Solid concentration and velocity distributions in an annulus turbulent fluidized bed☆

Cheng Wu,Yongxiang Gao,Youwei Cheng,Lijun Wang,Xi Li*

Department of Chemical and Biological Engineering,Zhejiang University,Hangzhou 310027,China

Keywords:Fluidization Annulus bed Transition section Hydrodynamics Turbulence

ABSTRACT Solid concentration and particle velocity distributions in the transition section of a ϕ 200 mm turbulent fluidized bed(TFB)and aϕ200 mm annulus turbulent fluidized bed(A-TFB)with aϕ50 mm central standpipe were measured using a PV6D optical probe.It is concluded that in turbulent regime,the axial distribution of solid concentration in A-TFB was similar to that in TFB,but the former had a shorter transition section.The axial solid concentration distribution,probability density,and power spectral distributions revealed that the standpipe hindered the turbulence of gas–solid two-phase flow at a low superficial gas velocity.Consequently,the bottom flow of A-TFB approached the bubbling fluidization pattern.By contrast,the standpipe facilitated the turbulence at a high superficial gas velocity,thus making the bottom flow of A-TFB approach the fast fluidization pattern.Both the particle velocity and solid concentration distribution presented a unimodal distribution in A-TFB and TFB.However,the standpipe at a high gas velocity and in the transition or dilute phase section significantly affected the radial distribution of flow parameters,presenting a bimodal distribution with particle concentration higher near the internal and external walls and in downward flow.Conversely,particle concentration in the middle annulus area was lower,and particles flowed upward.This result indicated that the standpipe destroyed the coreannular structure of TFB in the transition and dilute phase sections at a high gas velocity and also improved the particle distribution of TFB.In conclusion,the standpipe improved the fluidization quality and flow homogeneity at high gas velocity and in the transition or dilute phase section,but caused opposite phenomena at low gas velocity and in the dense-phase section.

1.Introduction

Compared with liquid–solid fluidization,gas–solid fluidization is characteristic of uneven axial and radial distributions of velocity and solid concentration because of the great density difference between continuous and dispersed phases.This difference results in nonideal mixing and poor two-phase contact.To overcome this shortage,various methods including internals have been used to generate better gas–solid distribution in bed to accommodate the targeted chemical reactions.Internals can be divided into two categories based on their purposes:(1)high-resistance ones to break up bubbles and agglomeration,including horizontal internals(e.g.mesh,baffle,and paddle)[1–3],pagoda-shaped body,ridge-shaped body[4,5],and packing;and(2)low-resistance ones to change flow direction and distribution in bed,including ring,swage,tube bundle,bluff body,spiral flow pate,and wedge-shaped internal[6–10].The former internals,which are usually used in bubbling fluidized bed,can inhibit bubble growth,facilitate bubble break-up,enhance mass transfer between bubbles and emulsion phase,and increase bubble residence time[11].The latter internals,which are principally used in fast fluidization,can break the coreannular structure,inhibit a thick ring near the wall,increase the central solid concentration,and improve the gas–solid residence time distribution(RTD)[1].

The turbulent fluidized bed(TFB)widely used in MTO(methanol to olefins)[12,13]has two characteristics:(1)coexistence of bubble phase and emulsion phase like in bubbling fluidized bed,and(2)core-annular structure as in a riser.Although the bubbles update in a high frequency and mass transfer is efficient in bed,the gas and solid backmixing and the resultant broad RTD are big problems of the turbulent bed.Thus,internals are generally used to inhibit axial backmixing and facilitate radial gas–solid movement rather than bubble break-up,eliminate gas bypass,or facilitate gas exchange between bubble and emulsion phases[14].Among many internals,vertical tube has very small pressure drop.Early research is principally focused on heat exchange and abrasion influidized bed,whereas few studies are focused on the effects of vertical tube on gas–solid flow.Meanwhile,recent works are concentrated on two equipments.First is integral circulating fluidized bed(o-ICFB)in fast fluidization regime[15–17],in which the S-type axial concentration profile and a dense–dilute–dense three-ring radial distribution are observed;second is a fluidized bed involving a vertical membrane tube for coupling of reaction and separation[18].These studies involved fast fluidized bed or bubbling fluidized bed.Few works have considered the effect of a standpipe in TFB.

