Dynamic rock tests using split Hopkinson(Kolsky) bar system-A review

Review

Dynamic rock tests using split Hopkinson(Kolsky) bar system-A review

Kaiwen Xia*,Wei Yao

Department of Civil Engineering,University of Toronto,Toronto,M5S1A4,Canada

A R T 1 C L E 1 N F O

Article history:

Received 22 March 2014

Received in revised form

11 June 2014

Accepted 24 June 2014

Available online 26 December 2014

Rock

Dynamic properties of rocks are important in a variety of rock mechanics and rock engineering problems. Due to the transient nature of the loading,dynamic tests of rock materials are very different from and much more challenging than their static counterparts.Dynamic tests are usually conducted using the split Hopkinson bar or Kolsky bar systems,which include both split Hopkinson pressure bar(SHPB)and split Hopkinson tension bar(SHTB)systems.Signifcant progress has been made on the quantifcation of various rock dynamic properties,owing to the advances in the experimental techniques of SHPB system. This review aims to fully describe and critically assess the detailed procedures and principles of techniques for dynamic rock tests using split Hopkinson bars.The history and principles of SHPB are outlined, followed by the key loading techniques that are useful for dynamic rock tests with SHPB(i.e.pulse shaping,momentum-trap and multi-axial loading techniques).Various measurement techniques for rock tests in SHPB(i.e.X-ray micro computed tomography(CT),laser gap gauge(LGG),digital image correlation(DIC),Moiré method,caustics method,photoelastic coating method,dynamic infrared thermography)are then discussed.As the main objective of the review,various dynamic measurement techniques for rocks using SHPB are described,including dynamic rock strength measurements(i.e. dynamic compression,tension,bending and shear tests),dynamic fracture measurements(i.e.dynamic imitation and propagation fracture toughness,dynamic fracture energy and fracture velocity),and dynamic techniques for studying the infuences of temperature and pore water.

©2015 Institute of Rock and Soil Mechanics,Chinese Academy of Sciences.Production and hosting by Elsevier B.V.All rights reserved.

1.Introduction

The accurate determination of rock dynamic properties has always been a very important issue for a variety of rock engineering and geophysical applications,including rock quarrying,rock drilling,rockbursts,blasts,earthquakes,and projectile penetrations.In these applications,rock materials are subjected to dynamic loading over a wide range of loading rates.Therefore,accurate determination of dynamic strength and fracture properties of rocks over a wide range of loading rates is crucial.However,in sharp contrast to many static rock testing methods suggested by the International Society for Rock Mechanics(ISRM),only three dynamic testing methods have recently been suggested by the ISRM Commission on Rock Dynamics(Zhou et al.,2012),including dynamic compression, dynamic Brazil test,and dynamic notched semi-circular bend (NSCB)test using split Hopkinson pressure bar(SHPB),while other methods are good candidates for future ISRM suggested methods.

SHPB system is an ideal and reliable high strain rate loading technique to measure dynamic properties of rocks under high strain rates(102-103s-1).As a widely used device to quantify the dynamic compressive responseof various metallic materials at high loading or strain rates,SHPB was invented by Kolsky in 1949 (Kolsky,1949,1953).Shortly after,researchers started to use SHPB to test brittle materials such as concretes(Ross et al.,1989,1995), ceramics(Chen and Ravichandran,1996,2000),and rocks (Christensen et al.,1972;Dai et al.,2010a).However,some major limitations of using SHPB for brittle materials were not fully explored until two decades ago(Subhash et al.,2000).

Several comprehensive reviews have been conducted concerning dynamic behaviors of brittle materials,such as mortar,ceramic, concrete and rocks(Bischoff and Perry,1991;Malvar and Ross, 1998;Zhao et al.,1999;Toutlemonde and Gary,2009;Walley, 2010;Zhao,2011)and dynamic experimental techniques(ASM, 2000;Field et al.,2004;Ramesh,2008).There are also reviews on rock dynamics and applications(Barla and Zhao,2010;Zhao et al., 2012)and dynamic experimental techniques and results(Xia,2012; Zhao et al.,2012;Zhang and Zhao,2014).The systematic discussion of dynamic experimental techniques for rocks using SHPB system isnot yet available.Therefore the objective of this work is to provide detailed procedures and principles of techniques for dynamic rock tests using SHPB.

This review is organized as follows.After the Introduction, Section 2 briefy describes the history and principles of SHPB system.Section 3 presents new loading techniques for dynamic rock tests and Section 4 discusses the advanced measurement techniques deployed in SHPB for testing rock materials.In Section 5,the dynamic strength measurements for rocks using SHPB system are frst critically assessed,including dynamic compression,tension, bending and shear tests.Dynamic fracture tests are then presented, followed by dynamic techniques concerning the infuences of temperature and water saturation level.Section 6 summarizes the entire paper.

2.History and principles of SHPB system

2.1.History of SHPB system

The name of SHPB was derived from John Hopkinson(1849-1898)and his son Bertram Hopkinson(1874-1918).John Hopkinson investigated the propagation of stress waves in the iron wire in 1872,and his son,Bertram Hopkinson,invented a pressure bar to obtain the pressure-time curve with the dynamic load exerted by detonation(Hopkinson,1914).However,the measurements were not accurate because of the limitation of the measurement technique.Davies(1948)improved the measurement technique by utilizing an electrical method.Later,Kolsky(1949)developed the split bar system,which included two bars(known as incident bar and transmittedbar)with a specimen in between.That is why SHPB is also called the Kolsky bar.Using his SHPB system,Kolsky obtained the dynamic relationship between stress and strain for several materials with condenser microphones.Shortly after that, Krafft et al.(1954)adopted strain gauge to measure the stress waves and applied a striker bar to produce a repeatable impact stress wave in the incident bar.In order to measure valid dynamic properties of different materials,Lindholm(1964)combined previous modifcations and designed an updated version of Kolsky bar system,which became a template of current SHPB system.Thereafter,the SHPB system has been continually improved to obtain more accurate measurements for different materials under high strain rate loading.

In addition to the compression version of Kolsky bar system-SHPB,the tensile version of Kolsky bar system-split Hopkinson tension bar(SHTB)was also developed to obtain the characteristics of materials under dynamic tensile loading.The initial design of dynamic tension apparatus was a hollow tube inside which a single elastic bar and a specimen were attached (Harding et al.,1960).This design was later replaced by placing the entire bar system inside a tube(Hauser,1966;Harding and Welsh, 1983).Meanwhile,the methods using the compression bar system to achieve tensile experiments were also proposed,such as the tophat specimen(Lindholm and Yeakley,1968),and a specimen with a rigid collar(Nicholas,1981).Moreover,other direct tension loading methods for SHTB were also developed:store elastic energy to stretch a section of incident bar in tension(Staab and Gilat,1991; Cadoni et al.,2009),an explosive loading device(Albertini and Montagnani,1974),a ballistic apparatus(Goldsmith et al.,1976),a rotating disk(Kawata et al.,1979;Li et al.,1993),a tubular striker (Ogawa,1984)to impact the fange attached to the incident bar.The design of a tubular striker in SHTB was followed by many researchers(Ross,1989;Li et al.,1993;Chen et al.,2002;Nie et al., 2009;Huang et al.,2010a)and became the standard design of modern SHTB system.The detailed SHTB confguration and procedure are discussed in Section 5.2.1.

The details of the Kolsky bar history,recent modifcation and application have been discussed in ASM handbook(Gray,2000),in the recent book(Chen and Song,2010),and in recent reviews (Nemat-Nasser,2000;Field et al.,2004;Gama et al.,2004;Jiang and Vecchio,2009;Ramesh,2008;Zhang and Zhao,2014).We will discuss the techniques and methods using SHPB for testing rocks in this work.

2.2.Principles of SHPB system

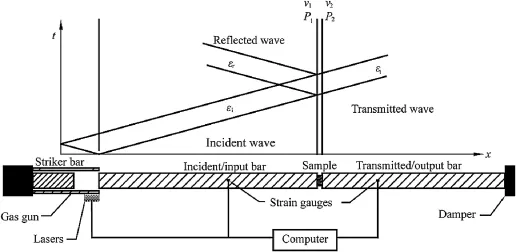

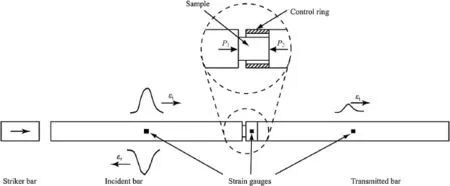

SHPB consists of three bars:a striker bar,an incident bar,and a transmitted bar(Gray and Blumenthal,2000).The impact of the striker bar on the free end of the incident bar induces a longitudinal compressive wave propagating in both directions.The leftpropagating wave is fully released at the free end of the striker bar and forms the trailing edge of the incident compressive pulse εi(Fig.1).Thus,the duration of εidepends on the length and longitudinal wave velocity in the striker.Upon reaching the bar-specimen interface,partof the incident wave is refected as the refected wave εrand the remainder passes through the specimen to the transmitted bar as the transmitted wave εt.Strain gauges are used to record the stress wave pulse on both incident bar and transmitted bar.The principles of the SHTB are similar to those of the SHPB,except that the way to generate the loading pulse and the way to grip the specimen are different as will be discussed later.

