Experimental research of air-throttling ignition for a scramjet at Ma 6.5

Weixin DENG,Jialing LE,Shunhua YANG,Wanzhou ZHANG,Ye TIAN

Science and Technology on Scramjet Lab,Hypersonics Aerodynamics Institute,China Aerodynamics Research and Development Center,Mianyang 621000,China

Experimental research of air-throttling ignition for a scramjet atMa6.5

Weixin DENG*,Jialing LE,Shunhua YANG,Wanzhou ZHANG,Ye TIAN

Science and Technology on Scramjet Lab,Hypersonics Aerodynamics Institute,China Aerodynamics Research and Development Center,Mianyang 621000,China

Available online 8 May 2017

*Corresponding author.

E-mail address:dengweixin21@aliyun.com(W.DENG).

Peer review under responsibility of Editorial Committee of CJA.

Production and hosting by Elsevier

http://dx.doi.org/10.1016/j.cja.2017.03.017

1000-9361©2017 Chinese Society of Aeronautics and Astronautics.Production and hosting by Elsevier Ltd.

This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

An experimental investigation on ignition characteristics with air-throttling in an ethylene-fueled scramjet under flightMa6.5 conditions was conducted.The dynamic process of air-throttling ignition was explored systematically.The influences of throttling parameters,i.e.,throttling mass rate and duration,were investigated.When the throttling mass rate was 45%of the inflow mass rate,ambient ethylene could be ignited reliably.The delay time from ignition to throttling was about 45–55 ms.There was a threshold of throttling duration under a certain throttling mass rate.It was shorter than 100 ms when the throttling mass rate was 45%.While a 45%throttling mass rate would make the shock train propagate upstream to the isolator entry in about 10–15 ms,four lower throttling mass rates were tested,including 30%,25%,20%,and 10%.All of these throttling mass rates could ignite ethylene.However,combustion performances varied with them.A higher throttling mass rate made more ethylene combust and produced higher wall pressure.Through these experiments,some aspects of the relationships between ignition,flame stabilization,combustion efficiency,and air-throttling parameters were brought to light.These results could also be a benchmark for CFD validation.

©2017 Chinese Society of Aeronautics and Astronautics.Production and hosting by Elsevier Ltd.This is an open access article under the CC BY-NC-ND license(http://creativecommons.org/licenses/by-nc-nd/4.0/).

Air-throttling;

Combustion;

Flame stabilization;Ignition;

Scramjet;

Shock

1.Introduction

The resident time of fuel in a scramjet combustor decreases remarkably under a flightMa6.5 condition than that of aMa4.5 condition.1Although hydrocarbon fuels have greater fuel densities and endothermic cooling capabilities than hydrogen,2it is more difficult for hydrocarbon fuels to mix sufficiently and combust with inflow air because of their long ignition delay time.3Therefore,some aided ignition techniques must be employed to increase resident time and facilitate local mixing.4,5Air-throttling is a widely used ignition method,which injects high-pressure air into a scramjet combustor to produce a throttling effect.6Throttling can slow down the flow speed of inflow air and increase the mixing time for the fuel.A pre-combustion shock train can be formed and a local environment with a high temperature and a low flow speed can be established.Furthermore,shock/boundary interaction could produce flow separation near the wall and distortion of the main flow,which would ease the difficulty of ignition.7–10

