Impact ofmaterial and energy flow variation-based iron/steel ratio on production cost

Lu BiaoChen GuangChen Dem inYu WeipingDing Yi

(1School of Energy and Environment,Southeast University,Nanjing 210096,China)

(2School of Civil Engineering,Anhui University of Technology,Ma’anshan 243032,China)

(3Ma’anshan Iron&Steel Co.Ltd.,Ma’anshan 243000,China)

Impact ofmaterial and energy flow variation-based iron/steel ratio on production cost

Lu Biao1Chen Guang2Chen Dem in2Yu Weiping1Ding Yi3

(1School of Energy and Environment,Southeast University,Nanjing 210096,China)

(2School of Civil Engineering,Anhui University of Technology,Ma’anshan 243032,China)

(3Ma’anshan Iron&Steel Co.Ltd.,Ma’anshan 243000,China)

This paper establishes a model for the production cost of iron and steel enterprise.The variation rule of the production cost versus the iron/steel ratio for two cases,namely,fixed steel production and a fixed amount of molten iron,is analyzed,and the concept of a steel scrap threshold price is proposed.According to the analysis results,when the steel scrap unit price exceeds the steel scrap threshold price,an increase in the iron/steel ratio can reduce the production cost,and vice versa.When the gap between the steel scrap unit price and the steel scrap threshold price is relatively large,the impact of the iron/steel ratio on the production cost is more prominent.According to the calculation example,when steel production is fixed(284 358 t/month)and the steel scrap unit price is 263.2 yuan/tmore than the steel scrap threshold price,an increase of 0.01 in the iron/steel ratio causes a monthly production cost reduction of approximately 750 000 yuan(2.63 yuan/t).When the amountofmolten iron is fixed(270 425 t/month)and the steel scrap unit price is 140.7 yuan/tmore than the threshold price,an increase of 0.01 in the iron/steel ratio causes amonthly production cost reduction of approximately 430 000 yuan(1.5 yuan/t).The results indicate that iron and steel enterprise should adjust the production strategy in time when the scrap price fluctuates,and then the production costw ill be reduced.

iron/steel ratio;material flow;energy flow;model of production cost;steel scrap threshold price

The steel production process is a dynam ic process.The physical nature of its operation involves dynamic and orderly material flow in a“process network”under the driving force of energy flow,which proceeds according to a predefined“program”to achievemulti-objective optim ization[1].Therefore,material flow and energy flow are two major factors that affect the operations of a steel manufacturer.Currently,studies ofmaterial flow and energy flow focus on two aspects.The first one is from the perspective of a time and space relationship between material flow and energy flow.For example,Yin et al.[15]elaborated the steelmanufacturer’s operational nature and proposed that Chinese steel manufacturers should enter a new phase that is characterized by the setup of an energy flow network and energy control center.The second one is from the perspective of thematerial flow structure.For example,Lu et al.[6]exam ined the impact of thematerial flow structure on the total energy consumption and proposed some important concepts,such as a referencematerial flow diagram and a steel ratio coefficient.The iron/steel ratio is the most critical material flow structure parameter for descriptions of before ironmaking(BIM)and after steelmaking(SM).Recently,many researchers have conducted related studies.Huang et al.[711]carried out research in depth on scrap steel from a view of environmental and economic sustainable development.

This paper outlines the production cost and establishes amathematicalmodel on the basis of a standard material flow diagram[6].The impact of the iron/steel ratio on the production cost is obtained by model analysis when the BIM total cost and the steel scrap unit price change.The concept of a steel scrap threshold price is proposed and verified by examples.

1 M odel of M anufacturer’s Production Cost

A manufacturer’s production cost primarily includes the directmaterial cost,the direct labor cost and the manufacturing cost.The directmaterial cost includes the cost of raw material,auxiliary material and the cost of fuel and power;the direct labor cost includes the wages and benefits of workers;and themanufacturing cost includes the wages and benefits ofmanagement personnel.The direct material cost accounts for more than 75%of a manufacturer’s production cost[11].This cost can be divided into two categories:thematerial flow cost and the energy flow cost.The direct labor cost and themanufacturing cost remain constant w ithin a statistical cycle.When the output capacity increases,the unit cost decreases,which is consistentw ith themarginal effect in econom ics.In this paper,the change in unit cost is defined as the marginal cost.Since the unit price of steel scrap can vary,a reasonable iron/steel ratio should be established toachieve the lowest cost.

