Research on Assessment Methods of Spectral Reflectance Data Quality for Computer Color Matching

HE Cheng-dong, WAN Xiao-xia*, HUANG Xin-guo,2,3,CHEN Hua-pei, OU Li-guo, ZHAO De-fang

1. Department of Printing and Packaging,Wuhan University,Wuhan 430079,China 2. School of Packaging and Material Engineering,Hunan University of Technology,Zhuzhou 412007,China 3. Time Publishing and Media Co.,Ltd.,Hefei 230071,China 4. Changde Jinpeng Printing Co.,Ltd.,Changde 415000,China

Research on Assessment Methods of Spectral Reflectance Data Quality for Computer Color Matching

HE Cheng-dong1, WAN Xiao-xia1*, HUANG Xin-guo1,2,3,CHEN Hua-pei4, OU Li-guo4, ZHAO De-fang1

1. Department of Printing and Packaging,Wuhan University,Wuhan 430079,China 2. School of Packaging and Material Engineering,Hunan University of Technology,Zhuzhou 412007,China 3. Time Publishing and Media Co.,Ltd.,Hefei 230071,China 4. Changde Jinpeng Printing Co.,Ltd.,Changde 415000,China

Spectral reflectance data quality is important for computer color matching. There are two existing methods for evaluating the quality—spectral reflectance method andK/Smethod, which are too complex to apply. In this paper, 45°/0° andd/8° geometric conditions are used in the measurement of spectral reflectance of the offset ink samples printed on coated paper and silver-foiled paper while improvement on the geometric condition is made on the basis of the spectral reflectance method. Moreover, a new evaluation method—lightness and chromaticity comparative method is put forward, and comparison is made among the three methods. The results show that both 45°/0° andd/8° are feasible in the measurement of spectral reflectance of coated paper; however the former one cannot meet the requirement of spectral reflectance measurement of silver-foiled paper. In addition, as tod/8° Specular Component Included (SCI), when the silver-foiled paper is taken as the substrate, the reflectance of transparent white ink samples are smaller than that of other primary inks; and abnormal intersections appear in the curves of cyan and magenta ink respectively at the concentration of 60%, resulting in a poor spectra quality at high ink concentration; In the figure of lightness and chromaticity curves, there is significant divergence of the cyan and magenta ink curves from the referenced coated paper. In conclusion, the spectral reflectance of the transparent ink should be greater than or at least equal to other primary inks, and the maximum concentration of cyan and magenta should be limited; when the coated paper with good diffusion performance is taken as the reference, the comparative analysis is more intuitive than the two existing methods.

Computer color matching;Basic color samples;Spectral reflectance data;Quality evaluation;Geometries

Introduction

The spectral reflectance data of primary ink samples is the prerequisite for computer color matching. Spot color is widely used in packaging printing industry so that the accuracy of spot color is of vital importance for the quality of printing products with spot colors. Usually at least three primary inks are taken as basic inks in terms of the acquisition of spectral reflectance data of basic color samples, and there are 8-12 different concentrations for each ink[1-2].

At present, the two major methods for computer color matching are spectra matching and tristimulus value matching, and the common core of both methods is the linear relationship between the target color sample and the spectral reflectance of basic ink samples. It can be seen that the accuracy of spectral reflectance of basic ink samples directly influences the formula of spot color. To grantee the accuracy, Jin fujiang made correction by subtracting the minute constant reflectance on the surface and Saunderson made correction for the measured reflectance with coefficients based on the specular reflection on the surface[3-4].

Two major evaluation methods for quality of spectral reflectance data are spectral reflectance evaluation method andK/Sevaluation method. The former one is based on the graphic relationship between the spectral reflectance and the concentration of each basic ink, while the later one is based on the graphic relationship between theK/Svalue and the concentration. The figure is complex and not intuitive because of the measurements of the spectral reflectance andK/Svalue of each sample. Meanwhile, the spectral energy of the illuminant overwhelms that of the object surface because of the high gloss of silver-foiled paper[5-6], resulting in the poor accuracy of color matching and the difficulty in application in production. Therefore in this paper, a more intuitive methods the lightness and chromaticity comparative methods is puts forward, with the coated paper as reference due to its good diffusion performance and mature application in color matching for offset printing, and ultimately analysis of the problems in the ink database and improvement on the accuracy of basic spectral data are made.

