Half-Heusler热电材料的研究进展

严 潇,袁 波

(1.休士顿大学物理系,德州超导中心,美国 德克萨斯 77204;2.西华大学先进材料及能源研究中心,四川 成都 610039)

Half-Heusler热电材料的研究进展

严潇1,袁波2

(1.休士顿大学物理系,德州超导中心,美国 德克萨斯 77204;2.西华大学先进材料及能源研究中心,四川 成都 610039)

摘要:Half-Heuslers热电材料由于热稳定性好、机械强度高,已成为中高温废热回收领域具有潜力的候选材料。在该材料体系中,p型和n型half-Heuslers 的ZT值在最近几年得到逐步改善,其最高值已超过1.0。本文综述half-Heuslers体系的最新研究进展,包括纳米复合技术的应用、利用原子质量和尺寸差异增强合金散射、三元合金和新half-Heusler材料等,指出尽管half-Heusler的ZT值已经超过了1.0,但其成本仍然较高,如何降低half-Heusler材料的生产成本及优化新型half-Heusler材料将是未来的研究重点。目前,half-Heuslers 的ZT值的提高仍具有较大的空间,如热压后样品的平均晶粒尺寸超过了100 nm,进一步降低晶粒尺寸可提高ZT值,开展势垒过滤效应在half-Heuslers中的应用也有望提高其热电性能。

关键词:热电材料;half-Heusler;纳米复合物;合金散射

热电材料能够以环保以及低成本的方式回收工业应用和汽车尾气中排放的废热[1-2],由于这些废热排放温度约500 ℃,中高温热电材料更有应用前景。在中高温热电材料中,PbTe[3-5]、skutterudites[6]和half-Heuslers[7-8]已经得到大量研究;但是,PbTe材料具有毒性和较弱的力学强度,skutterudites的热稳定性较差,使这2种材料的大规模工业应用受到限制。可喜的是,half-Heusler材料不具有上述缺点,显示出了良好的综合性能,这使它成为在中高温应用范围内极有前途的热电材料。热电器件的能量转换效率与材料的ZT值有关,ZT值越高,则转换效率就越高。ZT定义为(S2σ/κ)T,其中S是塞贝克系数,σ是电导率,κ是热导率,T是热力学工作温度;因此,我们总是期望热电材料具有高的塞贝克系数、电导率,以及低的热导率。由于half-Heuslers热导率较高,传统的p型和n型half-Heuslers材料的最大ZT值分别仅为0.5和0.8左右[9-10]。最近,纳米复合技术在half-Heusler材料体系中得到了成功应用,使p型和n型材料的ZT值都达到了约1.0[11-18]。在已有关于half-Heusler材料综述[19-22]的基础上,本文主要介绍half-Heusler 材料的最新研究进展,包括纳米复合技术的应用、利用原子质量及尺寸差异增强合金散射及探讨三元合金和新材料等。

1Half-Heusler 的结构和性能

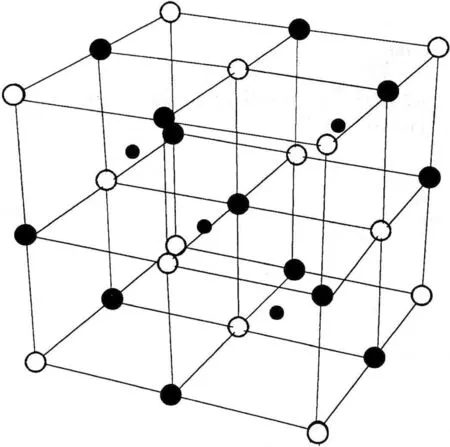

Half-Heusler通式为ABX,具有立方MgAgAs型结构。它形成了3个相互贯穿的面心立方亚晶格和1个空位亚晶格[23],如图1所示。到目前为止,p型[24-27]和n型[7,28-29]half-Heuslers的大部分研究工作分别基于ACoSb和ANiSn形式,其中A是Ti、Zr或Hf。同时,也有一些工作关注NbFeSb[17]、NbCoSn[30]和VFeSb[31]等体系。在half-Heusler中,A、B和 X 3个晶格位置具有高的可替代性,为调整half-Heuslers的热电性能提供了大量空间。例如,基于质量起伏和应力场起伏效应[24-27],对A[9,10,13-18,32-33]和B[34-36]位置元素进行取代能降低晶格热导率。同时,对X位置元素的取代能调整载流子的浓度,进而调控Seebeck和电导率[37-40]。

图1 Half-Heusler的ABX型晶体结构(大、小2种实心圆圈分别代表A和B原子,空心圆圈代表X原子,B原子占据AX亚结构立方间隙的一半[8])

在很长一段时间里,由于half-Heuslers具有相对高的热导率,其ZT值一直不高[9-10]。除了利用合金散射和晶界散射降低热导率外,纳米复合技术也能降低热电材料的热导率,从而提高材料的热电性能[41]。这一技术的应用使p型的ZT值从0.5上升到0.8[11],n型的ZT值从0.8增加到1.0[12]。ZT值提高的主要原因是在基体中形成的纳米结构物质能降低晶格热导率[11-12]。纳米复合技术已经在其他体系的热电材料上得到了应用,其在half-Heusler上的进一步应用证实了这种技术的通用性[42-47]。为探讨原子质量和不同尺寸对晶体结构及热电性能的影响,p型 Hf1-xTix体系[13]和n型Hf0.75-xTixZr0.25体系[14]也得到了研究,同时p型half-Heuslers三元合金体系的(Ti, Zr, Hf)的研究实现了用更少量的Hf取得了ZT等于1.0的目标,进一步降低了成本[16]。近期在p型[18]和 n型[15]half-Heuslers材料上的研究实现了降低材料成本的同时维持了较高的ZT值,为实现大规模的工业应用奠定了基础。同时,新型half-Heuser材料的诞生,将进一步促进热电技术的发展。