1.1 Scope of study

The cost of a BIM system is considered as a whole in the raw material cost,which is referred to as the BIM total cost,including the material flow cost,energy flow cost,and marginal cost of the BIM system.The scope of this study is represented by the area enclosed by dotted line in Fig.1.Here,CC,HR,CR,and SS represent continuous casting,hot rolling,cold rolling,and scrap steel,respectively.

Fig.1 Scope of system study

In Fig.1,P0is the addition ofmolten iron,t;Psis the steel scrap addition,t;Eiis the total energy consumption of the i-th process,tce(ton coal equivalent);Aiis the auxiliary material total consumption of the i-th process,t;Piis the production of the i-th process,t;P is the gross output of steel,t.

Fig.1 indicates that the material flow consists of the molten iron,steel scrap and auxiliary material that enter each process and that the energy flow consists of the energy that enters each process.Therefore,thematerial flow cost is the sum of the BIM total cost,the steel scrap cost and the process auxiliary material cost.The energy flow cost is the sum of the energy cost for each process.To construct themodel of the production cost in this paper,the follow ing assumptions aremade:

1)In the CC,HR and CR processes,the auxiliarymaterial cost is not counted,i.e.,A2=A3=A4=0,and the auxiliary material in the SM process is determined by the amount ofmolten iron.

2)The recycled material consumed in each process serves as an internal accounting index and is not included in the cost.

3)The relationship between the raw material flow and the product flow in each process can be represented by the product resource utilization,the material yield and the product yield.

4)A steel manufacturer’s material flow and energy flow have a very strong coupling relationship[12];a significant change in energy flow occurs after the change in material flow.Their relationship can be obtained by a regression method.

1.2 Establishm ent ofm odel

This paper establishes amodel ofmaterial flow cost,in which the energy flow cost is obtained based on a coupling relationship between thematerial flow and the energy flow.This cost is combined w ith themarginal cost to obtain the production cost.

1.2.1 Model ofm aterial flow cost

As previously described,the output of each process in Fig.1 has the follow ing relationships:

whereηiis the total production efficiency of the i-th process;αsis the steel scrap yield,%.When i=1,ηi=αs.

Based on the definition of the iron/steel ratio[6],the amount of steel scrap can be obtained after processing:

The steel scrap cost is calculated as

where Csis the steel scrap unit price,yuan/t;csis the steel scrap production cost yuan/t;kiris the iron/steel ratio.

The amount ofmolten iron is calculated as

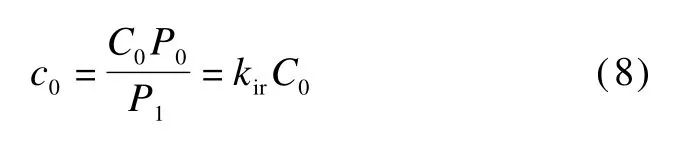

Themolten iron cost is

where C0is thematerial unit price,yuan/t;c0is thematerial production cost,yuan/t.

During the production process,the purpose of the auxiliary material is to remove impurities and provide cooling.Its amount is determined by the upstream process output.The amount of auxiliary material is obtained as

where Aiis the auxiliary material total consumption of the i-th process,t;αiis the auxiliary material consumption rate of the i-th process,%;aiis the ratio of the auxiliary material consumption of the i-th process to steel production.

The auxiliary material cost only exists in the steelmaking process,and its major function is to remove phosphorus,sulfur and silicon from molten iron.Therefore,Eq.(9)can be expressed as

The auxiliary material cost is

where Cais the auxiliary material unit price,yuan/t;caisthe auxiliary material production cost,yuan/t.

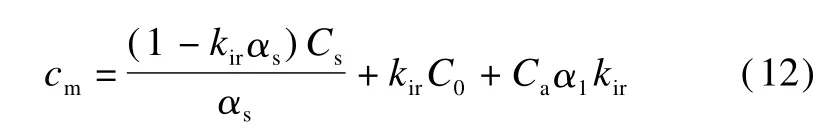

Thematerial flow production cost is

where cmis thematerial flow production cost,yuan/t.

