Effect of Vacuum Packaging on Storage Quality of Peanut

, , ,

Institute of Agricultural Product Processing, Henan Academy of Agricultural Sciences, Zhengzhou 450002, China

EffectofVacuumPackagingonStorageQualityofPeanut

AnjianWANG*,ShuaipingGAO,GuangruiTIAN,LinaLIU

Institute of Agricultural Product Processing, Henan Academy of Agricultural Sciences, Zhengzhou 450002, China

The purpose of the study is to investigate the effect of vacuum packaging on storage quality of peanut. The acid value, peroxide value, relative conductivity, mildew rate and germination rate of peanut were examined in both vacuum-packed bags and control packaging bags. The results showed that the acid value, peroxide value, relative conductivity and mildew rate of peanut were maintained at a lower level and germination rate was maintained at a higher level in vacuum-packed bags than in control packaging bags. The storage quality of peanut in vacuum-packed bags was better than in control packaging bags. The order of different vacuum degree of vacuum-packed bags from good to bad according to storage quality of peanut was-0.06 MPa>-0.09 MPa>-0.03 MPa, and -0.06 MPa was the most beneficial vacuum degree for the peanut storage.

Peanut, Vacuum packaging, Storage, Quality

1 Introduction

Peanut is one of the important oil crops in China, and its production and export volume rank first in the world. With the continuous development of the food industry, it has gradually become an important raw material for the food industry[1-2]. Peanuts are rich in protein and fat, and prone to oxidative rancidity and oil immersion, thus making peanut surface color deepen and produce rancid smell. The storage and packaging material for peanut in China is primarily the ordinary woven bag, and the packaging is simple with poor moisture resistance and barrier properties. After the peanut raw material is dried to achieve safe water content, it will be inevitably subject to high temperature and high humidity during the storage process, leading to fungal infection and frequent pests. It can causes highly carcinogenic aflatoxin, seriously affecting the edible and economic value of peanuts[3-5]. Therefore, finding a mildew-proof and pest-proof peanut storage method is important for reducing peanut losses and improving economic efficiency. Studies have shown that ozone treatment, carbon dioxide inflatable packaging and UV packaging can enhance peanut’s aflatoxin resistance and improve peanut storage quality[6-8]. However, the cost of acquiring ozone, carbon dioxide and UV in the above methods is high, and it requires certain equipment; the operation is complex and the applicability is low. Therefore, it is very necessary to seek new peanut storage method to reduce storage costs and improve the application level. The vacuum packaging is to use the anaerobic respiration of fresh produce for the spontaneous formation of a hypoxia and hypercapnia environment, thereby inhibiting nutrient metabolism and cell senescence, and also effectively inhibiting activity of pathogenic bacteria and reducing decay[9]. Currently, the role of vacuum packaging in maintaining the quality and nutritional content of fruits and vegetables has been widely studied[10-11], but the application of vacuum packaging technique in peanut storage is rarely reported. In view of this, with polypropylene (PP) as the vacuum packaging material, we select -0.03 MPa,-0.06 MPa,-0.09 MPa as the degree of vacuum of control group, and take the ordinary woven bag packaging as control, to study the influence of vacuum packaging on peanut storage quality, in order to provide a theoretical basis for the application of vacuum packaging in peanut storage and transportation.

2 Materials and methods

2.1MaterialsThe peanuts for experiment are picked from the Yanjin peanut producing area, transported back to the lab that day, and dried to moisture content of 8%. We select the same size rotten peanuts with no mechanical damage and germination as the experimental materials.

2.2ExperimentaldesignThe ordinary woven bag (thickness 0.1 mm) and PP (thickness of 0.09 mm) are taken as the packaging materials for control group and treatment group, respectively, and the treatment group uses -0.03 MPa, -0.06 MPa and -0.09 MPa for vacuum packaging, respectively. The weight of each group of peanut is 200 g. The packaged peanut is placed under 40 ℃ and 80% humidity conditions to be stored for 35 d (equivalent to the storage for 1 a at 20 ℃[12-13]). Each treatment and control group sets 18 individual packages. In the process of storage, sampling is conducted once a week, and 3 individual packages are taken each time for the determination of acid value, peroxide value, relative conductivity and germination rate as the indicators to measure the peanut storage quality. By taking average, the three groups are compared in parallel. The mildew rate is measured based on the method of Chen Hongetal.[3]. 20 full intact peanut samples are selected to be disinfected with 75% ethanol, and washed three times with sterile water. The processed peanut is placed in a sterile petri dish, and 5 mL of 106/mL Aspergillus flavus spore suspension is added and mixed evenly, so that the suspension is evenly coated on the surface of each peanut. The peanuts treated with suspension are packaged according to the method described above. Each treatment and control group sets 3 parallel groups, to be stored at constant temperature of 30 ℃. The number of peanut infected by mildew is observed every 7 d, and the mildew rate is calculated.

