Combustion behavior and NO emission characteristic of biomass in O2/CO2 atmosphere

Duan Feng Sun Xiaoru Zhang Yousong Hu Aifeng Chyang Chiensong

(1School of Energy and Environment, Anhui University of Technology, Maanshan 243002, China)(2Key Laboratory of Energy Thermal Conversion and Control of Ministry of Education, Southeast University, Nanjing 210096, China)(3Department of Chemical Engineering, Chung Yuan Christian University, Chungli 32023, China)

Combustion behavior and NO emission characteristic of biomass in O2/CO2atmosphere

Duan Feng1,2Sun Xiaoru1Zhang Yousong1Hu Aifeng1Chyang Chiensong3

(1School of Energy and Environment, Anhui University of Technology, Maanshan 243002, China)(2Key Laboratory of Energy Thermal Conversion and Control of Ministry of Education, Southeast University, Nanjing 210096, China)(3Department of Chemical Engineering, Chung Yuan Christian University, Chungli 32023, China)

The thermogravimetric analyzer and horizontal tube furnace are used to study the effects of operation parameters such as temperature, fuel type, and oxygen concentration on the combustion and NO emission characteristics of the rice husk, rice straw, and peanut shell in the O2/CO2atmosphere. The results show that the combustion performances of volatile matter and fixed carbon of the three biomasses increase with the increase in the O2content. The mean NO emission increases sharply when the reaction temperature increases from 700 to 800 ℃. However, it increases slightly when the temperature exceeds 800 ℃. Meanwhile, the mean NO emission and nitrogen conversion decrease with the increase in the nitrogen content in biomass. The mean NO emission changes little with different oxygen concentrations, and the NO emissions of the three biomasses are all lower than the requirement for the minimum NO emission. Increasing the oxygen concentration favors the biomass combustion in the O2/CO2atmosphere, and oxygen concentration has little effect on the NO emission.

biomass; combustion; thermogravimetric; NO emission; O2/CO2

Biomass resources in China are rather abundant, and the annual available biomass resource is about 3.14×108t of the coal equivalent. Direct biomass combustion has been widely used owing to its lower consumption, higher efficiency, and lower CO2emission. However, many pollutant emissions are also generated from direct combustion[1]. Meanwhile, the structure, composition, and element composition of biomass are considerably different. These also affect combustion behavior and pollutant emission characteristics[2]. For biomass combustion, the oxidation of fuel-N is the major source of NOxemissions. It can be attributed to the low operating temperature that prevents the formation of the thermal NOxduring the biomass combustion process. In general, the formation and control mechanisms of the fuel NOxare complicated. Many studies on the pollutant emission characteristics and combustion efficiency of biomass in the fluidized bed[3-4]have been carried out. Results show that the nitrogen model compounds in biomass and operating parameters in the combustion system have significant effects on the NOxformation.

O2/CO2combustion technology is a new and promising technology which has the characteristics of higher CO2concentration and controlling pollutant emissions. Recently, it has attracted much more attention and it has become more advanced in pulverized coal combustion[5-6]. However, reports on combustion behavior and NOxemissions characteristics of biomass in the O2/CO2atmosphere are few. In this study, the thermogravimetric analyzer and horizontal tube furnace are used to investigate the effects of operation variables such as temperature, fuel type, and oxygen concentration on the combustion behavior and NO emission characteristics of the rice husk, rice straw, and peanut shell in the O2/CO2atmosphere.

1 Experiment Methods

1.1 Materials

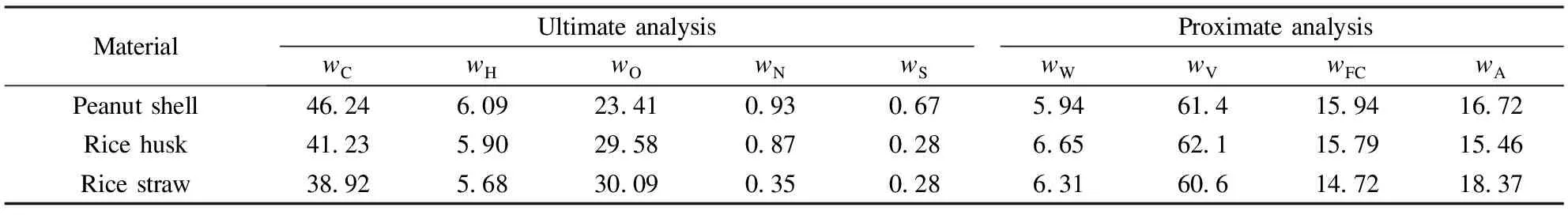

A peanut shell, rice husk, and rice straw are used in the study. The results of analysis data are given in Tab.1.