2Half-Heuslers的研究进展

2.1 纳米复合技术的应用

通过高能球磨加直流热压法,块体half-Heusler基体中形成了纳米复合相,使p型和n型half-Heuslers的性能得到明显提高[11-12]。结果表明,p型Hf0.5Zr0.5CoSb0.8Sn0.2的最大ZT值从0.5提高到0.8,n型Hf0.75Zr0.25NiSn0.99Sb0.01从0.8上升到1.0。ZT值的显著增加是由于所形成的纳米复合相加强了声子散射,导致晶格热导率显著下降。

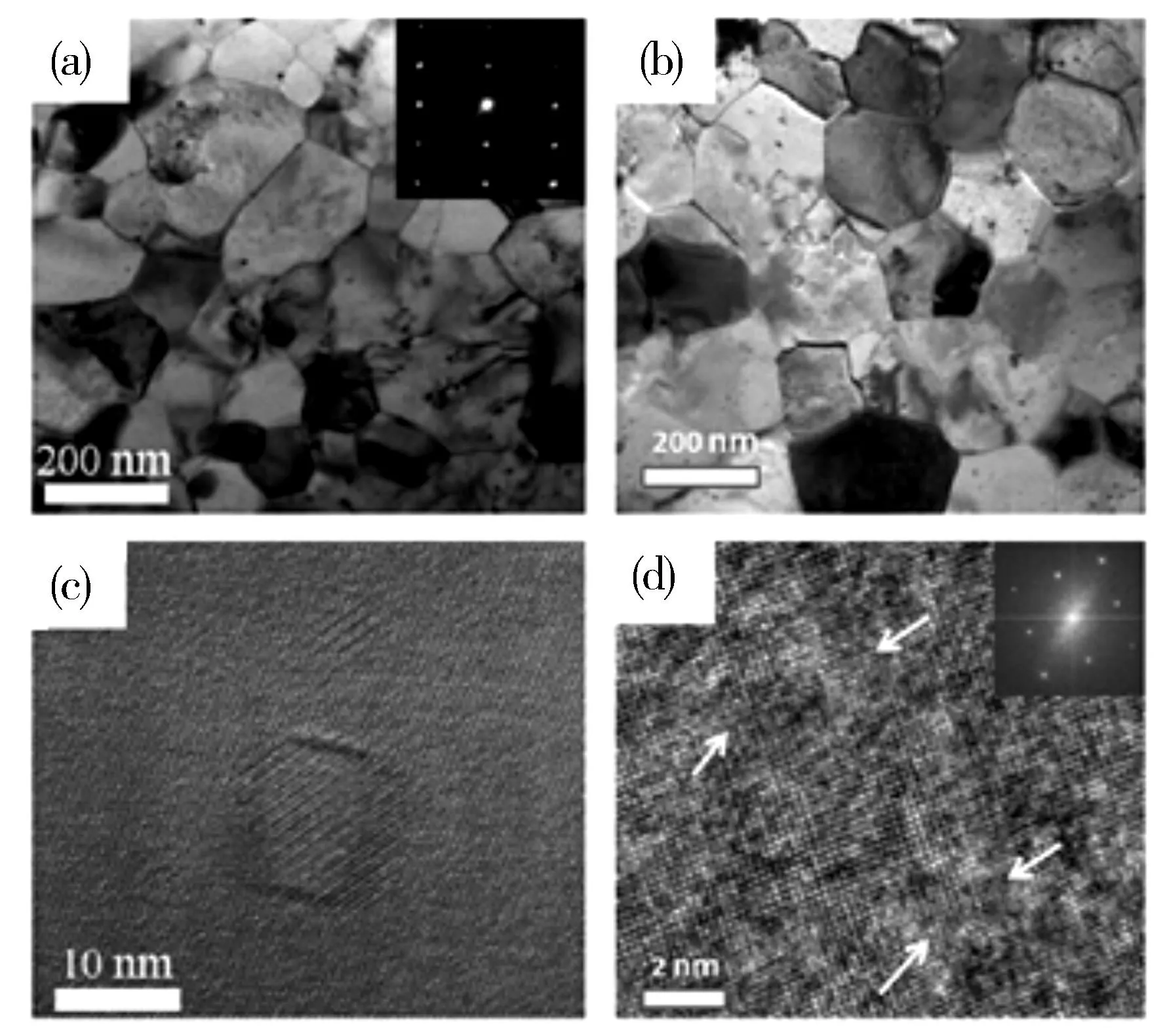

图2是p型和n型half-Heuslers的TEM微观结构图。采用球磨加热压法制备的half-Heuslers材料的平均粒径约100~300 nm,与之前的研究结果比较[48-49],晶粒尺寸更加细小,有利于加强声子散射。此外,在这些样品中存在一些值得注意的纳米结构特征物质,如图2(c)所示,在基体中嵌入了一个纳米点,进一步的EDS显示了纳米点处的成分和其周边地区的成分有所不同。图2(d)中的箭头标出的是晶格畸变区域。细小的晶粒尺寸、纳米点及晶格畸变都可能加强声子的散射,从而得到更低的热导率。

图2Half-Heusler纳米复合材料的TEM图(a. Hf0.5Zr0.5CoSb0.8Sn0.2[11]的低倍率TEM图;b. Hf0.75Zr0.25NiSn0.99Sb0.01[12]的低倍率TEM图;c. Hf0.5Zr0.5CoSb0.8Sn0.2基体中的纳米点[11];d. Hf0.75Zr0.25NiSn0.99Sb0.01中的晶格畸变区域[12])

