Discussion on Development of Pumpkin Sausage

Qingmei JIAN

Biological Engineering Institute, Jingchu University of Technology, Jingmen 448000, China

Pumpkin is rich in nutrients,such as pectin, pentosan,mannitol, amino acids (citrulline, aspartic acid, etc.), vitamins(Vc, VE, VB, etc.), minerals (Fe, P, Se,etc.),as well as alkaloids,cucurbitine,trigonelline, soluble fiber, B2carotene,lutein and other physiologically active substances and nutrients[1]. In traditional Chinese medicine, pumpkin is warm in nature and sweet in taste,and it has functions of invigorating spleenstomach and replenishing qi, diminishing inflammatory and relieving pain and detoxicating and destroying in testinal worms[2]. Modern medical researches have found that pumpkin also has a variety of medical values, including promoting the secretion of insulin in people infected with diabetes and controlling and assisting the treatment of diabetes, as well as kidney disease, liver disease and hyperten sion[3]. The alkaloids, cucurbitine and trigonelline in pumpkin can catalyze and decompose carcinogenic substances (i.e. nitrosamines), accelerate the dissolution of kidney stones and bladder stones,help to remove excessive cholesterol and prevent arteriosclerosis. Pumpkin is rich in citrulline that can get rid of parasites and treat schistosomiasis and advanced schistosomiasis. In addition, pumpkin can also improve eyesight, reduce blood fat and treat asthma.

Traditional sausage is a kind of meat product with rich flavor and long shelf life. It is popular among people.But traditional sausage, with meat as the main raw material, contains high content of fat,but is lacking in minerals and vitamins[4]. The addition of fresh pumpkin juice into sausage can not only improve the flavor and color of sausage,but also balance the nutrition and reduce the fat content of sausage.The pumpkin sausage can reduce costs on one hand, and on the other hand, it can also improve flavor and nutrition of sausage, coordinating animal and plant nutrition. Currently,there have been corn sausages on the market, but there have been no ripe pumpkin sausage products. In this study, the development of pumpkin sausage by adding fresh pumpkin juice into traditional sausage was discussed so as to provide some reference for the comprehensive utilization of pumpkin and provide consumers with nutrition, health and snack meat product with comprehensive nutrition and unique flavor.

Material and Methods

Materials

The materials used in this studyincluded fresh pork (lean and fat),fresh pumpkin, soy protein[5], sugar[6],slat, mushroom powder, ginger powder, orange peel powder, garlic powder and monascus red pigment[7].

Main instruments

The instruments and equipment used in this study included electronic balance, electronic scale, manual sausage stuffer, sausage machine,meat grinder, cooking pan and baking machine.

Methods

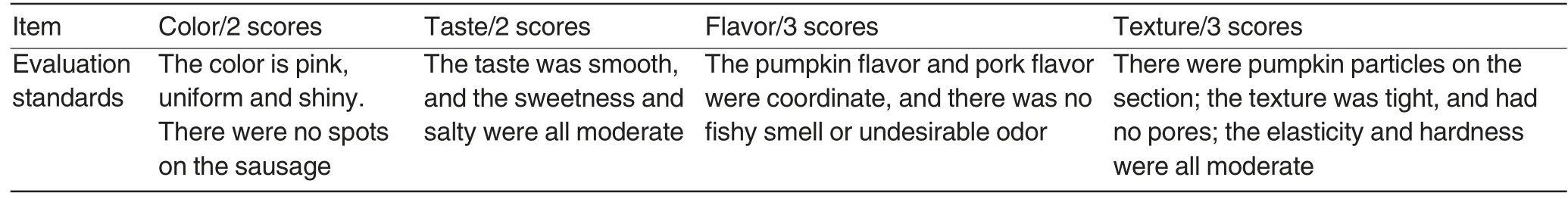

Sensory evaluation The color,taste, flavor and texture of prepared pumpkin sausage were evaluated.The evaluation group consisted of 10 staff. The evaluation standards were shown in Table 1. Using weighting method, the final score of prepared pumpkin sausage was calculated with color weight of 0.2, taste weight of 0.3, flavor weight of 0.3 and texture weight of 0.2. The average score of prepared pumpkin sausage from the 10 evaluation staff was treated as its final score[8].