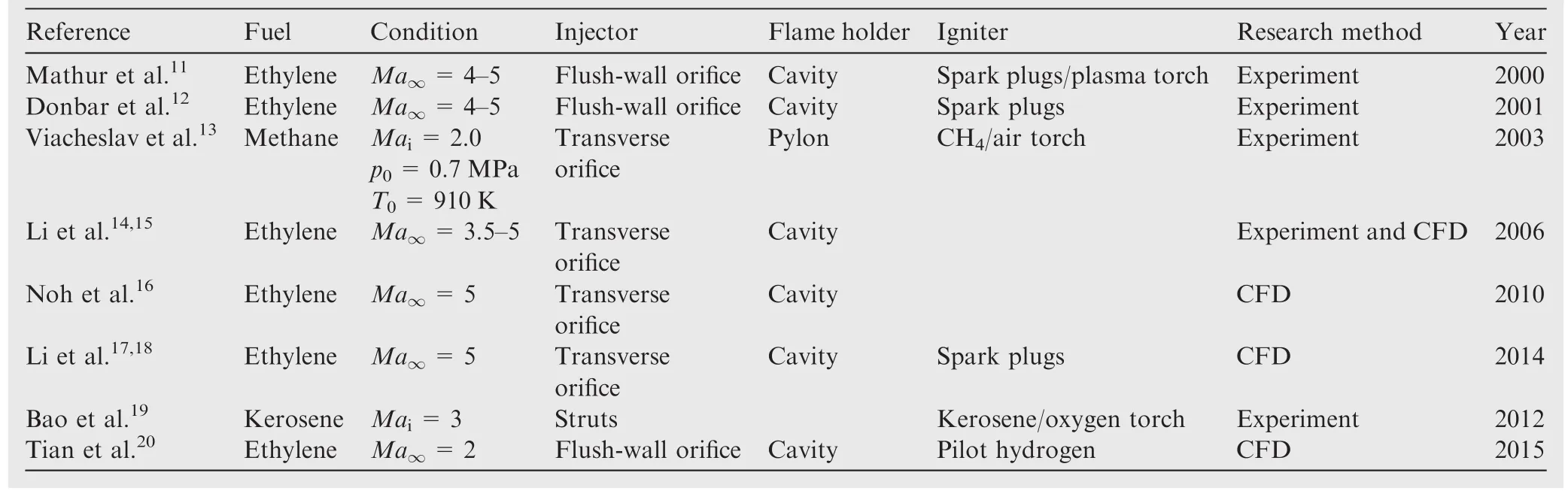

Previous investigations on ignition and combustion in scramjets with air-throttling are brief l y summarized in Table 1.T0is total temperature of inflow,p0is total pressure of inflow,Maiis Mach number at isolator entry.Mathur et al.conducted an experiment to research air-throttling aided combustion.11It was shown that if the heat release from combustion was strong enough to maintain a pre-combustion shock train,combustion could be stabilized;otherwise,combustion couldn’t persist.Donbar et al.studied the influence of throttling timing.12Viacheslav etal.ignited preheated methane with airthrottling and a methane/air torch.Flame-out happened after throttling off if the heat release was not enough to stabilize combustion.13Li et al.investigated the transient dynamics of air-throttling ignition.The dynamic optimization of airthrottling was achieved by implementing a genetic algorithm in the quasi-one dimensional code.14,15Noh et al.studied the ignition process of ethylene with air-throttling numerically under aMa3 condition.16Li et al.used the computational fluid dynamics(CFD)method to study the cold and reacting flow field in a combustor with/without air-throttling.17,18Bao et al.ignited liquid kerosene with air-throttling and a kerosene/oxygen torch.19Tian et al.studied the flow-field of a scramjet and flame stabilization with air-throttling using the CFD method.20

Although a series of excellent results has been gotten,most of them were accomplished by CFD.The other experimental results were mainly conducted under flightMa5 or less conditions.So far there is almost no experimental investigation on ignition characteristics under flightMa6.5 conditions,when air-throttling is the unique aided ignition technique.However,the re-ignition ability offered by air-throttling is important for a scramjet cruising at a high Mach number.A higher flow speed increases the difficult of ignition and makes the ignition process different from that under a lower speed.Meanwhile,the throttling mass rate and duration must be precisely controlled and optimized.An excess throttling mass rate or a too long throttling duration would result in the shock train propagating upstream to the isolator entry and make the inlet un-start.However,insufficient throttling could not produce a low-speed region with a high local pressure and temperature to facilitate ignition.

In this study,the dynamic process of air-throttling ignition in an ethylene fueled scramjet is explored systematically.The influences of throttling parameters,i.e.,throttling mass rate and duration,are investigated.The inflow conditions simulate those of flightMa6.5.The development of flame with airthrottling is exposed by wall pressure measurements and high-speed photographs.Through these experiments,some aspects of the relationships between ignition,flame stabilization,combustion efficiency,and air-throttling parameters are brought to light.

