GMP Regulations in China: Problems and Countermeasures

ZHU Shui-qing, SUN Li-hua(School of Business Administration, Shenyang Pharmaceutical University, Shenyang 110016, China)

GMP Regulations in China: Problems and Countermeasures

ZHU Shui-qing, SUN Li-hua

(School of Business Administration, Shenyang Pharmaceutical University, Shenyang 110016, China)

Objective To discuss the problems and their causes in GMP regulations and to provide references for improving GMP regulations in China. Methods The relevant literatures in the China National Knowledge Infrastructure (CNKI) were systematically studied to explore the problems of GMP implementation and the causes. And corresponding countermeasures and suggestions were raised to provide references for making relevant decisions. Results and Conclusion GMP for drug quality assurance depends not only on the rationality of GMP standards, but also on the implementation of GMP standards. Rational GMP standards and their implementation are the key part for pharmaceutical production quality assurance.

GMP; GMP regulation; standard promotion; standard implementation

Drug is a special commodity and drug quality is crucial. GMP is a globally recognized effective measure to guarantee the quality of pharmaceutical production. While the GMP’s protective effect on drug quality depends on two aspects: one is to establish scientific and reasonable GMP standards; the other is the effective implementation of GMP standards. Therefore, GMP regulation should be based on GMP standard for pharmaceutical production quality assurance and its implementation or realization.

1 The present situation of GMP implementation in China

China Food and Drug Administration (CFDA) was established in 1998 and it started GMP mandatory certification after that. The objective of all the drugs must be in line with pharmaceutical GMP was achieved on July 1st, 2004[1]. It is usually referred to as “post-GMP era”in the pharmaceutical industry after July 1st, 2004. Good Manufacturing Practice (revised 2010) (the newly revised GMP) formally was implemented on March 1st, 2011, the revised GMP absorbed international advanced experience and it is in line with international standards[2]. Therefore, there are no significant differences between China’s GMP standards and international standards. However, since a number of safety incidents of pharmaceutical production occurred in post-GMP era, China’s drug production quality has not been guaranteed after the implementation of GMP and we still have a long way to go.

Therefore, we searched the results of drug GMP flight check, GMP tracking check from websites of CFDA, various provinces, autonomous regions and municipalities, then we eliminated the repeated results of the publication. By the end of January 20th, 2015, CFDA and the Provincial Food and Drug Administration had inspected pharmaceutical enterprises for more than 12917 times and taken back 305 drug GMP certificates. What is more, 565 companies were ordered to carry out rectification. After the drug incident occurred in Qiqihar second pharmaceutical enterprise in 2006, the drug administration organization implemented the special operation to rectify and standardize the order of pharmaceutical market in the nationwide for one and a half years, which was deployed by the State Council. This special operation was one of the biggest supervision and inspection for implementation of pharmaceutical GMP in pharmaceutical production enterprises conducted by Food and Drug Administration Departments. More than 12000 pharmaceutical producing enterprises were checked and 144 drug GMP certificates were taken back, and 203 companies were ordered to halt production. As to the supervision and inspection result from drug administration department, China’s GMP implementation is not satisfactory and the supervision of GMP should be improved.

2 Analysis of the problems of China’s GMP regulation

We used CNKI as a literature searching platform, drug safety incident and phytotoxicity event as the keywords, the relevant publications from July 1st, 2004 to January 1st, 2015 were retrieved, and we got 2245 papers. 55 serious incidents of drug safety were screened out after deleting the publications that can’t be downloaded, incident of drug safety mentioned repeatedly, incidents of pharmaceutical production occurred before post-GMP era, cases of adverse events and incidents of imported drugs. 23 accidents of pharmaceutical production were found out by further excluding adverse drug reactions events, incidents caused by irregularities in drug distribution and use. Further collecting and analyzing the reasons and events, we found 12 cases were due to illegal production by the enterprises without production license, and the other 11 cases were caused by GMP certified companies that did not follow the GMP standard (See Table 1).

Table 1 Accidents of pharmaceutical production in post-GMP era

From Table 1, after post-GMP era, we can see the incidents occurred in the enterprises with drug GMP certificate because they did not follow GMP standards strictly such as Qiqihar Second pharmaceutical incident and Xinfu incident. In those events, the large number of bad quality products shows China Food and Drug Departments did not work properly for drug GMP certification supervision to some degree.

