Effects of salinity on the nail-holding power of dimension lumber used in light-frame wood building

Zeli Que•Ling Yang•Feibin Wang•Xuna Zhu•Yongbing Wang•Takuro Mori

Effects of salinity on the nail-holding power of dimension lumber used in light-frame wood building

Zeli Que1•Ling Yang1•Feibin Wang2•Xuna Zhu1•Yongbing Wang3•Takuro Mori4

We studied the effect of salinity on nail-holding power in wood construction.In saline solution,the holding powerofnails was less than in purified water.With the increase ofsaltconcentration,the surface and side nailholding power of the wood specimens both declined,but the differences between salinity treatments were not significant.However,compared to the surface and side nailholding power,the power on the edge was generally less and the difference was not obvious in different salt concentrations.In the same salt concentration,with the extension of the processing cycle,the performance of holding power of nails showed a downward trend,expect the temporary rise in the middle.

Nail-holding power·Salinity·Mechanical properties·Dimension lumber·Joints

Introduction

Because of many advantages of wood construction,China has witnessed a boom in the construction of wooden architecture(Zhou 2012)allover the country.Lightframe wood building is a traditionaltype ofconstruction in North America,where more than 90%of houses have been built by this type.The common use type is called platform frame construction,which was introduced to China from North American in the end of the twentieth century.Today, thousands of such buildings have been built in some rich southern coastal regions in China.Southern coastal areas have the climate characterized with high temperatures, high humidity and high salinity.High salinity environment has a certain impact on the life of wooden structures.In wood frame construction(Lawrence 1999),each component transmits force through the connections(Fei and Wang 2010).There are many forms of connections including nail connection,tooth connection,bolt,pin connection and mortise and tenon joint connection.The nail connections are tough and flexible,easy to fabricate and closely connected.Therefore,it has become a wide connection in wood structure building.Nail connection node load can be divided into two directions,namely lateral shearing force perpendicular to the screw rod and pullout force parallel to the nail rod.Therefore,the lateral bearing force and nail holding power(Skulteti et al.2001; Douglas et al.2001;Zhang et al.2002)are two basic strength indexes to value the connection properties.

Many scholars studied the nail holding power from the wood,the types of nails,wood density and wood moisture content.Fei(2008)found that wood density had the greatest influence on the nail holding power,and screw diameter and screw holding capability had a linear relation. Dolan and John(1995)studied the influences of differentphysical properties by different moisture content of wood on nail holding power.He tested nail holding power with the moisture content of 19 and 12%,respectively,and the latter was obviously higher than the former in nail holding power.Butthis was notwellreflected in the currentdesign specifications.So he suggested the environmentadjustment coefficient should be added to the calculation formula of humidity to ensure the stability of the structure.Stern (1950)found that in damp environment,the round nails hammered into steelstuds even with the coverpanelwould also rustby 9.5 mm above the surface of the wood because of moisture infiltration.Nailrusting willcause wood decay around the nail rod and make the nail holding power decrease significantly in the long term.

Yet the salt solution(Selim et al.2009)can segregate and discolor wood and even speed up the rusting and deforming ofmetalconnections,which harms the safety of timber structure buildings.In China,although a number of light frame wood buildings have been built in the high salinity coastal regions of China,there is evidently inadequate research on the effects of salinity on the nail-holding power of dimension lumber.Therefore,we tested the nailholding power under simulated salinity to obtain a deeper understanding of the behavior of the structure.

Materials and methods

Nails

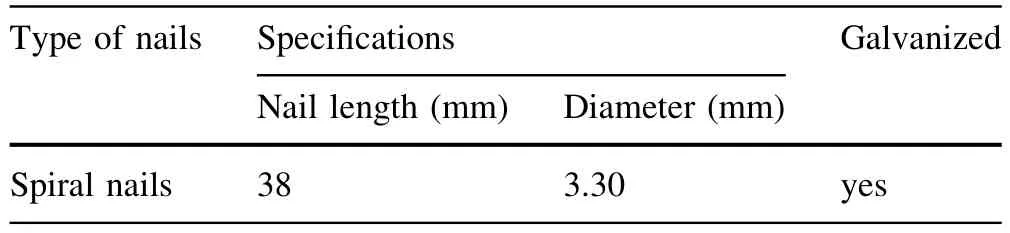

The nails used in wood structure construction can be divided into round nails,screw(including wood screw and square head screws),twist nails,and U-nails in terms ofshape.According to Chinese Standard(GB/T 14018-2009) and the actual production,we selected the spiral nails that were widely used in wood structure constructions.Specific parameters were showed in Table 1.