In most of the tests,the distance between the strain gauges and the sample should be known,which is needed to determine the starting point of incident,refected and transmitted pluses.Besides, the velocity of the striker bar can be measured by simple optical methods and the strain signals are usually collected using the Wheatstone bridge circuit with amplifcation.

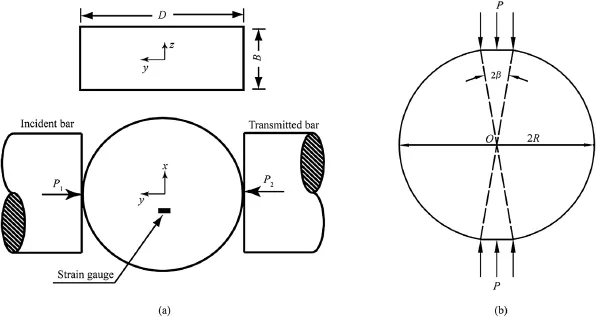

The diameter of bar is governed by the diameter of rock specimen,which should be at least 10 times the average grain size of the rock(Dai et al.,2010b;Zhou et al.,2012).Based on the onedimensional(1D)stress wave theory,the dynamic forces(see Fig.1)on the incident end(P1)and the transmitted end(P2)of the specimen are(Kolsky,1949,1953):

where E is the Young’s modulus;A is the cross-sectional area;εiand εrare the incident strain signal and refected strain signal, respectively.

The velocities at the incident bar end(v1)and the transmitted bar end(v2)are:

where c is the 1D longitudinal stress wave velocity of the bar.

The displacement of the incident bar end(u1)and the transmitted bar end(u2)are thus:

where t is the time.

Fig.1.Schematics of a split Hopkinson pressure bar(SHPB)system and the x-t diagram of stress waves propagation in SHPB(after Xia et al.,2011).

One of the objectives of an SHPB test is to determine the material dynamic stress-strain curve,from which the mechanical properties can be derived,e.g.dynamic failure strength,dynamic failure strain and dynamic Young’s modulus.Thus,several methods have been proposed to determine the dynamic stress-strain curve, i.e.one-wave analysis(Gray,2000;Mohr et al.,2010),two-wave analysis(Gray,2000;Gray and Blumenthal,2000),three-wave analysis(Gray,2000;Mohr et al.,2010),direct estimate(Mohr et al.,2010),foot-shifting method(Mohr et al.,2010),hybrid analysis(Perkins et al.,1970;Shan et al.,2000;Gilat et al.,2009),and inverse analysis(Zhao and Gary,1996;Peirs et al.,2011;Pierron and Forquin,2012).These methods have been widely used to calculate stress-strain curves.However,among these methods,one-wave analysis method is very popular because of the simplicity of the formula.The direct estimation method is recommended because it could provide the most accurate stress-strain curves(Mohr et al., 2010).The methods for determining the stress and strain histories in SHPB are critically reviewed(Gama et al.,2004;Zhang and Zhao,2014).To ensure the accuracy of the measurement results with the simple one-wave analysis,one has to guarantee valid testing conditions with some testing techniques,e.g.stress equilibrium for sample,failure sequencesof sample,slenderness ratio of sample,proper lubrication for minimizing the friction effect(Dai et al.,2010b;Zhou et al.,2012).

3.Loading techniques in SHPB system for testing rocks

3.1.The pulse shaping technique

Unlike ductile metals,brittle materials have small failure strains (<1%)and hence if the loading is too fast as in a conventional SHPB test,the specimen may fail in a non-uniform manner(i.e.the front of the sample may be shattered while the back remains intact).The loading pulse in the conventional SHPB system has an approximately trapezoidal shape accompanied by high level of oscillations. The oscillations induced by the sharp rising portion of the incident wave results in diffculty in achieving dynamic stress equilibrium state or constant strain rate in the sample.However,the stress equilibrium is a prerequisite for valid SHPB tests and the constant strain rate mainly depends on the rise of the incident wave. Moreover,the steep rise of the incident pulse can induce premature failure before dynamic stress equilibrium in the rock sample.

As a rule of thumb,it takes the loading stress wave to travel in the specimen 3-4 rounds for the stress to achieve such an equilibrium state.To achieve accurate measurements in SHPB tests,the dynamic loading has to be slow enough so that the specimen is experiencing an essentially quasi-static load,and thus the deformation of the specimen is uniform.

Frantz et al.(1984)discussed the incident pulse shaping for SHPB experiments of metal samples.Theyemphasized that a slowly rising incident pulse is a preferred loading pulse in order to minimize the effects of dispersion and inertia,and thus facilitate dynamic stress equilibrium of the sample.They also presented experimental results to show a properly shaped loading pulse cannot only provide stress equilibrium in the sample,but also generate a nearly constant strain rate in the sample.Gray and Blumenthal(2000)also discussed these issues in their review paper.Due to larger diameter of rock specimen,longer time is required to facilitate dynamic stress equilibrium of the sample,i.e. the equilibrium time should be 3-10 times of the transit time,the time for stress wave to transverse the sample once(Davies and Hunter,1963;Lindholm,1971;Ravichandran and Subhash,1994).

To change the shape of the incident pulse and to slow down its rising,one way is to modify the geometry of the striker.For example,Christensen et al.(1972)used striker bars with a truncated-cone on the impact end in an attempt to produce ramp pulses.Frantz et al.(1984)used a striker bar with a large radius on the impact face to generate a slowly rising incident pulse for the tests.Li et al.(2000)and Zhou et al.(2012)used tapered or coneshaped striker to generate an approximate half-sine loading waveform,which can achieve the dynamic stress equilibrium and constant strain rate in the rock sample.Another approach for shaping pulse is to place a pulse shaper rod(Gerlach et al.,2011)or an extra specimen between the striker and the incident bars (Ellwood et al.,1982).

The third way for shaping pulse,maybe a more convenient way, is to place a small thin disc made of soft materials between the striker and the incident bars.The disc is called the pulse shaper and can be made of paper,aluminum,brass or stainless steel,with 0.1-2.0 mm in thickness.During tests,the striker impacts on the pulse shaper before the incident bar,thus generating a non-dispersive ramp pulse propagating into the incident bar.This incident pulse with slow-rising front facilitates the dynamic force balance across the specimen(Frew et al.,2001,2002).The function of the pulse shaper is to(i)guarantee constant strain rate during the loading and(ii)maintain force equilibrium across the sample.A wide variety of incident pulses can be produced by varying the geometry of the pulse shaper(Fig.2).Depending on the materials under investigation,different loading pulses are needed and can be achieved with proper shaper design.

The pulse shaping technique is especially useful for investigating dynamic response of brittle materials such as rocks(Frew et al.,2001,2002).Without proper pulse shaping,a large fuctuation of dynamic force occurs on the incident side and a sizeable distinction exists between forces on the two ends of the specimen, thus,it is diffcult to achieve dynamic stress equilibrium in such materials because the sample may fail immediately from its end in contact with the incident bar upon the arrival of the incident wave.With a proper pulse shaper(e.g.copper),the incident wave is modifed from a rectangular shape to a ramped shape.In addition,a small rubber disc is placed in front of the copper shaper to further reduce the slope of rising portion of the pulse to a desired value.In this case,the forces on the two ends of the specimen do not have fuctuation and are almost identical before the maximum value is reached.Thus,the balance of dynamic forces on both ends of the sample can be achieved.

Fig.2.Different loading pulses produced by pulse shaping with shaper(after Xia, 2012).

3.2.Momentum-trap technique

Fig.3a is the photograph of the momentum-trap system for SHPB,which is composed of a momentum transfer fange that is attached to the impact end of the input bar and a rigid mass that is attached to the supporting I-beam for the bar system.

