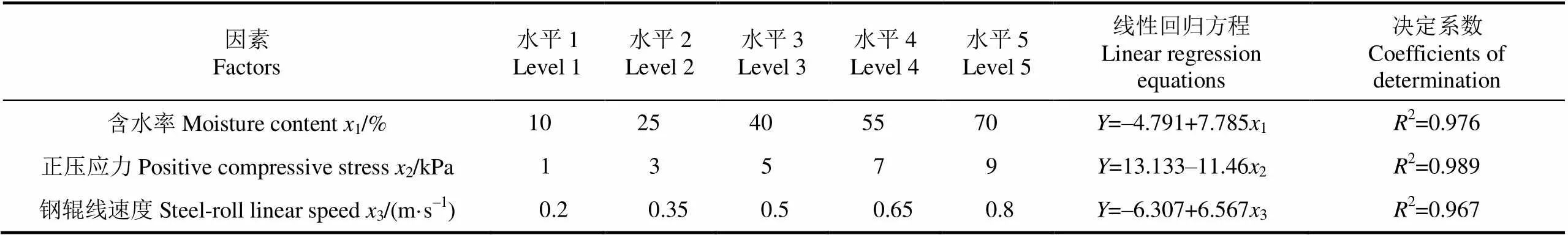

依据影响稻秆与钢辊之间滑动摩擦系数的稻秆含水率、正压应力和钢辊线速度,设计三因素三水平正交试验,考虑一级交互作用的影响,3个试样,共18种处理,每种处理重复5次,确定各影响因素及其交互作用的显著性水平及因素影响的主次顺序。然后对重要的影响因素做单因素试验,研究各影响因素对试验指标的影响规律,获得对应的回归方程,为稻秆与钢辊之间滑动摩擦系数的估测提供依据。根据预试验确定正交试验的因素水平如表1所示,试验方案采用L27(313)如表2所示。

表1 试验因素水平

2 结果与分析

2.1 正交试验结果与方差分析

试验结果如表2所示,通过对比分析可知:影响稻秆与钢辊之间滑动摩擦系数的因素主次顺序依次为稻秆含水率、正压应力和钢辊线速度。采用Design-expert 8.0.6软件对试验数据进行方差分析[34],由分析结果可知:稻秆与钢辊之间滑动摩擦系数受稻秆含水率、正压应力及稻秆含水率与正压应力的交互作用×影响显著,受钢辊线速度影响较显著,而不受稻秆含水率与钢辊线速度的交互作用×及正压应力与钢辊线速度的交互作用×的影响,如表3所示。

2.2 单因素试验结果与分析

从正交试验结果可知,稻秆含水率、正压应力、稻秆含水率和正压应力之间的交互作用×及钢辊线速度是影响稻秆与钢辊之间滑动摩擦系数的主要因素,其中交互作用×对于试验指标的影响,后续将在本文研究的基础上根据不同稻秆含水率、正压应力值进行大量的基础性探究试验研究,以获悉其规律。为了获取稻秆在实际工况中与钢辊之间滑动摩擦系数的回归方程,及各影响因素对稻秆与钢辊之间滑动摩擦系数的影响规律,本文选取稻秆含水率、正压应力和钢辊线速度分别在其合理取值的条件下进行单因素试验研究。试验中稻秆含水率、正压应力和钢辊线速度分别选取5个水平值,其中稻秆含水率的水平取值为10%、25%、40%、55%、70%,正压应力的水平取值为1.0、3.0、5.0、7.0、9.0 kPa,钢辊线速度的水平取值为0.2、0.35、0.5、0.65、0.8 m/s。取5个试样,共15种处理,每种处理重复5次,其结果如表4所示。根据回归决定系数的值,说明回归模型与试验结果拟合程度较好,可用于预测稻秆与钢辊之间的滑动摩擦系数在不同稻秆含水率、正压应力和钢辊线速度下的变化情况。如图3所示为稻秆与钢辊之间的滑动摩擦系数随稻秆含水率、正压应力和钢辊线速度的变化曲线图,可知稻秆与钢辊之间的滑动摩擦系数随稻秆含水率、正压应力和钢辊线速度的变化总体上呈单方向变化的趋势。

表2 试验方案(L27(313))及结果

表3 方差分析表

注:“***”表示极显著(<0.01);“**”表示显著(0.01≤<0.05);“*”表示较显著(0.05≤<0.1)。

Note: “***”means extremely significant (<0.01); “**”means very significant(0.01≤<0.05);“*”means significant(0.05≤<0.1).