2.3Determinationitemsandmethods

2.3.1Acid value and peroxide value. The peanut kernel is obtained after husking peanut samples and crushed to be placed in stoppered flask. 30-60 ℃ 100 mL of petroleum ether is added, shaken for 1 min, and placed overnight. After being filtered through the funnel containing anhydrous sodium sulfate, the filtrate is placed in a rotary evaporator, and petroleum ether is distilled off to obtain peanut oil sample under 60℃ water bath conditions. Acid value and peroxide value are measured based on GB/T 5009.37-2003.

2.3.2Relative conductivity. It is measured based on the method of Zhang Wenmingetal.[14], with slight changes. Under each treatment, 3 peanuts are taken and 200 mL of double-distilled water is added. The samples are soaked for 24 h at constant temperature of 25 ℃, to measure the soaking solution conductivityC1. The peanut and soaking solution are placed in boiling water for 10 min, and after cooling, the soaking solution conductivityC2is measured. The relative conductivitys=C1/C2×100%.

2.3.3Germination rate. By referring to GB/T 3543-1995 test procedures for crop seeds, the petri dish method is used for germination experiment and counting method is used to measure. The germination number in the 7th d is counted and germination rate is calculated.

2.4DataprocessingandanalysisAll data are processed using Excel and SPSS, each group of data set 3 parallel groups, and the average is taken.

