Response Characteristics of PBX-6 Explosive in Slow Cook-off Tests

CAO Luo-xia, CAO Wei, WEN Shang-gang, SHEN Chun-ying, CHEN Liang-jun, ZHOU Jian-hua, GAO Da-yuan

(1. Institute of Chemical Materials, CAEP, Mianyang 621999, China; 2. Robust Munitions Center, CAEP, Mianyang 621999, China)

1 Introduction

The cook-off tests have been carried out in some western countries early in the 1980s[1-2], and methods of fast and slow cook-off tests have been set up in Institute of Chemical Materials in the early 21st century[3-5]. Commonly, there are two forms of heating in ammunitions: the whole-body heating from the heat source and the ambient flame heating, which respectively resemble the slow cook-off test and the fast cook-off test. The slow cook-off test has been widely used to evaluate the thermal safety of propellants and explosives under various constraints and slow heating process. Dai Xiao-gan, et al[6]conducted researches of PBX-2 cylindrical explosives under different heating rates. Zhi Xiao-qi, et al[7]conducted researches on the fast cook-off behaviors of RDX explosives under different constaints. Chen Ke-quan, et al[8]conducted fast cook-off numerical computations of PBX based on ABAQUS. All these cook-off tests and numerical simulations were mainly focused on the study of high explosive cylinders, but no slow cook-off tests for aging spherical explosives have ever been reported.

In order to study the effects of aging of explosive components on the ammunition safety, our project group has conducted series of accelerated aging tests of PBX-6 under various temperatures and days, and has studied its physical properties, safety and detonation behaviors before and after aging tests[9-12]. However, the flame temperature is unable to be controlled and the fire is greatly affected by the wind in fast cook-off tests. Referring to the device for slow cook-off tests of cylindrical explosives, a new device for slow cook-off tests of spherical explosive components was designed, and a slow cook-off test method ofΦ100 mm explosive sphere under closed system was established in the year of 2014. Based on the production of the explosives, the accelerated aging test of 140 days was firstly conducted at 55 ℃ for the HMX-based plastic-bonded explosive (PBX-6) components. Subsequently, the slow cook-off tests of PBX-6 explosive components were conducted respectively at the heating rates of 2 ℃·min-1and 5 ℃·min-1. The effect of heating rate on the safety of accelerated aging explosive components was discussed, expectantly to obtain the response characteristics of SR50 mm PBX-6 spheres under slow heating process.

2 Experimental

2.1 DSC Analyses

The samples were PBX-6 explosive powders with particle sizes ranging from 0.18 mm to 1.40 mm[13]. The device applied was German NETZSCH high pressure DSC 204 HP. Under atmospheric pressure tests, the samples were under dynamic nitrogen gas circumstances with a flux of 50 mL·min-1, heating rates respectively of 2 ℃·min-1and 5 ℃·min-1; under high pressure tests, the static pressure was 1MPa of nitrogen gas, heating rates respectively of 2 ℃·min-1and 5 ℃·min-1. The sample weighed around 1.00 mg in each test, and the temperature of the tests ranged from 20 ℃ to 300 ℃.

The German NETZSCH high pressure DSC 204 HP was applied to analyze the PBX-6 powders at heating rates of 2 ℃·min-1and 5 ℃·min-1, and under the pressure of 0.101 MPa and 1 MPa, respectively in the dynamic nitrogen gas circumstances with a flux of 50 mL·min-1. The temperature of the tests ranged from 20 ℃ to 300 ℃. The PBX-6 powder sample is around 1.00 mg, and its particle size is 0.18-1.40 mm.

2.2 Accelerated Aging Test

Four SR50 mm PBX-6 hemispheres were aged in an AHX-863 oil-bathing safe oven whose temperature can be controlled from the room temperature to 95 ℃, with accuracy of ±1 ℃. The accelerated aging temperature was 55 ℃ for 140 days. The masses, densities and ultrasonic parameters of PBX-6 hemispheres before and after the accelerated aging test were measured,and the effects of the accelerated aging on the physical properties of PBX-6 hemispheres were analyzed.