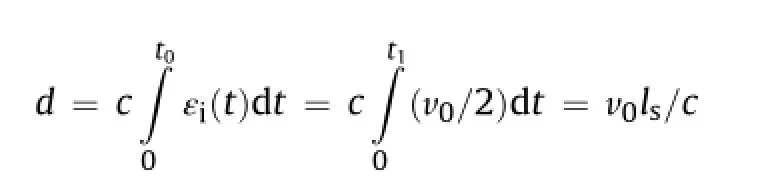

Denoting the length of the incident bar by l,it takes t0=2l/c for the refected wave to arrive at the impact end of the incident bar. The refection wave is then refected and changes from the tensile wave to compression wave at the input end.As a result,it will exert dynamic compression to the sample for a second time.In this way, the sample in a conventional SHPB will thus experience multiple compressive loading.This kind of multi-loading complicates the post-mortem examination of tested samples(Nemat-Nasser et al., 1991).A momentum-trap system similar to that proposed by Song and Chen(2004)is adopted here.The main idea of this method is to absorb the frst refection by a big mass that can be considered as rigid because of its large impedance(which is equal toρcA,whereρis the density)as compared with the bar.

As shown in Fig.3b,there is a gap between the fange and the rigid mass.The distance of the gap,d,is determined by the velocity of the striker,v0,the length of the input bar,l,and the shape of the input pulse.It is required that when the refection wave arrives at the front end of the incident bar,the fange is in contactwith the big mass.As a result,the refected compressive wavewill be changed to tension due to the interaction between the incident bar and the big mass through the fange.This requirement is expressed as

If there is no pulse shaper between the striker and the input bar, the particle velocity of the input bar after impact is 0.5v0for the case where the striker and input bar are made of the same material. Denoting the length of the striker by ls,the total duration of the loading pulse is t1=2ls/c,which is usually much smaller than t0=2l/c.The total displacement of the end of the incident bar (fange),which is equal to the gap between the fange and the rigid mass that we need to set is then

Fig.3.The momentum-trap system:(a)photograph and(b)x-tdiagram showing its working principle(after Xia et al.,2008).

If there is a pulse shaper between the striker and the incident bar,we should use the measured incident pulse to determine the size of the gap using Eq.(4).

As an example shown in Fig.4,the second compression is indeed reduced substantially by the momentum-trap so that the sample will experience essentially a single pulse loading.The second loading pulse is composed of a low amplitude compressive portion followed by a tensile portion.The tensile portion of the pulse will separate the incident bar from the sample,resulting in soft-recovery of the sample for valid post-mortem examination.It is noted that in this test only incident bar is used and thus the incident wave is 100%refected when there is no trap.

The momentum-trap can also be used in SHTB system.Nemat-Nasser et al.(1991)proposed a momentum-trap bar to get the single tension loading and Huang et al.(2010a)further developed this method,as shown in Fig.5.

Fig.4.Comparison of stress waves from the incident bar with and without momentum-trap(after Xia et al.,2011).

The tensile pulse is refected as a compression pulse at the interface between the incident bar and the specimen.If there is no momentum-trap with appropriate gap between the momentumtrap and the fange,the compression pulse will be refected as a secondary tensile pulse,propagating backand pulling the specimen again.The absorption bar 1 is placed next to the fange on the incident bar with a gap.The gap,which can also be calculated byEq. (4),should be accurately set to guarantee that the absorption bar 1 is in contact with the fange when the frst tensile pulse propagates into the incident bar through the fange.The compression pulse transmits into the absorption bar 1 and is trapped because the interface between the absorption bar 1 and the fange cannot support tension.

Moreover,to avoid the refection in the transmitted bar,a back absorption technique is developed,in which the absorption bar 2 is attached to the back end of the transmitted bar using a special joint (Fig.5).The absorption bar 2 has a fange attached to its front end. Before test,the absorption bar 2 is separated from the transmitted bar so that this joint is able to sustain tensile load.When the tensile load is refected at the back end of the absorption bar,it becomes compressive.The joint cannot sustain compressive load and thus the refected wave is trapped in the absorption bar 2.

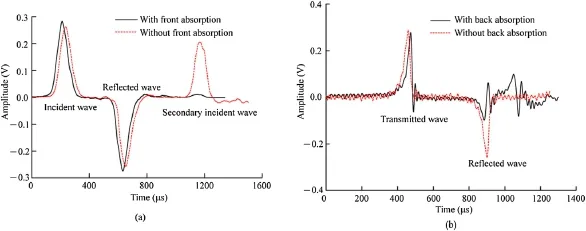

Fig.6a compares incident wave with and without front absorption bar.The second wave in the incident bar is reduced by 90% with the front absorption design.Fig.6b shows that the refection wave in the transmitted bar is signifcantly reduced by the back absorption method.The specimen is thus subjected to one tensile loading due to the combined momentum-trap method in SHTB.

3.3.Multi-axial loading techniques

There are two types of approaches to achieve multi-axial loading on specimen in SHPB,including true triaxial loading and multi-axial confning loading.For the former,Cadoni and Albertini (2011)designed the true triaxial loading apparatus.However,it is diffcult to carry out synchronized multi-axial dynamic loading during very short dynamic loading time.

The multi-axial confning loading can be classifed as axial confnement,lateral confnement and triaxial confnement,which are highly relevant to underground rock engineering problems.As shown in Fig.7,the rock mass around an underground opening can be divided into three zones depending on the distance to the opening.The confning stress states vary from the dominantlyhydrostatic state in the far zone,to the triaxial state in the intermediate zone,and to the tensile state in the near zone.To effectively consider the dynamic responses of underground rocks,it is thus desirable to submit rock samples to all of these three stress states before the dynamic loading.

Fig.5.Momentum-trap technique in SHTB system(reproduced from Huang et al.,2010a).

Fig.6.Comparison of(a)the waves in the incident bar with and without front absorption bar and(b)the waves in the transmitted bar with and without back absorption bar(after Huang et al.,2010a).

Fig.7.Zoning of the confning stress states around an underground opening.

In tradition the confned SHPB tests for brittle solids,usually lateral confnements were used,which were achieved by a hydraulic pressure chamber(Christensen et al.,1972;Malvern et al., 1991;Gary and Bailly,1998)or a passive thick confning vessel (Gong and Malvern,1990;Rome et al.,2004;Forquin et al.,2008, 2010).For fne-grained brittle solids like ceramics,other types of confnements were possible,such as a shrink-ft metal sleeve(Chen and Ravichandran,1996,1997;Yuan et al.,2011)and planar confnement(Paliwal et al.,2008).

Lindholm et al.(1974)conducted the pioneer work in the dynamic tests of rocks under hydrostatic confnement and proposed a system to determine the dynamic properties of rocks under triaxial confnement.It is composed of an SHPB system with two hydraulic cylinders and the sample is enclosed in the lateral confning cylinder.The lateral confning cylinder exerts confning stresses in the transverse direction and the axial confning cylinder applies the axial confning stress.Their original design was only recently improved by other researchers(Li et al.,2008;Frew et al.,2010).In their experimental design,Li et al.(2008)connected the two pressure cylinders with two tie-rods.Although they claimed that they can do triaxial confnement,they only showed results on axial confnement in their work.Using a very similar idea,Frew et al. (2010)designed a system that can apply hydrostatic confnement with four tie-rods to connect the two cylinders(shown in Fig.8). The method to achieve such a confning state is to frst expose the cylindrical rock sample to the confning fuid and then to maintain the same fuid pressure in both cylinders.They reported dynamic compressive responsesofIndiana limestone athydrostatic confning pressures up to 200 MPa and strain rates of 400 s-1.

3.4.Strain controlling technique

The ideal way to study the dynamic damage evolution in the brittle materials would be to use the real-time three-dimensional (3D)scanning,which has been applied in quasi-static studies (Raynaud et al.,1989;Kawakata et al.,1999;Feng et al.,2004; Desrues et al.,2006).However,it is very challenging to employ this method in dynamic tests.Thus,strain controlling technique, also known as deformation controlling method,was developed.

The principle of this method is to control the strain of specimen during dynamic tests.Huang et al.(2013)performed the SHPB tests with strain control ring to examine microscopic damage accumulation in brittle solids subjected to dynamic compressive loading. The system consists of a striker bar,an incident bar,a transmitted bar,and a strain control ring(shown in Fig.9).Pulse shaping technique was utilized to achieve dynamic stress equilibrium and to eliminate the inertia effect inside the sample subjected to dynamic loading.The forces on both ends of the specimen can be calculated by Eq.(1)and the history of the stress,strain and strain rate are then calculated(see Section 5.1.3).