3 Cause analysis

The reasons are various for the unsatisfactory implementation of GMP standard, but the main reasons from the GMP supervision are the following aspects:

3.1 GMP certification is lax and substandard enterprises can become qualified“Administrative measures on the GMP certification”was promulgated by China Food and Drug Administration in 2005 which provided that Food and Drug Administration Department at provincial level was responsible for GMP certification for pharmaceutical production enterprises except for the injection, radiopharmaceuticals and biological products. The Food and Drug Administration Department at provincial level inevitably represents local interests which lead to the lax certification process and some unqualified enterprises are able to survive through bribery. For example, Qiqihar second pharmaceutical factory spent 100,000 yuan on the drug certification, in fact, it did not conform to the standard of GMP (inspection personnel could not analyze drug inspection patterns). At the same time, in the GMP certification process in 1998, many provinces had the policy of strictness first and laxation later, some unqualified enterprises became qualified before GMP deadline (2004) due to the lax policy[3].

3.2 Supervision can not be in place after GMP certification

GMP certification is only a means to make sure that enterprises can produce in accordance with the requirements of GMP rather than purpose and it can be fulfilled with an effective supervision. The occurrence of Xinfu event and other incidents of pharmaceutical production show that the supervision of GMP certification didn’t work properly. At present, supervision and inspection on GMP mainly focus on the process of GMP certification, and track inspection and flight inspection after certification is not strict which is unable to regulate the implementation of GMP standard effectively. In 2006, 24 enterprises had the flight inspection and 82 enterprises had track inspection, and the coverage rate of spot checks was only 2.1%[4].

3.3 Punishment for violations of GMP is not strong enough which can’t effectively restrain the enterprises

“Law of Drug Administration” provides drug manufacturing enterprise should be given a warning and a deadline for correction if it is not in accordance with the provisions of GMP. If it does not correct its mistake, it shall be ordered to stop production or imposed a fine of five thousand yuan to twenty thousand yuan. If the offence is serious, medicine production license shall be revoked. But“Law of Drug Administration” doesn’t clearly define what is the serious offence to the violation of GMP standard, resulting in poor operation of the law[5]. What is more, the punishment for GMP violation is not strong enough and the cost for GMP violation is low which can not curb their GMP violation.

