Pouring characteristics analysis on the concrete pump truck boom based on rigid-flexible coupling method

Juan HUANG,Jiang-yong WANG,Tie-zhong XIAO

(1 Department of Mechatronics Engineering,Sichuan Engineering Technical College,Deyang 618000,China)(2Changzhi Qinghua Machinery Factory,Changzhi 046000,China)

1 Introduction

Concrete pump is a special vehicle because pumping mechanism and boom systems are integration mounted on the vehicle chassis.During pouring operations,pump could transmit the power provided by chassis engine to the pump through the transfer case,thereby drive concrete pumping mechanism and boom system.Pump working environment was bad and boom was shaking incessantly in pouring process due to cyclical shocks of pump and boom flexible effects,which will not only affect the casting quality,but also lead to fatigue failure.

Rigid-flexible coupling model for the concrete pump truck boom was established based on ANSYSand ADAMSsoftware in this paper.Its most dangerous working conditions,namely the level of working conditions were analyzed.Based on the results,the boom strength was checked,which had some reference value for truck boom design and checking.

2 Build virtual prototype model

ADAMS,as a large-scale dynamics analysis software,the main analysis target was rigid body and could ignore the impact of its flexible effects caused by the movement[1].ANSYSas finite element analysis software could analyze the object stress,strain and natural frequency and other characteristics.But for the assemblies and a large range of motion object,its analysis capabilities was weak[2-3].Through bidirectional interface between these two software,movement analysis and strength checking could be carried on for large flexible parts.

In ANSYS through modal analysis for parts,modal neutral file(ie.mnf file)of flexible body could be generated.Import this file into ADAMS,flexible body model will be generated,thus the deformation produced by dynamics simulation process in flexible body and influence on the hinge of force generated by the deformation could be analyzed.Then in system dynamics computing,deformation influence of flexible body and coupling between flexible body and rigid body could be considered,which will improve the reliability of the simulation results,so the simulation results will be more close to the real situation[4-6].

Conversely,after the completion of the system analysis in ADAMS,flexible or rigid body forces information could be exported,and load files(ie.lod file)could be generated.The file was read into ANSYS software,then parts load spectrum information could be produced in the specified time period or the specified time,the boundary conditions of parts was formed,and then we could carry out static analysis,transient response and fatigue life prediction and research.This boundary condition was based on the dynamics accurate simulation results,which eliminates the need for complex manual calculations,could greatly improve the efficiency and accuracy[7].Cosimulation flow chart between ANSYS and ADAMS was shown in Fig.1.

