Tensile performance of groove sintered fiber composite wick porous material

Su-lian TAO

(Department of Mechanical Engineering,Guangdong Technical College of Water Resources and Electric Engineering,Guangzhou 510925,China)

1 Introduction

Composite wick porous metal material,an interesting engineering material,is being explored due to the porous structure and unique properties[1-3],the main composite wick porous material includes:porous layer sintering on microgrooves[4-6],powder sintering on silk screen[6],metal foam sintering with copper powder[7],delaminating sintering[8-9],subsection sintering[10]and group cluster composite wick[11].Nowadays GSFCWPM used broadly in heat transfer field is studied,breakage becomes the key problem of the structure design and application.However,few researches on mechanical properties of GSFCWPM have reported in the literature to date[12].In this paper,we studied the effect of copper fiber parameter and the manufacture parameter of GSFCWPM on its stretching performance.Our study will provide theory guide for us to fabricate high intensity GSFCWPM.

2 Experiment procedures

2.1 Manufacturing process of GSFCWPM

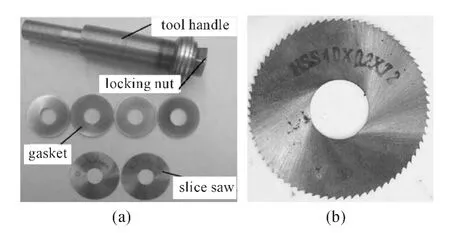

The test samples were produced by sintering copper fiber on perpendicular micro grooves of copper plate,the thickness of copper plate was only 1mm,so the micro grooves were fabricated on milling machining.Multiple slotting saws were stacked together to fabricate multiple perpendicular microgrooves in order to achieve efficient processing.Multiple slotting saws stacked together comprised tool handle,locking nut,several slice saws and gasket,as shown in Fig.1(a).The slice saw and gasket were stacked together and riveted by locknut in order to replace slice saw rapidly.The diameter of slice saw is 40mm,the material is the high speed steel W18Cr4V.There are 72 triangular teeth,the rake angle of slice saw is 5 degrees,the tool clearance is 16°,the tooth depth is 1mm.The thickness of slice saw is selected by the width of orthogonal micro groove.The thickness of test slice saw is 0.3 mm.

Fig.1 Multiple slotting saws stacked together and slotting saw

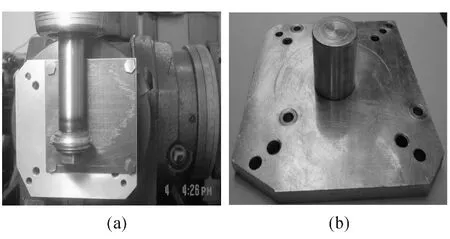

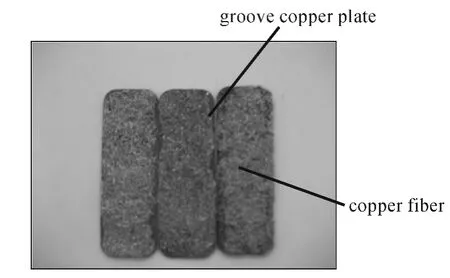

Fig.2(a)is the scene diagram for multi cutter milling orthogonal micro-groove on copper plate.The experiments were carried out on X5032 vertical milling machine,the material of work piece was T2 copper plate of 90 mm ×90 mm ×1 mm.Clamp(Fig.2(b))was made by interference fit between a flat plate and a cylindrical metallic rod.The work piece was fixed on the fixture plate with four fixed bolts;a cylindrical metal rod of clamp was fixed on the dividing head.Similarly,microgrooves were processed by the main motion of milling cutter and the feed movement of worktable.When milling was completed,the dividing head was rotated 90°;orthogonal micro grooves could be gotten.Copper plate with 20 mm×60 mm×1 mm was obtained by wire-electrode cutting,and then copper fibers were covered on micro-grooves of copper plate at high temperature sintering.The samples were obtained as shown in Fig.3.