2.Experimental setup

2.1.Pulse combustion wind tunnel

The pulse combustion wind tunnel is a directly-connected experiment facility.It consists of several subsystems,including an oxygen-rich-air supply system,a hydrogen supply system,a combustion heater,a facility nozzle,and a vacuum tank.The wind tunnel uses hydrogen as fuel combusting with oxygenrich-air to produce experiment inflow.Meanwhile,the mole fraction of oxygen after combustion remains 21%just as the same as that in atmosphere.21–23

Once stable combustion is established in the combustion heater,the high-temperature gas would be accelerated by the two-dimensional facility nozzle to achieve a needed Mach number.Combined with the currently availableMa2,2.6,and 3 facility nozzles,the combustion heater is fine-tuned to simulate flight conditions fromMa4 to 6.5.For the presented study,the experiment inflow conditions simulate those of fightMa6.5.The gas parameters at the scramjet isolator entry are listed in Table 2.The total temperature is measured by a platinum-rhodium Type-B thermocouple.The total pressure is calculated by the wall static pressure and the Mach number with the Rayleigh Pitot tube formula.The ratios of specific heat and combustion efficiency of the heater are supposed to be 1.36 and 0.85,respectively.The mass flows of hydrogen and oxygen-rich-air are computed by their supply pressures and the area of the sonic throat.

Table 1 Survey of investigations of ignition and combustion in scramjets using air-throttling.

Table 2 Gas parameters at isolator entry.

2.2.Scramjet model

The scramjet model consists of a heat-sink constant area isolator,a rectangular combustor featuring a recessed cavity flame holder and several flush wall perpendicular injectors,and a diverging nozzle.A 2D schematic of this scramjet model is shown in Fig.1.The height and width of the isolator entry are 50 mm and 100 mm.The length of the isolator is 415 mm.The total length of the scramjet model is 1700 mm.The cavity flame holder is located at the divergent upper wall.The cavity geometry is fixed with a depth of 30 mm and a length of 300 mm,which is measured from the step to the end of the aft ramp,so the ratio of length to depth equals to 10.

Ambient ethylene is used as fuel.Based on the CFD results,four banks of injectors are designed to provide various fueling options.There are twelve orifices at each injector bank,which are distributed symmetrically span-wise.The diameters of the sonic fuel injector orifices are Ø1.0 mm.The location of airthrottling in the scramjet combustor is 870 mm from the isolator entrance.The location is chosen according to the CFD results.Throttling at an upstream location makes it easy for the inlet to un-start.However,throttling at a downstream location could not produce a strong enough shock train.Throttling air could be injected into the combustor from the twelve sonic orifices at the upper wall.The diameters of the air-throttling orifices are Ø3.0 mm.The first fuel injector bank is located upstream 10 mm to the cavity leading edge.The third fuel injector bank is located at the lower wall just opposite to the aft end of the cavity.The second and fourth injector banks have the same flow-wise coordinate,and their distances to the air-throttling point are 110 mm(shown in Fig.2).The mass flow rates of ethylene and throttling air are computed by their pressures,densities,and the area of orifices.

The research conclusions of post-air-throttling combustion performance are related to the initial air-throttling mass.In order to shorten the opening or closing time of the valve,an electromagnetic valve assembled with a pneumatic executor is employed to inject throttling air.This assembly could open or close in 20 ms.It is located just near the throttling orifices,so the residual mass in the air-throttling line could be reduced as little as possible.

2.3.Measurement

The dynamic process of ignition and combustion with airthrottling is obtained by wall pressure measurements.The measurement system consists of an amplifier,a recorder,a controlling computer,and a 128-channel electronic pressure scanning system.Pressure tapsare strategically positioned throughout the entire rig for instrumentation and health monitoring.The locations of the pressure taps are shown in Fig.3,including five important pressure taps.Based on the value of pressure,three transducer scales are used at the same time,including 0.3 MPa,0.7 MPa,and 15 MPa.The measurement errors are 0.2%of their scales.The sampling frequency of pressure measurements is 10 kHz.

An optical high-speed camera is placed perpendicular to the flow-field.This camera records light emitted within the visible spectrum at a capture rate of 5000 frames per second.The intensity of each pixel is the product of line integration across the span of the cavity.The luminosity of an image is assumed to correlate to the combustion efficiency.

2.4.Test procedure

Table 3 Parameters of air-throttling.

Different ignition methods are tested to make clear the ignition ability of this scramjet model and prove the necessity of airthrottling.Both pilot hydrogen and a torch are used to ignite ethylene.However it couldn’t be ignited reliably.These results are not listed here because of the paper length.Therefore,airthrottling is introduced as the unique aided technique to solve the ignition problem in the next section.