Fig.1 Co-simulation between ADAMSand ANSYS

3 Establish rigid-flexible coupling model

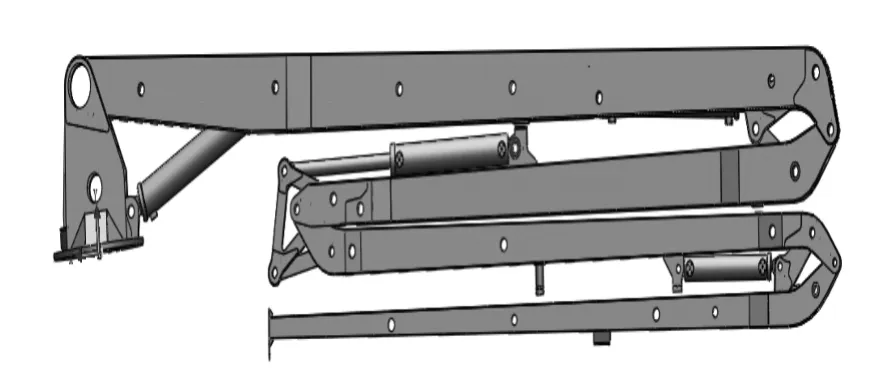

Concrete pump truck boom was longer and larger ranges of motion,then the flexibility effects were obvious as compared to other parts.In this paper,flexible body models of only four sections boom were established;turntable,hydraulic cylinders,connecting rods and other parts were regarded as rigid body.3D model of pump truck boom was established in threedimensional software named Solidworks,as shown in Fig.2.Firstly,the multi-body model of boom system was established in ADAMS,set the unit to MKS(length,mass,force,time,degree deg),the acceleration of gravity was 9.8.Boom material was a certain type of imported steel,the density was 7850,Young’s modulus was2.1E11,Poisson’s ratio was0.3.After defining the materials,mass and inertia of each component was determined automatically.Meshing on the boom in ANSYS,boom modal neutral file(.MNF)was generated.By Rigid to flex module in ADAMS,four boom modal neutral files generated in ANSYS separately introduced into ADAMS,then the multi-body model corresponding parts were replaced.And ensure that the centroid of two parts could coincide,Re-add the constraint,rigid-flexible coupling model of boom system was generated.

Fig.2 The boom assembly

4 Analysis of the boom vibration characteristics

4.1 Exciting calculation

When concrete pump was working,concrete pumps worked alternately and concrete was pumped to the specified pouring location through the delivery tube.Periodic exciting force was produced by this alternative working of pump,leading to the boom vibration.The exciting force at the turntable and the pump truck boom force generated by extremity hose when concrete flowing were considered in this paper.

1)Turntable exciting force computing

When the displacement of concrete was 110 m3/h,the amplitude of the pump turntable is about to 0.004 4 m[8].The displacement was 130 in pump low pressure working condition and the displacement was 76 in pump high pressure working condition.Based on proportional relationship,the corresponding amplitude of the turntable at the two conditions could be calculated as 0.005 2 m and 0.003 04 m,respectively.

According to the pump parameters,during low pressure working condition,theoretical pumping frequency of pump was 25 times per minute,so the excitation function of turntable displacement is as follows:

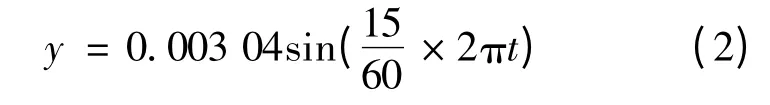

During high pressure working condition,theoretical pumping frequency of pump was 15 times per minute,so the excitation function of turntable displacement is as follows:

2)Extremity concentrated load calculation

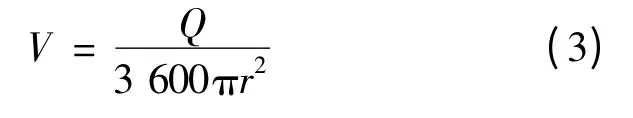

The maximum flow rate of concrete in delivery pipe was calculated as follows:

Where,Qwas the representatives of theoretical flow;rwas the representatives of delivery tube radius,according to the pump parameters,rwas taken to 0.062 5 mm.

When concrete flowing in the extremity hose,which was considered the free fall,the exit velocity of concrete could be determined as follows:

Where,gwas acceleration of gravity;Lwas the length of extremity hose,according to the pump parameters,Lwas taken to 3 m.

The average flow velocity of concrete in hose was

The extremity hose frictional force generated by concrete was

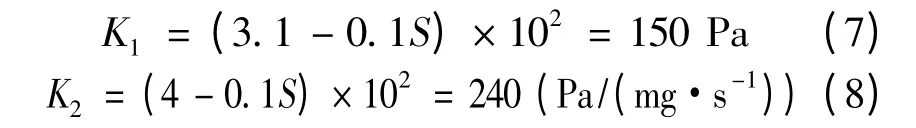

Where,K1was sticking coefficient,K2was speed coefficient,their units were Pa and Pa/(m·s-1),respectively,concrete slumpSwas taken to 16 mm,according to the empirical formula,they could be calculated as follows:

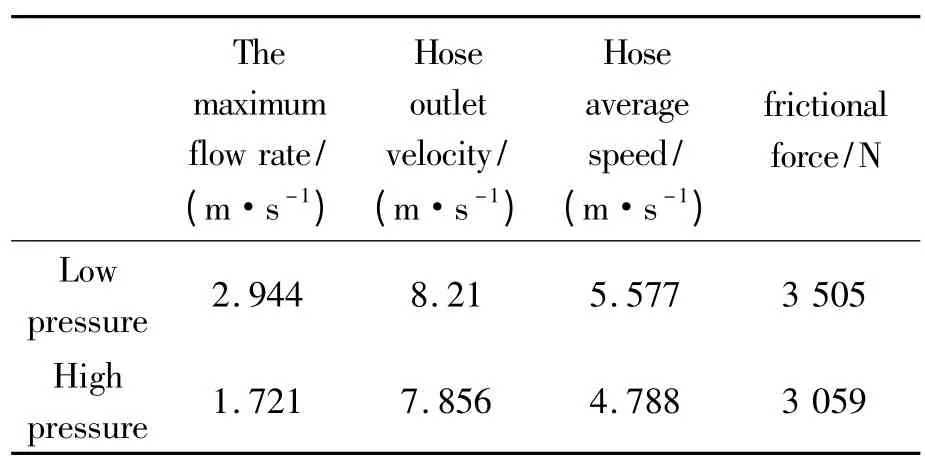

Use the formula from Eqs.(3)to(8),the pump parameters were obtained at low pressure flow and high pressure flow pump,as shown in Table 1.

4.2 Simulation

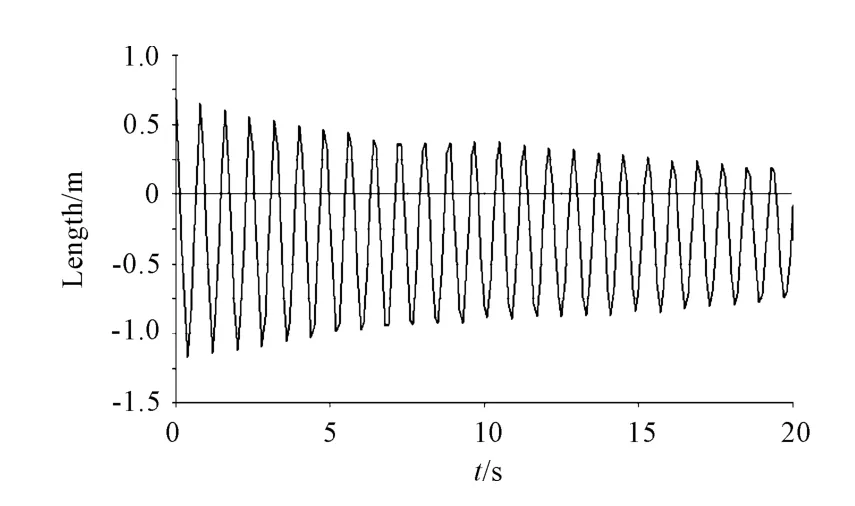

In ADAMS,the turntable and the earth were set moving deputy,adding slip deputy driving,excitation function as shown in formula(1)and(2).Applying a concentrated force in the extremity boom,the force was shown in Table 1.Simulation time was 20 s,step length was 0.1.Vibration displacement of extremity point was measured at low pressure working condition,as shown in Fig.3.At low pressure working condition,when the initial work,the maximum amplitude of extremity boom was reached up to 1.84 m,due to the damping effect,boom amplitude was decreased and eventually it was around 0.92 m.

Table 1 The velocity of concrete and the terminal friction force

Fig.3 The displacement of end point

The acceleration of end point was measured at low pressure working condition,as shown in Fig.4.If the acceleration Fourier transform was conduct,the results were shown in Fig.5.It could be seen that boom first order frequency was around 1.25 Hz,second-order natural frequency was about 2.46 Hz,three natural frequencies was approximately 3.71 Hz,much greater than the pumping frequency of pump,so the designed pump could meet the requirements.