A steel ring was mounted on the end of the transmitted bar (Fig.9).Because the impedance of the ring is the same as the bars and much larger than that of the rock,the deformation of sample will be essentiallyceased when its length is equal tothatof the ring. Before this point,the sample frst deforms freely.Thus,the strain of the sample is determined by the gap between the ring and the incident bar.With the different distances of the gap,the strain levels of specimen can be changed.

The stress-strain curves are shown in Fig.10 with the same loading condition.A complete stress-strain curve was achieved from the rock sample without constraining the strain.The stressstrain curves of all samples agree well with the complete stressstrain curve before contact points,where the incident bar hits the strain control ring.The good agreement validates this method of studying damage accumulation.The stress-strain curve after contact points represents the combination of behavior of the sample and the ring.This section of curve is dominated by the behavior of the ring,resulting in a deviation after the contact point in the curve.

4.Measurement techniques in SHPB system for testing rocks

Fig.8.Schematics of confned SHPB system for testing rocks(Frew et al.,2010).

Fig.9.Schematics of the SHPB with the strain control ring(after Huang et al.,2013).

Besides loading techniques in the SHPB system,quantitatively obtaining dynamic properties and strain(deformation)feld is critical for fully understanding the material behavior and failure mechanism.Traditional measurement techniques,such as strain gauges mounted on the bars and mechanical extensometers,provide limited information about dynamic behaviors of rock materials.Several optical measurement techniques were thus developed to capture fracture process and reveal fracture mechanism.The optical measurements for high rate deformation in rock-like materials have been reviewed by Field et al.(2004)and Zhang and Zhao(2014).In this section,the optical measurement techniques for rock materials in the SHPB test are discussed,along with X-ray micro computed tomography(CT)technique as a non-destructive pre-test and post-mortem material examination method for SHPB.

4.1.X-ray micro CT technique

The microscopic observation is critical for studying dynamic damage evolution and dynamic failure of brittle solids.X-ray micro CT can be used to examine the micro-cracks/voids inside the heattreated sample or rocks under static/dynamic loading(Feng et al., 2004;Huang et al.,2013).The CT value(Hounsfeld radiological density)is used to represent the attenuationwhen the X-ray passes through the material,and to indicate the density of materials after scaled with standard materials with the unit of Hu(-1000 Hu for air and 0 Hu for pure water).Thus,the average CT values of samples can be used to describe the damage introduced by the heattreatment or static/dynamic loading.

Fig.10.The stress-strain curves of samples under various strains(after Huang et al., 2013).

Because the damage of sample is usually presented as three dimensions,thetraditionaltwo-dimensional(2D)microscopic observation technique of SEM(Huang et al.,2010b;Yin et al.,2012) usually provides incomplete information and involves sample cutting and polishing(Curran et al.,1987).As a promising unique nondestructive method,X-ray CT technique can provide a 3D microscopic observation to investigate physical properties and failure mechanics of geomaterials(Vinegar,1986;Renter,1989;Vinegar et al.,1991;Van Geet et al.,2000;Mees et al.,2003;Otani and Obara,2004;Viggiani et al.,2004;Matsushima et al.,2006;Yun et al.,2013;Jia et al.,2014).Real-time X-ray scan has been introducedtoobservethefracturemechanismandthedamageevolution for rocks under static loading(Raynaud et al.,1989;Vinegar et al., 1991;Kawakata et al.,1999;Feng et al.,2004;Viggiani et al.,2004; Desrues et al.,2006;Bésuelle et al.,2010;Parab et al.,2014).However,it is diffcult and challenging to achieve this in dynamic tests. Recently,Luo et al.(2012)used X-ray phase contrast imaging(PCI) technique to acquire 2D image of samples under dynamic loading. Hudspethetal.(2013)alsoutilizedX-rayPCImethodtoimagesingle particle sand interaction,fber-epoxy interfacial failure and singlecrystal silicon fragmentation due to dynamic compression and tensile loading.The Kolsky bar systems with synchrotron X-ray PCI technique achieved an image with 500 ns temporal resolution and 2μm spatial resolution,through which the in situ interior of the materialsystemduringhighrateloadingwasanalyzed.Shortlyafter, high-speed synchrotron X-ray PCI technique was utilized to study thedamagemechanismsinsandparticlesunderdynamic compressive loading(Parab et al.,2014)and to monitor the in situ damage history in a dynamically deforming specimen(Chen et al., 2014).Whereas this technique has limited feld of view(2-10 mm)and can only offer a series of 2D results during dynamic loading.An effcient waytoovercome these limitations is torecover the sample at different deformation levels and conduct postmortem examination(Curran et al.,1987).

Huang et al.(2013)employed X-ray micro CT method and strain-control ring in the SHPB tests to observe microscopic damage accumulation in brittle solids subjected to dynamic compressive loading.X-ray micro CT with high resolution was used to examine the 3D microcrack inside the recovered rock sample under various strains.The low density areas are the cracks shown as black lines in Fig.11a;while the high density areas are the mineral grains shown as white and gray.Cracks were recognized and transferred to white pixels,while the remainder is transferred to black pixels in Fig.11b.

Two perpendicular views of the sample are provided in Fig.12, with gray dots representing low density constituents in the sample such as voids and cracks.

Fig.11.Processing of CT images:(a)8-bit gray image;(b)processed crack pattern image(cracks shown as white)(after Huang et al.,2013).

4.2.Laser measurement techniques

Thelasermeasurementtechniquesareusuallyused for measuring the specimen deformation(Li and Ramesh,2007; Ramesh and Narasimhan,1996)or the crack opening displacement(COD)(Tang and Xu,1990;Chen et al.,2009).The principle of laser measurement technique for obtaining the COD is that the luminous fux of laser or light passing through a chink on the specimen is proportional to the electrical signal.When the amount of laser passing through the chink on the specimen increases with the COD,the increasing illuminated energy can be detected by high frequency laser/light detector and thus the variation of COD can be also calculated by the electrical signal recorded.

In the fracture tests conducted by SHPB system,a laser gap gauge(LGG)system was utilized to monitor the opening of the notch and thus to reduce the opening velocity of the cracked fragments(Chen et al.,2009).As shown in Fig.13,the system consists of three major components:the collimated line laser source,the sensing system and the mounting system.LGG is mounted perpendicular tothe bar axis and the laser passes through the notch in the center of the specimen.

Fig.12.3D imagesof microcracks in the rocksample viewed from twoangles.Gray dots represent cracks and the black arrows are the view directions(after Huang et al.,2013).

Before the test,the calibration of LGG system should be conducted under both static and dynamic conditions(Chen et al., 2009).For static calibration,a set of high accurate gauges was used to partly block the probe laser.With the increase of blocking width,a specifc blocking width corresponded to a light-passing widthΔdand a certain amount of voltage readingΔUin the detector.Then,the calibration parameter of the LGG system can be calculated.For the dynamic calibration,while one end of the incident bar was impacted with the striker bar,the LGG was used to monitor the motion of the other free end of the incident bar.The displacement of the free end of incident bar can be obtained from the incident and refected waves measured from the strain gauge glued on the incident bar with the following formula:

During the test,as the notch opens up,the amount of light passing through the specimen increases,leading to a higher voltage output from the detector.The voltage is linearly proportional to the gap width and thus the crack surface displacement can be reduced. The detailed experimental procedures using the LGG system in the SHPB testing are presented in Section 5.4.

Fig.13.Schematics of the LGG system(after Chen et al.,2009).

4.3.Digital image correlation(DIC)

With the progress of advanced image processing methods (Siviour et al.,2011),high-speed calculation and high-speed camera,the DIC technique has become a promising and popular tool for brittle materials in high loading rate tests(Siviour and Grantham, 2009;Sutton et al.,2009;Zhang and Zhao,2013a;Gao et al., 2014).On one hand,this technique can be applied to experiments with a broad feld range from microscale to feld scale.On the other hand,adopting the high-speed camera with the high spatial and temporal resolution,the DIC technique can also be applied to a wide range of loading rates(Zhang and Zhao,2013a).

