Influence of Low Temperature on Laser Transmission Efficiency in Laser Initiation Subsystem

HE Ai-feng, CHU En-yi, CAO Chun-qiang, JING Bo, XU Feng-yi, LI Ming, ZHAO Dong-ya

(Shaanxi Applied Physics-Chemistry Research Institute (SAPC), Xi′an 710061, China)

1 Introduction

For coal mining engineering or weapon applications, the laser diode initiation (LDI) subsystem should be able to work at low temperature as -40 ℃[1]. Because of the loss of LDI subsystem at low temperature, thermal sensitivity of the tetraammine bis(5-nitro-tetrazolato)cobalt(Ⅲ) perchlorate (BNCP) reagent, the transmission loss of optical fiber elements is remarkable, the driving current of the semiconductor laser is changed with temperature, so the LDI subsystem is sensitive to low temperature. All these sensitive factors make the laser energy less than the design value, which affect the firing reliability of the subsystem. Many literatures[2-5]mention the optical fiber devices and semiconductor lasers in the LDI were sensitive to temperature, will cause the laser energy loss and may make the subsystem failure. In literatures [2-3], the effect of temperature variation on the laser power was studied. In literatures [4-5], the temperature sensitivity of various fiber optic line configurations was studied. However, the effect of low temperature on laser transmission efficiency in the whole laser initiation subsystem has not been studied.

In this work, the high reliability of the subsystem was verified via study about the effect of low temperature on the dual-way subsystem. Study on quantitative fitting of experimental results was performed. The results obtained can be used to guide the design and application of laser initiating device at low temperature.

2 Dual-way LDI Subsystem

A dual-way LDI subsystem composed of laser diode, optical fiber, optical switch, dual-way fiber optic splitter, and laser initiators in Fig.1 was developed. The function process is that: when laser source 1 receives a command to fire, it first gives the optical switch 5 a signal to remove the interrupter and makes the path unblocked, then laser source 1 emits a 10 ms laser pulse, the laser transmits to laser initiators 7 via fiber pigtail 2, fiber optic adaptors 3, dual-way fiber optic splitter 4, unblocked optical switch 5 and fiber optic cables 6, making laser initiators initiate.

Fig.1 Schematic diagram of dual-way laser initiation system

1—laser, 2—fiber pigtail, 3—fiber optic adaptor, 4—dual-way fiber optic splitter with two ports, 5—optical switch, 6—fiber optic cable, 7—laser initiator, 8—controlling electrical cable

2.1 Laser Initiator

A laser initiator was designed using grad-index optical component, standard optical connecting technique and BNCP(tetraammine bis (5-nitro-tetrazolato)cobalt(Ⅲ) perchlorate)[6-7], the pyrotechnic composition being sensitive to laser. The initial energetic material of the laser initiator was the fine BNCP composition doped with 3% photo-sensitizer, next to it was DDT and output coarse BNCP column.

2.2 Laser Source

The laser source employed in the laser initiation subsystem was a multimode laser diode with wavelength of 2 W and power of 976 nm (K976D06FN-3.00 W from BWT Beijing LTD.). It had a threshold current of 0.2 A and a peak laser power of 2 W under a driving current of 2.5 A. The laser source was driven by electrical circuit to output a 10 ms single laser pulse, with pulse energy of 15 mJ.

2.3 Transmitting and Coupling Fiber Optic Network

It was proved by analysis and experiment that a higher coupling efficiency could be gained between fiber optic pairs with same or similar specification. Accordingly, in the transmitting and coupling network of laser initiation subsystem, coupled fiber optic cable pairs should be made with same specification, in this work a grad-index 100/140 μm core multimode fiber with NA(numerical aperture)=0.29 (GI 100/140-29/250 type from YOFC) was employed.

Each optical fiber element intransmitting and coupling fiber optic network had a cable part. For example, laser diode′ pigtail cable was its cable part. The fiber optic cable had only cable part. While the dual-way fiber optic splitter and optical switch were composed of cable part and coupling part. The cable part was composed of GI 100/140-29/250, PVC inner jacket with diameter of 0.9 mm, Kevlar, buffer coating, outer jacket and FC/PC fiber optic connector.