2.2.1 含水率对稻秆滑动摩擦系数的影响

在所检验的影响因素中,稻秆含水率对稻秆与钢辊之间的滑动摩擦系数影响最为显著。如图3a所示,稻秆含水率为10%~70%时,稻秆与钢辊之间的滑动摩擦系数随稻秆含水率的增加总体上呈现增加的趋势。其中,稻秆含水率小于40%时,其滑动摩擦系数的增加较缓慢,大于40%时,滑动摩擦系数增加较快。

因此,在一定范围内适当增加稻秆含水率,可以使钢辊与稻秆之间的滑动摩擦系数增加,从而使钢辊式圆捆机卷捆过程中钢辊对稻秆的滑动摩擦力增加,进而在同样的卷捆条件下可使钢辊对稻秆沿其转动方向的周向作用力增大,这将有助于加快稻秆在卷捆室内的成捆过程并提高打捆效率。

以上增加稻秆含水率的情况主要在青绿稻秆打捆青贮时发生,一般情况下稻秆含水率在10%左右,因此,通常情况下稻秆含水率影响有限。

2.2.2 正压应力对稻秆滑动摩擦系数的影响

如图3b所示,正压应力为1~9 kPa时,稻秆与钢辊之间的滑动摩擦系数随正压应力的增加而呈现减小的趋势,但总体变化较平缓。

总体而言,相对于稻秆含水率,正压应力对钢辊与稻秆间的滑动摩擦系数的影响要小。在钢辊式圆捆机卷捆过程的初期,稻秆对钢辊的正压应力较小,尽管稻秆与钢辊之间的滑动摩擦系数稍大,但钢辊对稻秆的滑动摩擦力总体还较小;而随卷捆进程稻秆对钢辊的正压应力增加,尽管稻秆与钢辊之间的滑动摩擦系数稍小,但钢辊对稻秆的滑动摩擦力总体增加较大。

综合以上分析和前期研究[29-31],在钢辊式圆捆机卷捆过程的初期,进入卷捆室的稻秆较少,导致卷捆室内稻秆质量较小、稻秆对钢辊的正压应力更小,此时卷捆室下部钢辊对稻秆的摩擦作用力是促使进入卷捆室的稻秆形成卷绕累积过程(因此形成旋转草芯、进而形成草捆)的关键。因此,卷捆室下部钢辊应采取加大钢辊与稻秆间滑动摩擦系数的结构设计型式,如采用胶辊、表面加焊钢板条的钢辊等,以增加下部钢辊对稻秆的摩擦作用力。

表4 单因素试验结果

a. 含水率对滑动摩擦系数的影响

a. Effect of moisture content on sliding friction coefficient

b. 正压应力对滑动摩擦系数的影响

b.Effect of positive compressive stress on sliding friction coefficient

c. 钢辊线速度对滑动摩擦系数的影响

c.Effect of steel-roll linear speed on sliding friction coefficient

注:a:正压应力为5 kPa,钢辊线速度为0.5 m·s–1;b:含水率为40%,钢辊线速度为0.5 m·s–1;c:含水率为40%,正压应力为5 kPa。

Note: a: Positive compressive stress is 5 kPa, steel-roll linear speed is 0.5 m·s–1, b: Moisture content is 40%, steel-roll linear speed is 0.5 m·s–1; c: Moisture content is 40%, positive compressive stress is 5 kPa.