Table 1 Specification of nails in the test

Dimension lumber

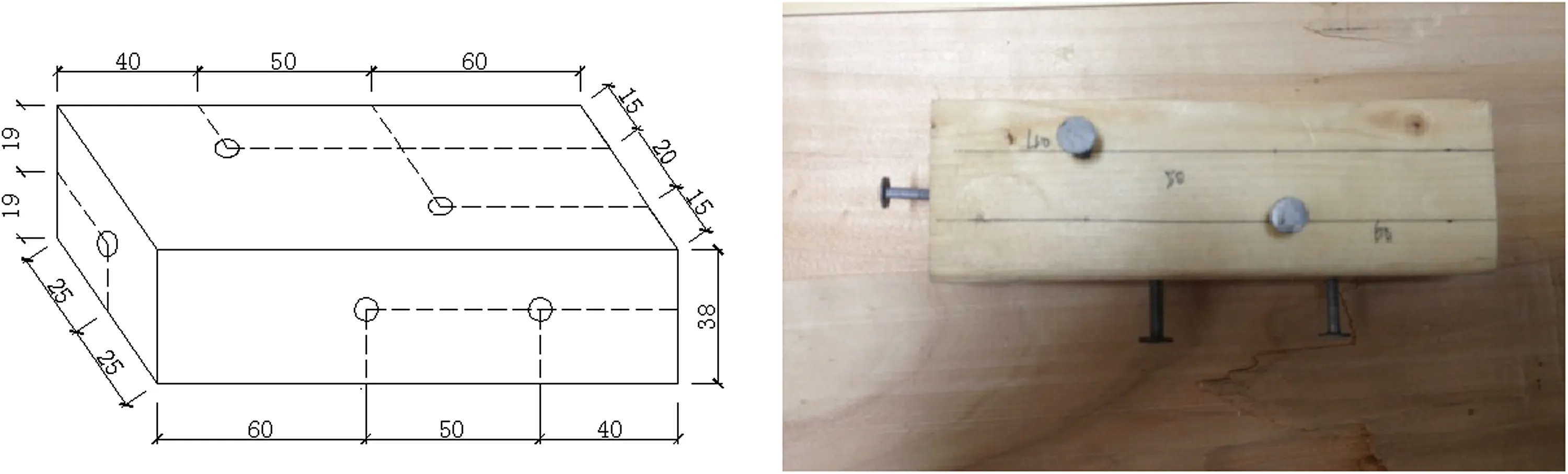

We used Spruce-Pine-Fir(SPF),the type of which was spruce.According to Chinese Standards(GB/T 14018-2009,GB 50005-2003)and the actual situation of production and processing,the size of specimen should be 150 mm in length and 89×38 mm in sectional dimension.The measured average air-dry density(GB/T 1993–2009)was 460 kg m-3.Moisture content(GB/T 1931–2009)was 15.4%.Before the test,the experimentershould clean the nails and mark atthe place of 15 mm away from the nailcaps.As shown in Fig.1,drive the nail vertically into the specimen atconstantspeed untilto the above mark on surface section,side section and edge section.The deviations were allowed within±1 mm.