3 Results and analysis

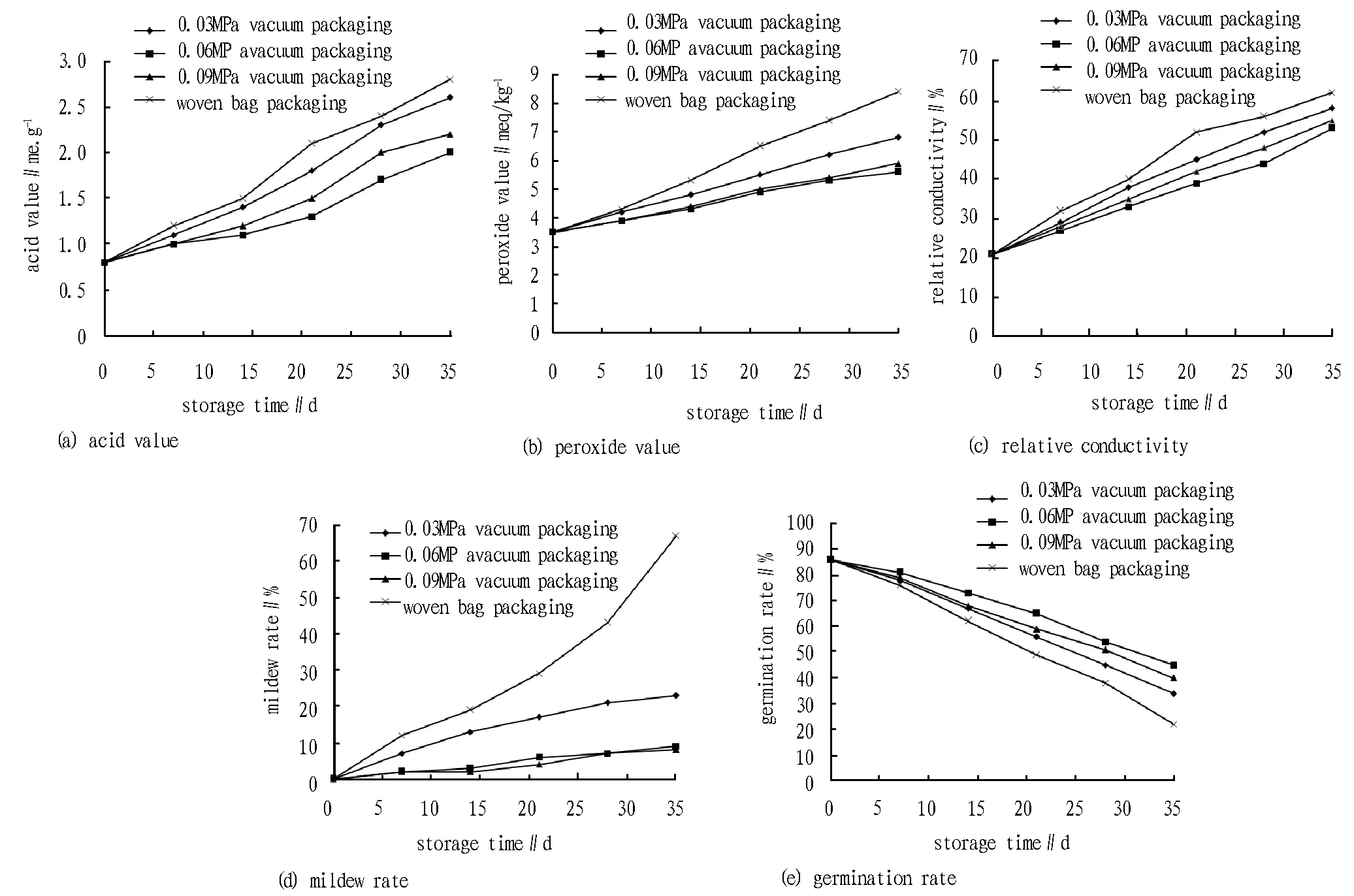

3.1EffectofdifferentdegreeofvacuumpackagingonacidvalueofpeanutThe acid value is an important indicator to evaluate the peanut storage quality. Affected by enzymes, oxygen or microorganisms, the lipid molecules in peanut will be slowly hydrolyzed, and release the free fatty acids to cause fat rancidity, resulting in rising acid value of oil in peanut and decreasing peanut quality[15]. Fig. 1 (a) shows that for woven bag packaging or vacuum packaging, the acid value of peanut will gradually increase with prolonged storage time. The peanut acid value of different degree of vacuum packaging is lower than that of woven bag packaging, indicating that the vacuum packaging can slow down the rising peanut acid value, because the oxygen concentration is one of the major environmental factors that affect lipid oxidation, that is, when the oxygen content is high in the environment, the oxidation rate is not related to oxygen concentration; conversely, there is a directly proportional relationship between the oxidation rate and oxygen concentration[16]. Vacuum packaging reduces the contact of peanut with the air, and decreases the aldehydes, ketones, acids and other harmful substances produced by oxidation of peanuts, while the peanuts packed with woven bags will inevitably absorb the water vapor under humid environment, so as to increase water content of peanut, enhance its respiration, and increase the acid value[17]. For the vacuum packaging, the acid value of peanuts treated with -0.06 MPa vacuum packaging is smaller than that of peanuts treated with -0.03 MPa and -0.09 MPa vacuum packaging. The acid value of peanuts treated with -0.09 MPa vacuum packaging is higher than that of peanuts treated with -0.06 MPa vacuum packaging, which is yet to be further studied.

3.2EffectofdifferentdegreeofvacuumpackagingonperoxidevalueofpeanutPeroxide value is also an important indicator to evaluate the peanut oil quality. Fig. 1 (b) shows that during storage, the peroxide value of peanut gradually increases, and the peroxide value of peanut under vacuum treatment is lower than under woven bag packaging, which is consistent with the finding of Fu Xiaojietal.[18]that vacuum packaging can reduce the peroxide value of peanut kernel. Compared with woven bag packaging, -0.06 MPa and -0.09 MPa vacuum packaging inhibits the rise of peanut peroxide value, while the peanut peroxide value under -0.03 MPa vacuum packaging is higher than under -0.06 MPa and -0.09 MPa vacuum packaging, but lower than woven bag packaging. One reason may be that the peanuts under woven bag packaging can be fully exposed to oxygen in the air, peanut tissue is obviously affected by oxidation, and low degree of vacuum packaging isolates external oxygen, but there is still a small amount of oxygen around peanut shells to cause peanut overoxidation, and high degree of vacuum packaging can remove oxygen inside the package to a large extent, thereby greatly easing the oxidation of peanuts, and inhibiting peroxide value increase.