The starting time of the measurement system is set as the zero point of the test time.The measurement system worked about 1 s earlier than the wind tunnel to ensure the integrality of recording.After the test inflow is steady att=1118 ms,ethylene and throttling air are injected into the combustor at the same time oft=1240 ms.Ethylene is supplied until the end of experiment att=1500 ms.The mass rates of ethylene at the four injectors are controlled by their pressures independently.In the presented paper,the fuel equivalence ratios at the four injectors are constant,which are Φ1=0.3,Φ2=0.3,Φ3=0.2,and Φ4=0.2,respectively.According to the volume of the air-throttling system,five levels of airthrottling mass flow rate are tested as shown in Table 3.

3.Results and discussion

3.1.Dynamic process of ignition

The wall pressure profiles and high-speed photographs are used to analyze the dynamic process of ignition with airthrottling.Results of Test 1 are shown in Figs.4 and 5.The frequency of the photos is 5000 Hz.The throttling mass rate is 45%and the duration is 160 ms.Because the research focuses on the combustor wall pressure development,only one ethylene supply pressure is drawn in Fig.4.The throttling mass rate is 45%and the duration time is 160 ms.

All pressures at the five locations in the combustor are magnified ten times.According to their importance,attention is paid to the pressures at five special locations in the scramjet model,named as isolator entry,cavity leading edge,cavity middle,cavity aft,and throttling point(see Fig.3).The pressures at the five locations are magnified ten times in Fig.4 for better exhibition.

Previous experiments showed that ethylene couldn’t be auto-ignited in the present condition without any aided ignition technique,because a high flow speed shortens the fuel resident time to achieve efficient mixing.Under the throttling condition shown in Fig.4,ethylene and throttling air were injected into the combustor att=1240 ms simultaneously,and it delayed about 55 ms before wall pressures increased in the combustor(see Fig.4).Then ethylene was ignited by throttling in the cavity(see Fig.5(a)).Pressures at the cavity downstream locations rose almost at the same time and achieved their peaks in about 20 ms.High-speed photos showed throttling making ethylene combust strongly(see Fig.5(b)).The shock train produced by air-throttling and combustion propagated upstream to the isolator entry in about 10 ms.The pressure at the isolator entry formed a step while throttling on,so the 45%throttling mass rate was too high to keep the inlet from un-starting.After the throttling air was closed att=1400 ms,pressures at all the five locations dropped to the normal level of combustion.The effect of the isolator resumed.It indicated that ethylene was combusting steadily with the test inflow(see Fig.5(c)).Although the location of the shock train moved downstream,it was maintained by the heat release from combustion.

Note that pressures at the five locations attenuated somehow.Reason for this is the decrease of the wind tunnel test inflow.The oxygen-rich air of this wind tunnel is supplied by a tube,the volume of which is fixed and finite,so the pressure of the test inflow decreases about 10%during the experiment.

This research showed that air throttling could generate a pre-combustion shock train in the combustor.The precombustion shock train could decrease flow velocity and increase temperature and pressure in the combustor section,which would improve the ignition characteristics and strengthen the flame stabilization process.

3.2.Different throttling durations

Results of Test 2 are drawn in Fig.6.The throttling mass rate is 45%and the duration time is 100 ms.All pressures at the five locations in the combustor are magnified ten times.

Pressures at the five locations in the combustor are also magnified ten times for the same reason as in Fig.4.The throttling mass rate is also 45%and the duration time is shortened to 100 ms.Ethylene and throttling air were injected into the combustor att=1240 ms simultaneously,and the delay from ignition to throttling was about 45 ms.The difference between the delay times in Tests 1 and 2 was only 10 ms.This difference didn’t change the physical nature and could be thought to be equal,considering the error in such a complicated experimental system.This phenomenon also validated the reliability of air-throttling ignition.Pressures at the five locations rose and achieved their peaks in the same way.Pressure disturbing propagated upstream to the isolator entry in about 15 ms.They dropped to the normal level of combustion when airthrottling was closed,and the steady combustion was maintained to the end of the experiment.