Our previous research on TFB[19–23]revealed that the transition section is the principal component of TFB reactor and that its flow parameter distribution determines reactor performance.However,few studies are involved with solid concentration and particle velocity distribution in the transition section.Therefore,we conducted systematic experiments and analyses on the axial and radial distributions of solid concentration and particle velocity in the transition section for both TFB and annulus-TFB(A-TFB)with a standpipe.The present study aims to explore the effect of standpipe internals on flow parameter distributions and lay foundations for developing this type of reactor.

The experimental setup is a stainless-steel circulating fluidized bed(CFB)(Fig.1).The main column(10)is 200 mm in diameter and 6500 mm in height,with a 300 mm(i.d.)expanded section on the top for solid recycle.The concomitant column(5)with a 300 mm i.d.is used to adjust the solid circulating flow rate.The gas distributor(above 14)used in the turbulent bed is a stainless-steel perforated plate(aperture ratio=5%;aperture=2 mm),on which multilayer fine stainless-steel screens were paved for material leakage prevention.Large and small flow meters were used to ensure accurate flow rate regulation of fluidizing gas.The third flow meter was used to adjust flow rate of aeration air in the concomitant fluidized bed(5).The exit gas from the top of the turbulent bed went through two-stage cyclones,in which most particles were recovered and the gas finally passed through a bag filter.To investigate the effect of standpipe internals on gas–solid flow pattern in turbulent regime,A-TFB was developed by inserting a 50 mm(i.d.)central standpipe in the traditional TFB.The fluidized particles used in this experiment are colorless glass beads with a true density of 2400 kg·m-3and a packing porosity of 0.4.The Sauter mean

2.Experimental

Fig.1.Schematic of experimental setup.1—bag filter;2—gas flow meter;3—stop valve;4—blower;5— fluidized bed;6—cyclone;7—expanded section;8—store tank;9—butter fly valve;10—turbulent bed;11—internal;12—feed port;13—measurement port;14—buffer tank.

diameter of the particles was 106 μm,as measured by a Malvern laser particle size analyzer(Mastersizer 2000).Thus,they were determined as Geldart A–B particles[1].

Solid particle velocity and concentration in turbulentbed were measured with a PV6D optical probe purchased from the Institute of Process Engineering,Chinese Academy of Sciences.Two 1×1 mm fiber arrays are situated on the probe top,and each optical fiber in the array can send and receive optical signals.The calibrated interval between the two arrays is 2.25 mm.The stainless-steel sleeve of the probe is 382 mm long and 4 mm in external diameter.The probe collects gas–solid flow pattern information in the bed through multi-measurement ports.In the TFB experiment,11 radial measurement points were selected in each measurement port according to the relative radial position ϕ=r/R2=0–1.In the A-TFB experiment,8 radial measurement points were selected according to ϕ =(r-R1)/(R2-R1)=0–1(r is the radial distance to the bed axis,R1is the radius of the internal,and R2is the radius of the turbulent bed).The measurement parameters after experiment optimization were as follows:sampling frequency,5 kHz;data length,131072;and 5 measurements at each point.

3.Results and Discussion

3.1.Cross-sectional average solid concentration

Fig.2.Axial distribution of cross-sectional average solid concentration of A-TFB under different conditions(H=6.5 m,D2=0.2 m,D1=0.05 m,(a)u g=0.84,1.21,1.86 m·s-1,H0=0.5 m;(b)u g=1.21 m·s-1,H0=0.5,0.75 m).