3.3EffectofdifferentdegreeofvacuumpackagingonrelativeconductivityofpeanutRelative conductivity is an important indicator to reflect membrane permeability. During storage at high temperatures and high humidity conditions, the cell membrane structure and function of peanut skin are destructed, leading to increasing membrane permeability with storage period[3]. Fig. 1 (c) shows that the relative conductivity of peanut under vacuum packaging treatment is lower than under woven bag packaging treatment, and the relative conductivity of peanut under -0.06 MPa vacuum packaging treatment is lowest. During the storage of peanuts under woven bag packaging, the respiration rate is high and it is possibly infected with mildew, which will result in enhanced membrane permeability and increased relative conductivity.

3.4EffectofdifferentdegreeofvacuumpackagingonmildewrateofpeanutFrom Fig. 1 (d) , it can be found that with the extension of storage time, the mildew rate of peanuts under woven bag packaging increases dramatically, and when the storage is over, its mildew rate is 70%, 2.9, 7.4 and 8.3 times that under -0.03 MPa , -0.06 MPa and -0.09 MPa vacuum packaging, respectively. Vacuum packaging effectively inhibits the growth of mildew, to make mildew rate of peanut remain at a low level. The role of -0.06 MPa and -0.09 MPa vacuum packaging is particularly evident, and the mildew rate of peanut under such packaging is always less than 10% throughout the storage process. Compared with woven bag packaging, vacuum packaging changes the gaseous environment, and hypoxic conditions inhibit the growth of Aspergillus flavus.

3.5EffectofdifferentdegreeofvacuumpackagingongerminationrateofpeanutGermination rate is an indicator to reflect the vitality of peanuts, and mildew, pests and oxidative rancidity will affect peanut germination. Fig. 1 (e) shows that the germination rate of peanut under vacuum packaging and woven bag packaging decreases with the increase of storage time, and the germination rate of peanut under vacuum packaging treatment is higher than under woven bag packaging treatment. This is due to the fact that the oxidation of peanut during storage produces aldehydes and ketones which damage peanut embryo cells, and decrease peanut germination ability[19-20], while the oxidation of peanut under vacuum packaging is lower than under woven bag packaging. The germination rate of peanut under vacuum packaging is highest, followed by -0.09 and -0.03 MPa vacuum packaging. At the end of the storage, the germination rate of peanut under -0.06 MPa vacuum packaging is 1.1 times that under woven bag packaging.

Fig.1 Effect of different degree of vacuum packaging on peanut

4 Conclusions and discussions

The experimental results show that with the extension of storage time, the quality of peanut decreases; vacuum packaging can make the acid value, peroxide value, relative conductivity and mildew rate of peanuts stored remain at a low level, and cause high germination rate; the storage effect of vacuum packaging is better than that of ordinary woven bag packaging. The effect of vacuum packaging on acid value and peroxide value is consistent with the findings of Sun Zhiweietal.[21]. Vacuum packaging can inhibit the oxidation of peanut, and protect peanut against pests and mold contamination, so the germination rate of peanut is high. The oxygen concentration is one of the main environmental factors affecting fat oxidation[7]. Under different degree of vacuum, there is a difference in the concentration of oxygen within vacuum package, and the results of this study show that the impact of different degree of vacuum on the vacuum packaging storage effect of peanut is in the order of -0.06 MPa> -0.09 MPa> -0.03 MPa. The higher the degree of vacuum, the less the oxygen inside the vacuum package, and the greater the impossibility of oxidative rancidity. When the degree of vacuum is too high, some peanuts can not stand the pressure, and the peanut shells are shrivelled, leading to peanut quality decline. Therefore,-0.06 MPa vacuum packaging is suitable for peanut storage.

[1] E JL, FENG JX, MIN H,etal. Overviews on the raw material peanuts storage[J].Nongchanpin Jiagong.Xuekan,2011(9):100-103. (in Chinese).

[2] FU Y. Overview of peanut storage technique research[J].Jiangsu Agricultural Sciences,2014,42(11):312-314. (in Chinese).

[3] CHEN H, XIONG LR, WANG J,etal. Influence of packaging materials on storage property of peanut under normal temperature[J].Transactions of the Chinese Society of Agricultural Engineering,2012,28(3):269-273. (in Chinese).

[4] LIU L, WANG Q, LIU HZ. Application and its present on method for drying storage of peanut[J].Farm Products Processing,2011(8):49-52. (in Chinese).