Salt treatments

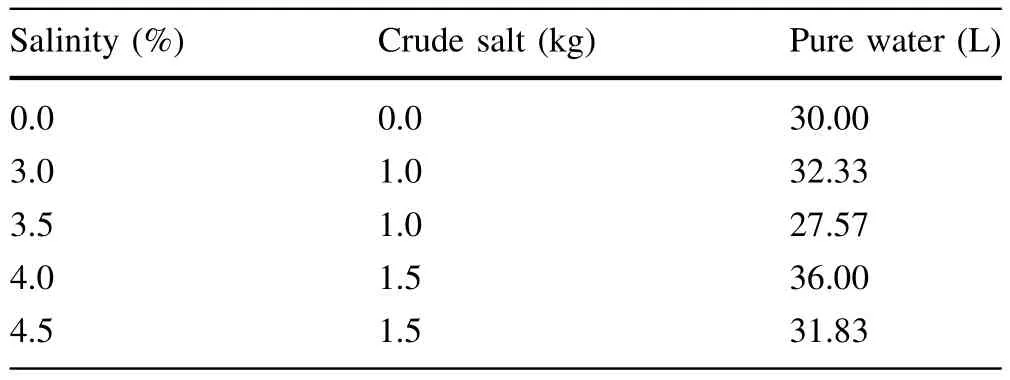

There were 5 concentration gradients including 0,3,3.5,4, and 4.5%,respectively.The ratios of compounding ingredients were showed in Table 2.

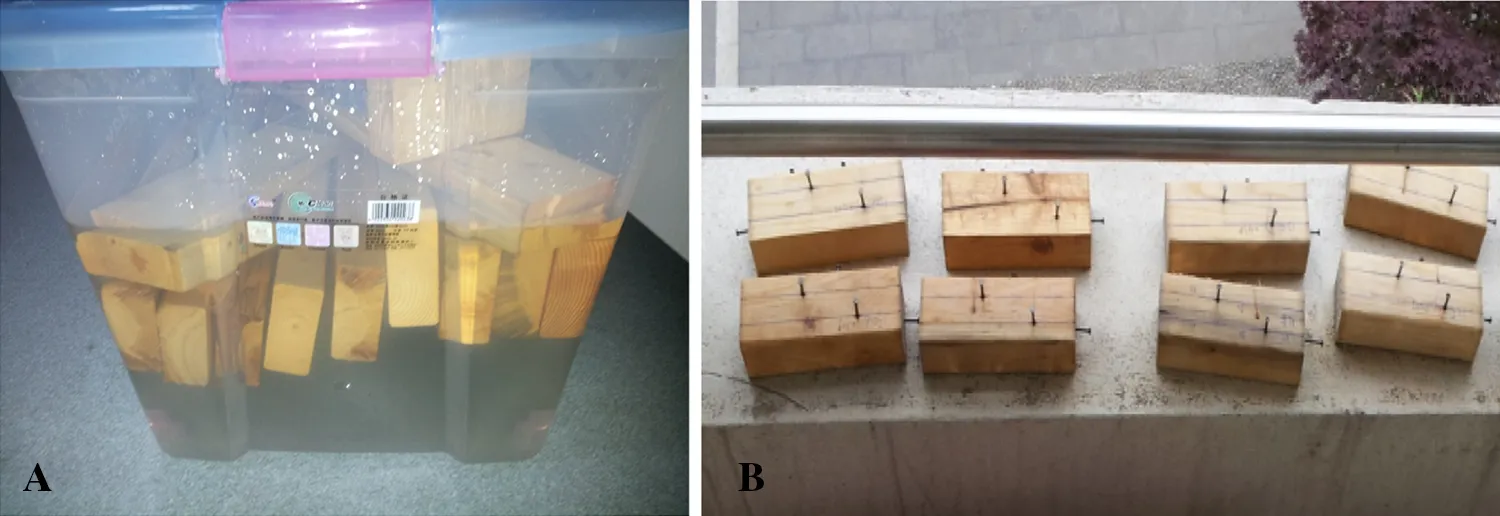

Different concentrations of salt solution were made according to the mass ratio in Table 2.We tested pieces of the same quantity and put the same type into simulated fluid.Atthe top,the specimen pieces of wood were placed against the cover to ensure that specimens were fully immersed and clear of the sink wall.During the experiment,in orderto preventthe rapid emission of salt,a piece of plastic wrap was covered on the cover.Meanwhile,the salt solution should be replaced once every other month and reconfigured to ensure the accuracy of salt concentration.In orderto study the salinity effecton the performance of lumbers,nail-holding power reasonably,3 days was set as one experimental period for soaking and two days for drying.In Figs.2,6 specimens were texted at each circle and concentration.

Fig.1 Schematic diagrams for holding power testof nails

Table 2 The proportion of high-salt simulated solution

Equipment

We used Suns Universal Mechanical Testing machine with the maximum load of 100 KN.According to GB/T14018-2009,we positioned the testpiece in the nail-holding force fixture by gripping the nail head with the speed of 2 mm min-1and then pulled the nail out within 1–2 min. Recorded the maximum load accurate to 10 N(Fig.3),and finally calculated the nail holding power according to the Eq.1(with the accuracy of 0.1 N mm-1).

where,P is the nail holding power(N mm-1),Pmaxis maximal load(N),and L is the depth that nails into the specimen(mm).