3.4 The enhancement of GMP standards affects GMP implementation

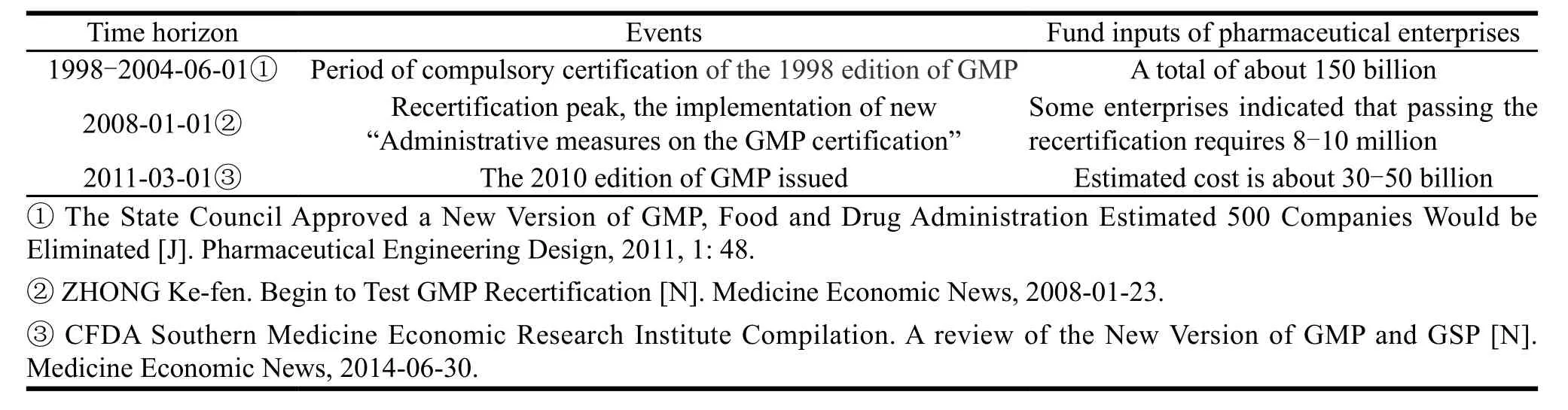

The enhancement of GMP standards inevitably leads to rising cost for pharmaceutical enterprises, and the higher GMP standard is, the larger input for implementation of GMP. Therefore, enterprises suffer more pressure from the rising cost. Looking back on the process of enhancement of China’s GMP standard (see Table 2), we can find the enhancement of GMP standards often occur when a large amount of capital investment is put into the enterprises to resume production after a massive transformation. In the face of large amount of GMP transformation inputs and high inputs for GMP daily operation, pharmaceutical enterprises suffer pressure of funds. And the pharmaceutical asset specificity results in higher barriers for pharmaceutical enterprises to exit, which makes some enterprises with GMP certificates can’t maintain GMP daily operations. In order to save cost, these pharmaceutical enterprises tend to simplify GMP requirements; therefore, the violation of GMP events occurs often. We must point out that the enhancement of GMP standards is necessary. Even though GMP standards can ensure the quality of pharmaceutical production, pharmaceutical companies have difficulties in implementing higher GMP standards and they cannot achieve the expected goal of GMP, which is hard to be in line with international GMP standards.

Table 2 GMP standard promotion and its effect on pharmaceutical enterprises in recent years

3.5 Relevant incentive policies are not in place, resulting in drug safety risks

From Table 2, we can see the implementation of GMP transformation is a high investment project. But China’s drug policy especially bidding policy can not reflect the principle of “high price for high quality”. Once getting the new GMP certification, enterprises are not able to have preferable price in China, but they may suffer the rising cost due to the new GMP standard and operating system. The advantage of product quality resulted from the implementation of GMP is likely to become cost disadvantages in the production and operation for pharmaceutical enterprises. In addition, it may cause more strict GMP, the higher the cost which makes enterprises uncompetitive and the phenomenon of unbalanced input and output[6]. The high cost of GMP implementation cannot get high returns without the related incentive measures like prices and sales. Pharmaceutical enterprises face with huge economic pressure and some pharmaceutical enterprises reduce business operating costs by cutting GMP execution so that they can survive which will result in the hidden dangers in drug safety and medical risks.

4 Countermeasures and suggestions

At present, GMP standards in China can not be effectively implemented. GMP standard has no problem, we should adjust GMP regulation by establishing a supervision system to ensure the effective implementation of GMP standard so that we can ensure the quality of pharmaceutical production. Therefore, the author put forward the following suggestions:

4.1 Improving the system of GMP certification

The imperfect certification management system will directly lead to lower certification standards, which makes GMP certification effect less. And if the certification process is lax, unqualified enterprises will continue production that can increase the risk of public medication. In order to avoid the potential unfairness in GMP certification and inspection work, China’s GMP certification inspection system should be improved and GMP certification and inspection work must be unified and managed by CFDA. GMP certification and inspection work either is entrusted to the corresponding qualified examination institution by CFDA, or directly is in charge by CFDA. The process of certification inspection should be supervised and a system of accountability should be built to avoid irresponsible behavior.

4.2 Enhancing GMP inspection and consolidating GMP certification

The key to ensuring the implementation of GMP is to organize production according to GMP standards continuously. GMP standard and GMP certification are the priorities for the whole GMP regulation. If the supervision and inspection are not in place after the certification, it is not conducive to the implementation of GMP. Therefore, the administrative department of drug supervision should adjust its philosophy of GMP regulation, and supervision and inspection should be strengthened so that we can change the phenomenon of “certification first and regulation last”in the process of GMP implementation. The daily tracking inspection and flight inspection should be strengthened to further consolidate GMP certification.

4.3 Increasing the penalties for GMP violations with punitive actions

Increasing the cost of GMP violations by strengthening the punishment can warn those illegal production enterprises, it also can give a warning in advanceto those enterprises so that they can, behave themselves. Law of drug administration should be specified to lay a good foundation for violations punishment, and the cost for GMP violations should be increased. A detailed description of boundaries and punishment for different GMP violations should be made. The behavior of enterprises can be standardized through strong punishment measures to ensure the implementation of GMP.