1.2.2 Model of energy flow cost

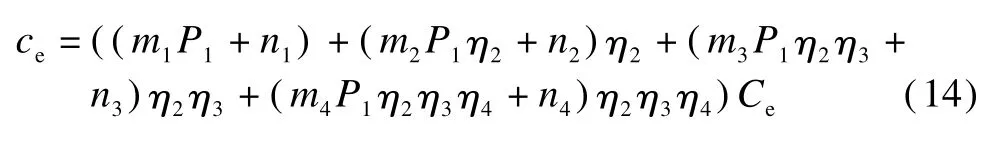

From the concepts of energy consumption in a process and the steel ratio coefficient[8],the product of the two concepts is the energy consumption multiplied by the energy unit price,that is,the energy cost.The sum of the energy cost for each process is the total energy cost,i.e.,

where Ceis the energy unit price,yuan/t;ceis the energy production cost,yuan/t.

There is a strong correlation between energy intensity of a process and its output through practical investigation.In this paper,a unary linear regression method is used to obtain the coupling relationship,i.e.,ei=fi(Pi)=miPi+ni.Combining w ith Eqs.(1)to(4),we obtain p1=1,p2=η2,p3=η2η3,p4=η2η3η4.Eq.(13)can be expanded and simplified as

1.2.3 Model ofm arginal cost

Themarginal cost is the ratio of the sum of the assets depreciation and the personnel benefits to steel production,i.e.,

where cbis themarginal production cost,yuan/t;K is the fixed cost,billion yuan.

1.2.4 M odel o fm anu facturer's p roduction cost

A manufacturer’s production cost consistsof thematerial flow cost,the energy flow cost and themarginal cost,i.e.,

2 M odel Analysis

Eq.(16)has two independent variables.First,when the iron/steel ratio and the steel production are independent variables,the variation in the iron/steel ratio is determ ined by the amount ofmolten iron and the steel production is fixed.Secondly,when the iron/steel ratio and the amount ofmolten iron are independent variables,the variation in the iron/steel ratio is determ ined by the steel production and the amount of molten iron is fixed.

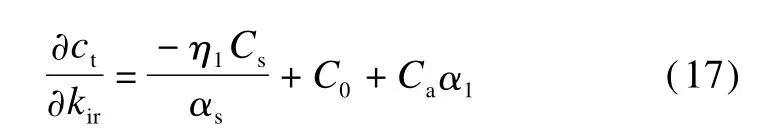

2.1 The varying pattern in fixed steel production

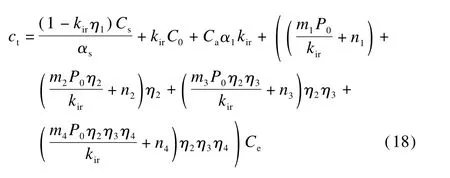

When the steel production is fixed,we obtain the partial derivative of Eq.(16)w ith respect to the iron/steel ratio,i.e.,

When Cs<αs(C0+Caα1)/η1,∂ct/∂kir>0.This finding indicates that the production costhas a positive correlation w ith the iron/steel ratio.Meanwhile,the steel scrap unit price dim inishes and reducing the iron/steel ratio causes a decrease in the production cost,which increases the amount of steel scrap and reduces the amount of molten iron.When Cs>αs(C0+Caα1)/η1,∂ct/∂kir<0.This finding indicates that the production cost has a negative correlation with the iron/steel ratio.Meanwhile,the steel scrap unit price increases and increasing the iron/steel ratio causes a reduction in the production cost,which reduces the amount of steel scrap and increases the amount of molten iron.When Cs=αs(C0+C0α1)/η1,∂ct/∂kir=0.Meanwhile,the production cost does not vary w ith the iron/steel ratio.

