基于大滑移温度非共沸工质双冷源制冷机组的分析

满 亮 张小松 刘 剑 徐国英

(东南大学能源与环境学院 能源热转换及其过程测控教育部重点实验室 南京 210096)

满 亮 张小松 刘 剑 徐国英

(东南大学能源与环境学院 能源热转换及其过程测控教育部重点实验室 南京 210096)

随着我国经济的发展,建筑能耗在全国总能耗中所占的比例不断增大。统计表明,暖通空调系统能耗占建筑总能耗55%[1],因此对暖通空调系统进行节能改造十分重要。为了降低暖通空调系统能耗,国内外学者对冷水机组进行了大量研究,其中温湿度独立控制系统因其节能、卫生等特点被广泛关注[2-3]。目前,温湿度独立控制主要通过固体吸附除湿或溶液吸收除湿等方法排出室内湿负荷实现湿度控制,通过冷水机组制取高温冷冻水排出室内热负荷实现温度控制,研究表明具有良好的节能效果[4-5]。但固体吸附除湿存在设备体积大、需要较高的再生热源温度(140 ℃以上)等问题[6],溶液吸收除湿存在溶液对管道腐蚀,除湿效率低等问题[7]。因此,国内一些学者提出通过制取高低温冷冻水的方式实现温湿度独立控制。梁彩华等[8]通过两套以R22为工质的冷水机组来制取两种温度的冷冻水(7 ℃和16 ℃),用于空调负荷的热湿分段处理。研究表明:当表冷器设计温差为7 ℃、出风温度为16 ℃时,冷水机组的COP相对于传统空调方式提高9.14%,在回风干球温度为25 ℃、湿球温度为21 ℃时,冷水机组COP提高达8%以上。但采用两套机组存在造价高、耗材量大的问题。刘剑等[9-10]利用非共沸混合工质的特性[11],提出一种以大滑移温度非共沸工质R32/R236fa为循环工质的新型双冷源制冷机组,通过该冷水机组可制取不同温度的高低温冷冻水,从而实现温湿度独立处理。研究表明当冷却水进水温度为32 ℃,高、低温冷冻水的出水温度分别为18 ℃和7 ℃,R32质量组分比例为60%时,机组COP可达3.92,可见该双冷源制冷机组具有一定的节能潜力,对该系统的进一步分析和优化具有重要意义。

1 构建双冷源制冷机组分析模型

(1)

I=exq-Δexh-Ws

(2)

exh=h-h0-T0(s-s0)

(3)

(4)