1.2 Apparatus and data processing

The STA449C thermal analyzer made by NETZSCH-Gerätebau GmbH is used in the thermogravimetric test. The mean diameter of biomass is 0.074 mm. The mass loss percentage and mass loss rate of samples are recorded continuously under non-isothermal conditions with a temperature range of 20 to 950 ℃. A sample mass of 8 mg is used for the thermogravimetric analysis in an O2/CO2atmosphere at a gas flow rate of 50 mL/min. The O2content is increased from 20% to 40% in volume. The characteristics index of the comprehensive combustionSis used to evaluate the combustion of samples, min-2/K3. This index reflects the ignition and burnout characteristics of the sample. It can be obtained as

Tab.1 Ultimate and proximate analyses of biomass on air-dry basis

whereTiandThare the ignition and burnout temperature, respectively, K; (dw/dt)maxand (dw/dt)meanare the maximum and mean weight loss rate, respectively, %/min.

Fig.1 shows the process flow chat of the tube furnace facility system. A sample of 200 mg is used for the horizontal tube furnace test at a fixed gas flow rate of 700 mL/min. The flue gas components are continuously measured by KM9106E gas analyzer. The mean NO emission is integrated the instantaneous NO concentration by time.

Fig.1 Flow diagram of NO emission test

2 Results and Discussion

2.1 TGA analysis

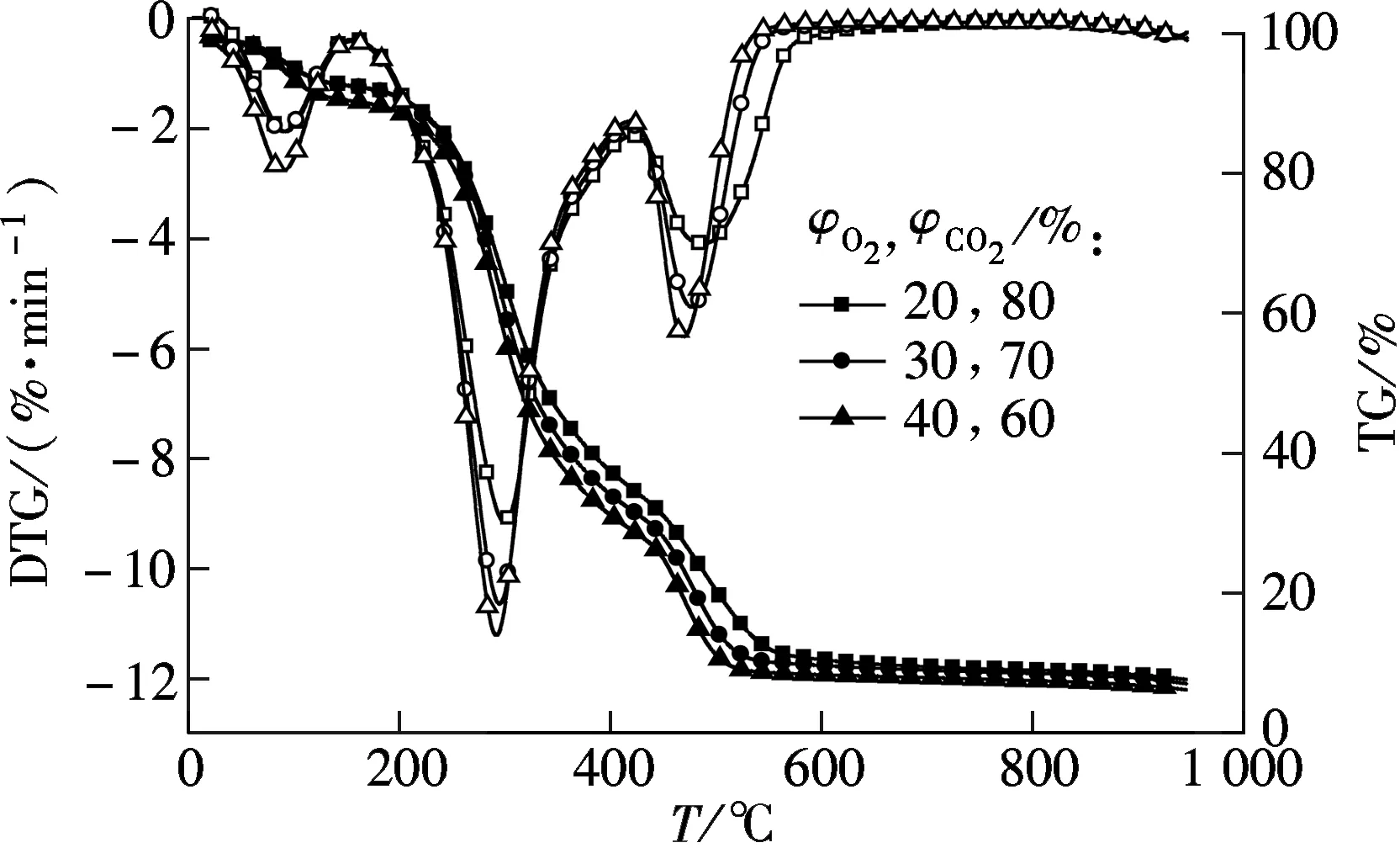

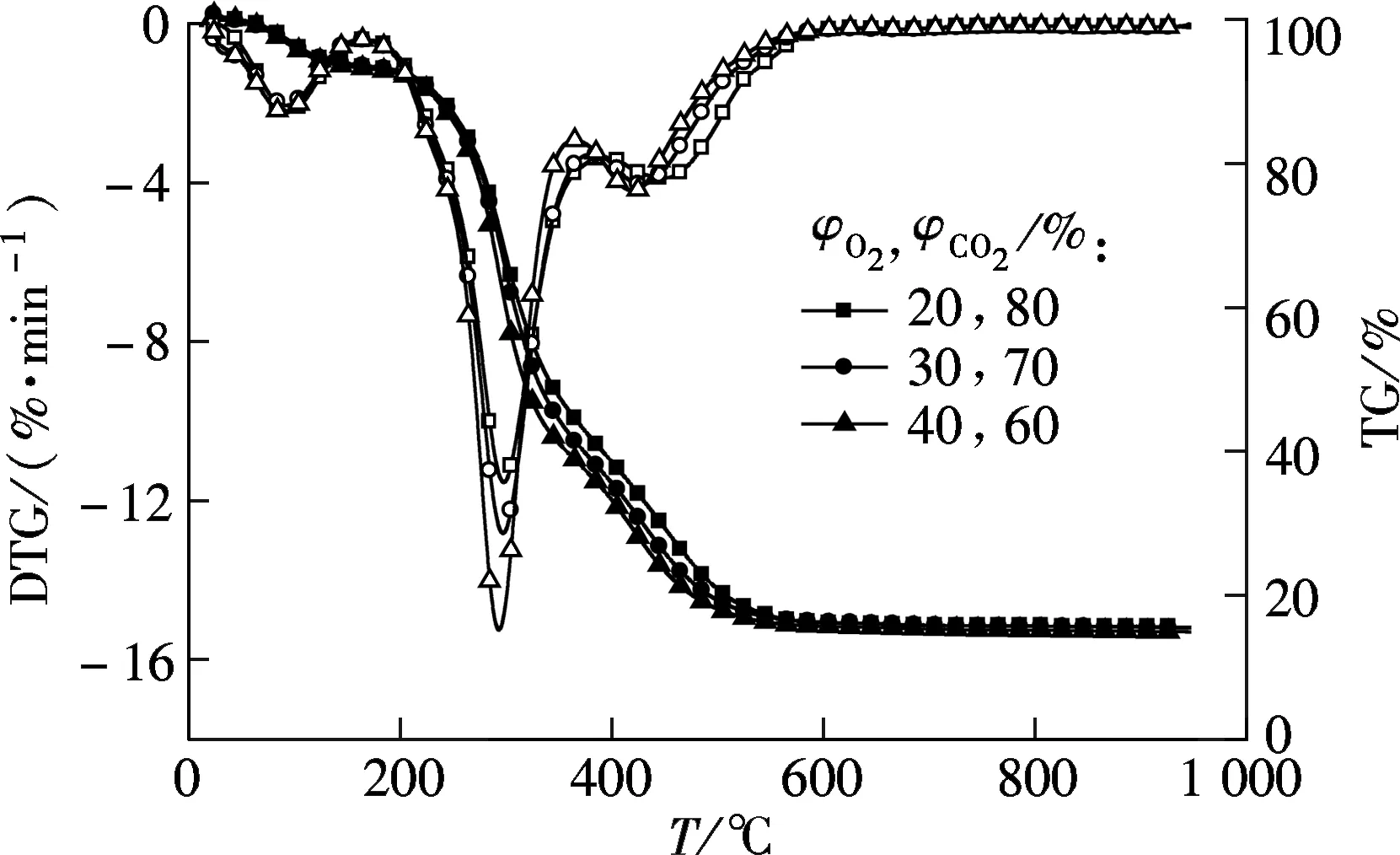

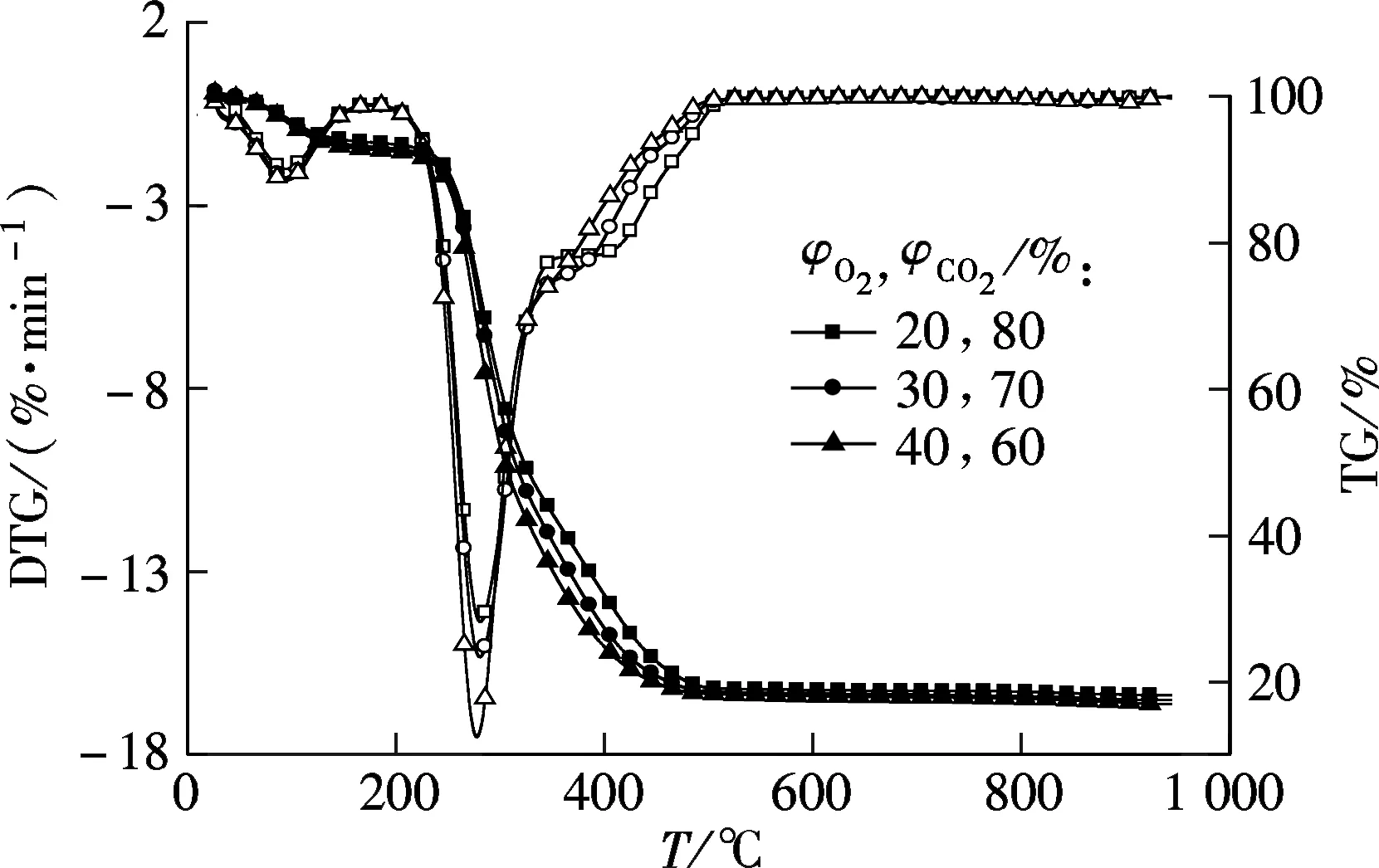

The TG and DTG curves of the peanut shell, rice husk and rice straw combustion in an O2/CO2atmosphere are shown in Fig.2. As seen in these graphs, there are three peaks in the curves, indicating that the biomass combustion processes can be divided into water evaporation (stage Ⅰ), volatile release and combustion (stage Ⅱ), and fixed carbon combustion (stage Ⅲ). Three biomass combustions have the sharpest peak at stage Ⅱ, and the peak shrinks as the oxygen ratio increases, implying that the oxygen diffusion velocity is the main factor that affects the biomass combustion rate. With the increase in the oxygen concentration, the devolatilization of biomass accelerates, which increases the oxygen diffusion velocity and decreases the ignition temperature. Significant differences appear in the carbon combustion stage. The peanut shell and rice husk have more significant weight loss peaks than those of the rice straw, and the peaks shift to a low temperature with the increase in the O2concentration.