4.4 Improving GMP standard and adopting national and enterprises’ standards classification mode

GMP is the minimum standard for the quality of pharmaceutical production. That is to say, GMP is the basic standard for quality management, not the highest one[7]. GMP standard should be the basic standard for all pharmaceutical companies to ensure the quality and safety of pharmaceutical production. So regulators should be cautious to improve GMP standard based on the capacity of enterprises and pharmaceutical market. Mandatorily and overall implementing GMP standards must be avoided. In China, pharmaceutical GMP standards should be based on the actual drug production and drug GMP standard can be improved by using classification and grading mode. Beneficial incentives can be used to promote the implementation of the drugs GMP for pharmaceutical production enterprises. We should carry out the national and enterprise standards classification mode in the process of implementing drug GMP, which can encourage large and medium-sized pharmaceutical companies to establish higher internal standards than national standards by taking advantage of their rich resources, thus we can promote the process of GMP in China. Small enterprises should design and transform GMP reasonably based on ensuring the quality and safety of pharmaceutical production to reduce the cost of GMP implementation to the minimum extent. That is to say, with the minimum capital investment they can achieve the best level of GMP and grow bigger and stronger in the future. By improving the standard of GMP, we can promote the upgrade of industry standard to achieve the best effect of GMP implementation.

4.5 Making relevant incentive policies to promote the implementation of GMP

As the profit organization, pharmaceutical enterprises will have great motivation to implement GMP only when they can gain more profits after the implementation of GMP. The implementation of GMP is a good thing and we can’t only use administrative means to carry out it. We must take the difficulties of pharmaceutical enterprises into consideration when we implement it. In the actual process, different pharmaceutical enterprise with GMP standard can be provided with corresponding loans and tax incentives to compensate their high cost resulting from the implementation of GMP standards. Meanwhile, it is also available to have product quality assessment for those enterprises with different GMP standards so that different incentives can be given to them such as a hierarchical preferential price in the process of bidding. The goal of high price for high quality can be truly achieved to promote the implementation of GMP in China.

5 Conclusions

The new version of GMP has been officially promulgated and implemented; we should adjust the philosophy of GMP regulation based on the past experience of GMP implementation to establish a feasible way for GMP regulation, ensuring the subsequent GMP work smoothly and guaranteeing the public safety of drug use.

[1] YANG Yue. Pharmaceutical Administration [M]. Committee of Construction of Teaching Material at Shenyang Pharmaceutical University, 2008: 163.

[2] WANG Yao-cui. GMP Standard Greatly Improved, Enterprises are Facing with High Input [N]. China High-tech Industry Herald, 2011-02-21.

[3] WANG Zhuo-ming. Investigations of Large Scale Stop Production of Hepatitis B Vaccine: “No Following Supply Problems” [N]. Twenty-first Century Economic Report, 2014-01-03.

[4] ZHEN Wu. Speech on 2007 National Drug Safety Regulation Work Conference [R]. 2007-02-01.

[5] WANG Peng. Study on Chinese GMP Certification System in the Field of Administrative Law [D]. Shandong University, 2008.

[6] XIA Zhen-hua, XUE Su-dong. Analysis of New Edition“Good Manufacturing Practice” (GMP Expert Revision) [J]. Pharmaceutical and Clinical Research, 2010, 18 (3): 216-217.

[7] LIANG Yi. Research on the Characteristic of GMP Drugs [J]. Modern Management Science, 2011, (9): 71-72.

Author’s information: SUN Li-hua, Professor. Major research area: Pharmacoeconomics. Tel: 024-23986553, E-mail: slh-3632@163.com

- 亚洲社会药学杂志的其它文章

- Risk Reviews of Preclinical Pharmaceutical Studies on Traditional Chinese Medicine Injection

- Risks and Risk Control Measures of in vivo Genotoxicity Test in New Drug R&D

- Regional Studies of Bio-pharmaceutical Industry in China

- Analysis and Evaluation of Measures for the Administration of Medical Device Registration

- Australian PBS and Its Enlightenment to Drug Price Reform in China

- Hot Issues about Drug Price in China from the View of Internet Public Opinion Monitoring