Based on the results mentioned above,the duration time must be longer than the ignition delay time.There must be enough time for the shock train produced by throttling to stabilize and promote fuel mixing.Therefore,a deduction can be made that the throttling duration has a threshold under a given throttling mass rate.If the throttling duration is longer than the threshold,fuel could be ignited by air-throttling.In the present experiment condition,the threshold is shorter than 100 ms and longer than 55 ms when the throttling mass rate is 45%.

However,an accurate value of threshold for each throttling mass rate is difficult to get without a great deal of experiments.It is more practical to analyze qualitatively from the trend.A reasonable estimation can be made that the threshold of duration is longer with a lower throttling mass rate.

3.3.Different throttling mass rates

A 45%throttling mass rate makes the shock train propagate too upstream,which produces disturbance at the isolator entry,so a lower throttling mass rate is needed to keep the shock train at the proper location and produce an enough low-speed and high-temperature region to ease ignition.Four different throttling mass rates are tested in this section to study its influence on ignition.

The influence embodies in two aspects.Firstly,a lower throttling mass rate needs a longer delay time to ignite ethylene.This can be explained by the fact that a lower throttling mass rate produces a weaker shock train.The main flow doesn’t slow down so sharply.It is comparatively difficult for ethylene mixing.More time is needed to achieve the lean ignition limit.The delay time for each throttling mass rate is obtained from the measurement system and drawn in Fig.7.It is up to 350 ms when the throttling mass rate is as low as 10%.

Secondly,different throttling mass rates would offer different ignition energy,which would change combustion performance.Wall pressures in the scramjet with different throttling mass rates are drawn in Fig.8.While a 45%throttling mass rate would produce pressure disturbance,a 30%or lower throttling mass rate could keep the isolator in effect.Although all the five throttling mass rates from 45%to 10%could ignite ethylene reliably,the wall pressures vary with them.A higher throttling mass rate would make more ethylene combust,which means a higher combustion efficiency and wall pressure.Notice that the wall pressures in Fig.8(a)are extracted att=1320 ms,so they are produced by both combustion and throttling.Not all the ethylene could combust in the scramjet model after throttling was taken off,which is the reason of the wall pressure variation in Fig.8(b).Obviously,there is an optimum throttling mass rate,which could maximize the combustion performance and prevent the inlet from un-starting.Under the presented experimental conditions,a throttling mass rate between 20%-30%may be the rational choice.

4.Conclusions

This study presents experimental research on air-throttling ignition in a scramjet atMa6.5.The dynamic process of ignition is investigated by wall pressure measurements and highspeed photographs.Main conclusions include:

(1)Under present experimental conditions,when the throttling mass rate is 45%of the inflow mass rate,ethylene could be ignited reliably.

(2)The delay time from ignition to throttling changes with the throttling mass rate.There is a threshold of throttling duration under a certain throttling mass rate.

(3)While a 45%throttling mass rate would make the shock train propagate upstream to the isolator entry,four other throttling mass rates are tested,i.e.,30%,25%,20%,and 10%.All of these throttling mass rates can ignite ethylene.However,combustion performances vary with them.A higher throttling mass rate makes more ethylene combust and produces higher wall pressure.A lower throttling mass rate needs a longer delay time to ignite ethylene.

(4)There are optimum throttling mass rate and duration,which could maximize the combustion performance and prevent the inlet from un-starting.These values intensively depend on the inflow conditions,scramjet geometry,and fueling scheme.However,the design principles for throttling discovered in this paper could be a general reference.These results could also be a benchmark for CFD validation.

Acknowledgements

This work was supported by the National Natural Science Foundation of China(No.51406222 and No.51376194).The authors would like to thank Mr.Lairong ZENG and Mr.Xiaoqian DU for their supports in experiments.

1.Curran ET.Scramjet engines:the first forty years.J Propul Power2001;17(6):1138–48.

2.Bao W,Yang QC,Chang JT.Dynamic characteristics of combustion mode transitions in a strut-based scramjet combustor model.J Propul Power2013;29(5):1244–8.

3.Corin S.The scramjet engine:processes and characteristics.Cambridge:Cambridge University Press;2009.

4.Gruber MR,Donbar J,Jackson K.Newly developed directconnect high-enthalpy supersonic combustion research facility.J Propul Power2001;17(6):1296–304.