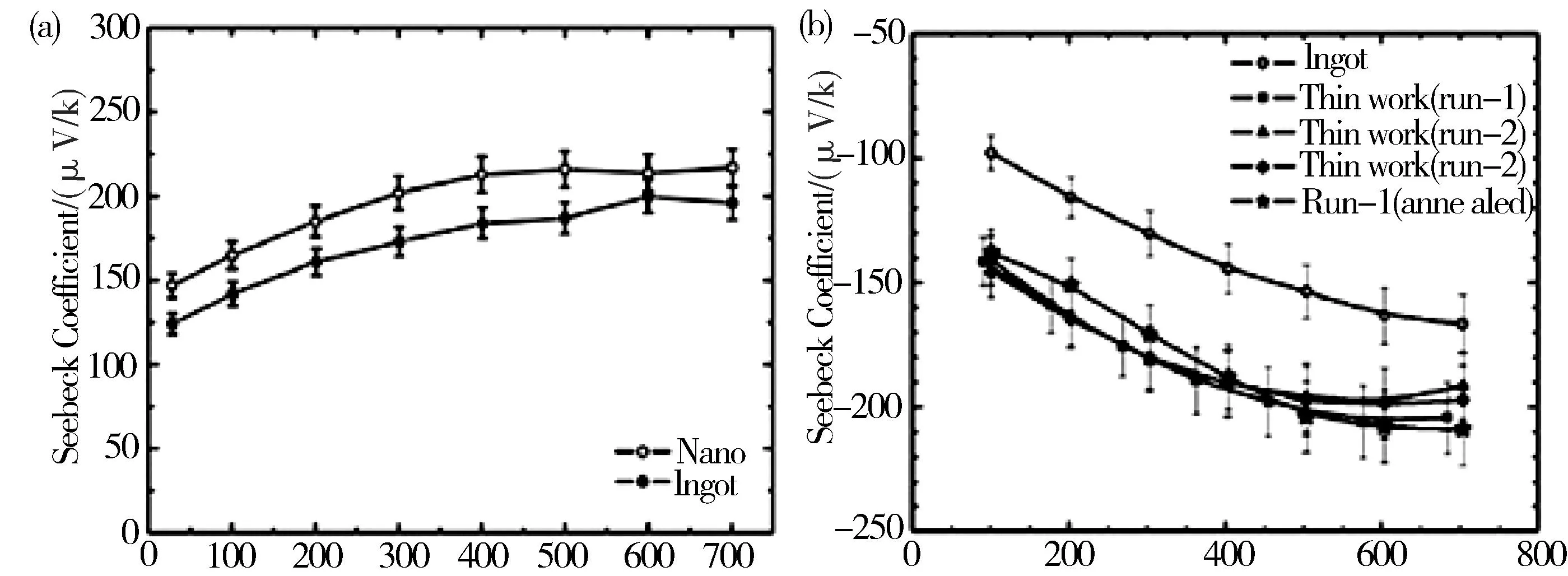

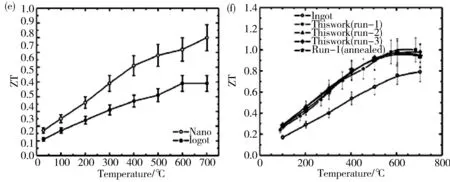

图3是p型和n型half-Heuslers的热电性能与温度的关系曲线图。由于各种纳米结构物质的出现加强了声子散射,p型和n型纳米复合材料的热导率在整个温度测量范围内比同组其他试验材料要低得多(见图3(c)和图3(d))。进一步计算表明,热导率降低主要是电子热导率和晶格热导率的同时下降所致[11-12]。p型Hf0.5Zr0.5CoSb0.8Sn0.2的室温晶格热导率从4.1 Wm-1K-1降到了 2.8 Wm-1K-1,降低了29%[11]。对于n型Hf0.75Zr0.25NiSn0.99Sb0.01,室温晶格热导率从4.0 Wm-1K-1降到了3.1 Wm-1K-1,降低了23%[12]。另外应注意的是,p型half-Heuslers的双极效应在高温区间有所削弱[11]。图3(a)和3(b)为p型和n型half-Heuslers的塞贝克系数与温度的关系曲线图,从图得出,二者的塞贝克系数有所提高[11-12]。通常塞贝克系数的提高和电子热导率的下降表明了载流子浓度的减少,这种现象一般发生在n型half-Heusler中[12];然而,p型 half-Heusler 材料中塞贝克系数的提高与双极效应的削弱得出了另一种机制,即能量过滤效应,使低能空穴在晶界优先被散射。先前的研究结果[50-51]表明,第2相纳米粒子的存在可以作为势垒,阻碍低能载流子输运,从而提高塞贝克系数。能量过滤效应已成功地应用到了p型 Hf0.3Zr0.7CoSb0.7Sn0.3上,其中起势垒作用的就是ZrO2纳米颗粒[19]。另外,half-Heusler相中嵌入的InSb纳米粒子也起势垒作用[52];但是,到目前为止,仍然缺乏能量过滤效应在half-Heuslers中的相关研究,如何灵活地调整势垒以优化热电性能仍是一个挑战。

目前,尽管p型和n型half-Heusler合金的ZT值已经取得了显著的提升,但还是存在一些不足。比如热压后的块体样品的平均粒径为100~300 nm,比球磨后的粉末粒径(5~10 nm)要大得多,这不利于热导率的进一步降低。同时应当指出,在half-Heusler纳米复合材料中,载流子迁移率并没有显著降低,这意味着允许晶粒尺寸进一步下降以降低热导率而保持电导率。如果能够保留球磨后纳米粉末的原始晶粒尺寸,就可以得到非常低的热导率及更高的ZT值。

图3a和b、c和d、e和f分别为p型Hf0.5Zr0.5CoSb0.8Sn0.2[11]和n型 Hf0.75Zr0.25NiSn0.99Sb0.01[12]的赛贝克系数、热导率、ZT值与温度关系曲线图