图3 稻秆滑动摩擦系数变化曲线

Fig.3 Variation curves of sliding friction coefficient of rice straw

2.2.3 钢辊线速度对稻秆滑动摩擦系数的影响

对比单因素试验结果可知,相对于稻秆含水率、正压应力,钢辊线速度对稻秆与钢辊之间的滑动摩擦系数的影响最小。如图3c所示,钢辊线速度为0.2~0.8 m/s时,稻秆与钢辊之间的滑动摩擦系数总体上随钢辊线速度的增加而缓慢增加。

因此,在一定范围内适当增大钢辊线速度,钢辊对稻秆的滑动摩擦系数增加,在同样的卷捆条件下可使钢辊对稻秆的滑动摩擦力增大,从而可在一定程度上增加钢辊对稻秆的摩擦作用力或导送能力,提高卷捆效率。因此,在钢辊式圆捆机打捆过程中,适当提高钢辊线速度,有助于增强钢辊卷捆能力并提高打捆效率。

综上所述,在稻秆含水率为10%~70%、正压应力为1~9 kPa和钢辊线速度为0.2~0.8 m/s时,稻秆与钢辊之间的滑动摩擦系数的变化范围为0.353~0.612。

3 结论与讨论

1)在本试验因素范围内,各因素对稻秆与钢辊(由碳素钢冷轧板卷制而成)之间的滑动摩擦系数的贡献率从大到小依次为:稻秆含水率、正压应力和钢辊线速度,且稻秆含水率、正压应力影响显著,而钢辊线速度影响较显著;在交互作用项中,稻秆含水率和正压应力之间的交互作用对稻秆与钢辊之间的滑动摩擦系数影响显著,其交互作用关系对于试验指标的影响,将在后续的研究中根据不同稻秆含水率、正压应力值进行大量的基础性探究试验研究,以获悉其规律。

2)当稻秆含水率为10%~70%时,稻秆与钢辊之间的滑动摩擦系数随稻秆含水率的增加而增加,其中,稻秆含水率大于40%,其滑动摩擦系数增加的趋势比含水率小于40%的趋势更明显;当正压应力为1~9 kPa时,稻秆与钢辊之间的滑动摩擦系数随正压应力的增加而减小;当钢辊线速度为0.2~0.8 m/s时,稻秆与钢辊之间的滑动摩擦系数随钢辊线速度的增加而缓慢增加。

[1] 李叶龙,王德福,李东红,等.辊盘式圆捆机卷捆机理分析与试验[J].农业机械学报,2016,47(12):45-52. Li Yelong,Wang Defu, Li Donghong, et al. Theoretical analysis and experiment of baling mechanism of roll-disk round baler[J]. Transactions of the Chinese Society for Agricultural Machinery, 2016, 47(12): 45-52.(in Chinese with English abstract)

[2] 朱建春,李荣华,张增强,等.陕西作物秸秆的时空分布、综合利用现状与机制[J].农业工程学报,2013,29(1):1-9. Zhu Jianchun, Li Ronghua, Zhang Zengqiang, et al. Temporal and spatial distribution of crops straw and its comprehensive utilization mechanism in Shanxi[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE)), 2013, 29(1): 1-9. (in Chinese with English abstract)

[3] 韩鲁佳,闫巧娟,刘向阳,等.中国农作物秸秆资源及其利用现状[J].农业工程学报,2002,18(3):87-91. Han Lujia, Yan Qiaojuan, Liu Xiangyang, et al. Straw resources and their utilization in China[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2002, 18(3): 87-91. (in Chinese with English abstract)

[4] 高海,李国东,刘伟,等.农作物秸秆综合利用现状及技术[J].现代农业技术,2011(18):290-291. Gao Hai, Li Guodong, Liu Wei, et al. Status and technology of comprehensive uitilization of crops straw[J]. Modern Agricultural Science and Technology, 2011(18): 290-291. (in Chinese with English abstract)

[5] 王正文,楚德江.秸秆收贮利用体系建设的困境与政策建议[J].中国环保产业,2013(9):66-69. Wang Zhengwen, Chu Dejiang. Puzzledom and policy suggestions on system building of straw harvest, store and utilization[J]. Environmental Protection Industry of China, 2013(9): 66-69. ( in Chinese with English abstract)

[6] 裴进灵.饲草收获加工机械的现状及发展趋势[J].当代农机,2007(7):12-14. Pei Jinling. Present situation and development trend of forage harvesting processing machinery[J]. Contemporary Agricultural Machinery, 2007(7): 12-14. (in Chinese with English abstract)

[7] 豆贺,高艳芳,胡逢时,等.国内外牧草收获机械发展现状及趋势[J].现代化农业,2017,450(1):61-64. Dou He, Gao Yanfang, Hu Fengshi, et al. Current situation and trend of pasture harvesting machinery at home and abroad[J]. Modern Agriculture, 2017, 450(1): 61-64. ( in Chinese with English abstract)