Coupling part of dual-way fiber optic splitter was made by fusion of two large diameter optic fibers. In the condition of laboratory, a total coupling and transmitting efficiency of about 80%, with a splitting uniformity of 50/50 was obtained with a 976nm laser diode.

The barrier-moving mode optical switch[8]was designed comprising of two GRIN lenses separated by an electrically driven barrier, each GRIN lens coupled with a pigtail fiber of FC/PC connectors. When switched on, the barrier between two lenses was driven to move away by a DC 5V signal, the laser entered from the INPUT fiber was aligned to parallel light by the aligning lens and arrived at the focusing lens, laser light was in turn focused to the OUTPUT fiber. When switched off, the barrier returned to its original position, no light could be coupled to the OUTPUT fiber pigtail.

3 Experimental Method and Set-up

3.1 Sensitivity Test Method for Laser Initiator

By using Bruceton sensitivity test method[9], firing tests to the BNCP laser initiator were carried out with a 976 nm 10 ms laser diode at 20 ℃ and -40 ℃ separately, their results were used to analyze whether there are significant performance differences.

3.2 Environmental Test Method and Set-up

The environmental test chamber used in this research was an EXCAL5423-H type chamber. The operating temperature range for the environmental test chamber is from -75 ℃ to +180 ℃, with a cooling rate of 5 K·min-1and a heating rate of 10 K/min according with IEC 60068-3-5. In order to be cooled adequately, the LDI subsystem or its individual part was put into the environmental test chamber at least 20 min.

3.3 Initiation Experimental Set-up

Fig.2 provides an experimental set-up for dual-way laser initiation network, by which the character parameters of the initiation system can be acquired. The testing process is described as following. At the same time of laser emitting, the synchronous signal is sent out by laser to data collection apparatus. The laser energy transmits to laser initiators via fiber pigtail, fiber optic adaptor and dual-way fiber optic transmitting network. Laser initiators are then initiated. The exploding output of laser initiator is transformed to electric signal by probe. The laser wave signal and transformed exploding signal are recorded and analyzed by the data collection apparatus. Function time for each laser initiator is calculated by time difference between the two signals of corresponding way.

Fig.2 Schematic diagram of experimental set-up for dual-way laser initiation system

1—test probe, 2—explosion protecting box, 3—multi-way data collection apparatus or oscilloscope, 4—electrical testing cable, 5—synchronous or trigger controlling cable

4 Results and Discussion

4.1 Environmental Performance of LDI Subsystem under Low Temperature

4.1.1 Laser Initiator

Two groups of sensitivity test results for BNCP laser initiators are shown in Table 1.

Table 1 Sensitivity results of the BNCP laser initiators at 20 ℃ and -40 ℃

temperature/℃averagefiringlaserenergy/mJamountsstandarddeviation99.9%firinglaserenergyat0.95confidencelevel/mJ0.1%firinglaserenergyat0.95confidencelevel/mJ200.525290.0830.7830.267-400.505300.0650.7470.263

From Table 1, we can find that at 20 ℃, 99.9% firing laser energy of the BNCP laser initiator at 95% confidence level is estimated as 0.783 mJ from laser sensitivity test. After exposure to -40 ℃, 99.9% firing laser energy of the BNCP laser initiator at 95% confidence level is estimated as 0.747 mJ. No significant performance decrease of the laser initiator is found.

4.1.2 Laser Source

As is well known in the art, laser diode is variable to its working temperature. The LD output power falls down as temperature rises up and vice versa. Consequently, when working under a lower temperature, the LD power may excess its upper limit, which may partially or completely cause the damage of the laser emitting surface, i.e., the damage of LD. To keep the LD from damage, the laser source is driven under a much lower current with the output power of about 1.4 W in this work. Temperature compensation design[3]to laser source makes it have an output of 1.322-1.413 W at -40-20 ℃, shown in Fig.3.