Fig.4 The acceleration of end point

Similarly,conduct the simulation at high pressure working condition,the maximum amplitude of pump in the initial stage was 1.69 m,and the final amplitude was about 0.9 m.So pump vibration was greater than that at low pressure working condition.

Fig.5 The Fourier transform of acceleration

5 Boom strength analyses

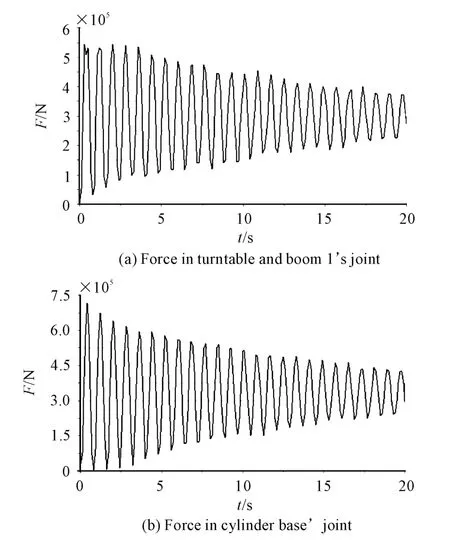

According to the analysis above,we can see that compared to the boom luffing movement and rotary motion,the vibration of the boom when pouring had a greater impact on its strength,and the strength of the boom when pouring was checked.The simulation parameters were set as indicated above,the force was measured at each joint,as shown in Fig.6(a)and Fig.6(b).

Fig.6 Force

Analysis of force curves at each joint,compared to the rigid model,flexible boom force of all the joints showed considerable volatilities,and boom fatigue damage was caused in the actual work.At the beginning of pouring,force at each boom joint was the maximum and fluctuate,then force become gradually stabilized over time.From this figure,it can be seen that the joints force when time was 0.4 s reached the maximum,at this time the deformation of the boom was maximum.