[5] XU XM, WANG WR, LIU GF. The research of vacuum packaging technique for rice considering circulation[J]. Packaging Engineering,2005,26(2):85-87. (in Chinese).

[6] CHEN H, REN JM, DU Y,etal. Application of ozone treatment in peanuts storage[J]. Cereals and Oils Processing,2008(11):119-121. (in Chinese).

[7] HE JL, FENG JX, FU XJ,etal. Study on the technology of carbon dioxide filling package of peanut[J]. Journal of Henan Agricultural Sciences,2013,42(5):169-172. (in Chinese).

[8] ZHANG K, DU Y, REN JH,etal. Application of UV irradiation treatment in peanuts storage[J].Hubei Agricultural Sciences,2008,47(9):1070-1072. (in Chinese).

[9] YOU YL, SU XG, JIANG YM,etal. Effects of vacuum packaging on postharvest Longan fruit quality[J]. Food Science,2004,25(10):327-331. (in Chinese).

[10] LIU CH, ZHANG P, LI JK,etal. Effect of de-astringent and crispness-keeping on Mopan persimmon of vacuum packing[J].Science and Technology of Food Industry,2008,29(11):244-247. (in Chinese).

[11] ZHANG Q, ZHANG WY, CHEN XD,etal. Study on the polylactic acid membrane vacuum package on the preservation of Flammulina velutipes[J].The Food Industry,2014,35(3):91-95. (in Chinese).

[12] LIU L. Principles and technologies of shelf-life evaluation of foods[J]. JOURNAL OF DAIRY SCIENCE AND TECHNOLOGY,2004(4):162-165. (in Chinese).

[13] CAI XF, LIU QC. Accelerated shelf life testing(ASLT) and application[J]. Machinery for Cereals Oil and Food Processing,2003(10):80-81. (in Chinese).

[14] ZHANG WM, ZHENG WY, REN C,etal. Study on testing method of seed vigor by electrical conductivity in soybean[J]. Seed, 2003(2):34-36,38. (in Chinese).

[15] XIA XT. A primary exploration on the relationship among arachidic acid, peroxide value and rancidity[J]. Grain Storage,1985(3):13-17. (in Chinese).

[16] VERCELLOTTI JR,ANGELO AJS,SPANIER AM. Lipid oxidation in foods[J]. Critical Reviews in Food Science and Nutrition,1996,36(3):175-224.

[17] LIN YG, FU XJ, ZHOU JY,etal. Effect of packaging materials on storage property of different moisture content peanut[J].Science and Technology of Food Industry,2014,35(19):331-334,339. (in Chinese).

[18] FU XJ, MIN H, ZHANG Q,etal. Study on gas filling packaging technology of peeled peanut[J]. Journal of Peanut Science,2012,41(4):26-29,36. (in Chinese).

[19] LIANG XQ, ZHOU GY, PAN RC. Wax and cuticle of peanut seed coat in relation to infection and afiatoxin production by Asperillus flavus[J].Journal of Tropical and Subtropical Botany,2003,11(1):11-14. (in Chinese).

[20] RAO R,SINGH PM, RAI M. Storability of onion seeds and effects of packaging and storage conditions on viability and vigour[J].Scientia Horticulturae, 2006, 110(1):1-6.

[21] SUN ZW, ZHOU JY, FENG JX,etal. Effect of packing with nitrogen in vacuum on the storage quality of baked peanut[J]. Science and Technology of Cereals,Oils and Foods,2013,21(4):45-48. (in Chinese).>

September 19, 2015 Accepted: November 25, 2015

Supported by Henan Science and Technology Opening and Cooperation Project (132106000051).

*Corresponding author. E-mail: nkyjgs@163.com

Asian Agricultural Research2016年1期

Asian Agricultural Research2016年1期

- Asian Agricultural Research的其它文章

- Application and Residue Pollution of Mulching Films in Xinjiang

- Resource Dependence Relationship between Grass-roots Government and Farmers’ Specialized Cooperatives

- Urban Residents’ Consumption Risk Perception about the Dairy Products

- Study on the Aromatic Components of Green Plum Wine by HS-SPME-GC-MS

- Innovative Development of Fishery and Ecological Protection of Poyang Lake

- Effect of Silicon Application on Rice Growth and Production Structure