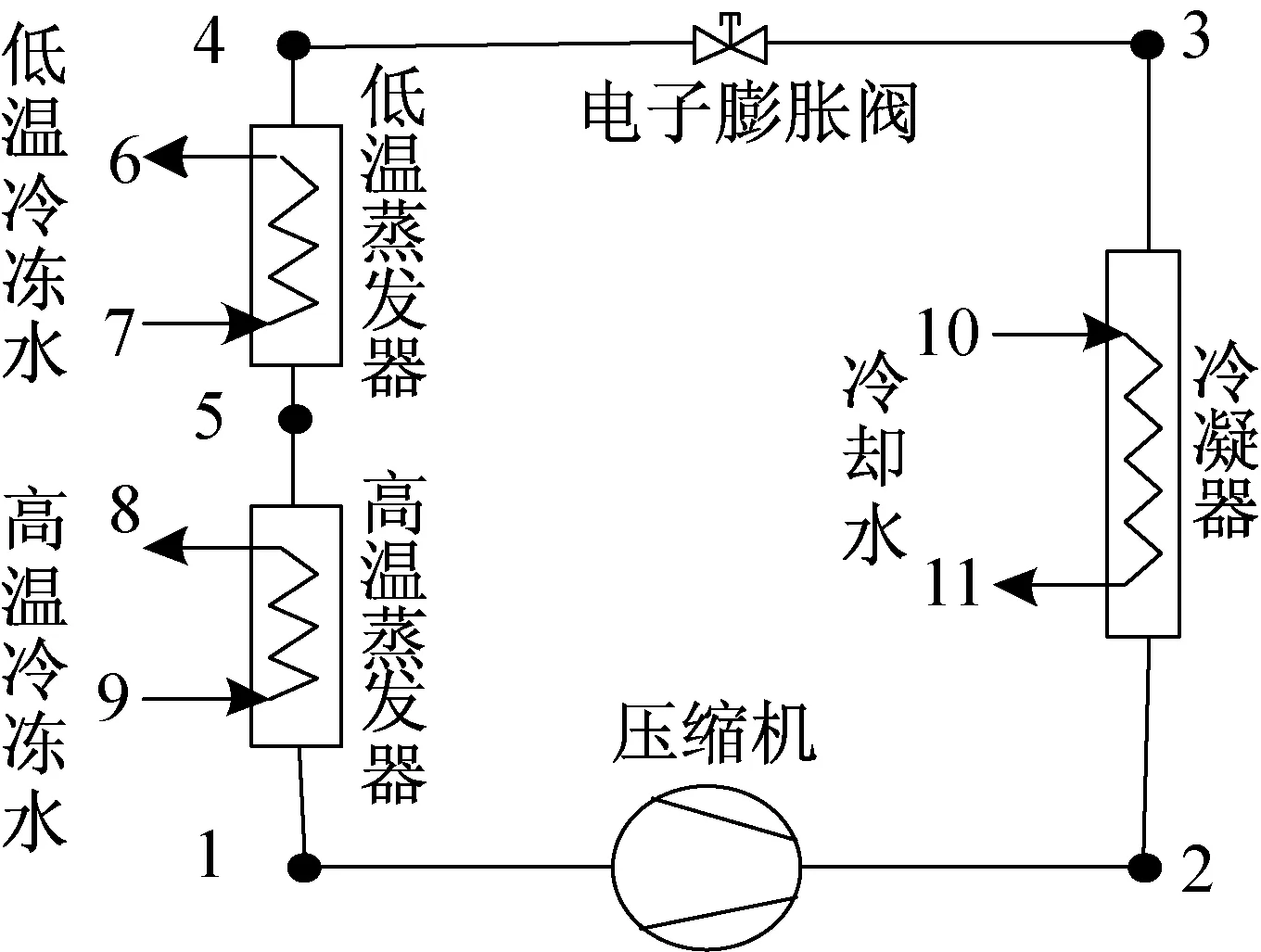

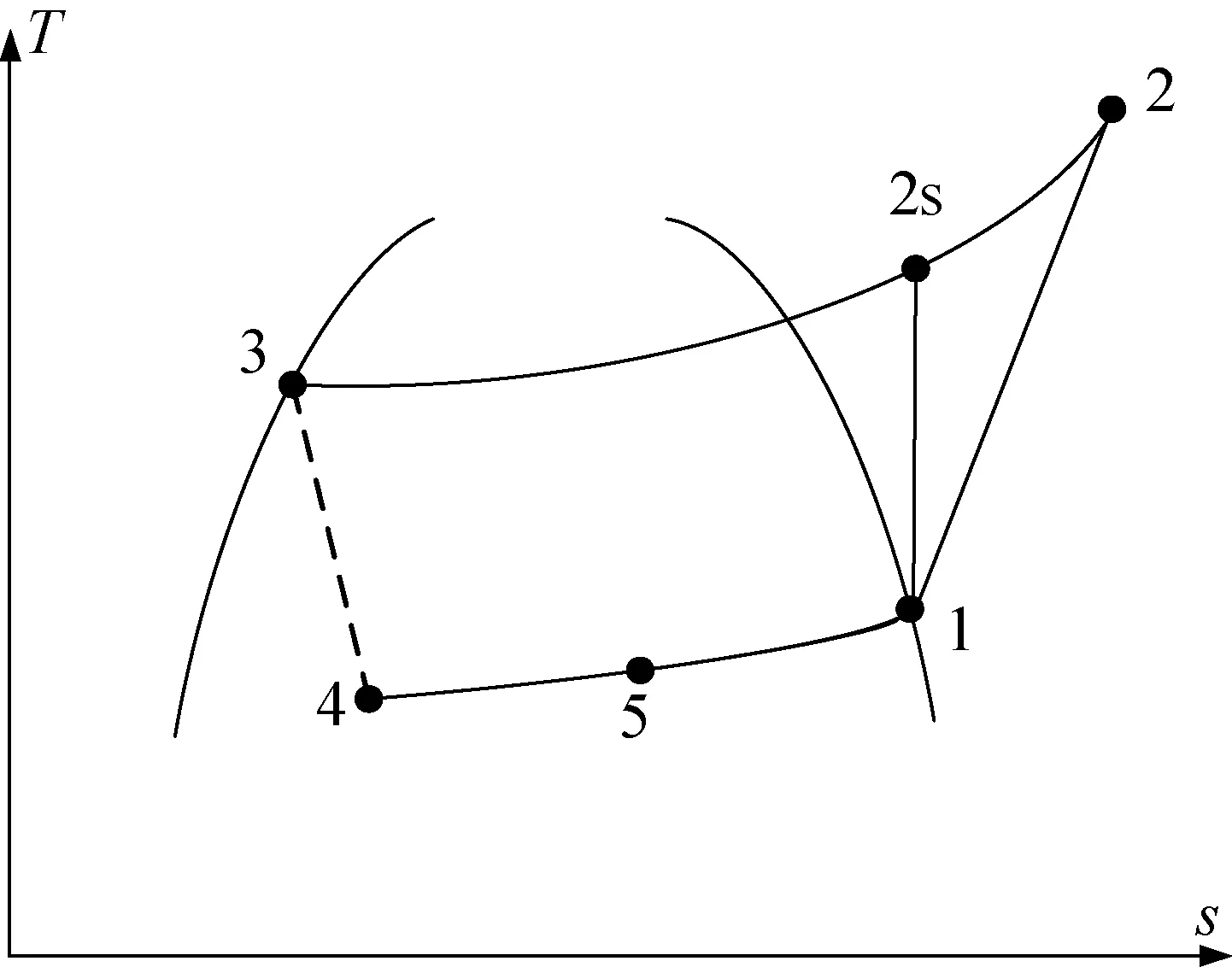

1.1建立系统模型

图1所示为采用混合工质R32/R236fa的双冷源制冷机组的系统流程图,与之相对应的理论循环T-s图见图2。该制冷循环由压缩过程(1-2)、等压冷凝过程(2-3)、节流过程(3-4,节流前后焓值相等,但非等焓过程)、等压蒸发过程(4-5)和等压蒸发过程(5-1)组成。

图1 双冷源制冷机组原理图Fig.1 Schematic diagram of double cooling source refrigerating unit

图2 制冷剂理论循环T-s图Fig.2 T-s diagram of the theoretical cycle

mrexh1+Wcom=mrexh2+Lcom

(5)

Lcom=mrexh1+Wcom-mrexh2

(6)

mw,evalexh7+mrexh4=mw,evalexh6+mrexh5+Leval

(7)

Leval=mw,eval(exh7-exh6)-mr(exh5-exh4)

(8)

mw,evahexh9+mrexh5=mw,evahexh8+mrexh1+Levah

(9)

Levah=mw,evah(exh9-exh8)-mr(exh1-exh5)

(10)

mw,conexh10+mrexh2=mw,conexh11+mrexh3+Lcon

(11)

Lcon=mw,con(exh10-exh11)-mr(exh3-exh2)

(12)

mrexh3=mrexh4+Ltxv

(13)

Ltxv=mr(exh3-exh4)

(14)

Lsys=Leval+Levah+Lcon+Ltxv+Lcom

(15)