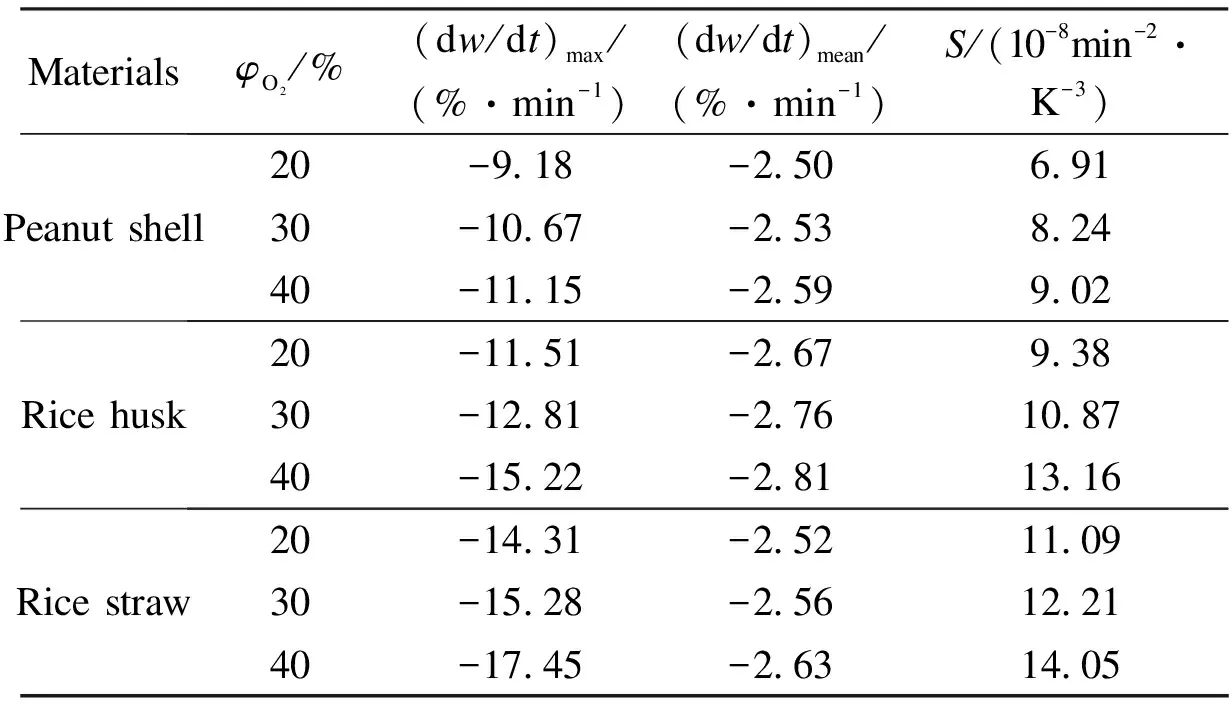

The combustion characteristics of the three kinds of biomass obtained from the TG and DTG curves at different O2contents in volume are given in Tab.2. As seen in this table, the three biomass combustions show similar trends at different oxygen contents. The maximum weight loss rate and maximum combustion rate increase with the increase in the O2contents. The comprehensive combustion characteristic indices of the peanut shell, rice husk, and rice straw are increased by 30.5%, 40.3%, and 26.7%, respectively. This also proves that these three kinds of biomass have good combustion characteristics in the O2/CO2atmosphere.

Tab.2 Combustion characteristics

2.2 NO emission characteristics

Fig.3 shows the mean NO emissions at different temperatures in the O2/CO2atmosphere. As seen in this figure, the mean NO emissions of the three kinds of biomass increase rapidly when the temperature increases from 750 to 800 ℃. This can be attributed to the combustion rate and activated molecules’ concentration increase along with the increase in the temperature. In addition, the conversions of HCN and NH3and the predecessors of NO also increase with the increase in temperature, resulting in a high NO emission[7-8]. However, the NO emissions increase slowly when the temperature increases from 800 to 950 ℃. This is because the reduction reactions of NO, both homogeneous and heterogeneous, occur simultaneously. In this biomass combustion process, the un-reacted char is a very active catalyst for the reduction of NO with NH3. Besides, a higher temperature will increase the HCN and NH3concentrations and this also increases the chance of the two predecessors reacting with NO.

(a)

(b)

(c)

NH3+NO=N2+H2O+H

(1)

HCN+NO=N2+CO+H

(2)

Fig.3 Effect of temperature on NO emission