Results

From the text process,the slot of spiral nails was stuffed with small wood particles.Screw threads and wood were fully occlusive.In Fig.4,in the loading process,the nail holding power linearly increased rapidly with the increasing of the displacement.The nail holding power subjected to the frictional resistance and the occlusion between the screw threads and wood reached the peak load until the nails were pulled out when the occlusive wood fractured and slipped.Then,the nail holding power was mainly affected by friction.The treated and untreated curves had a similartrend,butthe nailholding poweroftreated samples increased slower atthe beginning stage and reduced faster at the later stage than that of untreated samples.

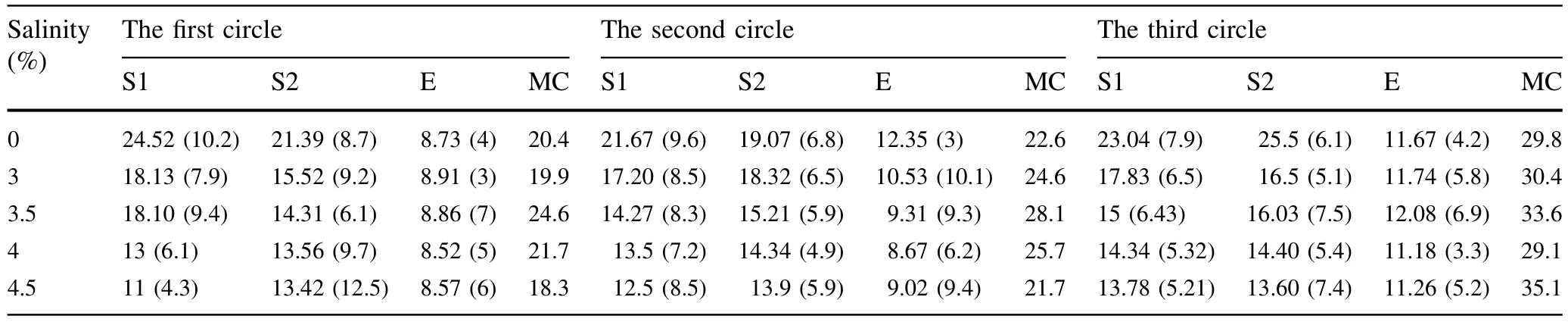

By testing untreated specimens,the average of surface holding power was 44.60 N mm-1,the average of side holding power was 45.07 N mm-1,and the average of edge holding power was 15.47 N mm-1.In different concentrations and circles,the nail-holding power of three sections was showed in Table 3.