Physical and chemical indexes determination The contents of proteins, fat and microorganisms in prepared pumpkin sausage were determined with national food standards methods[10].

Table 1 Sensory indexes evaluation standards for pumpkin sausage[9]

Technical processes and operation points Technical processes[11]Operation points

Pretreatment of raw materials The high-quality pork that passed through the health quarantine, with fat to lean ratio of 1∶4, was selected. The pork was cleaned and the skin was picked off. A certain amount of lean was weighed and minced through 8 mm orifice.Subsequently,the corresponding amount of fat was weighed and cut into cubes with length of 4-6 mm.

Preparation of instruments The interior of manual sausage stuffer and chopping machine was cleaned with detergent. A certain amount of water was added to the cooking pan and then heated to 85 ℃.

Chopping The minced lean was placed into the chopping machine and chopped for 2 min after adding a small amount of ice. Subsequently, certain amounts of sugar, spice, monascus red pigment and fat were added quickly, and they were chopped for 3 min. After then, soy protein and ice were added, and the mixture was chopped for another 2 min.At final,the pumpkin particles were mixed with the meat paste. After standing a few minutes,the stuffing was started[2].

Sausage stuffing One end of the cleaned casing was tied up with cotton. The other end of the casing was coated to the sleeve of the sausage stuffer. The stirred meat paste was placed into the sleeve. After installing the stuffer,the meat paste was stuffed into the casing by shaking the handle.After the stuffing was completed, the other end of the casing was also tied up with cotton. Whether there was air in the sausage body was checked,and if there was, the air was bled by needling hole[13].

Cooking for sterilization When the water in the cooking pan was heated to the set temperature, the prepared pumpkin sausage was placed into the water and cooked for 45 min for sterilization.

Baking The appropriate initial temperature for baking is 58-60 ℃. Too high temperature will cause exudation of oil from sausage body and darken the color of lean,affecting meat quality. Too low temperature will loose the meat structure and lead to the fermentation of carbohydrates in meat paste by tissue enzymes and microorganisms and the generation of fatty acids by hydrolysis, resulting in pale color and soft structure. After baked at 58-60 ℃for 4 h, the sausage was baked at 48-50 ℃for 20 h. The long-time baking could kill most of the microorganisms in sausage and improve its storability[14].