2.2 利用原子质量和尺寸差异增强合金散射

通过在 half-Heusler体系中应用纳米复合技术,热导率得到一定程度的降低,ZT值得到了较大提高;但是,half-Heusler与其他传统的热电材料(PbTe[3-4],skutterudites[6])相比,总热导率仍高出2~3倍,热导率降低的空间还很大。除了增强晶界和纳米结构散射外,增强合金散射也能进一步降低晶格热导率。例如,在half-Heusler晶格的A原子位置,Hf和Ti的组合比Hf和Zr的组合更能有效降低晶格热导率,这是因为Hf和Ti原子的质量和尺寸存在更大的差异。结果表明,p型Hf0.8Ti0.2CoSb0.8Sn0.2在800 ℃时,热导率低至2.7 Wm-1K-1,ZT值高达1.0[13]。同时,Joshi等[14]研究了Ti取代 Hf 对 n型 half-Heuslers Hf0.75-xTixZr0.25NiSn0.99Sb0.01热电性能的影响。与 Hf0.75Zr0.25NiSn0.99Sb0.01相比,虽然它们二者的最佳ZT值一样,但是Hf0.75-xTixZr0.25NiSn0.99Sb0.01取得最佳ZT值的温度降低了;因此,Hf0.75-xTixZr0.25NiSn0.99Sb0.01在低于500 ℃就取得了较高的ZT值,这更有利于它应用在诸如汽车尾气回收等中温区域[14]。