1 Evaluation methods for spectral data quality

1.1 Spectral reflectance evaluation method

In this method, analysis is made on graphic relationship between the corrected spectral reflectance and the concentration of the basic inks. A regular parallel in the relationship indicates high quality of the spectral reflectance data of the samples. A minute constant reflectance on the surface is subtracted from the measured reflectance because of the direct reflectance on the surface and then the spectral reflectance data after the first correction is obtained[3].

r′(λ)=(1-1.0%)r(λ)

(1)

λis the visible spectrum (300~700 nm);r(λ) is the reflectance measured;r′(λ) is the spectral reflectance data after the first correction. Correction of the ink samples on the coated paper is unnecessary since the paper is evenly covered by the ink so thatr′(λ) equalsr(λ).

Kubelk-Munk(K-M) is based on the hypothesis of constant reflectance. However the calculation is very complex in fact as a result of the specular reflection on the interface between air and the ink. The formula by Saunderson is shown as follows[4,7].

(2)

ρ(λ) is the corrected reflectance;k1(about 0.04) is the Fresnel reflection coefficient of the parallel light;k2(about 0.4~0.6) is the Fresnel reflection coefficient of the diffused light inside out.

1.2 K/S evaluation method

The K-M theory is widely used in pigment color matching[8,10]. In this theory, the reflectance and transmission of light are described with the absorption coefficientKand diffusion coefficientS. TheSof ink is a constant because its diffusion can be neglected compared with that of the substrate as ink is transparent. As a result, theK/Scan be treated as a whole11. The following formula expresses the linear relationship between theK/Svalue and concentration (c) of the ink mixture.

(3)

(K/S)λ,mixis the ratio of the absorption coefficientKto the diffusion coefficientSof the ink mixture at the wave length ofλ; (K/S)λ,Subis the ratio of the absorption coefficientKto the diffusion coefficientSof the substrate;ciis the concentration of theithink;Φλ,Iis theK/Svalue of theithink at one unit concentration and at the wavelength ofλ.

The following formula describes the relationship of theK/Svalue and the concentration (c) of the ink in the evaluation of the spectral reflectance data of the primary ink.

(4)

It can be concluded that linear relationship exists between lg((K/S)i) and lg(ci) and the slope is 0 or 1. OnlyK/Svalue in accordance with this relationship can meet the requirement of the spectral reflectance data of the basic ink.

2 The acquisition of basic spectral reflectance data

In this paper, yellow, magenta, cyan and transparent white ink are mixed at a certain ratio to get the basic ink, then color samples are printed with the printability tester (IGT C1-5,at a printing pressure of 300 N) on 250 g·m-2silver-foiled paper and 128 g·m-2coated paper respectively, and finally the spectral reflectance of the samples is measured with Spectroeye (45°/0°) and ColorEye 7000A (d/8°).

