定子斜槽高压感应电动机三维磁场与运行性能分析

王庆山+梁艳萍

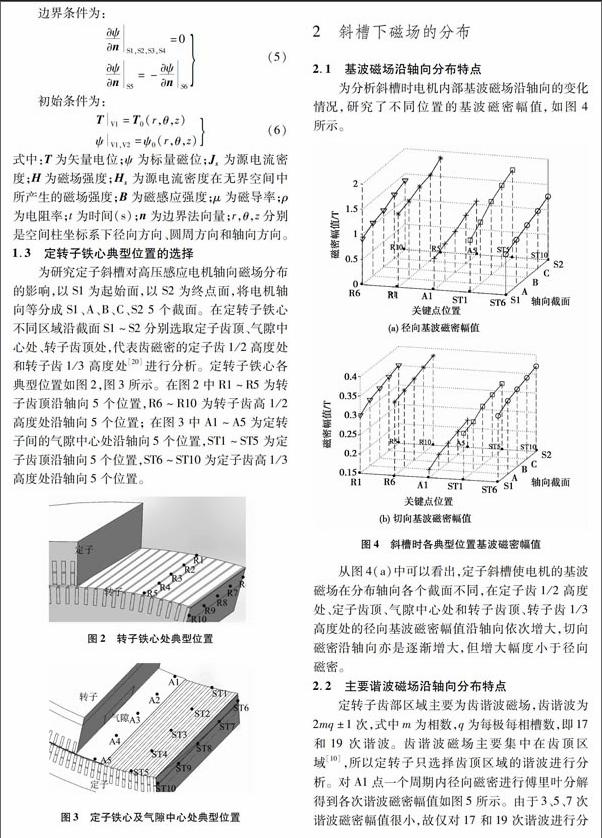

摘 要:针对高压感应电动机转子斜槽在工艺上的困难,提出了在定子上采用斜槽结构的设计方法。建立求解定子斜槽高压感应电动机的三维非线性瞬态场数学模型。通过对电机进行三维实体建模,并采用基于T,ψ-ψ电磁位对的三维有限元法对定子斜槽的高压感应电动机额定工况进行分析计算。分析了定子斜槽后电机基波磁场和齿谐波磁场沿轴向的分布情况,并研究了斜槽对主要齿谐波磁场的削弱作用,进一步对比分析了斜槽与直槽额定工况下主要性能参数,计算结果表明,定子斜槽高压感应电动机电气性能优于直槽电机,并大幅降低了齿谐波。

关键词:高压感应电动机;定子斜槽;三维有限元法;三维磁场;性能分析

DOI:10.15938/j.jhust.2017.03.015

中图分类号: TM343

文献标志码: A

文章编号: 1007-2683(2017)03-0085-05

Abstract:In view of the difficulties on technology of rotor chute in high voltage induction motor, the design method adopted stator chute structure is put forward. The mathematical model of three dimensional nonlinear transient field for solving stator chute in high voltage induction motor is set up. Through the three dimensional entity model of motor, three dimensional finite element method based on T,ψ-ψ electromagnetic potential is adopted for the analysis and calculation of stator chute in high voltage induction motor under rated condition. The distributions along axial of fundamental wave magnetic field and tooth harmonic wave magnetic field are analyzed after stator chute, and the weakening effects on main tooth harmonic magnetic field are researched. Further more, the comparison analysis of main performance parameters of chute and straight slot is carried out under rated condition. The results show that the electrical performance of stator chute is better than that of straight slot in high voltage induction motor, and the tooth harmonic has been sharply decreased.