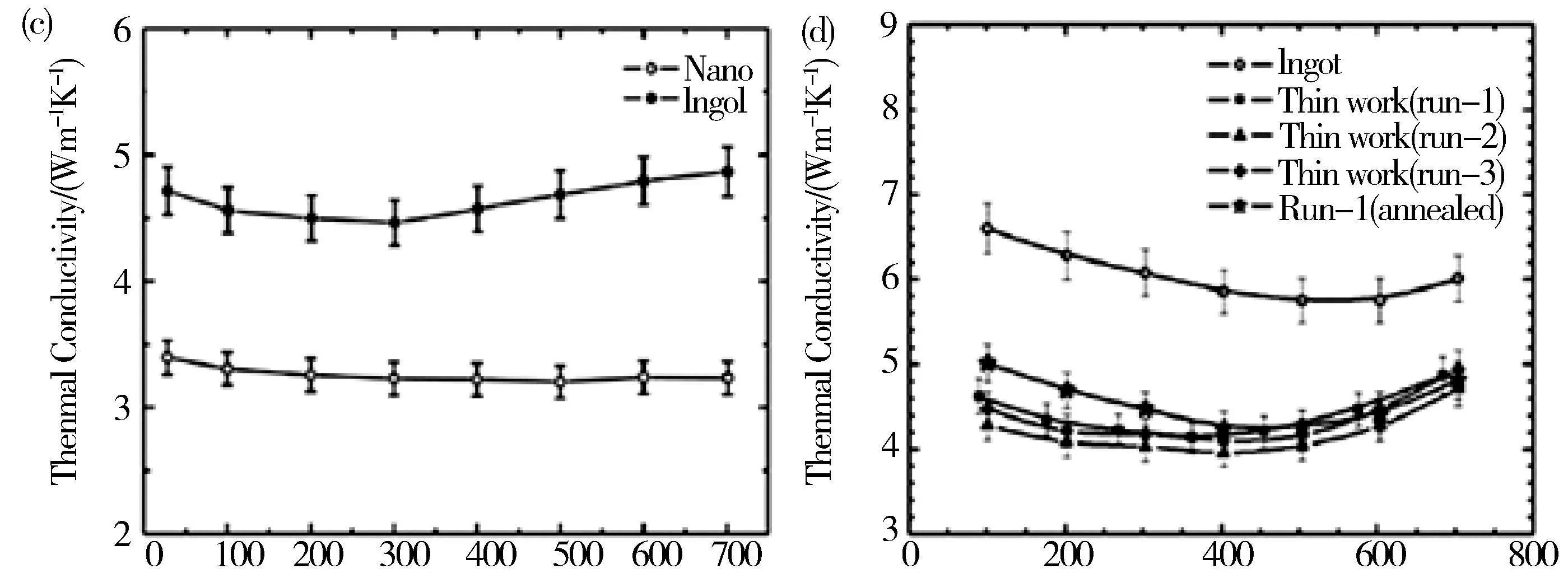

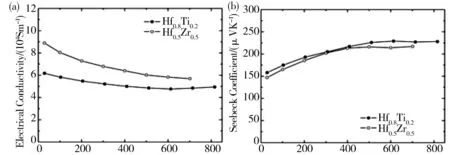

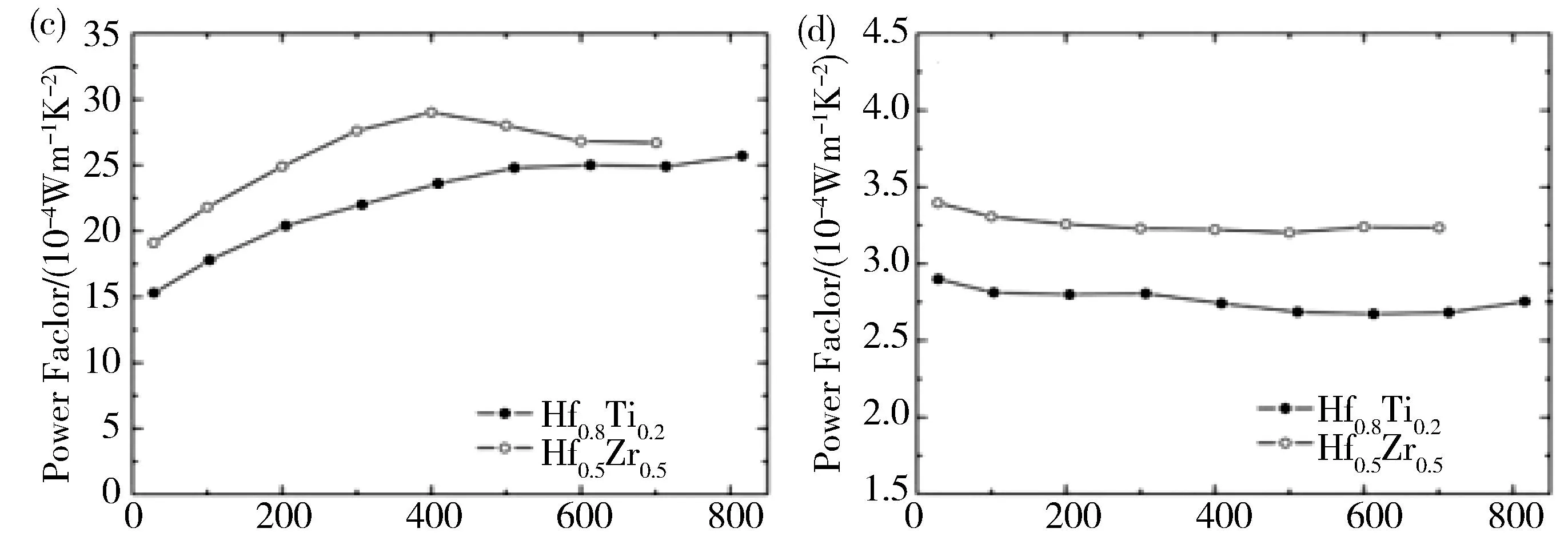

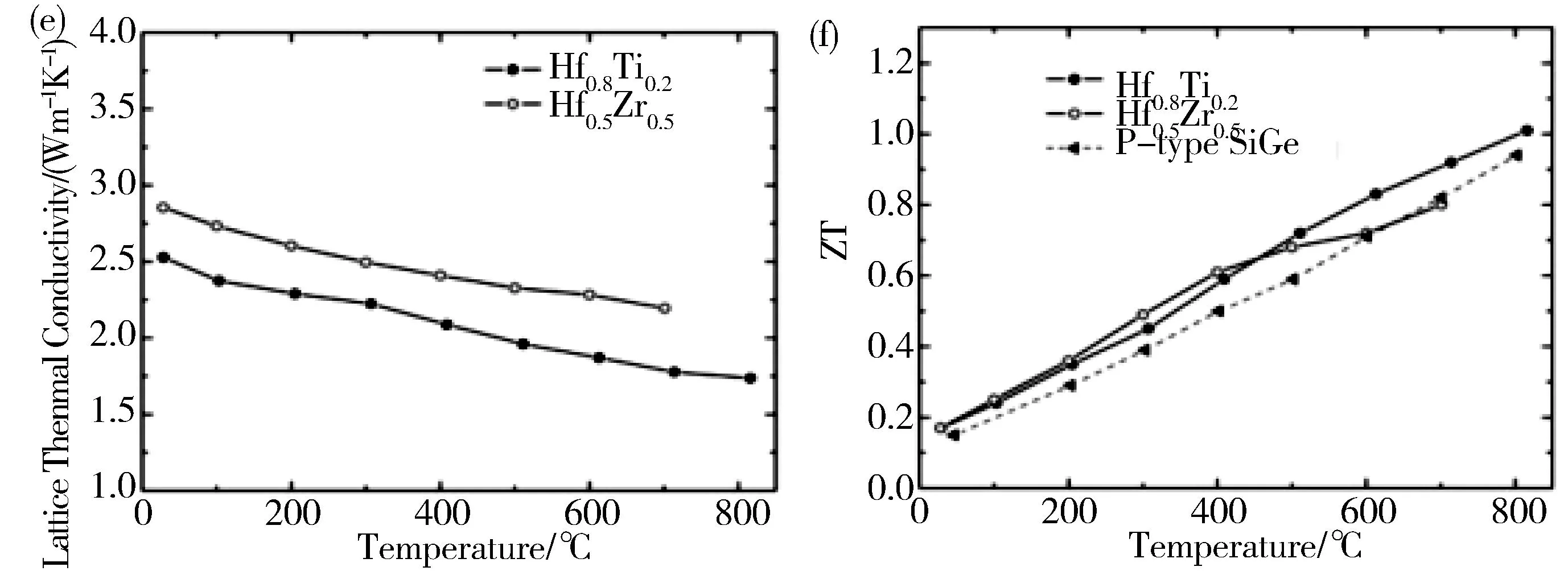

图4是采用相同的球磨和热压工艺条件制备的p型Hf0.5Zr0.5CoSb0.8Sn0.2和Hf0.8Ti0.2CoSb0.8Sn0.2的热电性能比较图。在整个测量温度范围内,Hf0.8Ti0.2CoSb0.8Sn0.2的电导率比Hf0.5Zr0.5CoSb0.8Sn0.2低(见图4(a)),两者的塞贝克系数几乎相等(见图4(b)),从而Hf0.8Ti0.2CoSb0.8Sn0.2的功率因子比Hf0.5Zr0.5CoSb0.8Sn0.2低(见图4(c));但是,Hf0.8Ti0.2CoSb0.8Sn0.2的热导率比Hf0.5Zr0.5CoSb0.8Sn0.2低(见图4(d)),可以更多地抵消相对较小的功率因子,因此其ZT值得到提升,尤其是在较高的温度下更加明显(见图4(f))。从图4(d)及图4(e)中得出,Hf0.8Ti0.2CoSb0.8Sn0.2的总热导率和晶格热导率分别比Hf0.5Zr0.5CoSb0.8Sn0.2的约低17%和11%,证实了Hf和Ti组合比Hf和Zr的组合更能有效地降低热导率,与n型 half-Heusler 体系中Hf 和Ti的组合降低热导率的报道一致。

图4a、b、c、d、e和f分别为Hf0.8Ti0.2CoSb0.8Sn0.2[13]和Hf0.5Zr0.5CoSb0.8Sn0.2[11]的电导率、赛贝克系数、功率因子、热导率、晶格热导率和ZT值与温度的关系曲线图,f还包括了p型SiGe[44]材料ZT值曲线