3 The evaluation of the quality of the spectral reflectance data and results analysis

3.1 The comparative analysis of spectral reflectance data

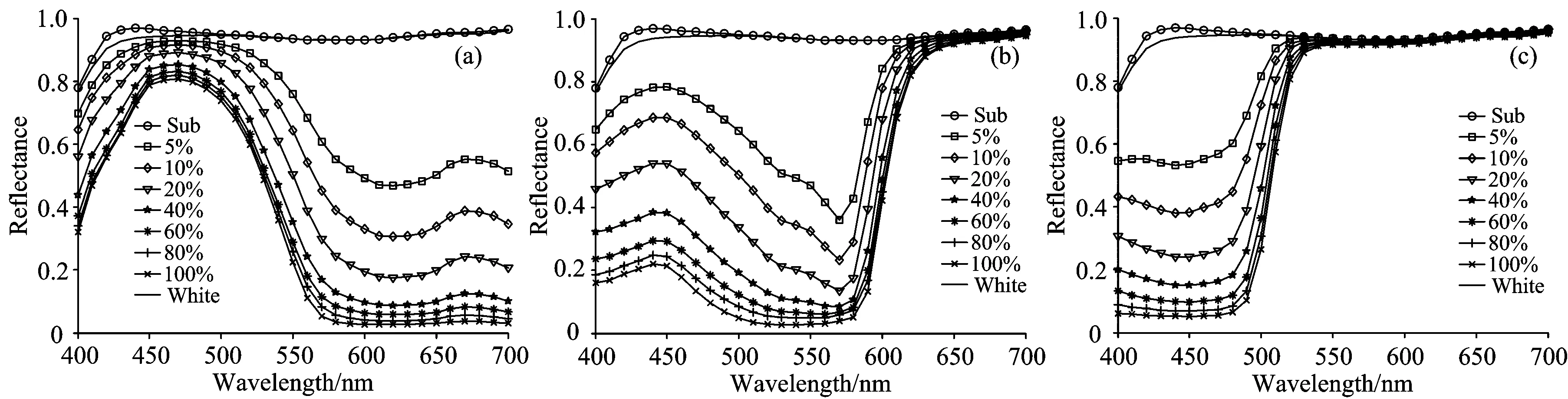

Fig.1 and Fig.2 show the reflectance curves of samples printed ink at different concentrations on coated paper and silver-coated paper respectively obtained with Spectroeye. It can be seen from Fig.1 that the spectral reflectance curves parallel regularly and the spectra quality is satisfying when coated paper is taken as the substrate. While Fig.2 shows that when silver-coated paper is taken as the substrate, the measured reflectance of the printed paper is greater than that of the unprinted paper because the 45°/0° geometry of the Spectroeye is only capable to measure the diffuse reflection and the diffuse reflection of the printed silver-foiled paper is greater than that of the unprinted paper. Obviously it cannot meet the requirement of the spectral reflectance data of basic inks. Therefore it can be concluded that the 45°/0° geometric condition can be applied to the measurement of the coated paper, but not to silver-coated paper.

Fig.1 Spectral reflectance of cyan (a), magenta (b) and yellow (c) on coated paper at different concentrations under 45°/0°

Fig.2 Spectral reflectance of cyan (a), magenta (b) and yellow (c) on silver-foiled paper at different concentrations under 45°/0°

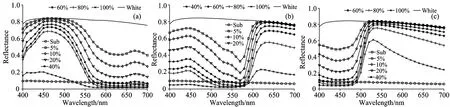

Fig.3 and Fig.4 show the reflectance (after correction) measured with ColorEye 7000A at SCI mode of samples printed on coated paper and silver-foiled paper respectively with ink at different concentrations. It can be seen from Fig.3 that the spectral reflectance curves also parallel regularly and the spectra distribution is satisfying when the samples are printed on coated paper. While in Fig.4 when samples are printed on the silver-foiled paper, it is different from that on the coated paper as the reflectance increases as the ink concentration decreased at the wavelength of 630~700 nm of magenta samples and at the wave length of 530~700 nm of yellow samples and the curves intersect with each other. This is because the reflectance of samples printed with transparent white ink on silver-foiled paper is smaller than that of the yellow and magenta samples over a certain spectra. And abnormal intersections also appear in the curves of cyan samples at the concentration of 60%~100% and the wavelength of 400~560 nm and of magenta samples at the concentration of 60%~100% and the wavelength of 400~480 nm. Therefore thed/8° (SCI) is feasible in the measurement of spectral reflectance of both coated paper and silver-foiled paper. Note that the concentration of cyan and magenta ink should be limited to a set maximum in color matching for silver-foiled paper.