2 双冷源制冷机组实验研究

2.1 实验装置

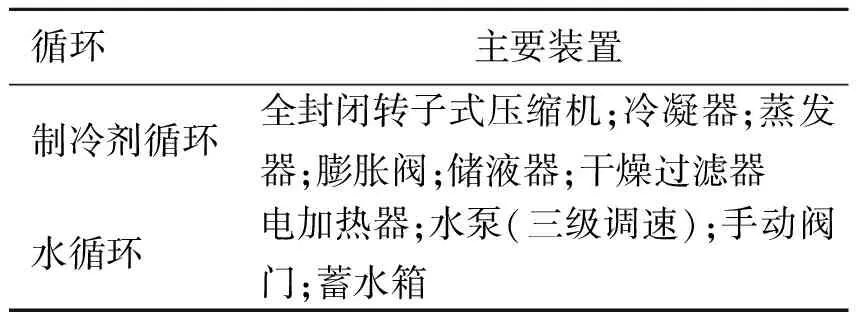

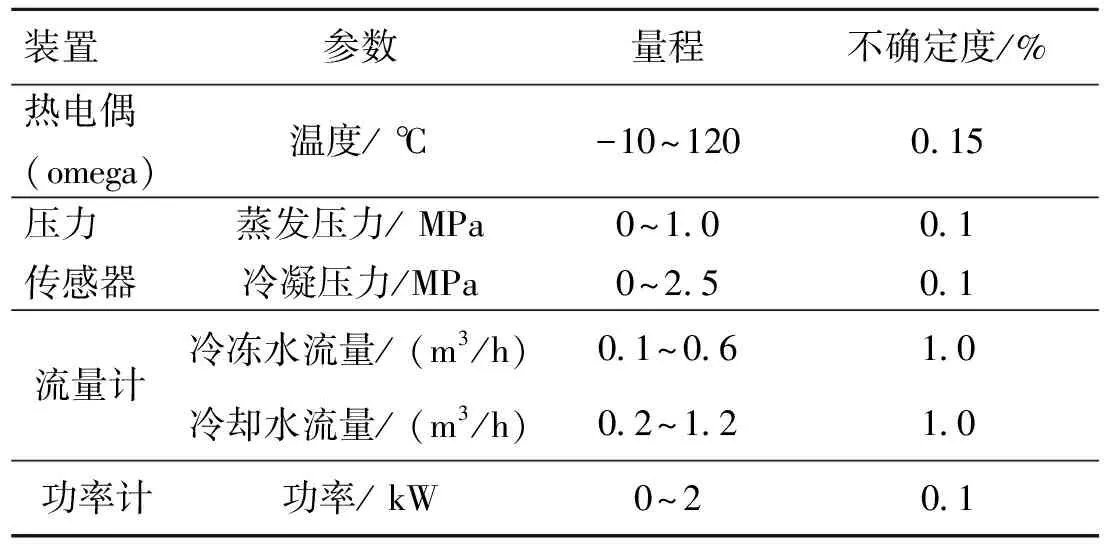

基于大滑移温度非共沸工质R32/R236fa的单级压缩水冷式双冷源制冷机组实验平台,由双冷源制冷机组装置和测量装置两部分构成,其中双冷源制冷机组循环由制冷剂循环和水(冷冻水与冷却水)循环组成。此外,双冷源制冷机组装置采用两个蒸发器将蒸发过程分为两段进行,利用温度不同的两个冷源获得高低温度冷冻水。具体情况如表1和表2所示。

表1 双冷源制冷机组装置

表2 测量装置

根据图2和图3可以判断制冷循环和冷冻水循环的大致流程。制冷循环:大滑移温度非共沸工质R32/R236fa先经压缩机压缩成高温高压的过热气体,再经冷凝器冷凝成高压过冷液体,高压过冷制冷剂液体流经储液器、干燥过滤器后,经电子膨胀阀节流到低温低压的两相区,然后混合工质先在低温蒸发器内蒸发,制取低温冷冻水,再经过高温蒸发器蒸发,制取高温冷冻水,蒸发后的工质由压缩机吸入,完成制冷循环。冷冻水循环:低温蒸发器所制取的冷冻水通过循环水泵排入低温冷冻水箱,之后经过电热器加热,消耗冷量。高温蒸发器制冷的冷冻水采用同样方式抵消冷量。通过控制电热器加热量,改变高低温蒸发器入口处高低温冷冻水的温度,可得实验所需的高低温冷冻水出水温度。在冷凝器中进行换热之后的高温冷却水,进入冷却水水箱与自来水补水混合,之后通过电加热器,将冷却水温度准确控制到32 ℃,之后再进入冷凝器,完成循环。

图3 双冷源制冷机组实验装置图Fig.3 Schematic diagram of experimental system

2.2 非共沸工质[18]

实验中采用质量比为60%/40%的R32/R236fa的混合工质作为制冷剂。R32与R236fa均属于环境友好型制冷剂,ODP均为0,GWP分别为650和6 300。

3 双冷源制冷机组分析

对不同常用高低温冷冻水组合进行变工况实验,具体运行工况如表3所示。

表3 变冷冻水温度运行工况表

为便于理论分析计算,做出如下假设:1)冷凝器与蒸发器出口工质为饱和状态;2)忽略混合工质在系统中的阻力;3)不计系统与环境间的散热;4)压缩过程绝热但不等熵,等熵效率取0.65;5)忽略润滑油对混合工质热物性的影响;6)蒸发器与冷凝器中最小传热温差取5 ℃。