Fig.2 Fabrication of groove copper plate with a single slotting saw

2.2 Uniaxial tension of GSFCWPM

Tensile tests were conducted on CMT5105 electronic universal testing machine,as shown in Fig.4.In order to avoid sample chucking deformation failure during stretching,chuck lining covered by rubber gasket,the effective test length of sample clamping by clamp holders is 40 mm,the testing process of all samples in the experiment was carried out in the clamp loading speed under the condition of 1.5 mm/s,the whole test process was carried out at room temperature 23℃.

Fig.3 Tensile test sample

Fig.4 Electronic Universal testing machine(No:CMT 5105)

3 Result and discussion

3.1 Unaxial tensile process

Copper fibers on copper plate laid randomly,fibers contact fibers,which form nodes.There form holes between adjacent fiber nodes,which present three-dimensional spatial distribution.When GSFCWPM is stretched,groove copper plate and sintered fiber porous material are stretched too,with the tensile deformation of fibers between nodes,the nodes will undergo great stress and deformation,even break away.There exits some difference between the side overall shape of fracture mouth formed at different process after the GSFCWPM is stretched and ruptured in the tensile fracture,but all showed complex irregular trend,its typical fracture morphology is similar to that showed in Fig.5.

Fig.5 Tensileand destroy processof GSFCWPMsintering1000℃for 60 minutes

Fig.5 is a typical uniaxial tensile failure process schematic diagram of GSFCWPM with 80%porosity sintered at 1000℃ for 60 minutes.What we can see from this graph is that the complex fracture mouth curve and the tensile load direction with any angle.At the beginning of stretching,GSFCWPM experiences short-term plastic deformation.With continuous increase of tension,the GSFCWPM as porous skeleton structure begins to certain plastically deflect,when the tension continues to increase and the maximum tension stress of a weak position in GSFCWPM exceeds the damage intensity of corresponding metal body,the GSFCWPM will be ruptured from one side of the weak position,and there exists tearing at the fracture process.The fracture direction is random at a large degree,thus the macroscopically whole fracture morphology is curved.There exist almost no macroscopically holistic necking phenomenon in the tensile fracture process.

But not the whole tensile process follows the maximum tensile stress criterion of brittle fracture mode,namely fracture mouth is orthogonal to the tensile load direction by any angle.However,as a plastic material of metal copper body,the tensile fracture is not the whole suitable for plastic flow failure modes of maximum shear stress criterion,namely the fracture surface and the maximum shear stress direction are consistent,the fracture of the copper occurred at 45 degree angle relative to the tensile loading direction,which is along the direction of maximum shear stress.Therefore,it cannot be regarded as plastic fracture or brittle fracture simply,which has particular characteristics:GSFCWPM has the characteristics of not only copper but also copper fiber porous body,it has new characteristic that the GSFCWPM is formed through pressure sintering copper and copper fiber.All materials of GSFCWPM are copper,so in the process of initial tensile,the GSFCWPM experiences a short-term stage of plastic deformation,however there exists porous fiber structure,so when the inner stress exceeds a certain value,the GSFCWPM experiences a certain plastic deflection,then it will produce tearing fracture.Furthermore,we don’t observe any overall plastic material necking phenomenon.

3.2 The effect of copper fiber parameter on tensile performance

The diameter of copper fiber has great influence on tensile property of GSFCWPM.Fig.6 shows the stress strain curve diagram of tensile destructive process for GSFCWPM with different fiber diameter and the same quality.What we can see from the chart that GSFCWPM experiences a long-term plastic deformation,the stress then increases rapidly until reaching the maximum with an increase of the strain.When it is approaching to the maximum,the stress begins to decrease quickly with the increase of strain.Yield stage and necking phenomenon will not occur at tension process.It can be seen from figure 6 that plastic deformation process becomes short with the increase of fiber diameter,the tensile strength gets decreased with the increase of fiber diameter.The main reason for this phenomenon is that the strain of metal fiberboard depends on the quantity of connection points between fiber silk and fiber silk as well as between fiber silk and copper board.The same quality GSFCWPM,the thicker fiber,the less containing fiber quantity,the less joint nods between fiber silk and fiber silk as well as fiber silk and copper board.In addition,the diameter of fiber has a certain effect on elongation ratio of GSFCWPM,the thicker fiber,the less elongation ratio,otherwise the greater.