5.Guo P,Chen Z.Ignition enhancement of ethylene/air by NOxaddition.Chin J Aeronaut2013;26(4):876–83.

6.Tian Y,Le JL,Yang SH.Numerical study on air throttling influence of flame stabilization in the scramjet combustor.J Propul Tech2013;34(6):54–61[Chinese].

7.Lin KC,Tam CJ,Jackson KR.Characterization of shock train structures inside constant-area isolators of model scramjet combustors.Reston:AIAA;2006.Report No.:AIAA-2006-0816.

8.Deng WX,Le JL,Wang XY.Air-throttling effect of scramjet combustion characteristics.JAeroPower2013;28(2):316–23[Chinese].

9.Deng WX,Le JL,Yang SH.Air-throttling ignition experiments of ethylene fueled scramjet atMa3.J Propul Tech2013;34(9):1240–7[Chinese].

10.Wu ZN,Bai CY,Li J.Analysis of flow characteristics of hyper flow.Acta Aeronaut Astronaut Sin2015;36(1):58–85[Chinese].

11.Mathur T,Lin KC,Kennedy P.Liquid JP-7 combustion in a scramjet combustor.Reston:AIAA;2000.Report No.:AIAA-383 2000-3581.

12.Donbar J,Powell O,Gruber M.Post-test analysis of flush-wall fuel injection experiments in a scramjet combustor.Reston:AIAA;2001.Report No.:AIAA-2001-3197.

13.Viacheslav AV,Yuri MS,Ruslan VA.Experimental research of pre-injected methane combustion in high speed subsonic airflow.Reston:AIAA;2003.Report No.:AIAA-2003-6940.

14.Li J.Ignition transient in an ethylene fueled scramjet engine with air throttling[dissertation].University Park(PA):Pennsylvania State University;2009.

15.Li J,Ma FH,Yang V.Control and optimization of ignition transient in scramjet engine using air throttling.Reston:AIAA;2006.Report No.:AIAA-2006-1028.

16.Noh JY,Choi JY,Byun JR.Numerical simulation of autoignition of ethylene in a scramjet combustor with air throttling.Reston:AIAA;2010.Report No.:AIAA-2010-7036.

17.Li J,Zhang L,Choi JY,Yang V,Lin KC.Ignition transients in a scramjet engine with air throttling part 1:nonreacting flow.J Propul Power2014;30(2):438–48.

18.Li J,Zhang L,Choi JY,Yang V,Lin KC.Ignition transients in a scramjet engine with air throttling part II:reacting flow.J Propul Power2015;31(1):79–88.

19.Bao W,Hu JC,Zong YH.Ignition characteristic of a liquid kerosene fueled scramjet by air throttling combined with a gas generator.J Aerosp Eng2014;27(5):1–27.

20.Tian Y,Yang SH,Le JL.Study on the effect of air throttling on flame stabilization of an ethylene fueled scramjet combustor.Int J Aerosp Eng2015;2015:1–10.

21.Le JL,Liu WX,He W.Preliminary study of integrated aeropropulsive performance of vehicle with CFD and experiments.Reston:AIAA;2006.Report No.:AIAA-2006-7982.

22.Le JL,Liu WX,He W.Preliminary aero-propulsive performance study for vehicle in short duration facility.Proceeding of international conference on methods of aerophysical research;2008 June 9–13;Glasgow,Scotland.ICMAR;2008.

23.Le JL,Yang SH,Deng WX.Ignition and combustion characteristics of an ethylene fueled scramjet combustor.Proceeding of international symposium on air breathing engines;2013 Sep 9–13;Busan,Korea.Berlin:ISABE;2013.

24 October 2015;revised 2 December 2016;accepted 30 December 2016

CHINESE JOURNAL OF AERONAUTICS2017年3期

CHINESE JOURNAL OF AERONAUTICS2017年3期

- CHINESE JOURNAL OF AERONAUTICS的其它文章

- Review on signal-by-wire and power-by-wire actuation for more electric aircraft

- Real-time solution of nonlinear potential flow equations for lifting rotors

- Suggestion for aircraft flying qualities requirements of a short-range air combat mission

- A high-order model of rotating stall in axial compressors with inlet distortion

- Experimental and numerical study of tip injection in a subsonic axial flow compressor

- Dynamic behavior of aero-engine rotor with fusing design suffering blade of f