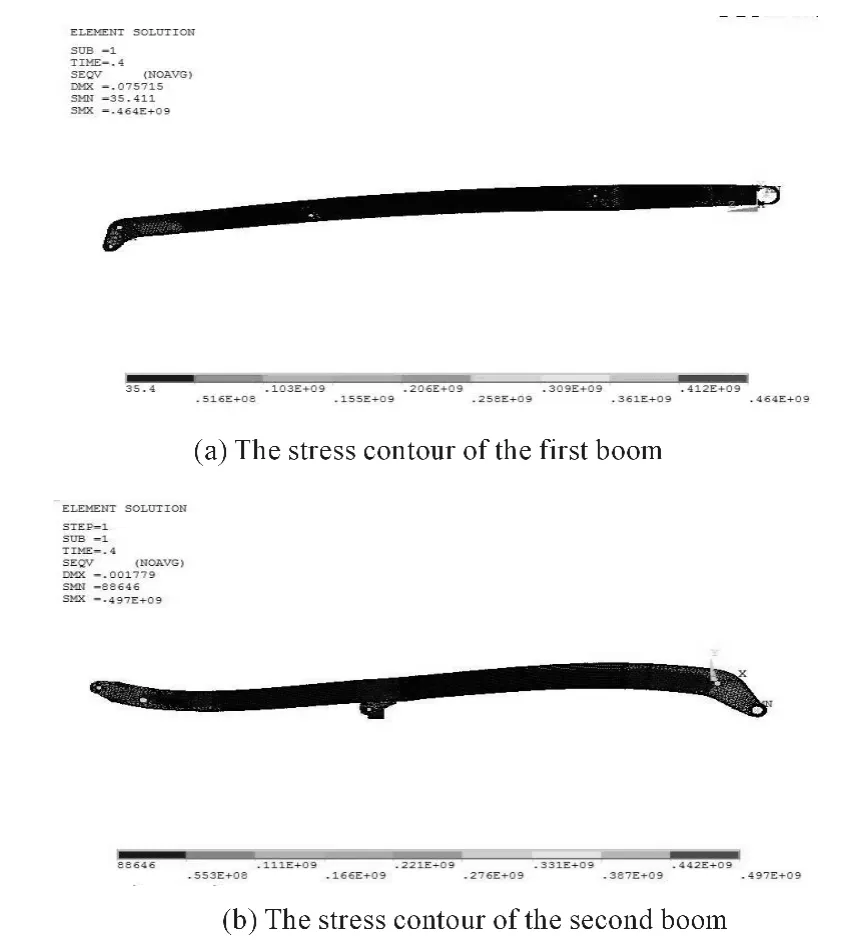

Based on the above analyses,select File-Export in ADAMS,then select the first boom,loads each external point of the boom on 0.4 s were outputted,generate finite element load files[9].Run ANSYS and open a finite element model of the first boom.Add displacement constraints at the hinge point,import load files and carry out static analysis.The stress situations throughout boom were shown as Fig.7.

Fig.7 The stress contour of the boom

From Fig.7,the maximum stress of the first boom was 464 MPa,the maximum stress of the second boom was 497 MPa,which could meet the strength design requirements.Since there was no consideration reinforcement ring influence,the forces at hinge and cylinder base were large.If reinforcement ring was increased,the force at the boom hinge would be appropriately reduced,and boom could safely run.

6 Conclusions

Based on ANSYS and ADAMS simulation platform,boom as a flexible body,a rigid-flexible coupling model of concrete pump truck boom was established.Turntable exciting force and extremity concentrated load at level working conditions were calculated,and the boom dynamics simulation was carried out.Based on the above simulation results,the boom displacement fluctuation characteristics were analyzed.And boom strength was checked.It has been confirmed that the boom flexible effect will not only affect the boom movements,but also affect the stress and strain of boom.Therefore,this paper could provide the study basis for the simulation of flexible manipulators.

Acknowledgement

This paper is supported by Chongqing Municipal Education Commission of Science and Technology research project(No.KJ130806)

[1]YUAN SQ,XU Q Y,ZHANG G L.Experiments on active vibration control of a flexible four bar linkage mechanism[J].ASME Journal of Vibration and Acoustics,2002,122(1):82-85.

[2]Li Zhibo,Yu Hongyun.Pro/E,ADAMSand ANSYScombined application of virtual design[J].Mechanical Engineering and Automation,2008,2:48-53.

[3]Chen D,Wang G,Xie X F.Research on Dynamic Characteristics of Boom System Vibration of Concrete Pump Truck[J].Machine Design and Research,2011,27(4):92-95.

[4]Pu Minghui,Wu Jiang.Study on cane flexible body modeling based on ADAMS[J].Journal of System Simulation,2009,21(7):1930-1932.

[5]Hao Jungang.Interface between CAE and CAD three-dimensional software[J].AECCtopics symposium proceedings,2007:84-86.

[6]Zhao LiJuan,Ma Yongzhi.Study on rigid-flexible Coupling System Modeling and Key Technologies[J].Computer Engineering and Applications,2010,46(2):243-248.

[7]Andreas H,Martin A,Ondrej V.Modal multifield approach for an extended flexible body description in multibody dynamics[J].Multibody System Dynamics(S1384-5640),2005,13(3):299-322.

[8]Tian Runli,Lv Pengming,Jia Jianfeng.Study on concrete Pump Truck system transient dynamic response[J].Construction machinery,2010(3):85-91.

[9]Taddei F,Martelli S.Finite element modeling of Researching Hip prosthesis:Estimation of Accuracy through Experimental Validation[J].Biomech.Eng.2010,132,11.

- 机床与液压的其它文章

- Overload intelligent detection method of lift platform’s number of people under auxiliary visual

- Introduction of the Fluid Control Engineering Institute of Kunming University of Science and Technology

- Impact of fluid properties on the injection process in a common-rail direct injection system

- The simulation study and verification on virtual prototyping of power end in diaphragm pump

- Study on rigid-flexible coupling multi-body dynamic model and simulation for wind turbine

- The research on engine stable frame report parsing of Boeing 747-400 by QAR data