Fig.6 Tensile stress and strain curve of GSFCWPM with different diameter

3.3 The effect of fabrication parameters for GSFCWPM on tensile performance

1)Effects of sintering temperature on tensile properties

Fig.7 shows the tensile stress-strain curve of GSFCWPM sintering at 800℃,900℃ and 1 000℃ for 60 minutes.What we can see from Fig.7 is that the stress-strain curve regulation of GSFCWPM fabricated at different temperature has similar trend.The tensile strength of GSFCWPM gets increased with the increase of sintering temperature when the sintering temperature is below 1 083℃.The maximum tensile strength of GSFCWPM sintered at 800℃,900℃,and 1 000℃ for 60 minutes are 43.6 MPa,56.2 MPa,and 74 MPa,respectively.We attribute these results to the following reasones:the increasing sintering temperature speeds up the velocity of material migration,impelling the copper fiber to fully diffusion weld the fiber and the copper board on the GSFCWPM,the contact nodes welding between fibers as well as fiber and copper board are firm.Over melting phenomenon will occur if sintering temperature is too high,and then it causes surface defect of GSFCWPM.Diffusion welding of contact nods is not completed when sintering temperature is too low.

What we can see from Fig.7 is that the elongation rate gets decreased with the increase of sintering temperature.The elongation rate of GSFCWPM sintered at 800℃,1 000℃ for 60 minutes are 27.7%,19.16%,respectively.

Fig.7 Effect of sintering temperature on tensile performance of GSFCWPM

2)The effect of sintering time on tensile performance

Uniaxial tensile stress-strain curves of GSFCWPM sintering at 900℃with different sintering time have similar trend,which are showed in Fig.8.Stress gets increased slowly with the increase of strain,once the maximum is reached,the stress begins to decrease rapidly to zero with the increasing of strain.The maximum tensile strength of GSFCWPM gets increased with the increase of sintering time.The maximum tensile strength of GSFCWPM sintering at 900℃for 30 minutes,60 minutes,90 minutes is 42 MPa,56.2 MPa,69.5 MPa,respectively.These results may be attributed to better combining action of the growth of sintering joints between fibers as well as fiber and copper board during longer sintering time,which can withstand greater unidirectional tension.What we can also see from the graph is that the elongation rate also gets increased with the increase of sintering time,but it has little difference.

Fig.8 Effect of sintering timeon tensileperformanceof GSFCWPM

3)The effect of porosity on tensile performance

The porosity of GSFCWPM is an important structural parameter,which has a great influence on tensile property.Fig.9 is the uniaxial tensile stress-strain curve diagram of GSFCWPM with different porosity.What can be seen from the chart is that the maximum tensile strength of GSFCWPM gets increased with the decrease of porosity.This could be explained as follows:there have more fiber silks and fiber nods of GSFCWPM,namely there exists more quantity of pore when its diameter is smaller in the same quality GSFCWPM with less porosity than that with more porosity.This means that when GSFCWPM undergoes uniaxial tensile force,the component force is born by unit cell composed of neighbor nodes,the pull born by porous unit cell with more pores is smaller than that with less pores,so the anti pull of GSFCWPM with less porosity is stronger than that with greater porosity.We can find that the elongation gets increased with the decrease of porosity through the further analyzing in Fig.9.