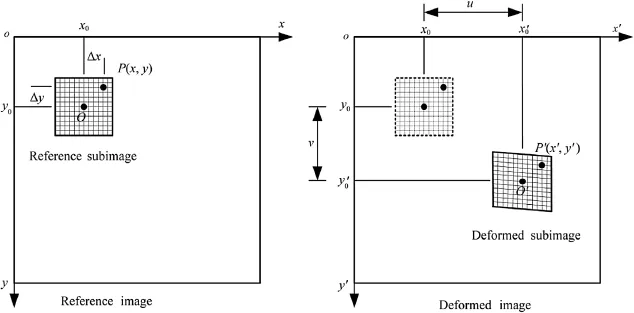

Asanon-contactandopticalfull-feldmeasurementmethod,the DIC technique is easy to be applied and provides satisfactory resolution of the displacement feld.The DIC method deals with a reference image recorded before deformation and a series of deformed images recorded after deformation.The basic principle of DIC is to track and match the same pixel points located in various deformedimages(asshowninFig.14).Generally,insteadoftracking a single pixel,a square reference subset or subimage (2N+1)×(2N+1)centered at the considered point is chosen and tracked in the deformed images using selected correlation function such as zero-normalized cross-correlation(ZNCC)(Bornert et al., 2009;Pan et al.,2009;Rastogi and Hack,2012;Amiot et al.,2013). The purpose of DIC algorithms is to fnd the displacement of the center of each subimage.By optimizing the correlation coeffcient, the location of a subimage in the deformed image is found and the displacement components of this subset center can be determined. The corresponding point P′(x′,y′)after deformation related to the coordinate P(x,y)in reference image can be calculated as

where u,v are the displacement components of the subset center point O in x,y directions,respectively;Δx andΔy are the distances from point P to point O;and∂u/∂x,∂u/∂y,∂v/∂xand∂v/∂yare the gradients of displacement components for the subset shown in Fig.14.By optimizing the correlation function,the peak position of the distribution of correlation coeffcient can be searched and thus the horizontal displacementuand the vertical displacementvcan be determined.If the same tracking procedure is repeated on the other points of interest,full-feld displacements of the zone of interest(ZOI)are obtained.Then,the full-feld strains can be computed from the full-feld displacement.Finally,other parameters,e.g.stress,fracture toughness,and fracture velocity,can be calculated from the full-feld strains(Hild and Roux,2006;Avril et al.,2008;Pan et al.,2009;Rastogi and Hack,2012;Gao et al., 2014).

The SHPB experimental setup for DIC measurement is shown in Fig.15,which mainly includes a striker,an incident bar,a transmitted bar,an absorption bar and a high-speed camera.The incident wave signal was used to synchronize the high-speed framing camera and the fash light in the tests.The focus of high-speed camera was adjusted manually under focused mode to obtain images with optimal quality.The captured images were processed frst to enhance image qualityand then used for post-analysis using a program to obtain the surface deformation characteristics(e.g. displacement and strain felds,onset of fracture).

With the DIC technique,the SHPB tests were performed to determine dynamic properties of rocks(Zhang and Zhao,2013a, 2013b;Gao et al.,2014).The displacement and strain felds during the whole process were frst determined using DIC method.The location of the crack tip,the fracture initiation toughness,the fracture propagation toughness,the fracture energy,the dynamic tensile strength,and the dynamic uniaxial compressive strength were subsequently calculated using the deformation felds.The DIC method also provides much more information on the fracture propagation process and the reliable full-feld strain felds in the specimens under dynamic loads(Zhang and Zhao,2013a).

4.4.Moiré methods

Moiré techniqueshavebeen introduced to measure the displacement felds of specimens.Dynamic Moiré techniques have also been developed to measure the critical time of dynamic fracture and wave and fracture propagation in rock samples(Daniel and Rowlands,1975;Yu and Zhang,1995;Zhang et al.,1999).

Fig.14.Schematics of reference and deformed subsets(after Gao et al.,2014).

Fig.15.Schematics of the SHPB testing system with high-speed camera(after Gao et al.,2014).

The confguration of dynamic Moiré method is shown in Fig.16. Two optical gratings were mounted to each side of the specimen separated by the main crack plane.The centers of both gratings were installed on the same section of the tip of the pre-machined crack.During dynamic fracture,the COD increases with time.Then, the value of COD can be recorded from the relative movement of the two gratings.Once the crack approaches the critical state,the speed of the crack open displacement(SCOD)reaches an extreme value.This moment is considered to be the critical time of dynamic fracture,which can be determined by the curve of the SCOD with time obtained by experimental results(Yu and Zhang,1995).

The magnitude of signal recorded from the two optical gratings on the specimen changes periodically.According to the operating principles of the optical gratings,one period of the signal represents a constant displacement in which the two gratings move relatively to each other.The total displacement represents the COD. Then the data of the COD with time can be obtained and thus the SCOD with time can be derived from the COD.The values of the critical time of dynamic fracture measured by the dynamic Moiré method can be determined and the corresponding fracture toughness can also be calculated(Zhang et al.,1999).Because the measurements are inferred from the gratings,the inertial effect of the gratings is assumed to be negligible.

4.5.Caustics method

The caustics method has been employed to investigate dynamic fracture of transparent materials(Field et al.,2004;Ravi-Chandar, 2004)and opaque material with refective surface(Yang et al., 2009).The caustics method for transparent materials requires mirror surface fnish of the specimen,which is hard for rocks. Therefore,this caustics system is not applicable for rock materials (Field et al.,2004;Zhang and Zhao,2014).A refective dynamic caustics system is shown in Fig.17.This system is employed with an impact load system,a multi-spark high-speed camera and a light to electric signal transducer.The high-speed camera system contains a 4×4 array point light source,feld lenses,a half-refective mirror, and a 4×4 array camera.The output aperture of the spark gapshould be small enough to generate a point light source for obtaining the caustic spot.The light from each spark is frst refected by the mirror surface of the specimen.It then enters into the camerawhere the caustic images are obtained.A time delaycontrol circuit was applied to synchronize the impact load with the sparks (Yang et al.,2009).

Fig.16.Schematics of the dynamic Moiré technique.(1)Rock specimen;(2)optical gratings;(3)He-Ne laser;(4)optical conductive fber;(5)photo-multiplier;(6)transient recorder;and(7)high-voltage power(after Zhang et al.,1999).

Fig.17.Schematics of experimental optical system for refected caustics.S-light source,F-feld lenses,M-half-refective mirror,L-camera,R-reference plane(after Yang et al., 2009).

With the caustic image,the location of crack tip during crack propagation can be accurately determined.Hence,the crack growth length and the crack growth velocity can be measured at each time instance.Besides,according to the caustic patterns of crack tip propagation in mode I,values of the dynamic stress intensity factor (SIF)can be determined as follows(Yang et al.,2009):

whereDmaxis the maximum transverse diameter of the caustic at the crack tip;ηis a convergence factor for incident light,η=Z1/ (Z1+Z0),Z0is the distance between the specimen plane and the image plane,Z1is the distance from the reference plane to the focus;dis the effective thickness of the specimen;ζis the dynamic optical constant;andF(v)is a velocity correction factor.

It is noted that the caustic method is based on singular term of the dynamic stress feld around a crack.For a fast propagation fracture,more terms are necessary to describe the stress feld and thus error of the caustic method would be signifcant(Xia et al., 2006).

4.6.Photoelastic coating method

The photoelastic coating method extends photoelastic method to measure the surface full-feld stress on opaque materials.The photoelasticcoatingtechniqueconsistsofalightsource,asetofrefection polarizer sheets,birefringent coatings and a camera.This method requires elaborate and well-polished surface of the specimen.Since a thin sheet of photoelastic material is glued directly to the wellpolished surface of materials with a refective cement,the photoelastic coating will deform with the material.Thus,in the coating,the strainfeldwillbeproduced,representingthestrainfeldofmaterials. By employing a set of refection polarizer sheets,the isochromaticfringe patterns can be recorded and thus used to determine the crack propagation and dynamic parameters of rock material.

A qualitative investigation of wave and crack tip propagation in marble specimen has been performed by Daniel and Rowlands (1975).However,the failure of a continuous birefringent coating on specimen may cause error since the coating failure may not represent the fracture of material.To address this problem,a split birefringent coating can be glued on the both sides of the anticipated path of the crack(Zhang and Zhao,2014).

4.7.Dynamic infrared thermography

Using the energy dissipation and temperature variation due to bulk dynamic deformation and fracture,the infrared thermography can transform the thermal energy emitted by specimen in the infrared band spectrum into a visible image.Shi et al.(2007) employed thermal infrared(TIR)imager to monitor the transient process of marble plates impacted by a high-speed striker.By using thermal infrared radiation camera,the thermal infrared radiation energy can easily be measured since there is a distinct variation in temperature due to impact.The results show that there is a critical impact velocity at which target thermography is regular and centrally symmetrical and this method might be extended to analyze the fracture and strain feld for rock materials under dynamic loading.