2.3 三元合金和新half-Heuslers材料

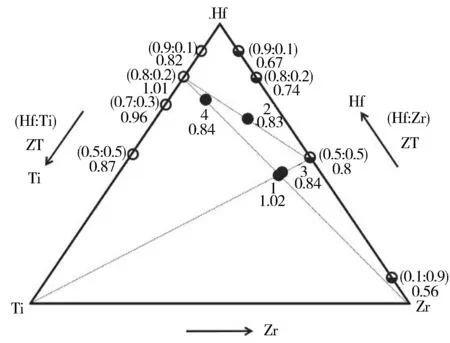

通常,调整Ti,Zr和Hf的比例对(Ti, Zr, Hf)CoSb0.8Sn0.2体系进行研究[16]。当Ti,Zr和Hf三个元素都出现在体系中时,称这个体系为三元合金体系,其相图如图5所示。试验结果表明,三元组成成分 Hf0.44Zr0.44Ti0.12CoSb0.8Sn0.2具有最佳的ZT值,并且元素之间的比例与之前报道最好的二元组成成分Hf0.5Zr0.5CoSb0.8Sn0.2和Hf0.8Ti0.2CoSb0.8Sn0.2大致相吻合。比较发现,Hf0.44Zr0.44Ti0.12CoSb0.8Sn0.2有2个优点:ZT值比Hf0.5Zr0.5CoSb0.8Sn0.2高,Hf用量比Hf0.8Ti0.2CoSb0.8Sn0.2少;然而,在Ti,Zr和Hf的总质量中,Hf的质量所占比例仍然较高,仍需进一步降低Hf的用量而维持其ZT值[16]。He 等[18]致力于减少Hf的用量,研究了p型half-Heusler Hfx(ZrTi)1-xCoSb0.8Sn0.2的热电性能。结果表明,Hf0.19Zr0.76Ti0.05CoSb0.8Sn0.2的ZT值在700 ℃达到了1.0,与Hf0.44Zr0.44Ti0.12CoSb0.8Sn0.2相比,大大减少了Hf的用量。同样,Chen等[15]对n型half-Heusler 体系进行了研究,发现减少Hf的用量同样可以获得高达1.0的ZT值,得出的最佳成分为Hf0.25Zr0.75NiSn0.99Sb0.01,与之前的最好成分相比,Hf的用量仅仅为它的1/3,这意味着材料的成本减少了50%。

与此同时,新型 half-Heusler 材料的研究也取得了一些进展。不同于传统的A位Zr、Ti或Hf,B位Co或Ni,X位Sn或Sb的材料,新型材料的A位为Nb或V,B位为Fe或Co,X位为Sb或Sn。例如:Joshi等[17]探索了NbFeSb基p型half-Heuslers,在700 ℃时,p型 Nb0.6Ti0.4FeSb0.95Sn0.05的ZT值高达1.0; Huang等[53]研究了未掺杂优化的n型NbCoSb 体系,并且其ZT值在700 ℃ 为0.4。这些新材料的开发进一步丰富了half-Heusler体系。

图5(Ti, Zr, Hf)CoSb0.8Sn0.2三元相图(1为Hf0.44Zr0.44Ti0.12CoSb0.8Sn0.2;2为Hf0.65Zr0.25Ti0.1CoSb0.8Sn0.2;3为Hf0.45Zr0.45Ti0.1CoSb0.8Sn0.2;4为Hf0.72Zr0.1Ti0.18CoSb0.8Sn0.2)

3结论

本文简要概述了half-Heuslers的研究进展,包括纳米复合技术的应用、增强合金散射、三元合金及新half-Heuslers材料。虽然n型和p型half-Heuslers的最高ZT值已经达到了1.0,但是昂贵的Hf用量较高;因此,降低成本的同时提高ZT值仍是未来的研究重点。另外,开发新型half-Heuslers材料、降低材料成本的工作仍需进一步关注。目前,half-Heuslers 的ZT值的提高仍具有较大的空间,例如,热压后样品的平均晶粒尺寸超过了100 nm,对于有效的晶界散射而言仍然较大,如何进一步降低晶粒尺寸是提高ZT值的一个突破口。同时,开展势垒过滤效应在half-Heuslers中的应用有望进一步提高热电性能。

参考文献

[1]Bell L E. Cooling, Heating, Generating Power, and Recovering Waste Heat with Thermoelectric Systems[J]. Science, 2008, 321(5895):1457.

[2]Yang J H, Stabler F R. Automotive Applications of Thermoelectric Materials[J]. Journal of Electronic Materials, 2009, 38(7):1245.

[3]Heremans J P, Jovovic V, Toberer E S, et al. Enhancement of Thermoelectric Efficiency in PbTe by Distortion of the Electronic Density of States[J]. Science, 2008, 321(5888):554.

[4]Pei Y Z, Shi X Y, LaLonde A, et al. Convergence of Electronic Bands for High Performance Bulk Thermoelectrics[J]. Nature, 2011, 473:66.

[5]张勤勇, 雷晓波. 国外块体热电材料PbTe的研究进展[J]. 西华大学学报(自然科学版),2012,31(3):81.

[6]Sales B C, Mandrus D, Williams R K. Filled Skutterudite Antimonides: A New Class of Thermoelectric Materials[J]. Science, 1996, 272(5266):1325.

[7]Uher C, Yang J, Hu S, et al. Transport Properties of Pure and Doped MNiSn (M=Zr, Hf)[J]. Physical Review B, 1999, 59(13): 8615.

[8]Tritt T M. Recent Trends in Thermoelectric Materials Research II, Semi-conductors and Semimetals[M]. New York: Academic Press, 2001:37.

[9]Culp S R, Simonson J W, Poon S J, et al. (Zr,Hf)Co(Sb,Sn) half-Heusler Phases as High-Temperature (>700 °C) p-type Thermoelectric Materials[J]. Applied Physics Letters, 2008, 93(2): 022105.

[10]Culp S R, Poon S J, Hickman N, et al. Effect of Substitutions on the Thermoelectric Figure of Merit of Half-Heusler Phases at 800 °C[J]. Applied Physics Letters, 2006, 88(4):042106.

[11]Yan X, Joshi G, Liu W S, et al. Enhanced Thermo-electric Figure of Merit of p-Type Half-Heuslers[J]. Nano Letters, 2011, 11:556.