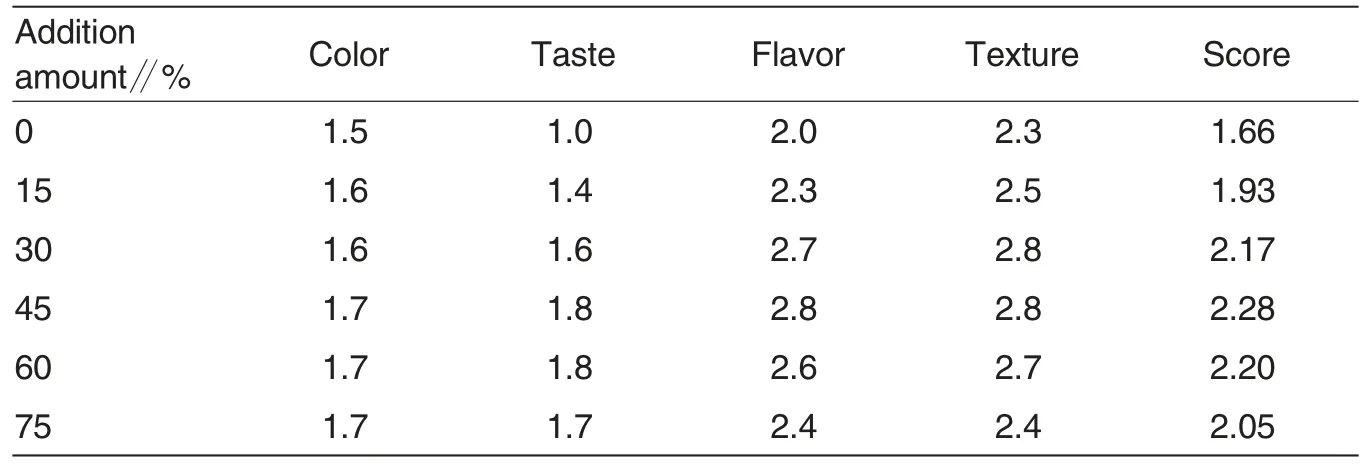

Table 2 Evaluation results of sensory indexes

Table 3 Factors and levels of orthogonal design

Results and Analysis

Determination of addition amount of pumpkin particles

The addition amounts of pumpkin particles were designed as 0%, 15%,30%,45%,60%and 75%,respectively. Under different addition amounts of pumpkin particles, sensory evaluation and physical and chemical indexes determination were performed for pumpkin sausage so as to determine the optimum addition amount of pumpkin particles[15].

As shown in Table 2, with the increased addition amount of pumpkin particles, the evaluation score of pumpkin sausage was first increased and then decreased. So the optimumaddition amounts of pumpkin particles were determined as 30%, 45% and 60%. Under theses addition amounts,the prepared pumpkin sausage showed better color, taste, flavor and texture.

Orthogonal test

Based on sing-factor test results,the main factors that affected the quality of pumpkin sausage were found, including pork, pumpkin particle,soy protein and sugar.For each of the four main factors, three different addition levels were designed (Table 3). In the premise of fixed addition amounts of spice (1%) and monascus red pigment (0.5%)and certain addition amount of ice, the four-factor and three-level orthogonal test [L9(34)]was designed[16].

Based on sensory evaluation and orthogonal analysis (Table 4), the ranking of addition amounts of each of the four factors was obtained.

Table 4 showed that the ranges of the four factors ranked as C>A>B>D.It suggested that the effect of addition amount of soy bean on sausage quality was greatest,the effects of addition amounts of pork and pumpkin particle were greater,and the effect of addition amount of sugar was least. The optimum combination for pumpkin sausage was A2B2C3D2with fat to lean ratio of pork of 2∶8, addition amount of pumpkin particles of 45% , addition amount of soy protein of 6%and addition amount of sugar of 7%.

Quality Inspections

The determination methods[17]and results of physical and chemical and microbiological indicators were shown in Table 5.

As shown in Table 5, the physical and chemical and microbiological indicators of prepared pumpkin sausage all met national standards.

Conclusions and Discussion

In this study, the optimum recipe was determined for pumpkin sausage.It was as follows:100%of pork (fat to lean ratio of 2∶8),45%of pumpkin particle, 6% of soy protein, 7% of sugar,3.5% of salt, 1% of spice, 0.5% of monascus red pigment and certain amount of ice. This study suggested that the processing and preparation of pumpkin sausage were feasible, and the physical and chemical and microbiological indicators of prepared sausage all met the national standards for meat product.

Pumpkin, as a health vegetable,has a variety of medical values and health functions. The preparation of pumpkin sausage by adding appropriate pumpkin into traditional sausage not only can improve the nutritional value, health functions and flavor oftraditional sausage, but also can reduce the consumption of meat and save costs.At the same time, the edible channel of pumpkin is broadened;a new way for deep processing of pumpkin is developed; and the diversity of meat products on market is enriched. In a word, pumpkin sausage has good market prospects and investment and development value.

[1]ZHANG F (张芳),JIANG ZM (蒋作明),ZHANG EM (章恩明).Functional characteristics of pumpkin and its application in food industry (南瓜的功能特性及其在食品工业中的应用)[J].Science and Technology of Food Industry (食品工业科技),2000,6:62-64.

[2]PENG LQ (彭络泉).China Diet Science(中国药膳学)[M]. Beijing: People’s Publishing House (北京: 人民出版社),1985.