2.3 Slow Cook-off Test

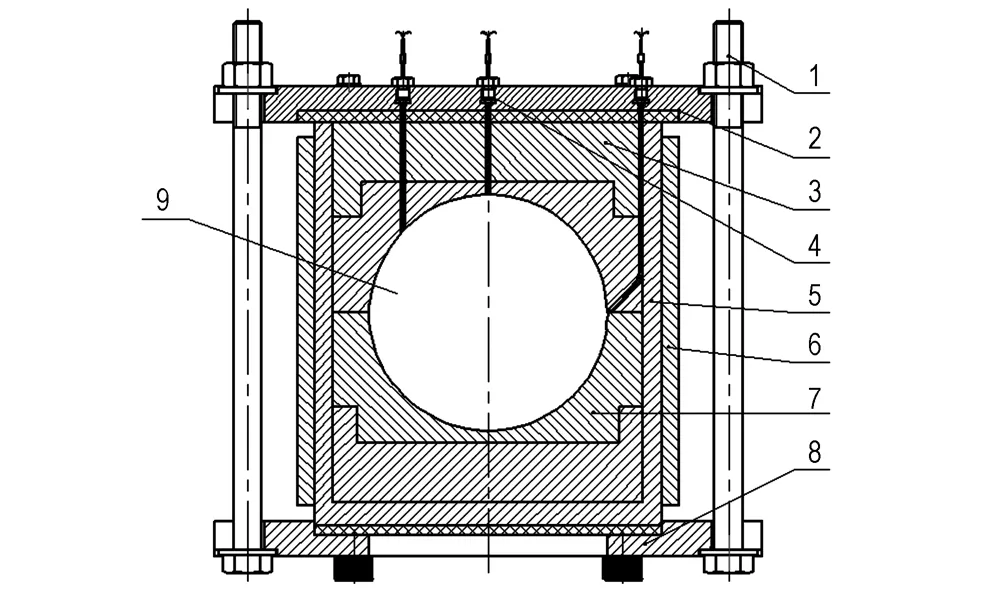

The special slow cook-off test set-up used in the research was designed by Institute of Chemical Materials,and its schematic diagram was shown in Fig.1. The set-up had a power of 1500 W, and the heating rate could range from 0.5 ℃·min-1to 10 ℃·min-1, and the temperature could range from the room temperature to 450 ℃. In the slow cook-off test, We put PBX-6 hemisphere in test set-up and heated by the electric heating cord, meanwhile the equal heating components of another PBX-6 hemisphere was heated with an intelligent temperature controller to adjust the heating rate. Four PBX-6 hemispheres were assembled to one complete sphere, named sample S-1#and S-2#. Sample S-1#and S-2#were well sealed,and the thermocouples was utilized to obtain their temperature vs. time curves.

Fig.1 Schematic diagram of slow cook-off test set-up

1—pull rod; 2—upper platen; 3—upper equal heating component; 4—thermocouple; 5—heating cartridge; 6—electric heating cord; 7—lower equal heating component; 8—bottom platen; 9—explosive components

Various sheathed thermocouples were fixed on the slow cook-off test set-up to measure the central temperatures of the heating cartridge wall, the inner temperatures of equal heating components and the surface temperatures at different positions of PBX-6 sphere sample. Afterward, the PBX-6 sphere sample was put in the hemispherical hole of lower equal heating component, and the upper equal heating component was assembled in the set-up and was tightened by screws. The fixed slow cook-off test set-up is shown in Fig.2.