[12]Joshi G, Yan X, Wang H Z, et al. Enhancement in Thermoelectric Figure-of-Merit of an N-Type Half-Heusler Compound by the Nanocomposite Approach[J]. Advanced Energy Materials, 2011, 1(4): 643.

[13]Yan X, Liu W S, Wang H. et al. Stronger Phonon Scattering by Larger Differences in Atomic Mass and Size in P-type Half-heuslers Hf1-xTixCoSb0.8Sn0.2[J]. Energy&Environmental Science, 2012, 5:7543.

[14]Joshi G, Dahal T, Chen S, et al. Enhancement of Thermoelectric Figure-of-merit at Low Temperatures by Titanium Substitution for Hafnium in n-type Half-Heuslers HfTixZr0.25NiSn0.99Sb0.01[J]. Nano Energy, 2013, 2(1):82.

[15]Chen S, Lukas K C, Liu W S, et al. Effect of Hf Concentration on Thermoelectric Properties of Nanostructured N-Type Half-Heusler Materials HfxZr1-xNiSn0.99Sb0.01[J]. Advanced Energy Materials, 2013, 3(9):1210.

[16]Yan X, Liu W S, Chen S, et al. Thermoelectric Property Study of Nanostructured p-Type Half-Heuslers (Hf,Zr,Ti)CoSb0.8Sn0.2[J]. Advanced Energy Materials, 2013, 3: 195.

[17]Joshi G, He R, Engber M, et al. NbFeSb-based p-type half-Heuslers for Power Generation Applications[J]. Energy & Environmental Science, 2014, 7(12): 4070.

[18]He R, Kim H S, Lan Y C, et al. Investigating The Thermoelectric Properties of p-Type Half-Heusler Hfx(ZrTi)1-xCoSb0.8Sn0.2By Reducing Hf Concen-tration for Power Generation[J].RSC Advances, 2014, 4:64711.

[19]Poon S J, Wu D, Zhu S, et al. Half-Heusler Phases and Nanocomposites as Emerging High-ZT Thermo-electric Materials[J]. Journal of Materials Research, 2011, 26(22): 2795.

[20]Liu W S, Yan X, Chen G, et al. Recent Advances in ThermoeIectric Nanocomposites[J]. Nano Energy, 2012, 1(1): 42.

[21]Xie W J, Weidenkaff A, Tang X F, et al. Recent Advances in Nanostructured Thermoelectric Half-Heusler Compounds[J]. Nanomaterials, 2012, 2(4):379.

[22]Chen S, Ren Z F. Recent Progress of Half-Heusler for Moderate Temperature Thermoelectric Applications[J]. Materials Today, 2013, 16(10):387.

[23]Jeischko W. Transition Metal Stannides with MgAgAs and MnCu2Al Type Structure[J]. Metallurgical Transactions, 1970, 1(11):3159.

[24]Xia Y, Bhattacharya S, Ponnambalam V, et al. Thermoelectric Properties of Semimetallic (Zr, Hf)CoSb half-Heusler phases[J]. Journal of Applied Physics, 2000, 88(4):1952.

[25]Sekimoto T, Kurosaki K, Muta H, et al. Thermoelectric Properties of Sn-doped TiCoSb Half-Heusler Compounds[J]. Journal of Alloys and Compounds, 2006, 407(1/2): 326.

[26]Wu T, Jiang W, Li X Y, et al. Thermoelectric Properties of P-type Fe-doped TiCoSb Half-Heusler Compounds[J]. Journal of Applied Physics, 2007, 102:103705.