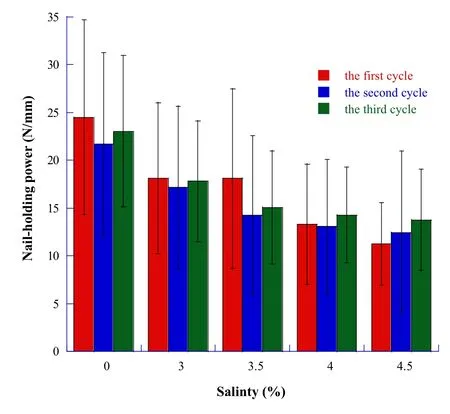

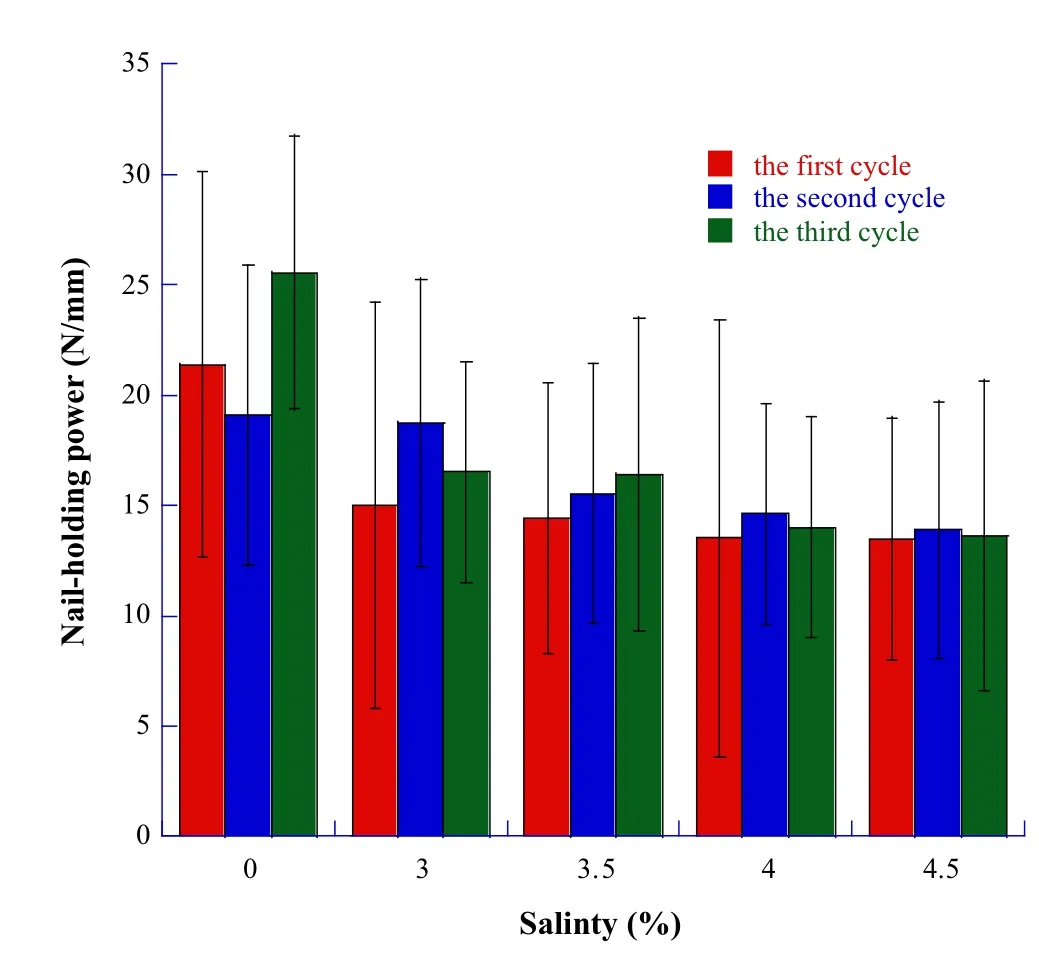

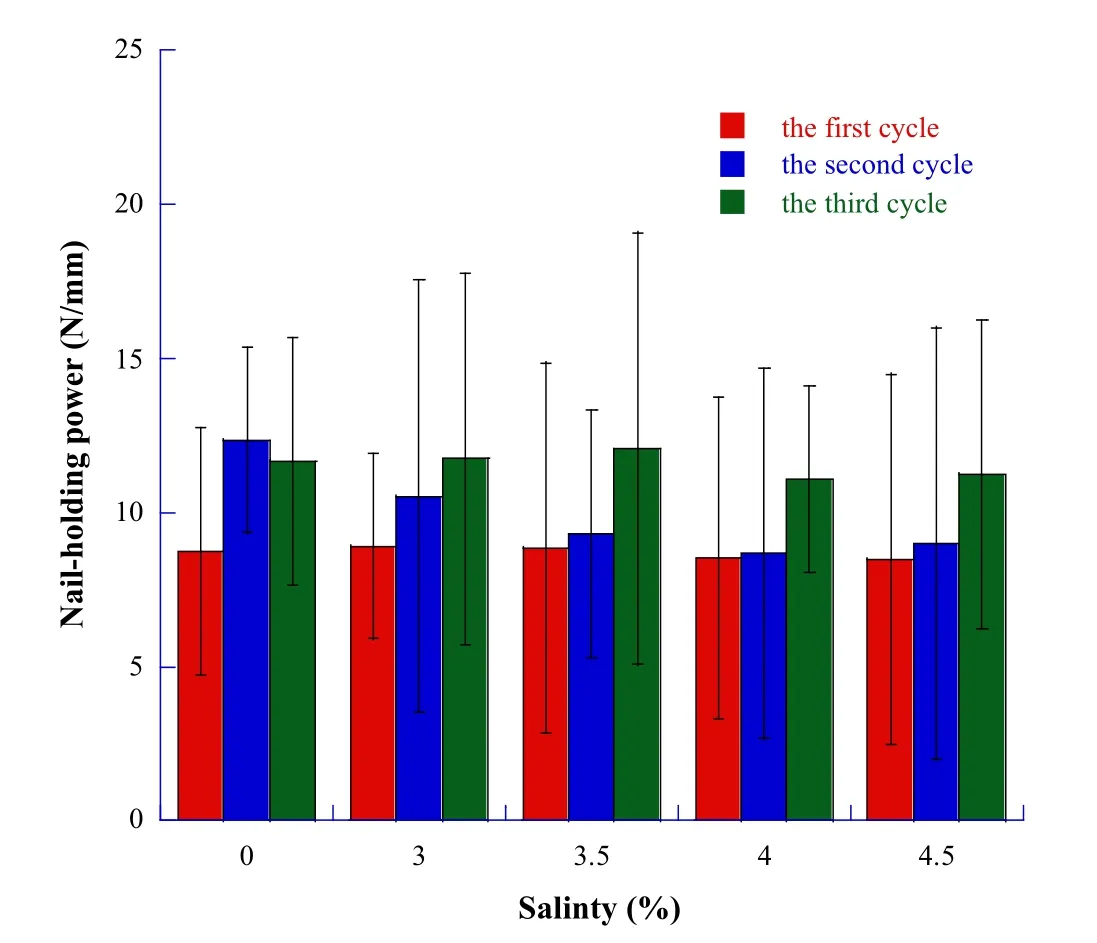

In Table 3,in different concentrations and circles,the nail-holding power change trends of 3 directions of the samples were in Figs.5,6,7.

In Figs.5,6,7,the nail-holding power was slightly elevated with the increase ofthe solution concentration,but was slowly increased from the firstcircle to the third cycle.

Fig.2 Salt treatment(a is soaking and b is drying)

Fig.3 Nail holding power test

Fig.4 The example of curves on withdraw tensile load and displacementfor partial nails