2.2 The varying pattern in fixed molten iron

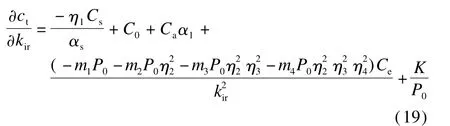

When the amountofmolten iron is fixed,we substitute P1=into Eq.(16)to obtain the model of a manufacturer’s production cost,i.e.,

We obtain the partial derivative of Eq.(18)w ith respect to the iron/steel ratio,i.e.,

Eq.(19)indicates that the varying pattern of the production costand the iron/steel ratio is determ ined by various factors,such as the iron/steel ratio,the amount of molten iron,the material and energy flow cost,and the resource utilization.Let X=αs(C0+Caα1+(-m1P0---+K/P0)/η1.According to further analysis,when Cs<X,the production cost has a positive correlation w ith the iron/steel ratio;when Cs>X,the production cost has a negative correlation w ith the iron/steel ratio;and when Cs=X,the production cost does not vary w ith the iron/steel ratio.

In the two previously described situations,a steel scrap unit price renders amanufacturer’s production cost insensitive to the iron/steel ratio.When the steel scrap unit price exceeds this price,increasing the iron/steel ratio can result in a lower production cost.To achieve a higher steel scrap unit price,more molten iron and less steel scrap should be used.When the steel scrap unit price falls below this price,reducing the iron/steel ratio can result in a lower production cost.To achieve a lower steel scrap unit price,lessmolten iron and more steel scrap should be utilized under the premise that the requirement of the converter steelmaking production process is satisfied.This steel scrap unit price under the BIM total cost is defined as the steel scrap threshold price.

3 Case Studies

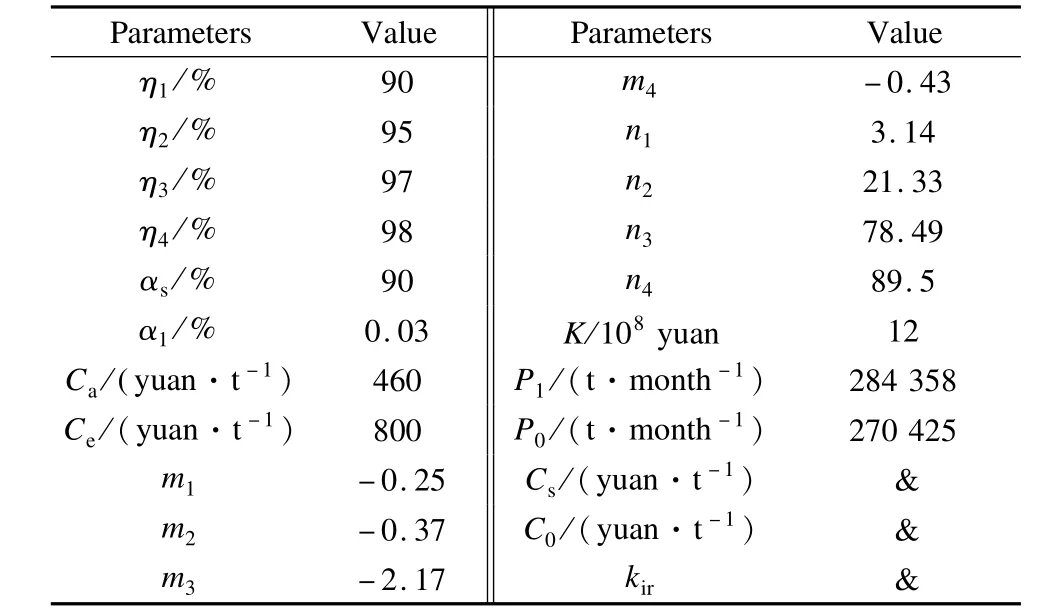

The data source for this case study consists of the monthly average data of one manufacturer in 2013.The discussion focused on the BIM total cost and the steel scrap unit price,which have a significant impact on the production cost;other parameters are set to bemarketand manufacturer’s average values.The details are shown in Tab.1.