The vertical distribution of cross-sectional average solid concentration,which was integrated from local solid concentration,in A-TFB under different operation conditions is shown in Fig.2.The superficial gas velocities all located in the regime of turbulent fluidization.Meanwhile,the static bed heights were not too high to cause plug flow,also not too low to result in incomplete transition section.The bed can be divided into three parts according to the steepness of the cross-sectional average solid concentration:dense-phase section at bottom,sharp transition section in the middle,and dilute-phase section on top.The axial part above 2 m has the nearly unchanged solid concentration and belongs to the dilute-phase section.The solid concentration at the lower part of the bed decreases but at the upper transition section and dilute phase section increases with the increasing superficial gas velocity.As a result,the S-shaped distribution becomes flatter,and the uniformity of axial solid distribution is improved at higher ug.With increased static bed height,the length of the dense-phase section increases,which is equivalent to moving the axial distribution curve of the cross-sectional average solid concentration upwards by a certain distance.These results agree with the measurement results obtained by the author in TFB and the literature[16,20].In other words,the variation in axial solid concentration distribution in A-TFB with superficial gas velocity and static bed height is similar to that in the traditional TFB.In addition,the standpipe cannot significantly change the axialgas–solid macroscopic distribution of the turbulent bed.

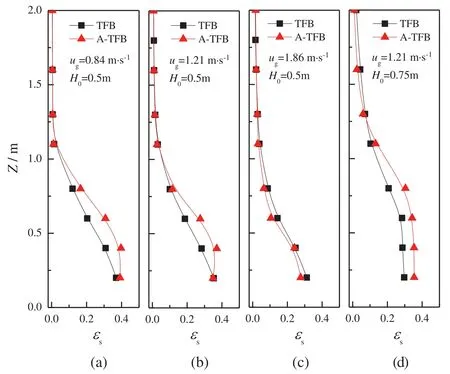

Fig.3 compares the axial distributions of the cross-sectional average solid concentration between TFB and A-TFB under different operating conditions.The installed standpipe changes remarkably the solid concentration in the transition section,while the corresponding transition section shortens,indicating that the flow pattern in the transition section develops quickly.This result agrees with that of Wang et al.[16]in fast fluidization regime.In Fig.3(a)and(b),the lower part of the transition section and the dense-phase section of A-TFB have a higher cross sectional average solid concentration than those of TFB at a low gas velocity.Such difference gradually decreases as the gas velocity increases and the cross-sectional average solid concentration of TFB exceeds that of A-TFB bottom when the gas velocity approaches fast fluidization[Fig.3(c)].This result is contradictory to that of Wang et al.[16],who determined the solid concentration growth in the whole bed by calculating the porosity limit.The causes of such variation must be analyzed by combining subsequent experimental results,as introduced in Sections 3.3 and 3.4.As shown in Fig.3(b)and(d),the solid concentration in the transition section of A-TFB and TFB(except for 0.2 m height influenced by the distribution plate)varies similarly with increasing static bed height.The cross-sectional average solid concentration curves on both A-TFB and TFB sections move upwards by a certain distance,thereby increasing the length of the dense-phase section.

3.2.Variation of radial solid concentration

Fig.4 shows that the radial solid concentration curve has a dilute center with two dense boundaries.However,the radial solid concentration distributions at different heights are influenced by the standpipe to different extents.In the dense-phase section with a high solid concentration at the bottom,the concentration near the internal wall is slightly higher than that in annular center,while in a typical TFB[1,11,14]the solid concentration is flat in the core region and lower than that near the wall.This result demonstrates that the standpipe slightly affects the radial solid concentration distribution in the dense-phase section.However,the standpipe significantly affects the solid concentration in the upper dilute-phase section,showing a new high-concentration area near the internal wall.As the bed height increases,the radial solid concentration distribution develops a typical three-ring structure(external high concentration ring–middle annulus–internal high concentration ring).The effect of the standpipe is not significant at a low gas velocity but significant at a high gas velocity.The axial height range(0.4–0.8 m)in Fig.4 belongs to the dense-phase section and the lower part of the transition section having a high solid concentration and causing bed expansion as the superficial gas velocity increases.Thus,the solid concentration decreases at all radial positions.The axial height range(1.1–2.0 m)belongs to the upper transition section and the dilute-phase section having a low solid concentration.The particles are likely to achieve this height as the superficial gas velocity increases,thereby increasing the solid concentration at all radial positions.Different from TFB,the standpipe serves as an additional internal wall that shifts the core-annular structure on the upper bed region into the three-ring structure,especially at a high gas velocity.