3.3 实验结果与讨论

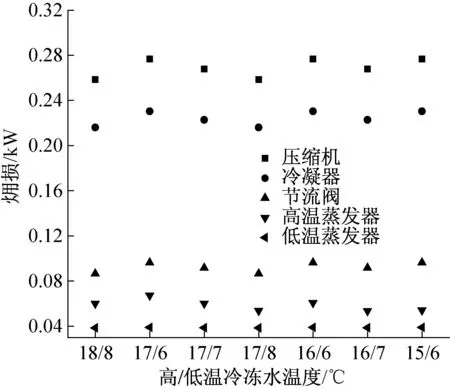

图4 双冷源制冷机组变工况条件下各部件的理论损Fig.4 Theoretical exergy loss of all parts in variable chilled water temperature

图5 双冷源制冷机组变工况条件下各部件的实验损Fig.5 Experimental exergy loss of all parts in variable chilled water temperature

表4 双冷源制冷机组系统变工况条件下的总损

图6 双冷源制冷机组系统高低温冷冻水温度17 ℃/8 ℃条件下各部件的损Fig.6 Exergy loss rate of all parts in 17 ℃/8 ℃

4 结论

符号说明

COP——制冷效率

GWP——全球变暖潜能值

ODP——臭氧层消耗能值

T——温度,℃

p——压力,MPa

W——压缩机功耗,kW

G——换热介质体积流量(水),m3/h

m——质量流量,kg/s

Q——制冷量,kW

下标

com——压缩机

r——制冷剂

con——冷凝器

sys——系统

eval——低温蒸发器

txv——节流阀

evah——高温蒸发器

w——水

[1] 江亿. 我国建筑耗能状况及有效的节能途径[J]. 暖通空调, 2005, 35(5): 64.(JIANG Yi. Current building energy consumption in China and effective energy efficiency measures[J]. Journal of HV&AC, 2005, 35(5): 64.)

[2] 张涛, 刘晓华, 张海强, 等. 温湿度独立控制空调系统设计方法[J]. 暖通空调, 2011, 41(1): 1-8. (ZHANG Tao, LIU Xiaohua, ZHANG Haiqiang.Design method of temperature and humidity independent control air conditioning system[J]. Journal of HV&AC, 2011, 41(1): 1-8.)

[3] 李伟. 基于热湿分段处理的空调系统优化与控制策略研究[D]. 南京: 东南大学, 2012.(LI Wei. Optimization and control strategy analysis of the segmented handling air-conditioning system[D]. Nanjing: Southeast University, 2012.)

[4] 李维, 葛杨慧, 陈立楠, 等. 实现温湿度独立控制的固体吸附材料吸附除湿性能研究[J]. 制冷学报, 2013, 34(3): 40-44. ( LI Wei, GE Yanghui, CHEN Linan. Research on dehumidifier performance of solid adsorbent for temperature and humidity independent control[J]. Journal of Refrigeration, 2013, 34(3): 40-44.)

[5] 代彦军, 腊栋. 转轮式除湿空调研究与应用最新进展[J]. 制冷学报, 2009, 30(4): 1-8. (DAI Yanjun, LA Dong. Rotary desiccant air conditioning systems: a state-of-the-art review[J]. Journal of Refrigeration, 2009, 30(4): 1-8.)

[6] Lowenstein A, Slayzak S, Kozubal E. A zero carryover liquid-desiccant air conditioner for solar applications[C]// In: Proceedings of the ASME International Solar Energy Conference, U.S.:American Society of Mechanical Engineers, 2007, 397-407.

[7] Yang K, Yao Y, Liu S Q. Effect of applying ultrasonic on the regeneration of silica gel under different air conditions[J]. International Journal of Thermal Sciences, 2012, 61: 67-78.

[8] 梁彩华, 张小松, 蒋赟昱, 等. 一种新型的空调系统空气处理方法及其节能分析[J]. 东南大学学报(自然科学版), 2009, 39(5): 973-977. (LIANG Caihua, ZHANG Xiaosong, JIANG Yunyu. Novel air handling method and its energy-saving potential in air-condition system[J]. Journal of Southeast University (Natural Science Edition), 2009, 39(5): 973-977.)

[9] Liu J, Zhang X S. Performance analysis of a novel double-temperature chilling water unit using large temperature glide zeotropic mixture[J]. Procedia Engineering, 2015, 121: 1222-1229.