[8] 徐秀英.中国牧草收获机械发展现状及其趋势[J].安徽农业科学,2007,35(8):2506-2508. Xu Xiuying. Current status and development of pasture harvesting machinery in China[J]. Journal of Anhui Agri. Sci. 2007, 35(8): 2506-2508. (in Chinese with English abstract)

[9] 房骏,尚力,王庆莹.我国牧草收获机械的发展现状及存在问题[J].农机质量与监督,2006(2):30-31. Fang Jun, Shang Li, Wang Qingying. The present situation and existing problems of herbal harvesting machinery in China[J]. Agricultural Machinery Quality and Supervision, 2006(2): 30-31. (in Chinese with English abstract)

[10] 华德.中国牧草收获机械的现状、发展趋势[J].农业机械,2014(2):26-30. Hua De. Current situation and development trend of Chinese forage harvesting machinery[J]. Agricultural Machinery, 2014(2): 26-30. (in Chinese with English abstract)

[11] 华荣江,唐尊峰,叶红艳,等.国内外圆捆机械研究与发展趋势[J].中国农机化,2012(3):23-26. Hua Rongjiang, Tang Zunfeng, Ye Hongyan, et al. Research and development tendency about balerin domestic and overseas[J]. Chinese Agricultural Mechanization, 2012(3): 23-26. ( in Chinese with English abstract)

[12] 张乐佳.国内外主要牧草收获机械发展概况[J].农业工程,2014,4(5):20-22. Zhang Lejia. Development situation about main hay- harvsting machine at home and abroad[J].Agricultural Engineering, 2014, 4(5): 20-22.( in Chinese with English abstract)

[13] 侯晓,张俊国,董佳佳.秸秆打捆机研究现状及发展趋势[J].农村牧区机械化,2016(2):16-17. Hou Xiao, Zhang Junguo, Dong Jiajia. Research status and development trend of straw baler[J]. Mechanization Rural Pastoral Areas, 2016(2): 16-17. ( in Chinese with English abstract)

[14] Shinners K J, Koegel R G, Lehman L L. Friction coeffic- ient of alfalfa[J]. Transactions of the Asabe, 1991, 34(1): 33-37.

[15] Joseph St. Friction coefficients of chopped forages[J]. American Society of Agricultural and Biological Engineer, 2008, 26(9): 1-2.

[16] Kakitis A, Nulle I. Friction of chopped straw [J]. AGRIS, 2005, 113(16): 98-107.

[17] Larsson S H. Kinematic wall friction properties of reed canary grass powder at high and low normal stresses[J]. Powder Technology, 2010, 198(15): 108-113.

[18] Phani A, Lope T, Greg S. Physical and Frictional prop-erties of non-treated and steam exploded barley, canola, oat and wheat straw grinds[J]. Powder Technology, 2010, 201(13): 230-241.

[19] 操夫子,赵婉宁,杨雨林,等.圆捆打捆机研究现状与发展趋势[J].农业与技术,2014,34(11):38-69. Cao Fuzi, Zhao Wanning, Yang Yulin, et al. Research status and development trend of round bundle[J]. Agriculture and Technology, 2014, 34(11): 38-69. (in Chinese with English abstract)

[20] 韩江,周宏平,王金鹏.农林业打捆机的发展概况及趋势探讨[J].林业机械与木工设备,2015(43):10-18. Han Jiang, Zhou Hongping, Wang Jinpeng. Development and trend of agricultural and forestry bundling machines[J]. Forestry Machinery and Woodworking Equipment, 2015(43): 10-18. (in Chinese with English abstract)

[21] 李永军,何芳,柏雪源,等.颗粒和粉体混合物沿斜滑道的滑动摩擦系数[J].山东理工大学学报自然科学版,2003,17(4):10-12. Li Yongjun, He Fang, Bai Xueyuan, et al. Sliding friction coefficient of granular and powder mixture in inclined tube[J]. Journal of Shandong University of Technology (Sci and Tech), 2003, 17(4): 10-12. (in Chinese with English abstract)