Fig.3.Axial distribution comparison of cross-sectional average solid concentration in TFB and A-TFB under different conditions(H=6.5 m,D2=0.2 m,D1=0.05 m,(a)u g=0.84 m·s-1,H0=0.5 m;(b)u g=1.21 m·s-1,H0=0.5 m;(c)u g=1.86 m·s-1,H0=0.5 m;(d)u g=1.21 m·s-1,H0=0.75 m).

Fig.4.Comparison of radial solid concentration distributions at various heights of A-TFB with different superficial gas velocities(H=6.5 m,D2=0.2 m,D1=0.05 m,u g=0.84,1.21,1.86 m·s-1).

Liu et al.and Wang et al.[15,16]measured the radial solid concentration distribution of o-ICFB in fast fluidization regime by using small and light particles.They found a similar three-ring structure on the bottom high-concentration area.However,they reported different solid concentrations at axial and radial positions.In[15],the radial curve shape slightly changes from bottom to top,and the solid concentrations near the internal and external walls are highly similar.According to the solid concentration curve in[16],the external wall is significantly denser than the internal wall.In this experiment,the solid concentration near the bottom external wall is significantly higher than that near the internal wall.This difference gradually reduces with increased axial height and can be attributed to two reasons.One is that this experiment is conducted in turbulent regime,where as previous authors focused on fast fluidization.The axial distribution of turbulent bed is more inhomogeneous than that of fast fluidized bed.The other is that the measurement is significantly interfered by reflected lights from the wall when the probe measures toward the internal wall at a short distance.This interference may explain the different solid concentrations near the internal and external walls in Refs.[15,16].

3.3.Variation in probability density distribution of solid concentration

The pulse signal of local solid concentration includes the gas–solid transient variation information and the occurrence frequency of different solid concentrations within a certain period,i.e.,the probability density distribution(PDD)of local solid concentration.PDD which was calculated from transient local solid concentration reflects the occurrence probability of the bubble and emulsion phases.

Fig.5(a)shows the PDD near the external wall(ϕ=1)and in the middle annulus region(ϕ=0.4)of TFB and A-TFB when ug=0.84 m·s-1.The two evident peaks at the low and high concentrations of the PDD curve are contributed by the bubble and emulsion phases,respectively[20].The emulsion peak at ϕ=1 in both TFB and A-TFB is higher than that at ϕ=0.4 because of the high solid concentration near the walls and the high occurrence frequency of the emulsion phase.The involvement of the standpipe significantly increases the emulsion peaks at two radial positions,indicating an increasing occurrence probability of emulsion phase.The concentration degree of the two peaks also significantly increases as the tailing trend sharply decreases.This result indicates that the involvement of the standpipe at a low gas velocity widens the gap between the bubble and emulsion phases but weakens the turbulence degree.

Fig.5(b)shows the PDD curve when ug=1.86 m·s-1.Compared with the significant difference between TFB and A-TFB at a low gas velocity,the standpipe slightly affects both the middle annulus and external wall at a high gas velocity.The PDD curves of TFB and A-TFB are similar.The standpipe does not increase but slightly decreases the difference between the bubble and emulsion phases.This result indicates that the standpipe can facilitate(at least does not weaken)the turbulence and mixing between the bubble and emulsion phases at a high velocity.This result differs significantly from the phenomenon at a low gas velocity.The PDD results agree with the variation in crosssectional average solid concentration with bed height(Section 3.1).The involvement of the standpipe increases the solid concentration at the bottom of the transition section and in the dense-phase section at a low velocity but slightly decreases the solid concentration at a high gas velocity.

3.4.Power spectral analysis of solid concentration

Power spectral analysis aims to obtain signal energy distribution at different frequencies by transforming the time-domain information of the original signal into frequency-domain information.Researchers on fluidization analyzed the power spectrum of original signals,including local solid concentration fluctuation,and determined the dominant frequency ofpulse signals and turbulence intensity of flows.The present study calculated the power spectrum according to the pulse signals of local solid concentration at different radial positions of TFB and A-TFB collected at a sampling frequency of 5 kHz in 131.07 s.A total of 655360 data were collected.The spectrum is shown in Fig.6.