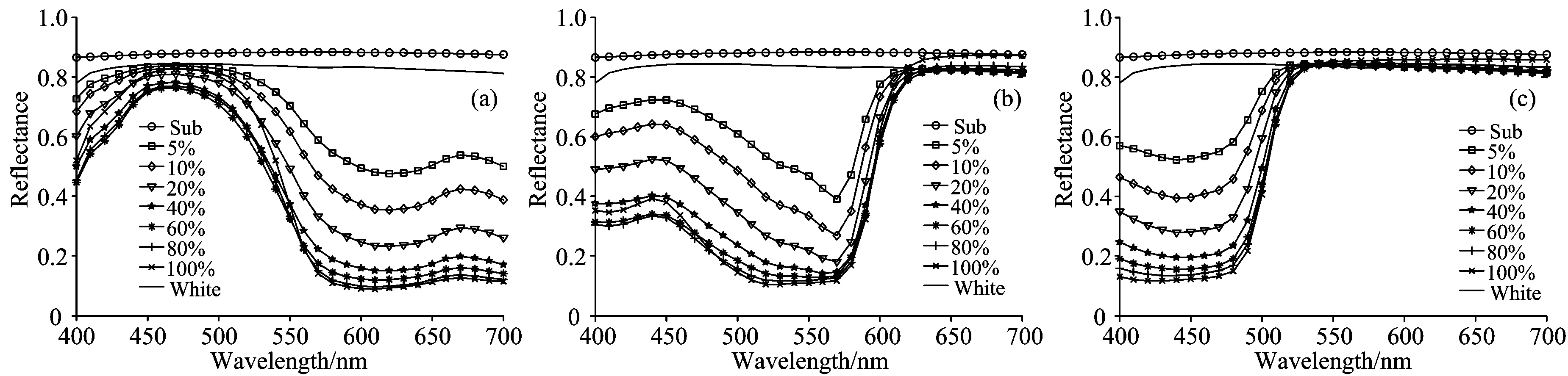

3.2 The K/S logarithm comparative method

Fig.5 shows the linear relationship between lg(K/S) and lg(C) of cyan sample printed on coated paper and silver-foiled paper underd/8°(SCI). For curves of cyan samples printed on coated paper, most slopes approximate to 1, which means that the basic data of the coated paper accord well with the theoretical relationship of lg(K/S) and lg(C). However, negative slopes appear in curves of cyan samples printed on silver-foiled paper, indicating that curves intersect with each other; part of ink concentrations for silver-foiled paper are in accordance with the theoretical relationship of lg(K/S) and lg(C) as the slopes approximate to 1 when the concentration of the cyan ink is under 60%. It is also the case for magenta and yellow samples. As a whole, the quality of the basic spectral reflectance data of the coated paper is better than that of the silver-foiled paper.

Fig.4 Spectral reflectance of cyan (a), magenta (b) and yellow (c) on silver foil paper at different concentrations under d/8°(SCI)

3.3 The lightness and chromaticity comparative method

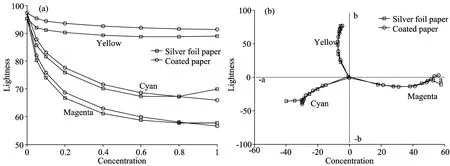

The lightness and chromaticity obtained underd/8°(SCI) of cyan, magenta and yellow samples are shown in Fig.6. It can be concluded from the aforementioned two methods that the basic spectral reflectance data of coated paper at all concentration is satisfying. Therefore, the quality of the spectral reflectance data of the silver-foiled paper is analyzed with coated paper taken as the reference.

From both Fig.6(a) and (b) it can be seen that the lightness curves of yellow ink almost parallel with each other, and there is a similar tendency for the chromaticity on both coated paper and silver-foiled paper, therefore the spectral data quality of yellow samples is better compared with that of cyan and magenta samples. However the lightness and chromaticity curves of magenta and cyan samples at the concentration of 60% on the silver-foiled paper deviate from that on the coated paper, and the divergence in the cyan sample curves is worse than magenta sample curves, indicating the poor quality of spectral reflectance data of magenta and cyan samples at high concentration. In conclusion, the maximum concentration of magenta and cyan ink should be limited when the silver-coated paper is taken as the substrate, and the lightness and chromaticity comparative method is much more intuitive than the spectral reflectance data comparative method and theK/Slogarithm comparative method.

Fig.6 Comparison of lightness L*(a) and chromaticiry a*b*(b) at different concentrations on coated and silver-foiled paper

4 Conclusion

In this paper, analysis is made for the spectral reflectance data on coated paper and silver-foiled paper, with different geometric conditions and different methods. The results show that both 45°/0° andd/8° are feasible in the measurement of spectral reflectance of coated paper, and the data of silver-foiled paper obtained with 45°/0° cannot meet the requirement of basic spectral reflectance data in color matching. In addition, underd/8°(SCI), the reflectance of transparent white ink samples are smaller than that of other primary ink samples when the silver-foiled paper is taken as the substrate, and abnormal intersections appear respectively in the curves of cyan and magenta samples at the concentration of 60%, resulting in a poor spectra data quality. Therefore the spectral reflectance of the transparent white ink should be greater than or at least equal to other primary inks, and the maximum concentration of cyan and magenta inks should be limited. When the coated paper with good diffusion performance is taken as the reference, the lightness and chromaticity comparative method is more intuitive than the two existing methods.