Tab.1 Relevant parameters of themodel

3.1 The varying pattern in fixed steel production

The BIM total cost of 2 860 yuan/t is used as an example to discuss the variation rule of the production cost vs.the iron/steel ratio.Fig.2 indicates the variation rule of the production cost vs.the iron/steel ratio for different steel scrap unit prices in the case of fixed steel production.When the steel scrap unit price is2 874 yuan/t,the production cost does not vary w ith the iron/steel ratio,i.e.,this price is the steel scrap threshold price for the BIM total cost of 2 860 yuan/t in the case of fixed steel production.When the steel scrap unit price exceeds2 874 yuan/t,the production cost decreasesw ith the increase in the iron/steel ratio.The more the steel scrap unit price exceeds 2 874 yuan/t,the higher the degree of negative correlation between the production cost and the iron/steel ratio.This finding indicates that the steel scrap utilization should be decreased and themolten iron utilization should be increased.When the steel scrap unit price falls below 2 874 yuan/t,the production cost increases w ith the increase in the iron/steel ratio.The more the steel scrap unit price falls below 2 874 yuan/t,the higher the degree of positive correlation between the production cost and the iron/steel ratio.This finding reveals that the steel scrap utilization should be increased and themolten iron utilization should be decreased under the premise that the requirement of the converter steelmaking production process is satisfied(Them inimum iron/steel ratio is0.8).W ith different BIM total cost values,the same conclusion can be obtained,w ith the exception that the steel scrap threshold price is slightly different.

Fig.2 The varying pattern in fixed steel production

3.2 The varying pattern in fixed m olten iron

The BIM total cost of 2 860 yuan/t is used as an example to facilitate a discussion on the variation rule of the production cost vs.the iron/steel ratio.Fig.3 indicates the variation rule of the production cost vs.the iron/steel ratio for different steel scrap unit prices in the case of a fixed amount of molten iron.When the steel scrap unit price is 2 996 yuan/t,the production cost exhibits a nonlinear relationship with the iron/steel ratio.In the case of the converter steelmaking process,the fluctuation in production cost is less than 0.03%.Thus,the results indicate that the production cost does not vary w ith the iron/steel ratio at this steel scrap unit price,that is,this price is the steel scrap threshold price for themolten iron total cost of 2 860 yuan/t in the case of a fixed amount of molten iron.When the steel scrap unit price exceeds 2 996 yuan/t,the production cost has a negative correlation w ith the iron/steel ratio.The larger the discrepancy,the smaller the amount of steel scrap and the larger the amount ofmolten iron that are to be used.When the steel scrap unit price is less than 2 996 yuan/t,the production cost has a positive correlation w ith the iron/steel ratio.Alarger discrepancy requires thatmore steel scrap and less molten iron should be used.The same conclusion can be obtained w ith different BIM total cost values,w ith the exception of slightly different steel scrap threshold prices.

Fig.3 The varying pattern in fixed molten iron

The steel scrap unit price(3 137 yuan/t)is used as an example for the calculations in the case of fixed steel production(284 358 t/month).An increase of 0.01 in the iron/steel ratio causes amonthly reduction of approximately 750 000 yuan in the production cost(2.63 yuan/t).In the case of a fixed amount of molten iron(270 425 t/month),an increase of 0.01 in the iron/steel ratio produces amonthly reduction of approximately 430 000 yuan in the production cost(1.5 yuan/t).

4 Conclusion

This paper establishes a model of the production cost.The concept of a steel scrap threshold price is proposed.When the steel scrap unit price in themarket exceeds the steel scrap threshold price,an increase in the iron/steel ratio causes a reduced production cost,and vice versa.

Based on actual data for the case of fixed steel production(284 358 t/month),an increase of 0.01 in the iron/steel ratio produces amonthly reduction of approximately 750 000 yuan in production cost(2.63 yuan/t)when the steel scrap unit price exceeds the steel scrap threshold price by 263.2 yuan/t(The current steel scrap threshold price is 2 874 yuan/t).In the case of a fixed amount of molten iron(270 425 t/month),an increase of 0.01 in the iron/steel ratio produces a monthly reduction of approximately 430 000 yuan in production cost(1.5 yuan/t)when the steel scrap unit price exceeds the threshold price by 140.7 yuan/t(The current steel scrap threshold price is 2 996 yuan/t).

[1]Yin R Y.Comment on behavior of energy flow and construction of energy network for steel manufacturing process[J].Iron&Steel,2010,45(4):1- 5.(in Chinese)

[2]Li H F,Cang D Q,Wen Y M.Analysis of present and future prospects for Chinese iron and steel industry energy conservation[J].Energy for Metallurgical Industry,2011,30(4):3- 7.(in Chinese)

[3]Matsuda K,Tanaka S,Endou M,et al.Energy saving study on a large steel plant by total site based pinch technology[J].Applied Thermal Engineering,2012,43(5):14- 19.