Fig.5.Probability density distribution of solid concentration of TFB and A-TFB under the same conditions(H=6.5 m,D2=0.2 m,D1=0.05 m,H0=0.5 m,Z=0.4 m,ϕ=0.4,1,(a)u g=0.84 m·s-1;(b)u g=1.86 m·s-1).

In Fig.6(a),the spectral intensity gradually declines from a low frequency to a high frequency and has various peaks ata low frequency,with an evident dominant frequency(frequency at the highest peak).This variation is similar to the spectrum in turbulent and bubbling regimes[24–26].Comparing the spectra of TFB and A-TFB at a low gas velocity[Fig.6(a)],we find that the involvement of internals significantly decreases the spectral energy and increases the dominant frequency from approximately 1 Hz to 1.1–1.2 Hz(frequency growth near the wall is less obvious than that of the middle annulus area).According to Refs.[25,26],the spectral energy increases,whereas the dominant frequency decreases when the flow pattern changes from bubbling fluidization to turbulent fluidization.This result demonstrates that the involvement of the standpipe at a low gas velocity changes the flow pattern from turbulent fluidization to bubbling fluidization,thereby depressing the turbulence and reducing the quality of fluidization.

Fig.6(b)shows the power spectrum at a high gas velocity.The involvement of the standpipe increases the spectral energy of solid concentration in the middle annulus area,indicating promoted turbulence in the area.Meanwhile,the power spectrum near the external wall shows no significant change.This result demonstrates that the standpipe at the current gas velocity significantly accelerates the internal turbulence but slightly affects the turbulence near the wall.Compared with the spectrum at a low gas velocity,the spectrum at a high gas velocity has a smaller energy peak value but more peaks and broader distribution.This variation is similar to the spectral change characteristics from turbulent fluidization to fast fluidization in Ref.[24].The dominant frequency also becomes indistinguishable,indicating the weakening large-scale periodic motion in the bed[25]and improved time-domain distribution uniformity of the solid.

Turbulent fluidization is a transition regime between bubbling fluidization and fast fluidization.The experimental results were compared with related studies concerning fast fluidization.Results show that the influence mechanism of the standpipe on the lower transition section and the dense-phase section of A-TFB is highly complicated.At a low gas velocity,the standpipe inhibits local turbulence,making the local flow pattern approach bubbling fluidization.However,the standpipe intensifies turbulence at a high gas velocity,making the flow pattern approach fast fluidization.According to[1,11,14],when flow regime changes from a low level to a high one(e.g.bubbling fluidization to turbulent fluidization),the solid concentration in the bottom of bed decreases.So the standpipe increases the solid concentration at a low gas velocity,while decreases it at a high gas velocity.