Fig.3 Temperature vs. power and fitted curve for diode laser generator

Using a cubic model, the LD power data were interpolated in Fig.3, with the norm of residuals=0.015586 W. An experiential formula (1) describing the curve of laser output versus temperature of the diode fiber generator is obtained.

P(LD)=2.3×10-6T3+7.4×10-5T2-0.0028T+1.3

(1)

4.1.3 Fiber Optic Cable

At -40-20 ℃, transmitting and coupling test to fiber optic cable is conducted(Fig.4). The mismatch between fiber and outer jacket may cause micro-bending and in turn can cause coupling loss increase if they are adhered together tightly. In our research, there is a 1 mm gap left between theΦ0.9 mm PVC inner jacket and the FC/PC fiber optic connector, which is helpful to eliminate or reduce the mismatch between GI 100/140-29/250 fiber and inner jacket while temperature decreases.

Fig.4 Experimental results and fitted curve of fiber optic cable under low temperature environment

Through mathematical analysis to the experimental results in Fig.4, an experiential formula (2) describing the curve of efficiency versus temperature of the fiber optic cable is obtained.

ηT(fiber)=-0.0048T2-0.016T+96

(2)

In design of laser initiation subsystem, a transmitting efficiency withTcan be calculated by Eqn.(2).

4.1.4 Dual-way Fiber Optic Splitter

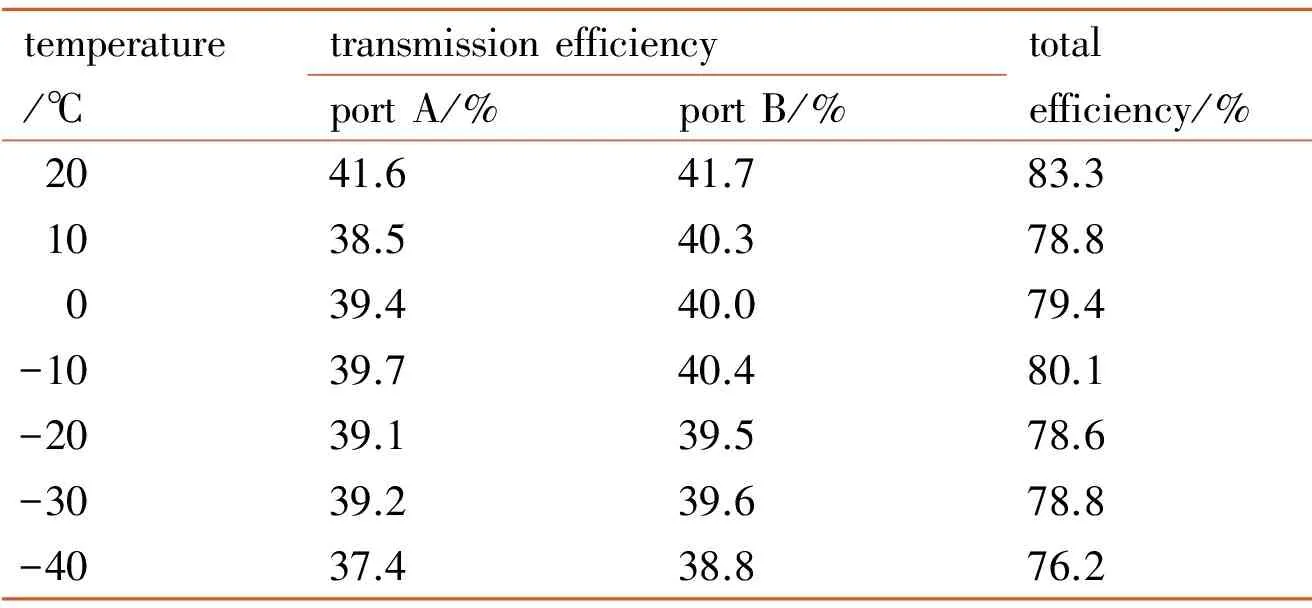

Fig.5 and Table 2 show the results by transmitting and coupling test under low temperature for dual-way fiber optic splitter. The splitting ratio for the two ports remains as 50/50. Under -40 ℃, the total efficiency has a decrease of about 7% compared to efficiency at 20 ℃. Stress due to temperature in the fusion coupling part will cause the increase of coupling energy loss under low temperature.