Fig.4 shows the mean NO emission and nitrogen conversion of different biomasses. As seen in this figure, the mean NO emission and nitrogen conversion of these three biomasses decrease with the increase in the nitrogen cont-ent in biomass (see Tab.1). This can be attributed to the fact that the volatile matter of the biomass is higher than the fixed carbon. In this test, volatile nitrogen is the main form of the nitrogen content of biomass. With a high fuel-nitrogen content, the reduction reactions (1) and (2) are also enhanced, resulting in a lower NO conversion. Fig.5 shows the mean NO emission at different oxygen concentrations. In general, the predecessors will favor oxidation to form NO at a higher oxygen concentration. However, as seen in this figure, the oxygen concentration has little effect on the mean NO emission. This is due to the effect of CO2in the biomass combustion process. In this test, CO2is used to replace N2for combustion, which increases the chance of CO2reduction with un-reacted carbon and NO reduction with CO[9]. Therefore, the NO emission increases slightly and it ranges from 20×10-6to 30×10-6. The mean NO emission meets the minimum NO emission requirement (100×10-6) of China.

Fig.4 Effect of biomass type on NO emission(40%O2/60%CO2,T=850 ℃)

Fig.5 Effect of oxygen concentration on NO emission(T=850 ℃)

3 Conclusions

1) Increasing the oxygen concentration favors the biomass combustion in the O2/CO2atmosphere, and oxygen concentration has little effect on the NO emission.

2) In the O2/CO2atmosphere, the mean NO emission increases rapidly with temperatures below 800 ℃. However, it increases slightly when the temperature exceeds 800 ℃.

3) The mean NO emission and nitrogen conversion decrease with the increase in the nitrogen content in biomass.

[1]Cao G, Zhang X, Gong S, et al. Investigation on emission factors of particulate matter and gaseous pollutants from crop residue burning [J].JournalofEnvironmentalSciences, 2008, 20(1):50-55.

[2]Duan F, Chyang C S, Chin Y C, et al. Pollutant emission characteristics of rice husk combustion in a vortexing fluidized bed incinerator [J].JournalofEnvironmentalSciences, 2013, 25(2):335-339.