Discussion

The same salinity in different periods

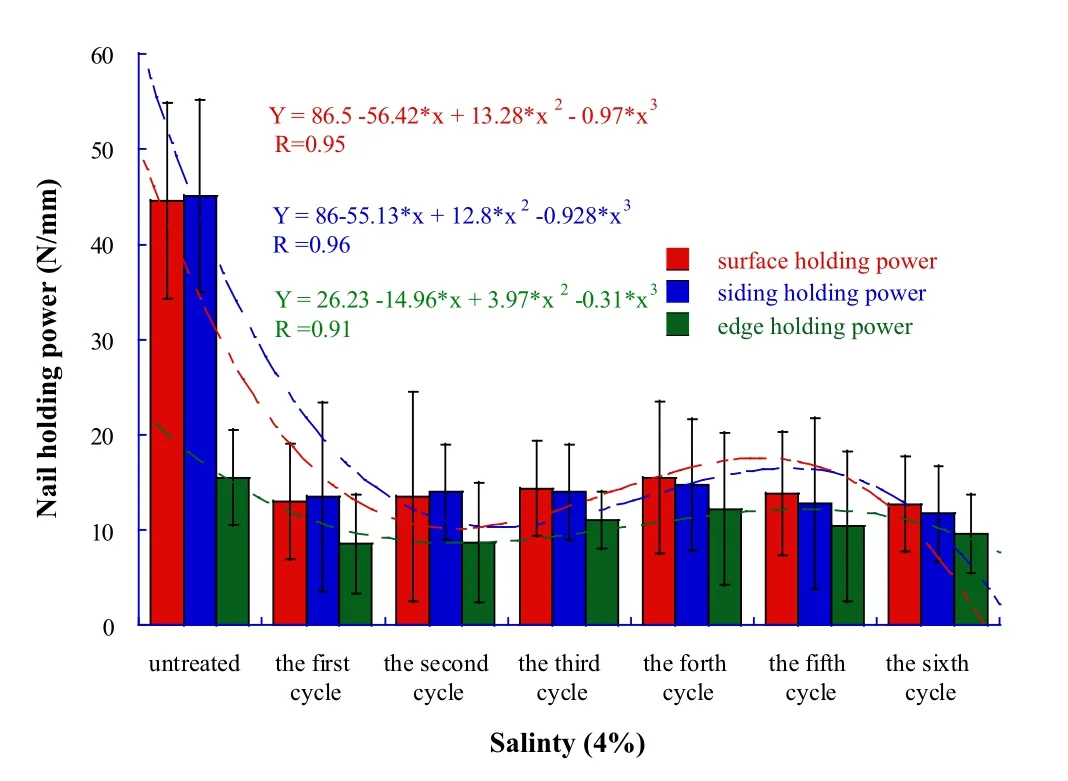

Durability is an important factor to evaluate the reliability of a structure.To great extent,the nail-holding power of wooden structure is connected with the processing time in salt environment.Under different treatment time,nailholding power of wooden structure changed accordingly. From the Table 3,the nail-holding power of specimens in these 5 different concentrations reflected the similar changing trend with the increase of periods,of which the most typical one was in 4%concentration.At the same time,the period of 4%concentration was extended to the sixth circle(Fig.8).

From the chart above,they could find that in the same salt environment,the edge nail holding force was smaller than the surface and side nail holding power.This was because the tangential shrinkage of the wood was much larger than the radial and longitudinal shrinkage,which made the edge of the wood aptto crack during the process of natural drying.As a result,the friction force became smaller between wood and nails,thus leading to the smaller edge nail-holding power.The nail-holding performance of dimension lumber would decrease obviously in general as the fourth cycle increased slightly while the sixth cycle decreased greatly with the extension of the treatment period.However,the edge nail-holding powerdecreased more slowly than the surface and side nail-holding power.This was because wood was firstsoaked in brine and afterwards exposed to the fiery sun,leading to its shrinkage,which made the distance become larger between the wood fiber and nails.So,that caused the obvious decrease of nailholding powerin firstcycle.On the otherhand,the nails in the sodium chloride solution formed a galvanic reaction. The cathode was Zn-2e-+2OH-=Zn(OH)2and the anode was O2+2H2O+4e-=4OH-.As the reaction progressed,the oxidization and gradualdissolution of zinc made the friction force become large.So the nail-holding power increased slightly in the fourth cycle.But with the further reaction,Zn was dissolved completely and the nail holding power would face a constant decline.The experiment also showed that backward from the fifth cycle,the nail has begun to rust,which also resulted from the dissolution of Zn.In Fig.8,there is rather good agreement between the salinity and the nail-holding power with a correlation coefficient of>0.9.

The same circle in different salinities

Under different salt concentrations,the nail-holding power would change.The size is determined by the concentration ofthe saltsolution and the degree ofhydrolysis(Zhang and Xie 2011).The third period was shown in Fig.9.

In Fig.9,the holding power in saline solution was smaller than that in clean water.With the salinity increasing gradually,nail-holding power showed a downward yet slow trend since the performance of wood in solution had correlations with its concentration and the hydrolysis degree.When the wood was soaked and thendried in the sun,especially in high temperature,NaCl would react with water vapor in the air to form hydrogen chloride.HCl reacted with ZnO to form ZnCl2.When Zn dissolved gradually,the friction force between the nailsand the wood fiber would reduce accompanied by corresponding reduce of nail-holding power.The more salt the solution had,the faster reaction became,and thus nailholding power would decrease with the increase of salinity. Butas the water vapor in the experimentwas nottoo much, the reaction was not complete,thatis,why the decline was slow and not obvious.At the same time,the regression curve and formula of each side nail-holding power can be obtained from Fig.9 on the same circle in different salinities.

Table 3 Nail-holding power(N/mm)after treated in different circles and concentrations

Fig.5 The surface holding power under differentconcentrations and test periods

Fig.6 The side holding power under different concentrations and test periods

Fig.7 The edge holding power under different concentrations and test periods

Fig.8 Nails holding power of 4%salinity under different test periods

The surface holding power model is:

The side holding power is:

The edge holding power is:

where,x is the solution concentration(%),and y is the holding power(N mm-1).