In one experiment, the heating rate of the heating cartridge wall was set, and the deflagration time was recorded till the specimen deflagrated. Six Ф1.5 mm sheathed thermocouples and LT-I8000-24 temperature measuring system were used to record the temperature changes at the center of heating cartridge wall, the upper surface of the explosive component and the inner of equal heating components, so as to analyze the heat conduction behavior of the set-up and the thermal decomposition process of the explosive component. Four overpressure sensors were placed 2 meters away around the slow cook-off test set-up to measure the deflagration overpressures of the explosive component. The time from the beginning of the heating to the initial combustion or response was recorded as the deflagration time, while the temperature of the combustion or response was recorded as the deflagration temperature, which was denoted by the temperature of the explosives′ upper surface in our experiments. The reaction grades of explosive components were evaluated by analyzing the shock wave overpressures, the testing fragments, and the damage of the vessel and the residues of the explosives. Those experimental results were synthetically analyzed to evaluate the integral safety of the PBX-6 explosive components under slow heating stimulation[14-16].

Fig.2 Photograph of slow cook-off test set-up with encased thermocouples and explosive components

3 Results and Discussions

3.1 Thermal Decomposition Characteristics of PBX-6

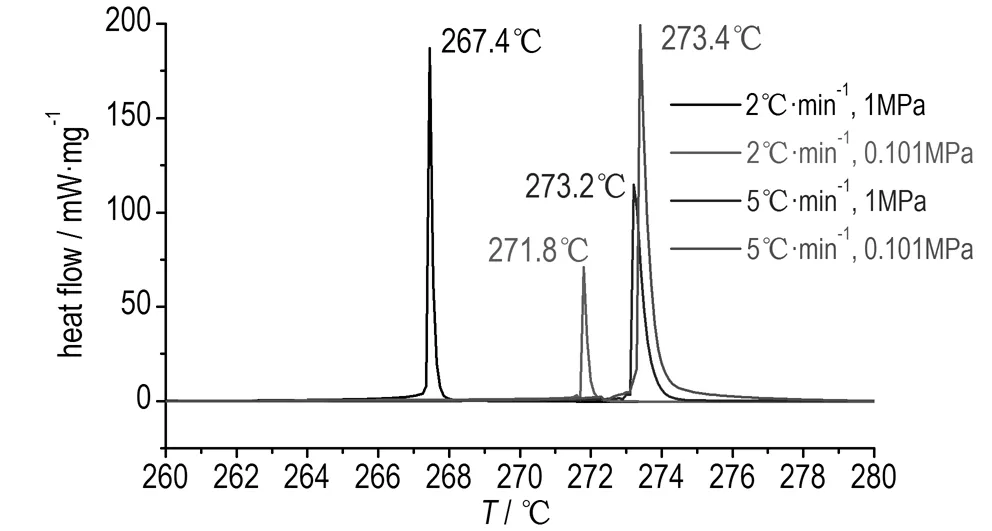

The results of DSC analyses for powder PBX-6 explosives under atmospheric pressure (0.101 MPa) and 1 MPa at 2 ℃·min-1and 5 ℃·min-1are shown in Fig.3.

Fig.3 DSC curves of PBX-6 at different pressures and heating rates

From Fig.3, the peak thermal decomposition temperatures for PBX-6 are 267.4 ℃ and 271.8 ℃, respectively under 1 MPa and 0.101 MPa at 2 ℃·min-1, which indicate that the peak temperature reduced 4.4 ℃ under high pressure. And the peak temperatures were 273.2 ℃ and 273.4 ℃ respectively at 5 ℃·min-1, and the peak temperature reduced 0.2 ℃ under high pressure. Because the gas products sublimated and decomposed from the low melting point component in PBX-6, could not escape under closed high pressure environment, and those decomposition products as catalyzers accelerated the thermal decomposition of PBX-6, and decreased the peak temperature of thermal decomposition.