3.5.Radial distribution of particle velocity

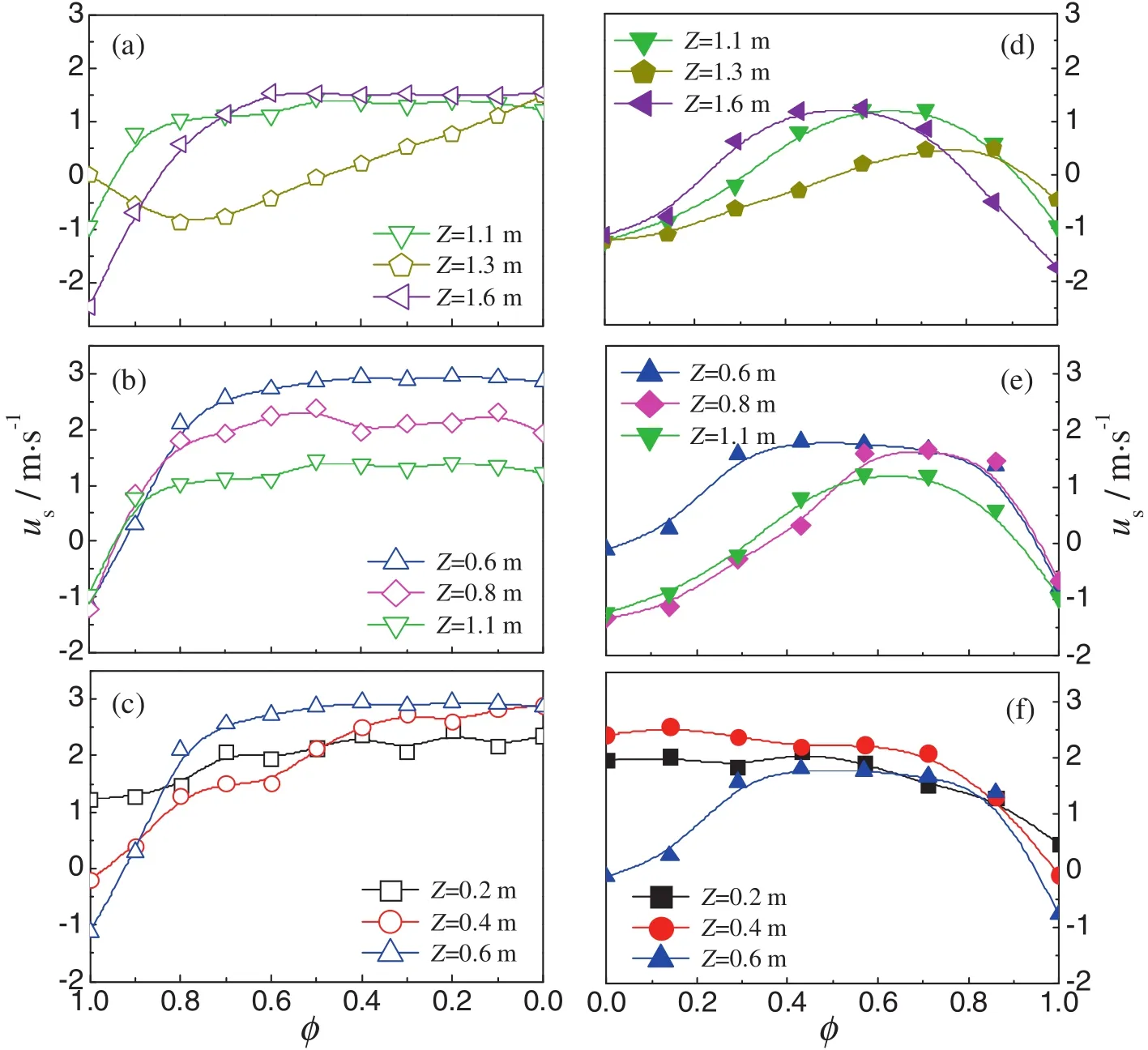

The above analysis indicates that the standpipe within the turbulent regime in this study decreases the uniformity of axial solid concentration distribution at a low gas velocity but improves the solid concentration distribution at a high gas velocity.Therefore,special attention should be paid to investigating the radial distribution of particle velocity with high gas velocity(ug=1.86 m·s-1).The radial distributions of particle velocity in TFB and A-TFB at various axial heights under the same operating conditions are shown in Fig.7.Fig.7(a)–(c)shows the experimental results of TFB,and Fig.7(d)–(f)shows the results of A-TFB.