[4]Lu SM,Lu C,Tseng K T,et al.Energy-saving potential of the industrial sector of Taiwan[J].Renewable and Sustainable Energy Reviews,2013,21(5):674- 683.

[5]Yin Z J,Zhu R,Liu G,etal.Research on energy saving of Chinese steel industry based on energy structure scale[J].M ining and Metallurgy,2009,18(1):49- 52.(in Chinese)

[6]Lu ZW,Cai JJ.The foundations of systems energy conservation[M].Shengyang:Northeastern University Press,2010:32- 42.(in Chinese)

[7]Huang B F,Tian N Y,Xu A J,et al.Paths to reduction of iron to steel of 100 t converter[J].Steelmaking,2008,24(6):44- 46.(in Chinese)

[8]Lu ZW.A study on the steel scrap resources for steel industry[J].Acta Metallurgica Sinica,2000,36(7):728 -734.(in Chinese)

[9]Lu ZW.On steel scrap resources for steel industry[J].Iron&Steel,2002,37(4):66- 70.(in Chinese)

[10]Oda J,Akimoto K,Tomoda T.Long-term global availability of steel scrap[J].Resources Conservation and Recycling,2013,81(6):81- 91.

[11]Wübbeke J,Heroth T.Challenges and political solutions for steel recycling in China[J].Resources Conservation and Recycling,2014,87(6):1- 7.

[12]Chen G,Gu M Y.Predicting process energy consumption by using neural networks[J].Journal of Xi'an Jiaotong University,2001,35(12):1319- 1320.(in Chinese)

基于物流能流变化的铁钢比对生产成本的影响

陆 彪1陈 光2陈德敏2虞维平1丁 毅3

(1东南大学能源与环境学院,南京210096)

(2安徽工业大学建筑工程学院,马鞍山243032)

(3马鞍山钢铁股份有限公司,马鞍山243000)

建立了钢铁企业生产成本模型,分别讨论了钢产量不变和铁水量不变的2种情况下,生产成本随铁钢比的变化规律,并提出废钢临界价格概念.分析表明,当废钢单价高于废钢临界价格时,增加铁钢比可以降低生产成本,否则相反.废钢单价与废钢临界价格相差较大时,铁钢比对生产成本的影响更显著.实例计算表明,当钢产量不变(284 358 t/月),废钢单价高于废钢临界价格263.2元/t时,铁钢比增加0.01,每月可降低生产成本75万元左右(2.63元/t);当铁水量不变(270 425t/月),废钢单价高于临界价格140.7元/t时,铁钢比增加0.01,每月可降低生产成本43万元左右(1.5元/t).结果表明,钢铁企业应根据废钢单价的波动情况及时调整生产策略,以降低生产成本.

铁钢比;物流;能流;生产成本模型;废钢临界价格

TK-9

10.3969/j.issn.1003-7985.2015.03.013

2015-02-25.

Biographies:Lu Biao(1979—),male,graduate;Yu Weiping(corresponding author),male,doctor,professor,wpyu@seu.edu.cn.

The National Key Technology R&D Program during the 12th Five-Year Plan Period(No.2012BAF10B05).

:Lu Biao,Chen Guang,Chen Demin,etal.Impactofmaterial and energy flow variation-based iron/steel ratio on production cost[J].Journal of Southeast University(English Edition),2015,31(3):375-379.

10.3969/j.issn.1003-7985.2015.03.013

Journal of Southeast University(English Edition)2015年3期

Journal of Southeast University(English Edition)2015年3期

- Journal of Southeast University(English Edition)的其它文章

- Representations of the Drazin inverse involving idem potents in a ring

- Com p lexity and applicability analysis among OVM,GFM and FVDM models

- Relationship between number of passing events and operating parameters in m ixed bicycle traffic

- Influence analysis of chevron alignment signs on drivers’speed choices at horizontal curves on highways

- Extraction of cable forces due to dead load in cable-stayed bridges under random vehicle loads

- Finite elementmodeling of pavement responses based on stress-dependent properties of asphalt layer