[22] 隋美丽.秸秆压块饲料机匀料充型区的物流分析与计算机仿真[D].保定:河北农业大学,2005. Sui Meili. Computer Simulation and Physical Distribution Analysis on the Filling Process of Extruding for Crop Straw[D]. Baoding: Agricultural University of Hebei, 2005. (in Chinese with English abstract)

[23] 田宜水,姚宗路,欧阳双平,等.切碎农作物秸秆理化特性试验[J].农业机械学报,2011,42(9):124-130. Tian Yishui, Yao Zonglu, Ouyang Shuangping, et al. Physical and chemical characterization of biomass crushed straw[J]. Transactions of the Chinese Society for Agricultural Machinery, 2011, 42(9): 124-130. ( in Chinese with English abstract)

[24] 霍丽丽,孟海波,田宜水,等.粉碎秸秆类生物质原料物理特性试验[J].农业工程学报,2012,28(11):189-195. Huo Lili, Meng Haibo, Tian Yishui, et al. Experimental study on physical property of smashed crop straw[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2012, 28(11): 189-195. (in Chinese with English abstract)

[25] 房欣,陈海涛,黄振华,等.不同含水率大豆秸秆与不同材料间滑动摩擦特性的研究[J].大豆科学,2012,31(5):838-841. Fang Xin, Chen Haitao, Huang Zhenhua, et al. Sliding friction characteristic of different moisture content of soybean stalk with different materials[J]. Soybean Science, 2012, 31(5): 838-841. ( in Chinese with English abstract)

[26] 卢彩云,赵春江,孟志军,等.基于滑板压杆旋切式防堵装置的秸秆摩擦特性研究[J].农业工程学报,2016,32(11):83-89. Lu Caiyun, Zhao Chunjiang, Meng Zhijun, et al. Straw friction characteristic based on rotary cutting anti-blocking device with slide plate pressing straw[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(11): 83-89. (in Chinese with English abstract)

[27]刘新柱,王玉花,韩平,等.稻草秸秆压缩特性研究[J].农机化研究,2016(6):225-229. Liu Xinzhu, Wang Yuhua, Han Ping, et al. Compression property research of rice straw[J]. Research on Agricultural Mechanization, 2016(6): 225-229. (in Chinese with English abstract)

[28] 王春光.钢辊外卷式圆捆机结构与原理[J].农业机械,2008(12A):43-45. Wang Chunguang. Structure and principle of steel-roll roller blowing machine[J]. Agricultural Machinery, 2008(12A): 43-45. (in Chinese with English abstract)

[29] 王德福,张全国.青贮稻秆圆捆打捆机的改进研究[J].农业工程学报,2007,23(11):168-171. Wang Defu, Zhang Quanguo. Improvement of round baler for rice straw ensiling[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2007, 23(11): 168-171. ( in Chinese with English abstract)

[30] 王德福,蒋亦元,王吉权.钢辊式圆捆打捆机结构改进与试验[J].农业机械学报,2010,41(12):84-88. Wang Defu, Jiang Yiyuan, Wang Jiquan. Structure- improving and experiment of steel-roll round baler[J]. Transactions of the Chinese Society for Agricultural Machinery, 2010, 41(12): 84-88. ( in Chinese with English abstract)

[31] 雷军乐,王德福,李东红,等.钢辊式圆捆机旋转草芯形成影响因素分析与优化[J].农业机械学报,2015,46(12):18-25. Lei Junle, Wang Defu, Li Donghong, et al. Influence factors analysis and optimization of forming rotary straw core by steel-roll round baler[J]. Transactions of the Chinese Society for Agricultural Machinery, 2015, 46(12): 18-25. (in Chinese with English abstract)

[32] 郑海.秸秆青贮技术规程[J].甘肃畜牧兽医,2011,217(2):30-31. Zheng Hai.Technical specification for straw silage[J]. Gansu Animal and Veterinary Sciences, 2011, 217(2): 30-31.( in Chinese with English abstract)

[33] 雷军乐,王德福,张全超,等.完整稻秆卷压过程应力松弛试验[J].农业工程学报,2015,31(8):76-83. Lei Junle, Wang Defu, Zhang Quanchao, et al. Experiment on stress relaxation characteristics of intact rice straw during rotary compression[J]. Transactions of the Chinese Society of Agricultural Engineering (Trans-actions of the CSAE), 2015, 31(8): 76-83.(in Chinese with English abstract)