Fig.9 Effect of porosity on tensile performance of GSFCWPM

4 Conclusions

The tensile tests were conducted to investigate the tensile properties of GSFCWPM produced by sintering process.The GSFCWPM with high porosity exhibited the unique properties in the tensile failure process.The fiber parameter and sintering parameter were changed to study the tensile strength of GSFCWPM.Our experimental results indicated that the porosity played an important role to affect the tensile strength of GSFCWPM.Less tensile strength of GSFCWPM could be obtained when the fiber diameter was increased;Greater tensile strength of GSFCWPM could be obtained when the porosity was decreased.Besides,the sintering parameters also play important roles on determining the tensile strength of GSFCWPM.The tensile strength of GSFCWPM got increased with the increase of the sintering temperature in the range of 800 and 1 000℃.Moreover,the holding temperature time also could affect the tensile strength due to change of the microstructures of GSFCWPM.These results obtained in this work will not only help to further develop the groove fiber porous materials,but also provide an important technical guideline to widen the potential application of GSFCWPM.

[1]TAO Su-lian,TANG Yong,PAN Min-qiang,et al.Forming method of wick structure for heat column [J].Transactions of Nonferrous Metals Society of China,21(2011):1587-1594.

[2]TAO Su-lian,TANG Yong.Forming Technology of Composite Capillary Wick Structure for Heat Column and Its Optimization[J].Journal of South China University of Technology(Natural Science Edition),2011,39(6):29-35.

[3]JIANG Le-lun,TANG Yong,WU Hui-yue,et al.Fabrication and thermal performance of grooved-sintered wick heat pipe[J].J.Cent.South Univ.,2014,21:668 -676.

[4]Wang J,Catton I.Enhanced evaporation heat transfer in triangular grooves covered with a thin fine porous layer[J].Applied Thermal Engineering,2001,21:1721-1737.

[5]Yong Tang,Daxiang Deng,Longsheng Lu,et al.Experimental investigation on capillary force of composite wick structure by IR thermal imaging camera[J].Experimental Thermal and Fluid Science,2010,34:190 –196.

[6]Zhao Y,Chen C.An investigation of evaporation heat transfer in sintered copper wicks with microgrooves[C]//Proceedings of 2006 ASME International Mechanical Engineering Congress and Exposition,Chicago,IL,United states,2006:675-680.

[7]Franchi G,Huang X.Development of composite wicks for heat pipe performance enhancement[J].Heat Transfer Engineering,2008,29(10):873-884.

[8]ZHOU Rui,LU Longsheng.Manufacture of Compound Sintered Porous Metal with Copper Powder and Copper Foam[J].Material& Heat Treatment,2011,40(4):59-62.

[9]Chen yaoming.Performance enhancement research of Multilayer sintered heat pipe[D].Taiwan:National Taiwan University,2009.

[10]Rich quasi Precision Industry(Shenzhen)Ltd.Manufacturing method of sintering heat pipe[P].China,Application numbe:200510034104.5,2008.

[11]Xie Tianjin.Research on Fabrication and Thermal Performance of Sublevel Composite Wick Micro Heat Pipe[D].Guangzhou:South China University of Technology,2010.

[12]North M T,Rosenfeld J H,Shaubach R M.Liquid film evaporation from bidispersed capillary wicks in heat pipe evaporators[C]//Proceedings of 9th IHPC,New Mexico,United States,1995:143-147.

[13]Tao Su-lian,Zhou Qin-he,Lin Qing-wen.Compressive Properties of Groove Copper Fiber Composite Wick Copper Board.

- 机床与液压的其它文章

- Co-simulation and consumption analysis of wheel loader on negative loading condition

- Study on rigid-flexible coupling multi-body dynamic model and simulation for wind turbine

- Introduction of the Fluid Control Engineering Institute of Kunming University of Science and Technology

- Influence of the underlap in the poppet valve on its performance

- The research on engine stable frame report parsing of Boeing 747-400 by QAR data

- Comprehensive reliability evaluation of foreign high-end gantry machining Center