[3]Madhiyanon T, Lapirattanakun A, Sathitruangsak P, et al. A novel cyclonic fluidized-bed combustor (ψ-FBC): combustion and thermal efficiency, temperature distributions, combustion intensity, and emission of pollutants [J].CombustionandFlame, 2006, 146(1/2):232-245.

[4]Ren Q, Zhao C, Duan L, et al. NO formation during agricultural straw combustion [J].BioresourceTechnology, 2011, 102(14):7211-7217.

[5]Jiang X, Huang X, Liu J, et al. NOxemission of fine-and superfine-pulverized coal combustion in O2/CO2atmosphere [J].Energy&Fuels, 2010, 24(12):6307-6313.

[6]Cong S, Duan F, Zhang Y, et al. SO2emission from municipal sewage sludge cocombustion with bituminous coal under O2/CO2atmosphere versus O2/N2atmosphere [J].EnergFuel, 2013, 27(11):7067-7071.

[7]Giuntoli J, de Jong W, Verkooijen A H M, et al. Combustion characteristics of biomass residues and biowastes: fate of fuel nitrogen [J].Energy&Fuels, 2010, 24(10):5309-5319.

[8]Bai J, Yu C, Li L, et al. Experimental study on the NO and N2O formation characteristics during biomass combustion [J].Energy&Fuels, 2012, 27(1):515-522.

[9]Duan F, Chyang C S, Wang Y J, et al. Effect of secondary gas injection on the peanut shell combustion and its pollutant emissions in a vortexing fluidized bed combustor [J].BioresourceTechnol, 2014, 154(1):201-208.

O2/CO2气氛中生物质燃烧及NO排放特性研究

段 锋1,2孙肖茹1张友松1胡爱凤1钱建嵩3

(1安徽工业大学能源与环境学院, 马鞍山 243002)

(2东南大学能源热转换及其过程测控教育部重点实验室,南京210096)

(3中原大学化学工程系,中坜32023)

采用热重分析仪、管式炉试验研究了反应温度、燃料种类、氧浓度等操作参数对稻壳、稻杆、花生壳3种生物质在O2/CO2气氛下的燃烧特性和NO排放特性.试验结果表明:随着O2含量的增大,3种生物质的挥发分和固定碳的燃烧性能均随之增加;当反应温度由700 ℃增加到800 ℃时,NO的平均排放量随温度升高迅速增加,当反应温度高于800 ℃,NO平均排放量增幅趋于平缓;NO平均排放量和氮转换率随着燃料中N含量的增加而减少;NO平均排放量随氧气浓度变化较小,低于NO排放标准.增加O2浓度有助于促进生物质在O2/CO2气氛中的燃烧,同时对NO生成的影响较小.

生物质;燃烧;热重;NO排放; O2/CO2

X511

Foundation items:The Natural Science Foundation of Anhui Province (No.1508085ME73), the Open Foundation of Key Laboratory of Energy Thermal Conversion and Control of Ministry of Education (No.201406).

:Duan Feng, Sun Xiaoru, Zhang Yousong, et al.Combustion behavior and NO emission characteristic of biomass in O2/CO2atmosphere[J].Journal of Southeast University (English Edition),2015,31(2):200-203.

10.3969/j.issn.1003-7985.2015.02.007

10.3969/j.issn.1003-7985.2015.02.007

Received 2015-01-11.

Biography:Duan Feng(1977—), male, doctor, associate professor, ddffeng@126.com.

——《2013年中国机动车污染防治年报》(第Ⅱ部分)

Journal of Southeast University(English Edition)2015年2期

Journal of Southeast University(English Edition)2015年2期

- Journal of Southeast University(English Edition)的其它文章

- Adaptive modulation in MIMO optical wireless communication systems

- An improving energy efficiency cooperation algorithm based on Nash bargaining solution in selfish user cooperative networks

- Performance analysis of an O2/CO2 power plantbased on chemical looping air separation

- Model of limestone calcination/sulfation under oxy-fuel fluidized bed combustion

- A novel carbon trap sampling systemfor coal-fired flue gas mercury measurement

- Applicability of Markov chain-based stochastic modelfor bubbling fluidized beds