[34] 吕金庆,王英博,李紫辉,等.加装导流板的舀勺式马铃薯播种机排种器性能分析与试验[J].农业工程学报,2017,33(9):19-28. Lv Jinqing, Wang Yingbo, Li Zihui, et al. Performance analysis and experiment of cup-belt type patato seed- metering device with flow deflector[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(9): 19-28. ( in Chinese with English abstract)

王德福,江志国,李百秋,王国富,蒋亦元. 稻秆与圆捆机钢辊间滑动摩擦特性试验[J]. 农业工程学报,2017,33(21):44-51. doi:10.11975/j.issn.1002-6819.2017.21.005 http://www.tcsae.org

Wang Defu, Jiang Zhiguo, Li Baiqiu, Wang Guofu, Jiang Yiyuan. Experiment on sliding friction characteristics between rice straw and baler steel-roll[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(21): 44-51. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2017.21.005 http://www.tcsae.org

Experiment on sliding friction characteristics between rice straw and baler steel-roll

Wang Defu1,2, Jiang Zhiguo1,2, Li Baiqiu1,2, Wang Guofu1,2, Jiang Yiyuan1

(1.150030,; 2.150030,)

Rice straw resource is abundant in China, and annual output of rice straw has been over 200 million t. In recent years, as a kind of renewable biomass resource, rice straw is being used widely in new areas. However, because of the scattered distribution, the loose structure and the large volume of rice straw resource, it is difficult for rice straw to be stored and transported, which has seriously restricted the large-scale utilization of rice straw resource. It is very important to use the round baler to harvest rice straw for the comprehensive utilization of rice straw. In view of the fact that the basic research of the steel-roll round baler is less in China, it is urgent to carry out the basic research on the sliding friction between rice straw and steel-roll. In order to provide the basis for the design of the steel-roll round baler, the experiments of the sliding friction characteristics between rice straw and steel-roll (prepared by the rolling of cold rolled plate of carbon steel) were performed in this paper. Using the self-made device for measuring steel-roll sliding friction coefficient, the effects of moisture content of rice straw, positive compressive stress, steel-roll linear speed, and the interaction between them on the sliding friction coefficient between rice straw and steel-roll were studied by L27 (313) orthogonal experiment. Three factors and 3 levels, 3 samples and a total of 18 kinds of treatments were selected and each treatment repeated 5 times, which were used to determine the significance of the impact of factors and the order of factors. Then 5 levels of moisture content of rice straw, positive compressive stress and steel-roll linear speed were respectively selected in the single factor experiment, and the influence of each factor on the experimental index was studied, obtaining the corresponding regression equations and the coefficients of determination. The results of orthogonal experiment showed that: The sliding friction coefficient between rice straw and steel-roll was significantly affected by moisture content of rice straw and positive compressive stress, while less significantly affected by steel-roll linear speed, and the influencing order of factors was moisture content of rice straw > positive compressive stress > steel-roll linear speed. In the interaction between the factors, the sliding friction coefficient between rice straw and steel-roll was significantly affected by the interaction between moisture content of rice straw and positive compressive stress. The results of single factor experiments showed that: The sliding friction coefficient between rice straw and steel-roll increased with the increasing of moisture content of rice straw, decreased with the increasing of positive compressive stress, and slowly decreased with the increasing of steel-roll linear speed. When the moisture content of rice straw was 10%-70%, the positive compressive stress was 1-9 kPa and the steel-roll linear speed was 0.2-0.8 m/s, the range of sliding friction coefficient between rice straw and steel-roll was 0.353-0.612. Regression models had a good fitting degree with experimental results, and could be used to analyze the changes of the sliding friction coefficient between rice straw and steel-roll. The results can provide theoretical basis for the research and design of key components of steel-roll round balers.

straw; agricultural machinery; mechanical properties; steel-roll; sliding friction coefficient

10.11975/j.issn.1002-6819.2017.21.005

S225.4

A

1002-6819(2017)-21-0044-08

2017-05-29

2017-06-28

国家重点研发计划项目(2016YFD0701300);国家自然科学基金项目(51405076);黑龙江省科技项目(GA16B301)

王德福,教授,主要从事畜牧机械方面的研究工作。 Email:dfwang640203@sohu.com