Keywords:high voltage induction motor;stator chute; three dimensional finite element method; three dimensional finite magnetic field; performance analysis

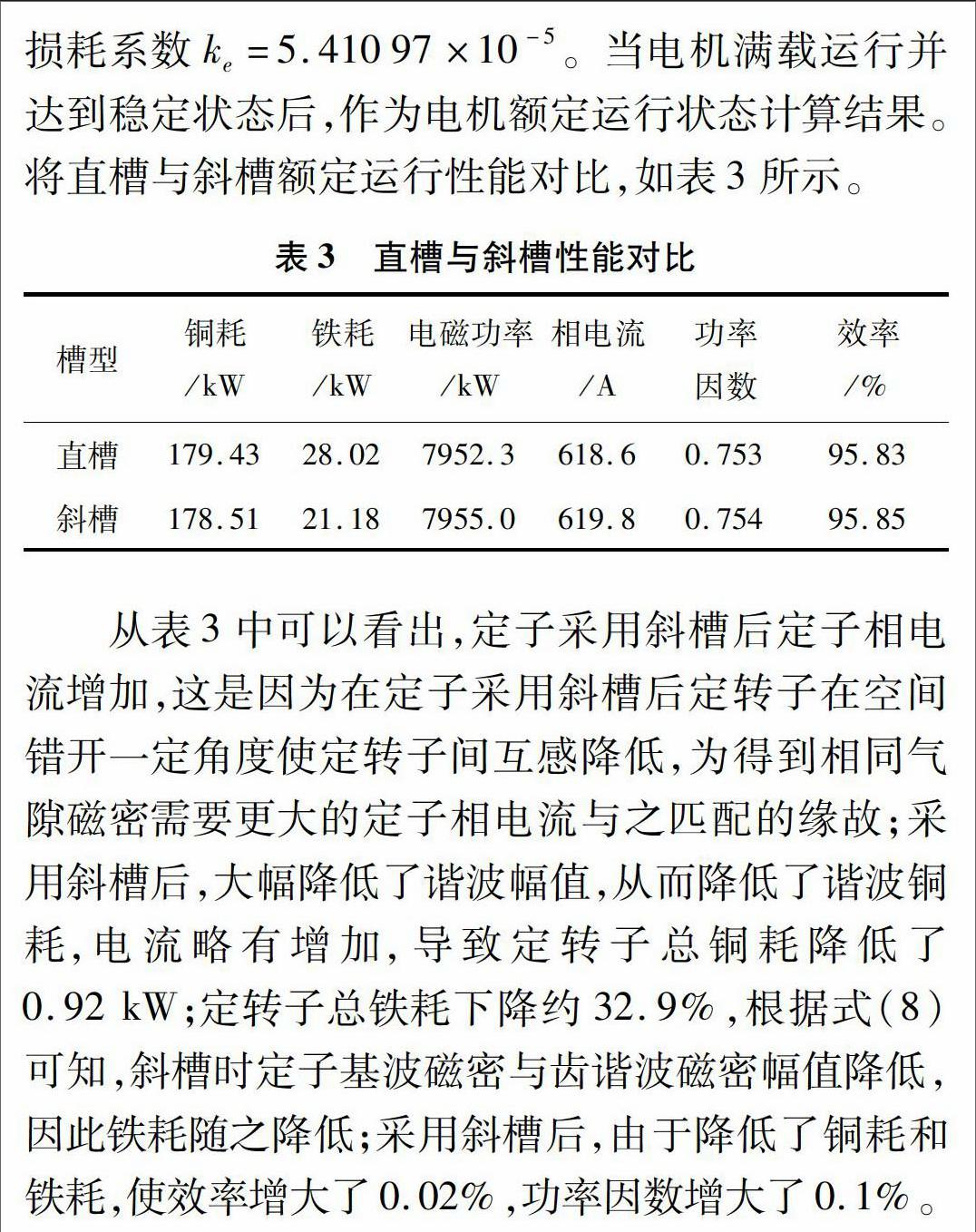

從表3中可以看出,定子采用斜槽后定子相电流增加,这是因为在定子采用斜槽后定转子在空间错开一定角度使定转子间互感降低,为得到相同气隙磁密需要更大的定子相电流与之匹配的缘故;采用斜槽后,大幅降低了谐波幅值,从而降低了谐波铜耗,电流略有增加,导致定转子总铜耗降低了0.92 kW;定转子总铁耗下降约32.9%,根据式(8)可知,斜槽时定子基波磁密与齿谐波磁密幅值降低,因此铁耗随之降低;采用斜槽后,由于降低了铜耗和铁耗,使效率增大了0.02%,功率因数增大了0.1%。