3.2 Slow Cook-off Tests at Different Heating Rates

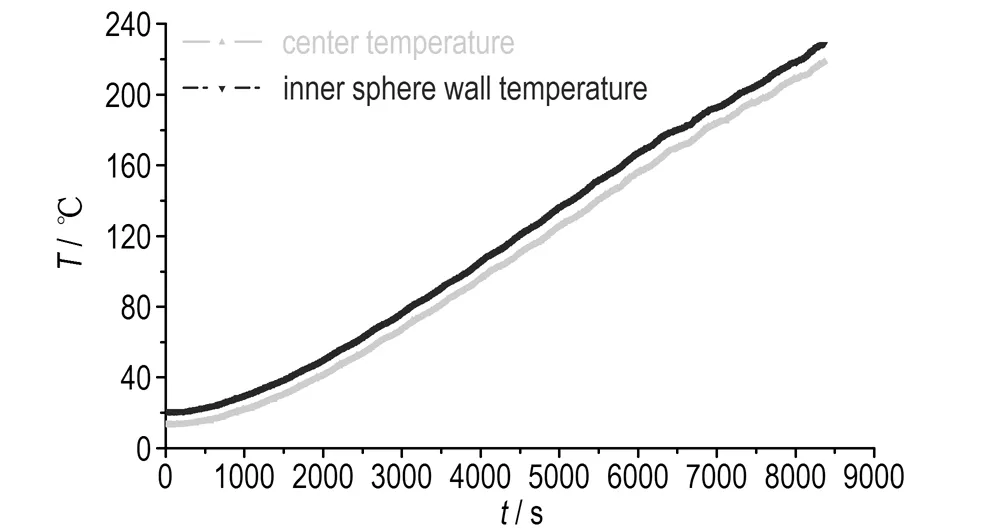

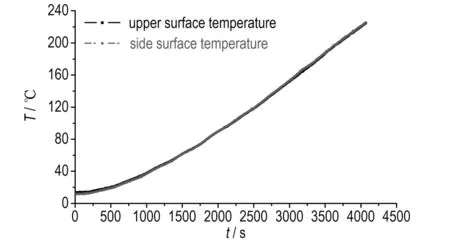

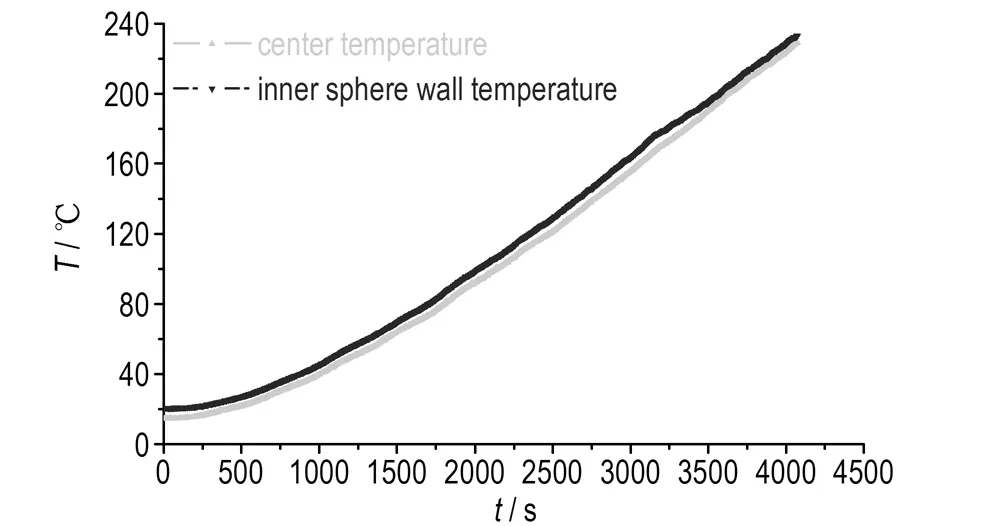

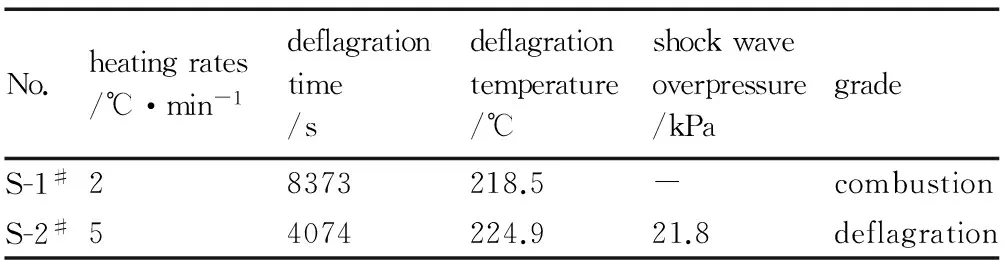

For specimens of S-1#and S-2#after 55 ℃ and 140 days of accelerated aging, the slow cook-off tests were conducted respectively at 2 ℃·min-1and 5 ℃·min-1. The curves of temperature vs. time at different positions are shown in Figure 4 and Figure 5, and the residues of the tests are demonstrated in Figure 6. All the results are summarized in Table 1.

a. surface temperature of the explosive sphere

b. temperature of the equal heating components

Fig.4 Temperature curves measured in slow cook-off test of explosive components at 2 ℃·min-1

The response process of the slow cook-off test was distinguished to three stages: (1) heating rate of the cartridge wall center was controlled through intelligent temperature controller and electric heating cord; (2) heat conduction in the cartridge wall, to the equal heating components form the cartridge wall, and to the explosive components from the equal heating components; (3) thermal decomposition till deflagration or reaction of the explosive components. The temperature vs. time curves of the cartridge wall, the equal heating components and the explosive surface were recorded by the temperature measuring system. When the cartridge wall center was heated at a constantheating rate, the heat fluxes were transferred to equal heating components from cartridge wall, and then transferred to the surface of the explosive component from equal heating components. Under continuous heating, the surface temperature of the PBX-6 explosive component continued to rise and gas products were produced as it decomposed.

From Fig.4,when the pressure of gas products from sphereical specimen S-1#exceeded the constraint limit of the cook-off set-up after 8373 s (2 h 19 min 33 s) at the heating rate of 2 ℃·min-1, the deflagration temperature was 218.5 ℃, and the thermal decomposition was relatively moderate that none of the four overpressure sensors had caught any overpressure signals.