[27]Ponnambalam V, Alboni P N, Edwards J, et al. Thermoelectric Properties of p-type Half-Heusler Alloys Zr1-xTixCoSnySb1-y(0.0 [28]Shen Q, Chen L, Goto T, et al. Effects of Partial Substitution of Ni by Pd on the Thermoelectric Properties of ZrNiSn-based Half-Heusler Com-pounds[J]. Applied Physics Letters, 2001, 79(25): 4165. [29]Hohl H, Ramirez A P, Goldmann C, et al. Efficient Dopants for ZrNiSn-based Thermoelectric Materials[J]. Journal of Physics: Condensed Matter, 1999, 11(7):1697. [30]Ono Y, Inayama S, Adachi H, et al. Thermoelectric Properties of Doped Half-Heuslers NbCoSn1-xSbxand Nb0.99Ti0.01CoSn1-xSbx[J]. Japanese Journal of Applied Physics, 2006, 45:8740. [31]Zou M M, Li J F, Guo P J, et al. Synthesis and Thermoelectric Properties of Fine-grained FeVSb System Half-Heusler Compound Polycrystals with High Phase Purity[J]. Journal of Physics D: Physics, 2010, 43:415403. [32]Liu X H, He J, Xie H H, et al. Fabrication and Thermoelectric Properties of Yb-doped ZrNiSn Half-Heusler Alloy[J]. International Journal of Smart and Nano Materials, 2012, 3:64. [33]Rausch E, Balke B, Ouardi S, et al. Enhanced Thermoelectric Performance in the p-type half-Heusler (Ti/Zr/Hf)CoSb0.8Sn0.2System via Phase Separation[J]. Physical Chemistry Chemical Physics, 2014, 16(46):25258. [34]Hsu C C, Liu Y N, Ma H K. Effects of The Zr0.5Hf0.5FexCo1-xSb0.8Sn0.2/Fe3Sn2Half-Heusler Com-posites on The ZT Value[J]. Journal of Alloys and Compounds, 2015, 621:324. [35]Takas N J, Sahoo P, Misra D, et al. Effects of Ir Substitution and Processing Conditions on Thermo-electric Performance of p-Type Zr0.5Hf0.5-Co1xIrxSb0.99Sn0.01Half-Heusler Alloys[J]. Journal of Electronic Materials, 2011, 40(5):662. [36]Maji P, Takas N J, Misra D K, et al. Effects of Rh on the Thermoelectric Performance of the p-type Zr0.5Hf0.5Co1xRhxSb0.99Sn0.01Half-Heusler Alloys[J]. Journal of Solid State Chemistry, 2010, 183(5): 1120. [37]Appel O, Gelbstein Y. A Comparison Between the Effects of Sb and Bi Doping on the Thermoelectric Properties of the Ti0.3Zr0.35Hf0.35NiSn Half-Heusler Alloy[J]. Journal of Electronic Materials, 2014, 43(6):1976. [38]Liu Y F, Poudeu P F P. Thermoelectric Properties of Ge Doped n-type TixZr1xNiSn0.975Ge0.025half-Heusler Alloys[J]. Journal of Materials Chemistry A, 2015, 3(23):12507. [39]Rausch E, Balke B, Deschauer T, et al. Charge Carrier Concentration Optimization of Thermoelectric p-type half-Heusler Compounds[J]. APL Materials, 2015, 3(4): 041516. [40]Maji P, Makongo J P A, Zhou X Y, et al. Thermo-electric Performance of Nanostructured p-type Zr0.5-Hf0.5Co0.4Rh0.6Sb1-xSnxhalf-Heusler Alloys[J].Journal of Solid Chemistry, 2013, 202:70. [41]赵立东, 张德培, 赵勇. 热电能源材料研究进展[J]. 西华大学学报(自然科学版),2015,34(1):1. [42]Poudel B, Hao Q, Ma Y, et al. High Thermoelectric Performance of Nanostructured Bismuth Antimony Telluride Bulk Alloys[J]. Science, 2008, 320(5876):634. [43]Ma Y, Hao Q, Poudel B, et al. Enhanced Thermoelectric Figure-of-Merit in p-Type Nano-structured Bismuth Antimony Tellurium Alloys Made from Elemental Chunks[J]. Nano Letters, 2008, 8(8): 2580. [44]Joshi G, Lee H, Lan Y C, et al. Enhanced Thermo-electric Figure-of-Merit in Nanostructured p-type Silicon Germanium Bulk Alloys[J]. Nano Letters, 2008, 8(12):4670. [45]Wang X W, Lee H,Lan Y C, et al. Enhanced Thermoelectric Figure of Merit in Nanostructured n-type Silicon Germanium Bulk Alloy[J]. Applied Physics Letters, 2008, 93:193121. [46]Zhu G H, Lee H,Lan Y C, et al. Increased Phonon Scattering by Nanograins and Point Defects in Nanostructured Silicon with a Low Concentration of Germanium[J]. Physical Review Letters, 2009, 102(19):196803. [47]Yang J,Hao Q, Wang H, et al. Solubility Study of Yb in n-type Skutterudites YbxCo4Sb12 and Their Enhanced Thermoelectric Properties[J]. Physical Review B, 2009, 80(11):115329. [48]Katsuyama S, Kobayashi T. Effect of Mechanical Milling on Thermoelectric Properties of half-Heusler ZrNiSn0.98Sb0.02Intermetallic Compound[J]. Materials Science and Engineering:B, 2010, 166(1): 99. [49]Xie W J, Tang X F,Zhang Q J. Fast Preparation and Thermal Transport Property of TiCoSb-based half-Heusler Compounds[J]. China Physics, 2007, 16:3549. [50]Kishimoto K, Tsukamoto M, Koyanagi T. Temperature Dependence of the Seebeck Coefficient and the Potential Barrier Scattering of n-type PbTe Films Prepared on Heated Glass Substrates by rf sputtering[J]. Journal of Applied Physics, 2002, 92(9):5331. [51]Popescu A, Woods L M. Enhanced Thermoelectricity in Composites by Electronic Structure Modifications and Nanostructuring[J]. Applied Physics Letters, 2010, 97(5):052102. [52]Xie W J, He J, Zhu S, et al. Simultaneously Optimizing the Independent Thermoelectric Properties in (Ti,Zr,Hf)(Co,Ni)Sb Alloy by in Situ Forming InSb Nanoinclusions[J]. Acta Materialia, 2010, 58(14): 4705. [53]Huang L H, He R, Chen S, et al. A New n-type Half-Heusler Thermoelectric Material NbCoSb[J]. Materials Research Bulletin, 2015, 70:773. (编校:夏书林) Recent Progress in Half-Heusler Thermoelectric Materials YAN Xiao1,YUAN Bo2 (1.DepartmentofPhysicsandTcSUH,UniversityofHouston,TX77204USA 2.CenterforAdvancedMaterialsandEnergyofXihuaUniversity,Chengdu610039China) Abstract:Half-Heuslers thermoelectric materials are potential candidates for medium-to-high temperature waste heat recovery, owing to their good thermal stability and mechanical strength. In this particular material system, the ZTs of both p-type and n-type half-Heuslers have improved gradually in recent years and its peaks have exceeded 1.0. This review serves as a guide to learn the recent progress in half-Heuslers system: including the application of nanocomposite approach, enhanced alloy scattering by larger atomic and size differences and the exploration of ternary systems as well as new classes of materials. Though the ZTs of half-Heuslers have surpassed 1.0 , the cost is still high. Therefore, reducing the cost and optimizing the performance of the new half-Heuslers materials will be the major study in the future. At present, enhancing the ZTs also has much potential. The average gain size of samples after hot pressing is more than 100 nm. So the further improvement of ZT will be realized by reducing the larger gain size. Meanwhile, the usage of energy filtering effect in half-Heuslers is expected to boost its thermoelectric properties. Keywords:thermoelectric materials; half-Heusler; nanocomposite; alloy scattering doi:10.3969/j.issn.1673-159X.2016.01.006 中图分类号:TB34 文献标志码:A 文章编号:1673-159X(2016)01-0029-06 基金项目:国家自然科学基金(51372208, 51472207)。 收稿日期:2015-10-15 第一作者:严潇(1981—),男,博士,特聘教授,主要研究方向为热电材料及器件。 ·先进材料及能源·