Fig.9 Nailholding powerofthe third period underdifferentsalinity conditions

Conclusion

Edge nailholding powerwas smaller than surface and side nail holding power.But the stability of edge nail holding powerwas better.Salinity could reduce nailholding power. The more saline was,the smaller nailholding power was. With the same salinity,the longerthe treatmentperiod was, the smaller the nail-holding power would become expect the temporary rise in the middle.Salt solution could make nails rust and discolor the wood.

We tried to avoid building wood structure construction in high salinity areas,and focused only on one mechanical property of nail holding power.Other connection performance of wood construction will be researched in the following days.Atthe same time,processing cycles should be increased in the test to get more reliable and valuable data and phenomena.

AcknowledgmentsThis work was supported by the Priority Academic Program Development of Jiangsu Higher Education Institutions(PAPD)and Jiangsu Overseas Research&Training Program for University ProminentYoung&Middle-aged Teachers and Presidents.

Dolan JD,John WS(1995)Variability and effects of moisture comment on the withdrawal characteristics for lumber as opposed to clear wood.Paper CIB-W18/28-7-7.Process of Working Commission W18-Timber Structures,Denmark

Douglas RR,Steve GW,Donald AB(2001)Withdrawal strength of threaded nails.J Struct Eng 127(4):442–449

Fei BH(2008)Nail withdrawal strength of Chinese fir plantation. Wood Process Mach 05:31–34

Fei JB,Wang P(2010)Summary and analysis of wood structure. Shang Xi Archit 36(19):100–101

GB/T(14018-2009)Method of testing nail holding power of wood

GB/T(1931–2009)Method for determination of the moisture content of wood

GB/T(1993–2009)Method for determination of the density of wood

GB50005(2003)Code for design of timber structures

Lawrence AS(1999)Wood handbook.United states Department of Agriculture.Chapter 7,pp 1–27

Selim S,Cihat T,Kamile T(2009)Fixation,leachability,and decay resistance of wood treated with some commercial extracts and wood preservative salts.Int Biodeterior Biodegrad 2(63):135–141

Skulteti MJ,Bender DA,Winistorer SG,Pollock DG(2001) Withdrawal strength of ring-shank nails embedded in southern pine lumber.Trans ASAE 40(2):451–456

Stern EG(1950)Deterioration of green wood along steel-nailshank and its influence on the nail-holding properties.Va J Sci1(3):200–218

Zhang Y,Xie LS(2011)Detection and evaluation of wood structure building.China Forestry Publishing House,Beijing,pp 45–46

Zhang JL,Vikram Y,Franklin Q(2002)Resistance of southern yellow pine to direct withdrawal of staples.For Prod J 52(9):75–81

Zhou HB(2012)Currentand future status of wood structure in china. China Wood Ind 26(1):7–10

20 December 2013/Accepted:5 June 2014/Published online:18 July 2015

©Northeast Forestry University and Springer-Verlag Berlin Heidelberg 2015

Project funding:This work was financially supported by the Priorit Academic Program Development of Jiangsu Higher Education Institutions(PAPD)and Jiangsu Overseas Research&Training Program for University Prominent Young&Middle-aged Teachers and Presidents.

The online version is available athttp://www.springerlink.com

Corresponding editor:Yu Lei

✉Zeli Que zelique.nfu@gmail.com

1College of Materials Science and Engineering,Nanjing Forestry University,Nanjing 210037,China

2College of Landscape Architecture,Nanjing Forestry University,Nanjing 210037,China

3Suzhou Crownhomes Co.,LTD.,Suzhou 215105,China

4Research Institute for Sustainable Humanosphere(RISH), Kyoto University,Kyoto 6110011,Japan

Journal of Forestry Research2015年3期

Journal of Forestry Research2015年3期

- Journal of Forestry Research的其它文章

- Management of pests and diseases of tropical sericultural plants by using plant-derived products:a review

- Gamma generalized linear model to investigate the effects of climate variables on the area burned by forest fire in northeast China

- Diversity,abundance,and structure of tree communities in the Uluguru forests in the Morogoro region,Tanzania

- Brazilian savanna re-establishment in a monoculture forest: diversity and environmental relations of native regenerating understory in Pinus caribaea Morelet.stands

- Carbon storage and sequestration rate assessment and allometric model development in young teak plantations of tropical moist deciduous forest,India

- Use of infrared thermal imaging to diagnose health of Ammopiptanthus mongolicus in northwestern China