a. surface temperature of the explosive sphere

b. temperature of the equal heating components

Fig.5 Temperature curves measured in slow cook-off test of explosive components at 5 ℃·min-1

From Fig.5, Specimen S-2#deflagrated after 4074 s (1 h 7 min 54 s) at the heating rate of 5 ℃·min-1, the deflagration temperature was 224.9 ℃, and the overpressures caught by the four sensors had an average value of 21.8 kPa.

a. 2 ℃·min-1b. 5 ℃·min-1

Fig.6 Photographs of scrap in slow cook-off test of explosive components

From Fig.6a, when the gas pressure produced from specimen S-1#thermal decomposition breached the upper equal heating component the at heating rate of 2 ℃·min-1, the electric heating cord was still fixed on the cartridge wall; some thermocouples were still in the damaged upper platen; the unreacted explosives were blasted to several large chunks and the lower equal heating component was still fastened in the bottom of the cartridge. From Fig.6b, when the deflagration of Specimen S-2#broke out at the heating rate of 5 ℃·min-1, the electric heating cord was blasted out of shape; the upper platen was torn to several large bulks; the thermocouples were pushed away; the unreacted explosives blasted to small pieces and the equal heating components were slightly deformed.

Table 1 Results of slow cook-off tests for explosive components

No.heatingrates/℃·min-1deflagrationtime/sdeflagrationtemperature/℃shockwaveoverpressure/kPagradeS-1#28373218.5-combustionS-2#54074224.921.8deflagration

Contrast of the testing result showed that for the slow cook-off specimens of S-1#and S-2#composed with PBX-6 explosive components under the same aging condition, when the heating rate rose, the deflagration time of specimen S-2#decreased 4299 s, the deflagration temperature increased 6.4 ℃, the reaction degree of deflagration increased compared with Specimen S-1#. Namely, the rise of the heating rate led to shorter deflagration time, higher deflagration temperature and higher reaction degree.