[3]KUANG AS (邝安生).Diabetes in China(糖尿病在中国)[M].Hunan:Hunan Science and Technology Press(长沙: 湖南科技出版社),1989.

[4]ZHOU YJ(周亚军),WANG K(王凯),SHI J (石晶).Research and development of compound sausage with fruit and vegetable (果蔬复合香肠的开发研究)[J].Food and Machinery (食品与机械),2002,6:17-19.

[5]XU JX (徐吉祥),HE ZW (何仲雯).The research on adding soy protein to improve the quality of sausages(添加大豆蛋白改善香肠品质的研究)[J]. Food Industry(食品工业),2010,3:34-35.

[6]MA HJ (马汉军), YANG GT (杨国堂),ZHOU GH (周光宏).The effects of different sugars on the fermentation of Chinese-style sausage(不同种类的糖对中式香肠发酵的影响)[J].Food Science and Technology (食品工艺), 2006, 3:39-41.

[7]SHEN SX (沈士秀). Study, production and application of ang-kak(红曲的研究、生产及应用)[J].Science and Technology of Food Industry (食品工业科技),2001,1:85-87.

[8]LIU Y(刘岩),SONG L(宋立),LU CX(吕长鑫), et al. Preparation of cayenne sausage (辣椒香肠的研制)[J].Machinery for Cereals Oil and Food Processing(粮油加工与食品机械), 2002, 11:53-54.

[9]TANG Y (唐勇),LI HJ (李红军),YAN Z( 颜治), et al. Study on appearance quality of low temperature -preserved sausages (低温冷藏灌肠制品的外观品质研究)[J]. Meat Industry (肉类工业),2002,5:29-31.

[10]JAING TB (蒋同彪).Development and processing of vegetable sausages (蔬菜灌肠的开发与加工)[J]. Sichuan Food Science and Technology(四川食品工业科技),1996,3:13-14.

[11]ZHAO JF (赵晋府). Food Technology(食品工艺学)[M]. Beijing: China Light Industry Press (北京: 中国轻工业出版社),2001.

[12]ZHOU WW (周伟伟), LIU Y (刘毅),CHEN X (陈霞),et al.Effects of chopping and mixing conditions on quality and microstructure of emulsion-type sausage (斩拌条件对乳化型香肠品质和微结构的影响)[J]. Meat Research(肉类研究),2007,3:38-43.

[13]ZHAO WY (赵伍英).Quality control of meat sausage production(肉灌肠制品生产的质量控制)[J]. Meat Research(肉类研究),1996,2:22-24.

[14]XIE W (谢文).Factors affecting quality of sausages (影响香肠质量的因素)[J].Meat Industry(肉类工业),1996,1:27-28.

[15]XU QY(徐群英).Preparation of pumpkin health food(南瓜系列保健食品的制作)[J]. Guangzhou Food Science and Technology(广州食品工业科技),2002,4:36-38.

[16]ZHANG HY(张红印),MA LQ(马丽卿),HAO XZ (郝修震),et al.Development of pumpkin nutrition sausages (南瓜营养灌肠的研制)[J].Meat Industry (肉类工业),1999,11:221.

[17]HOU MS(侯明适),ZENG SY(曾士远).Study on biological assay method on meat and meat product(肉与肉制品质量的生化鉴定法)[M].Food Science(食品科学),2000,21(12):121-123.

Agricultural Science & Technology2015年5期

Agricultural Science & Technology2015年5期

- Agricultural Science & Technology的其它文章

- Effect of Meteorological Factors on Yield of Cotton in Different Years

- Breeding of Mycoplasmal pneumonia-negative Swine Population Using Combination Therapy,Segregated Early Weaning(SEW)and Three-point Production System

- Land Use Situation and Strategies under the Background of New Urbanization in Yunnan Province

- Analysis of Heavy Rainstorm in Dongting Lake on July 4,2014

- Regeneration Cultivation Technology of Flammulina velutipes in Factories

- Study on FTIR Spectra of Corn Germs and Endosperms of Three Different Colors Combining with Cluster Analysis