5.Dynamic testing methods for rocks

5.1.Dynamic compression tests

The compression tests of SHPB are based on two fundamental assumptions:(i)1D elastic wave propagation in the bars and(ii) homogeneous deformation of the sample(Kolsky,1953).The assumption of 1D stress wave propagation is ensured by using long bars,and the elasticity of the bar deformation is guaranteed throughout the test bylimiting the impacting velocityof the striker. The homogeneity of the sample deformation is affected mainly by two factors:inertial effects(i.e.the axial inertial effect and the radial inertial effect)and the interfacial friction effect.

5.1.1.Inertia effects and slenderness ratio

For high strain rate tests,inertial effect becomes more signifcant,which has to be reduced or eliminated to carry out valid and precise dynamic tests.The inertial effect attributes to the apparentstress and the size of the specimens(Field et al.,2004).The ideal slenderness ratio(i.e.the length to diameter ratio)of the sample has long been studied because it plays a major role in the inertial effects during the dynamic SHPB test.Based on the synthetic analysis of both axial and radial inertia effects,Davies and Hunter (1963)suggested an optimal slenderness ratio ofL/D= 3ν/2, whereLis the length of the cylindrical sample,andνis the Poisson’s ratio of the testing material.This suggested slenderness ratio has been frequently used to design the sample geometry for metals (Meng and Li,2003).To limit the inertial effects associated with stress wave loading,the slenderness ratio of samples cannot be too large.When SHPB is frst introduced to the dynamic testing community,the incident wave is in rectangular shape with a sharp rising edge and high oscillation,it is harder to minimize the axial inertial effects because it takes longer time for the sample to reach stress equilibrium.However,with developed pulse shaping technique(Frew et al.,2001,2002),even a relative long compressive sample can easily obtain stress equilibrium,thus reducing the axial inertial effects to a negligible amount.For the radial inertia effect, signifcant progress has been accomplished in experimental tests (Zhang et al.,2009),theoretical investigations(Forrestal et al., 2007)and numerical simulations(Li and Meng,2003;Li et al., 2009;Lu et al.,2010).These studies demonstrate that inertialinduced radial confnement makes a large contribution to the enhancement of compressive strength when the strain rate is greater than the critical transition value,and the radial inertial effect is proportional toD2s,whereDsis the diameter of sample.A review of radial inertial effect on the compression behavior of concrete was presented by Bischoff and Perry(1991).

5.1.2.Friction effect

Friction effect is another major concern in SHPB test.As early as SHPB was frst introduced as a useful dynamic testing tool,it was realized that the interfacial friction on both ends of the sample may affect the testing results(Kolsky,1949,1953).When the sample is loaded by the compressive stress wave in the SHPB test,it expands radially due to the Poisson’s effect.If the sample/bar interfaces are notsuffciently lubricated,the resulting interfacial friction force can be signifcant.This friction force infuences the accuracy of the testingresultsby applyingadynamicconfnementtothe compressive specimen,whose stress state should be uniaxial by assumption.This additional sample stress can yield pseudo rate effects of the material(Scheyet al.,1982),e.g.Shewmon and Zackay (1961)mistakenly concluded that the aluminum alloy was a rate sensitive material because they glued the sample on the bars during their tests.In addition,the sample is no longer deforming uniformly because of this dynamic confnement(Narayanasamy and Pandey,1997),whose effect is the largest on the ends and diminishes toward the center of the specimen.Bell(1966)examined the distribution of stress and strain in the SHPB tests and found that there exists marked discrepancy between the measured strain from SHPB data reduction and the strain directly measured from the sample surface.With the fnite difference method,Bertholf and Karnes(1975)simulated SHPB tests on samples with three types of slenderness ratios and interfacial frictions to investigate both inertial effects and interface friction effects.They drew the same conclusions as Bell(1966)that without enough lubrication at the boundary interfaces,the stress state in the sample is inhomogeneous and big deviation of measurement occurs inevitably. Malinowski and Klepaczko(1986)presented a united analytic and numerical approach to investigate inertia and friction effects in SHPB tests on annealed aluminum with consideration of energy balance.They concluded that proper treatment of frictional effects along with inertia is crucial for the determination of accurate material response during plastic deformation.Some researchers have performed experiments on ring specimens and have suggested that the friction effect can be well reduced(Hartley et al.,2007;Zhang et al.,2009;Alves et al.,2012).Gray(2000)stated that friction can be reduced by minimizing the area mismatch between the specimen and bars(DS≈0.8DB).Meng and Li(2003)revisited the combined effects of slenderness ratio and the interface friction numerically.Lubrication is recommended to minimize the friction effect,but cannot eliminate the friction effect.

To limit the friction effect,the slenderness ratio of a compressive sample should be large enough.This can be manifested from a recommended slenderness ratio of 2 or larger for static compressive tests of rocks by the ISRM(Bieniawski and Bernede,1979).On the other hand,the slenderness ratio should be short enough to limit the inertia effects.Thus,an optimal slenderness ratio is needed to minimize both the inertial effects and the friction effect (Xia,2012).

5.1.3.Dynamic uniaxial compression method

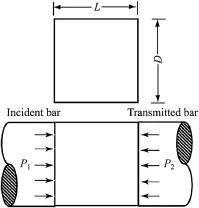

Dynamic compression is the most common test using SHPB.The histories of stressσ(t),strain ε(t)and strain rate˙ε(t)within the sample in the dynamic compression tests(Fig.18)can be derived as (Kolsky,1949):

whereAis the area,andA0is the initial area of the sample. Assuming that the stress equilibrium condition or uniform deformation prevails during dynamic loading(i.e.P1=P2or εi+εr=εt) in Eq.(8),Eq.(8)can be rewritten as

Fig.18.The sample in the compression test using SHPB(after Dai et al.,2010b).

To avoid end effect,the sample with slenderness ratio of 2 or larger is normally used in static compression tests.As discussed above,the slenderness ratio has been a fundamental issue in dynamic compression tests with SHPB because it has a majorinfuence on the axial inertia effects for the tests.Shorter samples facilitate dynamic stress equilibrium and are thus preferred.The higher the slenderness ratio of the sample,the higher the axial inertial effects,and the lower the relative radial inertial effects(also the friction effects).

In conventional SHPB tests,a rectangular incident wave is generated by a direct impact of the striker to the free end of the incident bar.This incident wave features a very sharp rising part with signifcant oscillations.Thus,for standard SHPB method,the recommended slenderness ratio is from 0.5 to 1(Gray,2000). However,for brittle solids like rocks with small failure strain,the sample may fail immediately from its end when it is impacted by the incident bar.Hence,the pulse shaping technique has been widely utilized for SHPB testing on brittle materials such as rocks. With the pulse shaping technique,the striker impacts the pulse shapers right before the incident bar,generating a non-dispersive ramp pulse propagating into the incident bar and thus facilitating the dynamic stress equilibrium in the specimen(Frew et al.,2001, 2002).Under stress equilibrium,the stress gradient vanishes,and inertial effects induced by stress wave propagation are thus minimized.Xia et al.(2008)used the C11000 copperdisc in combination with a small rubber disc together as the shaper to transform the incident wave from a rectangular shape to a ramped shape.Fig.19 shows the dynamic stress in a typical dynamic compression test.It is shown that the time-varying stresses on both sides of the samples match with each other before the peak point is reached during the dynamic loading.The sample is thus in a state of dynamic stress equilibrium.It is also noted that the resulting stress on either side of the sample also features a linear portion before the peak,thus facilitating a constant loading rate via˙σ=k1A/A0.The parameterk1in the equation is illustrated in Fig.19.Since there is no stress gradient in the sample(dynamic stress equilibrium has achieved), the axial inertial effect is thus negligible.

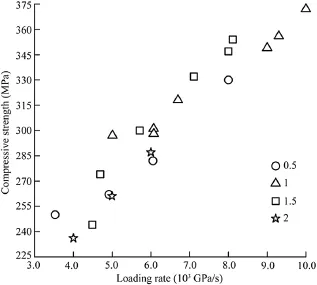

Without the axial inertial effect for brittle materials in SHPB tests,the effect of the slenderness ratio on dynamic compressive strength of rock-like materials has also been studied under the dynamic stress equilibrium(Dai et al.,2010b).As shown in Fig.20, there are no signifcant differences of strengths from samples with selected slenderness ratios.For dynamic compression tests on rocks,it can be concluded that with bar/sample interfaces fully lubricated and thus with axial inertial effects minimized,the slenderness ratio has little infuence on the testing results within the range of 0.5-2.Therefore,the samples with a slenderness ratio of 1 are recommended in dynamic compression tests of rocks for convenience since it is diffcult to hold shorter samples during sample fabrication.In the ISRM suggested methods for rock dynamic compression,both slenderness ratios of 0.5 and 1 are acceptable(Zhou et al.,2012).