[10] 刘剑, 张小松. 冷冻水流量和温度对基于混合工质的双温冷水机组性能影响[J]. 制冷学报, 2015, 36(6): 83-89.(LIU Jian, ZHANG Xiaosong. Effect of variable chilled water flow rates and temperature on performance of double temperature chiller with large temperature glide zeotropic refrigerant[J]. Journal of Refrigeration, 2015, 36(6): 83-89.)

[11] 芮胜军, 张华, 吴裕庆. 非共沸混合工质单级压缩回热循环试验研究[J]. 制冷学报, 2012, 33 (6): 63-67. (RUI Shengjun, ZHANG Hua, WU Yuqing. Experimental study of single-stage compression heat regenerative cycle of zeotropic refrigerant mixtures[J]. Journal of Refrigeration, 2012, 33(6): 63-67.)

[12] Bejan A. Advanced engineering thermodynamics [M]. Hoboken, New Jersey, United States: John Wiley & Sons, 1988.

[13] Ahamed J U, Saidur R, Masjuki H H. A review on exergy analysis of vapor compression refrigeration system[J]. Renewable & Sustainable Energy Reviews, 2011, 15(3): 1593-1600.

[14] Kabul A, Kizilkan Ö, Yakut A K. Performance and exergetic analysis of vapor compression refrigeration system with an internal heat exchanger using a hydrocarbon, isobutane (R600a)[J]. International Journal of Energy Research, 2008, 32(9): 824-836.

[16] Kaynakli O, Saka K, Kaynakli F. Energy and exergy analysis of a double effect absorption refrigeration system based on different heat sources[J]. Energy Conversion & Management, 2015, 106: 21-30.

[17] Yataganbaba A, Kilicarslan A, Kurtbas I. Exergy analysis of R1234yf and R1234ze as R134a replacements in a two evaporator vapour compression refrigeration system[J]. International Journal of Refrigeration, 2015, 60: 26-37.

[18] 刘兆永, 赵力, 赵学政. 高温热泵工况下非共沸工质在换热器中的换热特性[J]. 化工学报, 2011, 62(12): 3386-3393. (LIU Zhaoyong, ZHAO Li, ZHAO Xuezheng.Heat exchange characteristics of zeotropic mixture in heat exchangers in high temperature heat pump[J]. CIESC Journal, 2011, 62(12): 3386-3393.)

About the corresponding author

Zhang Xiaosong, male, professor, School of Energy and Environment, Southeast University, +86 13951974528,E-mail: rachpe@seu.edu.cn. Research fields: new technology of refrigeration and performance optimization of air conditioning system.

Exergy Analysis of Double Cooling Source Refrigerating Unit Based on Large Temperature Glide Zeotropic Mixture

Man Liang Zhang Xiaosong Liu Jian Xu Guoying

(School of Energy and Environment, Ministry of Education of Key Laboratory of Energy Thermal Conversion and Control, Southeast University, Nanjing, 210096, China)

To study the influence of the temperature of chilled water on the exergy loss of the double cooling source refrigerating unit, the model of exergy analysis on the unit that adopts the large temperature glide zeotropic mixture R32/R236fa (60%/40%) as refrigerant is established, and the experimental platform of the double cooling source refrigerating unit was set up for experimental exergy analysis in this paper. The theoretical exergy loss and the experimental exergy loss of the refrigeration unit are studied when the condensation temperature is 32 ℃ and the temperature of chilled water is 18 ℃/8 ℃, 17 ℃/6 ℃, and so on respectively. The results show that the minimum exergy destruction occurs when the inlet water temperature of the condenser is 32 ℃, higher and lower outlet water temperatures of the evaporator are 8 ℃ and 17 ℃. At the same time, the maximum exergy loss of the unit is compressor, followed by the condenser.

zeotrope; chiller; test conditions; exergy analysis

0253- 4339(2017) 02- 0089- 07

10.3969/j.issn.0253- 4339.2017.02.089

国家重点研发计划项目(2016YFC0700303)和国家自然科学基金(51376044)资助项目。(The project was supported by the China National Key R&D Program (No. 2016YFC0700303) and the National Natural Science Foundation of China (No. 51376044).)

2016年4月21日

TB61+2;TU831.4

A

张小松,男,教授,东南大学能源与环境学院,13951974528,E-mail: rachpe@seu.edu.cn。研究方向: 制冷新技术与制冷空调系统性能优化。