4 结 论

本文以一台7700kW高压感应电动机为例,采用基于T,ψ-ψ电磁位对的三维有限元法对定子斜槽的高压感应电动机额定工况进行分析计算。主要结论如下:

1) 定子斜槽改变了电机内磁场分布规律,使电机内轴向磁场在各个截面不同。基波磁场(径向、切向)磁密幅值沿轴向逐渐增大,定转子主要齿谐波磁密幅值沿轴向无明显分布规律,主要是由斜槽时谐波磁场沿轴向的相位移动大小引起。与直槽相比,大幅降低了齿谐波磁密幅值,对改善由气隙磁场引起的振动和噪声有很好的作用。

2) 斜槽对降低铁耗有显著作用,降低幅度达到32.9%,定转子总铜耗降低了0.92kW;由于降低了损耗,使效率增大0.02%,功率因数增大了0.1%。

参 考 文 献:

[1] 刘海龙.大型感应电动机电磁力及振动特性分析[D]. 沈阳:沈阳工业大学,2007:1-2.

[2] 汤蕴璆,罗应立,梁艳萍.电机学[M]. 北京:机械工业出版社,2006:136-138.

[3] 何山,王维庆,张新燕,等. 磁性槽楔对大型用磁锋利发电机性能的影响[J].电力设备,2008,9(5):53-56.

[4] WANG S,ZHAO Z,YUAN L,et al. Investigation and Analysis of the Influence of Magnetic Wedges on High Voltage Motors[R]. IEEE Vehicle Power and proplusion Conference (VPPC),Sep 3-5,2008,Harbin,China.

[5] JOVA K.A Study of the Effects of the Stator Slots Wedges Material on the Behavior of Aninduction machine[C], Proceedings of the 2008 International Conference on Electrical Machines. Paper ID 949.

[6] DAVIS M.Problems and Solutions with Magnetic Stator Wedge[C]. Iris Rotating Machine Conference,2007,TX,USA.

[7] HANNA R,HISCOCK W,KIOWSKI P.Failure Analysis of Three Slowspeed Induction Motors for Reciprocating Load Application[J].IEEE Transactions on Industry Applications,2007,43(2):429-435.

[8] 王晓辉,袁银眺.防爆高压电机斜槽铜条转子的紧固方式[J].电气防爆,2010,3(13):36-38.

[9] 孙立,周燕萍,陈怡如.斜槽定子线圈的复形[J].上海大中型电机,2005(3):35-37.

[10]江建中,傅为农.斜槽异步电动机的多截面有限元法分析[J].电工技术学报,1997,12(5):11-16.

[11]赵海森,王博,王翔宇,等.多工况条件下谐波磁场对异步电机附加损耗的影响[J].电机与控制学报,2014,8(8):1-6.

[12]KOMETANI H, SAKABE S, NAKANISHI K.3-D Electromagnetic Analysis of A Cage Induction Motor Skew[J]. IEEE Transactions on Energy Conversion,1996,11(2):331-337.

[13]TADASHI Yamaguchi, YOSHIHIRO Kawase,SHINYA Sano. 3-D FiniteElement Analysis of Skewed SquirrelCageInduction Motor[J].IEEE Transactions on Magnetics,2004,40(2):969-972.

[14]邹慧,范镇南.定子斜槽设计对贯流式水轮发电机空载電压的影响研究[J].水力发电,2012,38(2):50-53.

[15]刘长红,杨平西.定子斜槽同步发电机空载电压波形的数值计算[J].上海交通大学学报,2011,41(11):1891-1895.

[16]梁艳萍,张建涛,索文旭,等. 双屏蔽复合转子电机涡流损耗分析[J].中国电机工程学报,2009,29(4):78-83.

[17]汤蕴璆,梁艳萍.电机电磁场的分析与计算[M].北京:机械工业出版社,2010:74-75.

[18]高莲莲,梁艳萍.双屏蔽电机定子端部漏抗计算及其影响分析[J].电机与控制学报,2015,5(5):53-57.

[19]谢德馨,姚缨英,白保东,等.三维涡流场的有限元分析[M].北京:机械工业出版社,2001:36-39.

[20]陈世坤.电机设计[M].北京:机械工业出版社,2008:32-91.

(编辑:温泽宇)