3.3 Relationship between Slow Cook-off Behavior and Thermal Decomposition Characteristics

The PBX-6 explosive is a kind of multi-composite composed of HMX, desensitizers and polymeric binders. The DSC data of HMX and PBX-6 powder explosives at the heating rate of 5 ℃·min-1under atmospheric pressure showed that, endothermicβ→δcrystalline phase transition of HMX happened at 192.9 ℃, and thermal decomposition began at the onset temperature of 273.5 ℃. The gas products produced from micro-thermal decomposition of other ingredients and degradation of polymeric binders have catalyzed and accelerated the reaction of PBX-6 during heating. Thermal decomposition can be obviously seen in macroscopic view at 265.8 ℃,and large quantities of gas products are released. For open system, the gas products of the thermal decomposition can escape in time, so no heat-accumulation will be formed thus no deflagration reaction will occur.

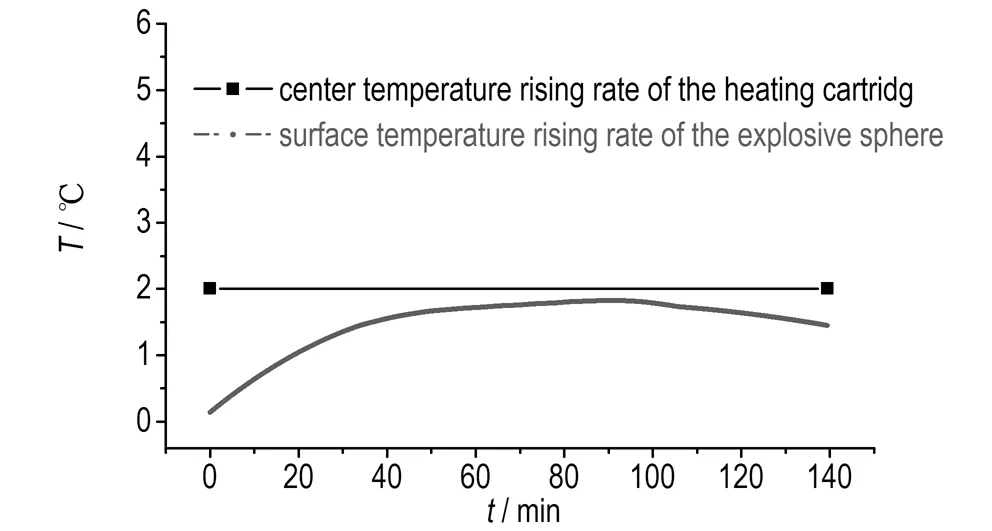

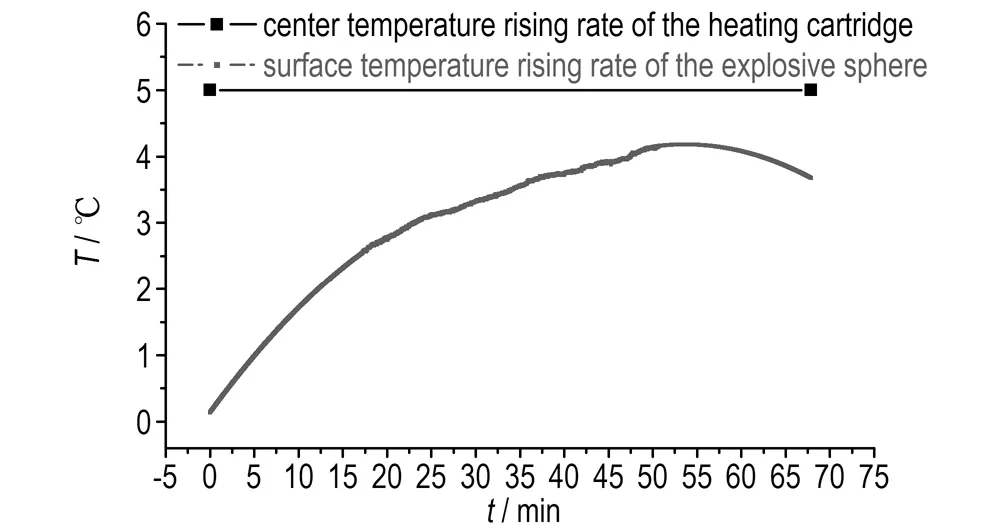

In the slow cook-off test ofspherical PBX-6 components, the explosives and the equal heating components were so well sealed up, that it was almost impossible for the decomposition products to escape. The heat flow continuously conducted from the radial direction to the inside during the constant heating rate of the cartridge, and the temperature of the equal heating components and explosives rose along with the heat conduction. Some gas products from thermal decomposition were sealed in the tiny gaps between the explosive components and the equal heating components, thus the whole explosive sphere was in a heating process with temperature and pressure differences between the inside and the outside. The PBX-6 explosive components would deflagrate when the external heating and the heat-accumulation of the thermal decomposition of PBX-6 reached the critical condition of thermal explosion. The temperature rising rates of explosive surface were derived from derivation of temperature vs. time curves of explosive surface measured by thermocouples. The results are shown in Fig.7.

From Fig.7, the surface temperature of the explosive component inclined as the inner temperature of the heating cartridge rose at the heating rate of 2 ℃·min-1, and the temperature rising rate of explosive surface reached a maximum of 1.82 ℃·min-1after 5432 s (90.53 min), and then the temperature rising rate declined slightly. It was 1.44 ℃·min-1when the reaction broke out. The temperature rising rate of explosive surface reached a maximum of 4.18 ℃·min-1after 3220 s (53.66 min) at heating rate of 5 ℃·min-1, and then the temperature rising rate declined slightly. It was 3.67 ℃·min-1when the deflagration broke out. The DTA and DSC testing data of PBX-6 explosive at heating rate of 2-20 ℃·min-1showed that[17], the temperature rising time shortened and the exothermic peak of thermal decomposition increased as the heating rate rose. As for the aging Φ100 mm PBX-6 components, contrasting of the slow cook-off results have shown that, the surface temperature rising rate of the explosive sphere will go up, the deflagration time will be shortened and the deflagration temperature will rise when the heating rate rise.

a. 2 ℃·min-1

b. 5 ℃·min-1

Fig.7 Heating rate curves of explosive components surface

In addition, thecook-off temperature and time for reaction is also related to the size of the explosive sample besides the heating rate, but further studies still remains to be carried out.

4 Conclusions

(1) The result of DSC analyses show that the thermal decomposition peak of PBX-6 reduces under high pressure, which is caused by the fact that the gas products decomposed from low-melting point compositions can not escape, and those products can catalyze the thermal decomposition of PBX-6, thus resulting in the temperature peak decrease of the thermal decomposition.

(2) A new kind of slow cook-off device for SR50 mm explosive component has been set up by referring to the slow cook-off device for explosive cylinder, and the method of slow cook-off test for enclosed PBX-6 component has been established. The explosive component and equal heating components are well sealed, and thermocouples can be utilized to record the temperature vs. time curves of the explosive surface and the equal heating components.

(3) The results of the slow cook-off testsshow that, with the heating rate of 2 ℃·min-1, the gas product pressure from thermal decomposition of Specimen S-1#exceeded the constraint limit of the slow cook-off set-up after 8373 s, and the deflagration temperature was 218.5 ℃. With the heating rate of 5 ℃·min-1, Specimen S-2#deflagrated after 4074 s with the deflagration temperature of 224.9 ℃. By contrasting with Specimen S-1#, the deflagration time of Specimen S-2#reduced 4299 s and the deflagration temperature increased 6.4 ℃ with higher deflagration grade when heating rate rose.

[1] Kent R, Rat M. Explosion thermique (cook-off ) des propergols solids[J].Propellant,Explosive,Pyrotechnics, 1982, 7(5): 129-136.

[2] Nakos J T , Knet L A , Gill W, et al. Fast cook-off testing in enclosed facilities with reduced Emissions, SAND-91-0470C[R]. A lbuquerque: Sandia National Labs, 1991.