Fig.19.Dynamic stresses on both ends of disc specimen tested using a modifed SHPB with careful pulse shaping(after Dai et al.,2010b).In,Re,Tr denote incident,refected and transmitted wave,respectively.

Fig.20.Dynamic compressive strengths with loading rates measured from rock samples with varying slenderness ratio of 0.5,1,1.5 and 2(after Dai et al.,2010b).

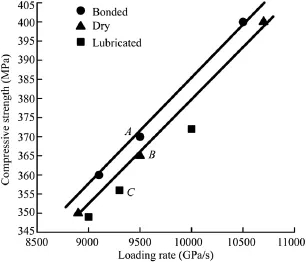

To manifest the friction effect on the measured strength,the samples with three different friction boundaries on the bar/sample interfaces for the sample slenderness ratio of 1 were used by Dai et al.(2010b):fully lubricated with vacuum grease,dry and bonded.The bonded bar/sample interface completely restricts the motion of the rock surfaces on the barand is believedtoprovide the maximum dynamic confnement to the sample.Fig.21 illustrates the trend of the rate effects of compressive strength under these three boundary friction conditions with dynamic stress balance on both ends of the sample and a constant loading rate.Samples with bar/samples interfaces fully lubricated yield the lowest measured compressive strength while the samples with bonded interfaces own the highest.Thus,the friction effect in dynamic compressive tests on rocks is signifcant.The measured compressive strength increases with increasing friction involved in the tests.To obtain the actual dynamic compressive response of rocks,the bar/sample interfaces should be suffciently lubricated.

Fig.21.Dynamic compressive strengths with loading rates measured from rock samples(L/D=1)with three interfacial friction boundaries(after Dai et al.,2010b).

With three types of lubricated bar/sample interfaces,the recovered samples from the tests with the data points ofA,BandCin Fig.21 show the quite different damage levels,although the samples in these three typical tests were approximately subjected to the same incident wave.With bar/sample interfaces fully lubricated,the samples are completely fragmented into small pieces, featuring a typical splitting failure mode.This failure mode confrms 1D stress states during the dynamic tests.In contrast,with friction constrain at the boundary interfaces,the splitting is constrained signifcantly and the recovered samples feature a shear cone.It can be concluded that without proper lubrication,the measured strength values will be over-estimated and the failure mode will also be quite different.

5.2.Dynamic tension test

For rock materials,dynamic tension tests can be approximately categorized into two approaches:direct tension(Howe et al.,1974; Goldsmith et al.,1976;Huang et al.,2010a)and indirect tension (Klepaczko and Brara,2001;Wu et al.,2005;Schuler et al.,2006; Dai et al.,2008;Kubota et al.,2008;Wang et al.,2009;Zhou et al.,2012).For dynamic direct tension method,the specimen is subjected to dynamic tensile load which is directly generated by SHTB.The dynamic indirect tension method includes Brazilian disc (BD)method(Zhou et al.,2012),semi-circular bend(SCB)method (Dai et al.,2008)and spalling method(Klepaczko and Brara,2001; Wu et al.,2005;Kubota et al.,2008;Erzar and Forquin,2010).

5.2.1.Dynamic direct tension method

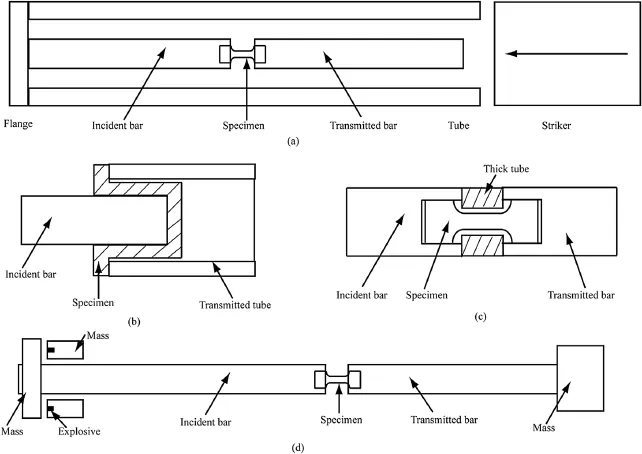

In order to generate directly dynamic tensile loading in specimen,the tensile versions of Kolsky bar system have been designed.The early design of dynamic tension experiments was a hollow tube,inside which incident and transmitted bars with a specimen sandwiched in between are placed(Hauser,1966; Harding and Welsh,1983)(Fig.22a).The principle of this device is to convert the external axial compression impact in external tube into tension wave in incident bar via the external tube where the Kolsky bar system is placed.This approach was just an extension of a compression version of Kolsky bar system and directly utilized the launching system of a compression bar system.However,since the whole setup was inside a solid tube,it is inconvenient for instrumentation(e.g.strain gauge)and direct observation of the specimen deformation.Then,a new confguration with top-hat specimen was proposed by Lindholm and Yeakley(1968),where a top-hat specimen is placed between the solid incident bar and the hollow transmission tube(Fig.22b). When the compression stress wave in the incident bar arrives at the specimen,a tensile load is produced on the specimen gauge section and a compression stress wave is transmitted into the transmitted tube.The advantage of this design is that the specimen does not need to be attached to the bar ends.Nicholas(1981) introduced a way to use only the compression bar system to achieve tensile experiments(Fig.22c).The modifcations include (i)the specimen which is threaded into the incident bar and transmitted bar,and(ii)a rigid collar placed over the specimen. The function of rigid collar allows the initial compression wave to pass through the collar without virtually touching the specimen and most of the initial compression energy is transferred into the transmitted bar.The transmitted compression wave is refected to be a tensile wave,and propagates back to load the specimen only because the collar cannot support tensile load.However,in this design,the specimen with the collar will inevitably deform when subjected to the initial compression wave.

Fig.22.Schematics of four types of dynamic direct tension methods.

The most effcient loading method for Kolsky tension bar is direct tension.The frst way is to store elastic energy bystretching a section of incident bar in tension(Staab and Gilat,1991;Cadoni et al.,2009).A clamp is used to divide the pre-stressed and stress free section in the incident bar.Suddenly releasing or breaking theclamp can release the stored energy and produce tensile stress waves which load dynamically on the specimen in form of tension. Nevertheless,it is diffcult to control this sudden release of energy. The second way of direct tension loading is to impact a fange at the end of the incident bar.A rotating disk with an impact hammer is an approach to strike the fange(Kawata et al.,1979;Li et al.,1993). The hammer,which is released by a controller at a certain speed, impacts on the block which is linked with the incident bar by a fxed metal bar.This fxed metal bar is then fractured by stretching, which generates a tensile stress wave in the incident bar.Albertini and Montagnani(1974)used both a rapid fracture of a clamp in a pre-stressed bar and an explosive loading device to produce a tensile pulse into the incident bar(Fig.22d).Goldsmith et al.(1976) employed a ballistic impact to generate a tensile pulse.In this design,a short platewas attached toone end of theincident barand a ball was shot at the plate using a gas gun placed next to the bars. The tensile pulse in the bar may be accompanied by the bending wave which was generated by the asymmetric loading.

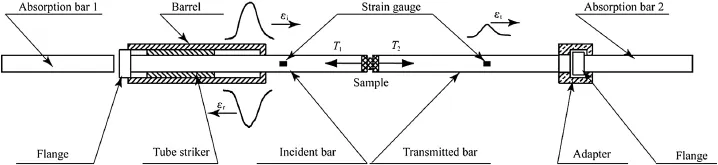

Another direct tension loading is to utilize a tubular striker to impact the fange of the incident bar.Sliding freely on the incident bar,the tube impacts on the fange attached to the end of the incident bar,producing a tensile stress wave(Ogawa,1984).The design is similar to the compression version of Kolsky bar except the tube striker and connection between the specimen and bars, and becomes the standard design of modern SHTB.