[1] Lin J,Xu L,Zhang H Y. Color Research and Application,2013,39(6): 607.

[2] Choudhury A K R. Principles of Colour Appearance and Measurement,1st end. Cambridge: Woodhead Publishing,2014. 117.

[3] JIN Fu-jiang,TANG Yi-ping. Journal of Wuhan University of Technology·Information & Management Engineering,2008,30(1): 83.

[4] Saunderson J L. J. Opt. Soc. Am.,1942,32(12): 727.

[5] Huang X G,Wan X X,Liu Z. Color Research and Application,2013,38(2): 130.

[6] YUAN Kun,YAN Hui-min,JIN Shang-zhong,et al. Acta Optica Sinica,2013,33(11): 1.

[7] Bondioli F,Manfredini T,Romagnoli M,et al. Journal of the European Ceramic Society,2006,26(3): 311.

[8] Furferi R,Carfagni M. J. Applied Sci.,2010,10(18): 2108.

[9] Kubelka P,Munk F. Zeit Tech. Phys.,1931,12: 593.

[10] WANG Gong-ming,LIU Zhi-yong. Spectroscopy and Spectral Analysis, 2015,35(6): 1682.

[11] Allen E. Journal of the Optical Society of America,1966,56(9): 1256.

*通讯联系人

O433

A

用于计算机配色的反射光谱数据质量评估方法研究

何成栋1,2,万晓霞1*,黄新国1,2,3,陈华培4,欧立国4,赵德方1

1. 武汉大学印刷与包装系,湖北 武汉 430079 2. 湖南工业大学包装与材料工程学院,湖南 株洲 412007 3. 时代出版传媒股份有限公司,安徽 合肥 230071 4. 常德金鹏印务有限公司,湖南 常德 415000

基础色样的反射光谱数据质量是影响计算机配色结果的重要因素之一。目前评价配色反射光谱数据质量的方法有反射光谱检测法和K/S检测法,但这两种方法需检测每种基础色样和各个波长的反射率与K/S值,检测过程过于复杂,故不适用于光谱数据质量的快速直观检测。本文使用45°/0°和d/8°几何条件的分光光度计测量以铜版纸和银卡纸为基材的胶印油墨基础色样反射光谱数据,基于光谱检测法优化获取基础色样反射光谱数据的几何条件,提出了一种明度色度对比检测法;并对比分析了反射光谱检测法,K/S检测法和明度色度对比检测法。结果表明,45°/0°和d/8°几何条件均可用于铜版纸基础色样反射光谱数据的测量,但45°/0°几何条件不符合银卡纸基础色样反射光谱数据的测量要求;而对于d/8°分光光度计,在包含镜面反射时,银卡纸为基材的透明白反射率小于各基色墨反射率,且青墨与品红墨反射率分别在浓度为60%开始出现异常交叉,从而导致高浓度区域光谱质量较差;而在明度色度对比检测图中,青墨与品红墨样条与参考铜版纸基础数据偏离更加明显。故须选择大于或等于各基色墨反射率的透明白,基础色样中需约束青墨与品红墨的最大浓度;以漫反射特性较好的铜版纸作为配色基材时,明度色度对比检测法检测效果较现有两种检测法更为直观。

计算机配色;基础色样;光谱数据;质量评价;几何条件

2015-11-12,

2016-03-10)

Foundation item: National Basic Research Program of China (2012CB725302) ,National Natural Science Foundation of China (61275172) ,National Natural Science Foundation of China (61575147) ,Postdoctoral Research Foundation of Anhui province, China (2015B060)

10.3964/j.issn.1000-0593(2016)11-3805-06

Received: 2015-11-12; accepted: 2016-03-10

Biography: HE Cheng-dong,(1990—),graduate student of Wuhan University e-mail:heironhand@163.com *Corresponding author e-mail: wan@whu.edu.cn