[3] DAI Xiao-gan, Lü Zi-jian, SHEN Chun-ying, et al. Study of reaction rule for different size PBX-2 explosives in fast cook-off test[J].ChineseJournalofExplosives&Propellants, 2008, 31(3): 47-49.

[4] DAI Xiao-gan, Lü Zi-jian, SHEN Chun-ying, et al. Reaction rule for different size PBX-2 explosives in fast cook-off test[J].ChineseJournalofExplosivesandPropellants, 2008, 31(3): 42-49.

[5] DAI Xiao-gan, WEN Yu-shi, Lü Zi-jian. Study of Reaction Rule for NEPE Propellant in Cook-off Test[C]∥International Autumn Seminar on Propellant, Explosives and Pyrotechnics, Kunming, 2009: 347-350.

[6] DAI Xiao-gan, HUANG Yi-min, Lü Zi-jian, et al. Reaction behavior for PBX-2 explosive at different heating rate[J].ChineseJournalofEnergeticMaterials(HannengCailiao), 2010, 18(3): 282-285.

[7] ZHI Xiao-qi, HU Shuang-qi, LI Juan-juan, et al. Cook-off response characteristics of desensitizing RDX explosive under different restriction conditions[J].ChineseJournalofExplosives&Propellants, 2009, 32(3): 22-24.

[8] CHEN Ke-quan, HUANG Heng-jian, LU Zhong-hua, et al. Numerical calculation of cook-off test for PBX explosive based on ABAQUS[J].ChineseJournalofExplosives&Propellants, 2014, 37(2): 31-36.

[9] GAO Da-yuan,SHEN Chun-ying,WEN Shang-gang, et al. Study on accelerated aging on effect of safety for explosive parts[J].ChineseJournalofEnergeticMateriats(HannengCailiao), 2011, 19(6): 673-678.

[10] GAO Da-yuan, SHEN Chun-ying, HUAN Qian. Reaction of explosive components under simulated drop test[J].ChineseJournalofExplosivesandPropellants, 2012, 35(5): 13-16.

[11] Gao Da-yuan, Shen Chun-ying, Wen Shang-gang, et al. Fast cook-off test of accelerated aging PBX-6 explosive components[J].ExplosionandShockWaves(Supplementary), 2013, 33: 1450150.

[12] Gao Da-yuan, Wen Shang-gang, Shen Chun-ying. Study on Accelerated Aging on Effect of Performance for PBX-6 Explosive Subassembly[J].ActaArmamentarii(Supplementary2), 2012, 33: 143-148.

[13] DONG Hai-shan, ZHOU Fen-fen. Performance of high explosives and correlates[M]. Beijing: Science Press, 1989: 345-349.

[14] GAO Li-long, WANG Xiao-feng, NAN Hai, et al. Experimental study on vulnerability of the explosive PMX-1[J].ChineseJournalofEnergeticMaterials, 2010, 18(6): 699-701.

[15] Craig M Tarver and Tri D Tran. Thermal decomposition models for HMX-based plasticbonded explosives[J].CombustionandFlame, 2004(137): 50-62.

[16] GAO Da-yuan, DONG Hai-shan, LI Bo-tao, et al. Research and application of thermal decomposition kinetics for explosives[J].ChineseJournalofEnergeticMaterials(HannengCailiao), 2004(Suppl.): 307-310.

- 含能材料的其它文章

- Synthesis and Characterization of Two New Energetic Polyamino and Nitro Pyridine Derivatives

- 《含能材料》2015年(第23卷)总目次

- Non-isothermal Decomposition Kinetics,Specific Heat Capacity and Adiabatic Time-to-explosion of Cu(pn)2(FOX-7)2

- Facile Synthesis and Crystal Structure of 3,4-Bis(1H-5-tetrazolyl)furoxan

- Synthesis and Properties of N,N-Bis((3,5-dinitro-1H-1,2,4-triazol-1-yl)methyl) nitramine

- Comparison with Molecular Surface Electrostatic Potential and Thermal Reactivity of Nitramines