Through mathematical analysis to the experimental results in Fig.5, an experiential formula (3) describing the curve of total efficiency versus temperature of the fiber optic splitter is obtained.

ηT(splitter)=0.00018T3+0.0056T2+0.016T+79

(3)Table 2 Results for influence of low temperature on optical splitter

Fig.5 Experimental result and fitted curve of fiber optic splitter under low temperature environment

4.1.5 Optical Switch

In the temperature range of -40 ℃ to +20 ℃, transmitting and coupling test to fiber optic switch is conducted. Experimental results are shown in Fig.6. The coupling part of the optical switch is GRIN lens coupled with a pigtail fiber, stress due to temperature in this part will cause the increase of coupling loss under low temperature.

Fig.6 Experimental results and fitted curve of optical switch under low temperature environment

Through mathematical analysis to the experimental results in Fig.6, an experiential formula (4) describing the curve of efficiency versus temperature of the optical switch is obtained.

ηT(switch)=0.00035T3+0.014T2-0.0044T+65

(4)

4.2 System Margin Analysis

The system margin is defined as:

Margin=E(fire,T)min/E99.9%@95%max

(5)

WhereE(fire,T)minstands for the minimum delivered firing energy to each laser initiator, andE99.9%@95%maxstands for the maximum 99.9% firing laser energy of the BNCP laser initiator at 95% confidence level (from Table 1,E99.9%@95%max=0.783 mJ).

For LDI subsystem in this work, the delivered firing energy to each laser initiator can be expressed as equation (6).

E(fire, T)=Elaser·ηsplitter·ηswitch·ηcable

(6)

WhereP(LD)×10 stands for the total energy of a 10 ms single laser pulse from the laser source.

Fig.7 shows the relationship between firing laser energy of each initiator and temperature calculated from equation (6). The minimum delivered firing laser energy to each laser initiator occurs at -40 ℃. Then it can be calculated with equation (6) as:

E(fire,T)min=E(fire,-40)=3.035(mJ)

(7)

Fig.7 Relationship between firing laser energy of each initiator and temperature

For LDI subsystem in this work, the system margin can be calculated with equation (5) as:

Margin =E(fire,T)min/E99.9%@95%

=3.035/0.783

=3.876

(8)