Fig.7 demonstrates that the general radial distribution trend of particle velocity in A-TFB is similar to that of TFB,i.e.,short accelerating period to decelerating period caused by local solid concentration and gas velocity distribution and then to secondary accelerating period caused by a fully developed flow pattern.Such distribution trend agrees with the author's previous research results on particle velocity in the TFB transition section[21],except for the slightly lower overall velocity.The surrounding area of ϕ=0 for TFB is the bed center,whereas that for A-TFB is close to the standpipe(internal wall).The standpipe slightly affects the dense-phase section(0.2–0.4 m height).Thus,the velocity distribution of A-TFB is similar to that of TFB,i.e.,higher near the internal wall but lower near the external wall:A unimodal distribution.However,the flow pattern of A-TFB gradually develops,and the particle velocity near the internal wall further slows down with increased axial measuring height.When the measuring height increases to higher than 0.6 m,the radial particle velocity distribution decreases near the internal and external walls but increases in the middle annulus area.This is a bimodal distribution.Combined with the radial solid concentration distribution in Fig.4,we observe a high solid concentration near the internal and external walls in the A-TFB transition section(higher than 0.6 m)and a downward movement of solid particles.Meanwhile,the middle annulus area has relatively lower particle concentration,and the particles move upward.The internal wall destroys the original core-annular structure of TFB and forms a dense area near the internal wall in the A-TFB center,thereby causing a more uniform solid concentration distribution and velocity distribution than TFB.This finding confirms that the standpipe can improve the fluidization performance of TFB at a high gas velocity.Furthermore,Fig.7 presents no significant difference in velocity distribution surrounding ϕ=1 between A-TFB and TFB,indicating that the standpipe can only affect the radial distribution of particle velocity in the central area.Such effect is inversely proportional to radial distance.

Fig.6.Power spectra of solid concentration at different radial positions of TFB and A-TFB with different gas velocities(H=6.5 m,D2=0.2 m,D1=0.05 m,H0=0.5 m,Z=0.4 m,ϕ=0.4,1).

Fig.7.Radial distribution of particle velocity in TFB and A-TFB under the same conditions(H=6.5 m,D2=0.2 m,D1=0.05 m,u g=1.86 m·s-1,H0=0.5 m).

4.Conclusions

(1)In turbulent regime,the axial distributions of solid concentration in A-TFB are similar to those in TFB.The bed can be divided into a dense-phase section,a transition section,and a dilute-phase section.However,the axial/radial solid concentration distribution,probability density distribution,and power spectral distribution reveal the following results.First,the standpipe hinders gas–solid turbulence at a low gas velocity,making the bottom flow of A-TFB approach bubbling fluidization and causing the solid concentration difference between the lower dense-phase section and the upper dilute-phase section of A-TFB to be greater than that of TFB.Second,the standpipe can facilitate gas–solid turbulence at a high gas velocity,making the bottom flow of A-TFB approach fast fluidization and bringing more uniform solid concentration distribution of ATFB than TFB.

(2)The experimental results show that the standpipe slightly affects solid concentration and velocity distribution in the lower dense-phase section at a low gas velocity.Both A-TFBand TFB show similar unimodal distribution.By contrast,the standpipe significantly affects the radial profiles in the transition and dilute-phase sections at a high gas velocity,presenting a bimodal distribution.High particle concentration and downward particle flow can be observed near the internal and external walls,whereas low particle concentration and upward particle flow can be observed in the middle annulus area.This result confirms that the standpipe destroys the core-annular structure of TFB in the transition and dilute-phase sections at a high gas velocity and also improves the solid distribution in the bed.

Nomenclature

D1diameter of internal,m

D2diameter of TFB or A-TFB,m

H height of the turbulent bed,m

H0static bed height,m

R1radius of internal,m

R2radius of TFB or A-TFB,m

r distance to bed axis,m

ugsuperficial gas velocity,m·s-1

usparticle velocity,m·s-1

Z height to the distributor,m

ϕ relative radial position(=r/R2)

εssolid concentration

Subscripts

g gas phase

s solid phase

Chinese Journal of Chemical Engineering2015年7期

Chinese Journal of Chemical Engineering2015年7期

- Chinese Journal of Chemical Engineering的其它文章

- Mixing time in stirred vessels:A review of experimental techniques☆

- A Reynolds mass flux model for gas separation process simulation:I.Modeling and validation☆

- Effects of the short blade locations on the anti-cavitation performance of the splitter-bladed inducer and the pump☆

- Fabrication of graphene oxide composite membranes and their application for pervaporation dehydration of butanol☆

- Extraction of rubidium by t-BAMBP in cyclohexane☆

- Scale-up of NaA zeolite membranes on α-Al2O3 hollow fibers by a secondary growth method with vacuum seeding☆