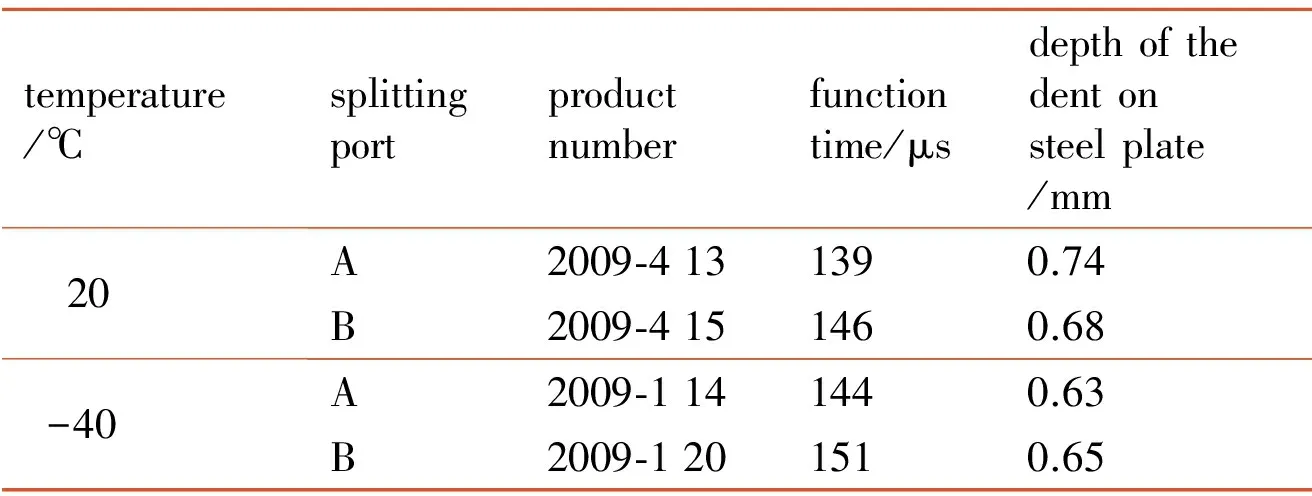

4.3 Initiation Experimental Comparison between before and after Environmental Tests

The initiation experiment was carried out on the dual-way LDI subsystem before and after the environmental tests of low temperature exposure(-40 ℃ for 4 h). The results of the experiment are listed in the Table 3.

Table 3 Initiation results of the dual-way LDI subsystem before and after low temperature tests

temperature/℃splittingportproductnumberfunctiontime/μsdepthofthedentonsteelplate/mm 20A2009⁃4131390.74B2009⁃4151460.68-40A2009⁃1141440.63B2009⁃1201510.65

From experimental results in Table 3, it can be seen that compared with performances at 20 ℃, the function time of the subsystem and the output dent of the initiator do not change significantly under -40 ℃. Fig.8 shows the typical explosion results acquired by the multi-way data collection apparatus.

Fig.8 Explosion results of the LDI subsystem

5 Conclusions

According to the sensitivity test results of BNCP laser initiator, 99.9% firing laser energy at 95% confidence level is estimated as 0.783 mJ at 20 ℃ and 0.747 mJ at -40 ℃. No significant performance difference is found.

At -40-20 ℃, a cubic fitting is introduced to mathematically analyze the influences on LDI subsystems and its parts.

Reliability and firing margin of the LDI subsystem are ana-lyzed, with a result of more than 3, meaning that an off-the-shelf LD of 2 W can meet the dual-way initiation acquirements for coal mining or weapons.

The successful initiation experiment for the dual-way LDI subsystem confirms a high reliability of subsystem.

Acknowledgement:The authors wish to thank Profs. LU Jian-cun, LIU Ju-peng, and ZHANG Rui for their given guidance in the laser energy transmission and subsystem designs, Mr. LIU Yan-yi for his suggestions in the power control of the laser source and FU Dong-xiao for his help in the laser ignition test data analysis.

[1] Denis Dilhan, Christian Wallstein, Claude Carron. Laser Diode Initiated Systems for Satellite Applications[C]∥31st International Pyrotechnics Seminar, 2004: 455-472.

[2] Richard R Craig, William Gignac, Philip Worland. Laser Diodes for Pyrotechnic Applications[C]∥AIAA-93-2359.

[3] HE Ai-feng, LIU Yan-yi, LU Jian-cun, et al. Temperature compensation of laser diode operating in pulse mode[J].ChineseJournalofEnergeticMaterials(HannengCailiao), 2004(Supplement): 618-621.

[4] Larry A Andrews, Randy J Williams. Characteriazation of Commercial Fiber Optic Connectors: Preliminary Report[R]. SAND98-1951.

[5] Thomas J Blachowski, Christopher W Brown, Dr. Peter Ostrowski. A Temperature Sensitivity Study of various Fiber Optic Line Configurations[C]∥AIAA 99-2415.

[6] Everett S Hafenrichter, Bill Marshall Jr, Kevin J Fleming. Fast Laser Diode Ignition of CP and BNCP[C]∥29thIPS, 2002: 787-793.

[7] LAO Yun-liang, SHENG Di-lun. The Science of Initiating Expolosives and Relative Composition[M]. Beijing: Beijing Institute of Technology Press, 2011.

[8] HE Ai-feng, LU Jian-cun, LIU Ju-peng, et al. Energy Interrupting Control for Laser Ordnance Firing System[C]∥25th International Symposium on Ballistics, 2010.

[9] Barry T. Neyer, James Gageby. ISO 14304 Annex B All-Fire/No-Fire Test and Analysis Methods [C]∥Proceedings of the Seventeenth Symposium on Explosives and Pyrotechnics,1999.