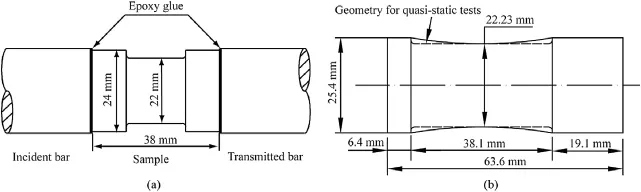

The SHTB system for measuring the dynamic tensile strength is shown in Fig.23,which consists of a striker tube,an incident bar,a transmitted bar,and two absorption bars.The stress pulse is measured by two strain gauges,which are mounted on the incident bar and the transmitted bar,respectively.For ductile material,the screw thread connection was widely utilized to employ the tension specimen in the bar system.This connection method usually induces inevitable gaps between specimen and bars,which causes multiple mini-impacts in the gaps and thus results in oscillations in stress wave and signifcanterror in data reduction.Thus,epoxyglue is used to attach the specimen to the incident bar and the transmitted bar,which signifcantly improves the quality of the waves. Two types of rock specimens for direct tensile test were designed: dumbbell-shaped specimen(Fig.24a)(Huang et al.,2010a)and bone-shaped specimen(Fig.24b)(Howe et al.,1974;Goldsmith et al.,1976).

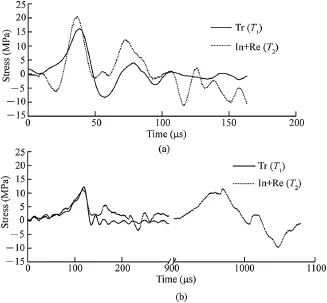

The tensile force on both ends of the specimen can be calculated by Eq.(1)and the histories of stress,strain and strain rate can be obtained from Eq.(9).In order to achieve dynamic force equilibrium,the pulse shaping technique was used during dynamic loading.Fig.25 shows a typical tensile force without and with the pulse shaper,whereT1andT2are the tensile force on both ends of the specimen,respectively.Without the pulse shaper,the force mismatch betweenT1andT2exists,which induces error for tensile strength.However,with the pulse shapers,the dynamic force balance is achieved during entire loading period and the inertial effects thus can be eliminated.Since the impact surface is the crosssection of tube,two copper discs are placed symmetrically on the incident fange.The striker tube impacts the two copper discs prior to the incident fange.The deformation of two copper discs generates a smooth rising tensile pulse propagating into the incident bar.

Fig.26 shows the tensile strength values of Laurentian granite increasing with the increase of the loading rate.This trend is characterized by a linear ftting in Fig.26.

The nominal surface energy of Laurentian granite can be calculated by fracture energy and the area of the new surface.The fracture energy can be derived from the difference of the energies carried by the incident,refected and transmitted waves.Fig.27 illustrates that the surface energy increases with the loading rate. The physical mechanism of this loading rate dependence is of the same nature as the loading rate dependence of the fracture energy for the same rock(Huang et al.,2010a).The increases of the surface roughness and volumetric damage of materials adjacent to the fracture plane mainly contribute to the increase of fracture energy.

5.2.2.Dynamic indirect tension method

For dynamic direct tension methods discussed above,there are several limitations:(i)the requirement of alignment is very strict to avoid bending;(ii)the complex shape of the specimen for avoiding pre-mature failure leads to high cost of sample preparation;(iii)a proper high strength epoxy glue is required for joining the sample to the bar.The dynamic indirect tension methods not only providealternative to overcome the diffculties of dynamic direct tension methods,but also are convenient for instrumentation.

Fig.23.Schematics of an SHTB system and thex-tdiagram of stress waves propagation in SHTB(after Huang et al.,2010a).

Fig.24.Schematics of two types of dynamic direct tension samples(unit:mm).

(1)Brazilian disc(BD)method

SHPB has also been adopted to conduct indirect tension tests for measuring the tensile strength of brittle solids like rocks.The BD method is based on the fact that the rock is much weaker in tension than in compression and thus the diametrically loaded rock disc specimen fails due to the tension along the loading diameter near the center.The BD specimen in the SHPB system is shown schematically in Fig.28a,where the sample disc is sandwiched between the incident bar and the transmitted bar.Provided a quasi-static state has been achieved in the sample during the test,the dynamic tensile strength is determined by the following equation (Iqbal et al.,2008):

whereσtis the tensile strength,Pfis the load when the failure occurs,andBis the disc thickness.Under quasi-static state,Pfcoincides with the maximum loading to the sample.

The conventional SHPB tests were conducted using the BD method on marbles(Wang et al.,2006)and argillites(Cai et al., 2007).These attempts followed the pioneer work on dynamic BD tests of concretes using SHPB(Ross et al.,1989,1995;Tedesco et al., 1989).The details of major development on the BD method using SHPB were reviewed by Zhang and Zhao(2014).

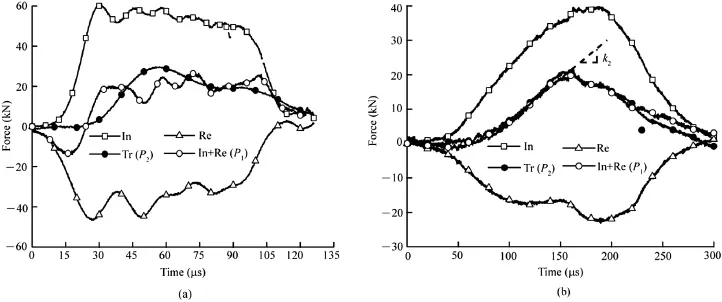

Fig.25.Dynamic force balance of SHTB test(a)without and(b)with the pulse shaping technique(after Huang et al.,2010a).

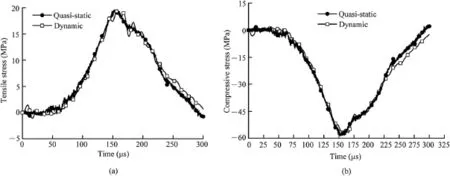

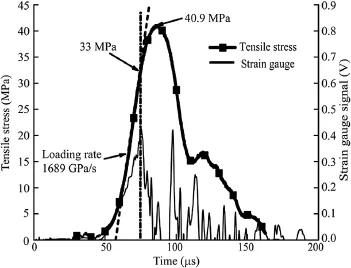

The BD method has been suggested by the ISRM as a recommended method for static tensile strength measurement of rocks (Bieniawski and Hawkes,1978).Using the BD method,Zhao and Li (2000)measured the dynamic tensile properties of granite using a hydraulic loading system.For quasi-static and low-speed BD tests, it is reasonable to use the standard static equation to calculate the tensile strength.For dynamic BD tests conducted with SHPB featuring stress wave loading,the application of the quasi-static equation to the data reduction is also verifed by numerical simulations(Hughes et al.,1993;Zhu and Tang,2006)and experimental methods(Gomez et al.,2001;Xia et al.,2011;Zhang and Zhao, 2013a).The condition under which the static analysis is valid is the satisfaction of dynamic force balance in dynamic BD tests. Gomez et al.(2001)utilized photoelastic method to obtain the photoelastic fringe patterns of Homalite-100 disc samples under both quasi-static and dynamic loading conditions.Both photoelastic fringe patterns showed that the stress equilibrium condition of disc samples is satisfed.Zhang and Zhao(2013a)employed DIC to gain high-speed image and dynamic strain felds of BD specimen of Fangshan marble,which demonstrates that the stress equilibrium on both ends of BD is also satisfed.Xia et al.(2011)investigated the stress equilibrium of BD specimens in the SHPB test using high-speed camera and numerical simulations.Fig.29 illustrates the time-varying forces in a typical test without pulse shaping and with careful pulse shaping technique.Without the pulse shaping, the generated incident wave is a square compressive stress wavewith a sharp rising edge,which inevitably introduces high frequency oscillations.Thus,the dynamic forces on both ends of the sample vary signifcantly and have a sizeable distinction betweenP1andP2.However,with the careful pulse shaping,it is evident that the time-varying forces on both sides of the samples are almost identical before the peak point is reached during the dynamic loading.The resulting force on either side of the sample also features a linear portion before peak,thus facilitating a constant loading rate via˙σ=2k2/(πDB),where the parameterk2is illustrated in Fig.29.

Fig.26.Dynamic tensile strength of Laurentian granite(after Huang et al.,2010a).

Fig.27.Nominal surface energy of Laurentian granite as a function of the loading rate (after Huang et al.,2010a).

For avalid Brazilian test,the disc sample should break frst along the loading direction somewhere near the center of the disc (Shewmon and Zackay,1961;Hudson et al.,1972).To verify this,Xia et al.(2011)used a high-speed camera to monitor the fracture processes of the BD test.The failure process of the BD test without and with pulse shaping is shown in Fig.30.Without pulse shaping, the frst breakage emanates from the incident side of the sample after the incident wave arrives at the bar/sample interface.Soon after that,damages also occur from the transmitted side of the sample.Thus,the splitting of the disc is triggered by the damages at the loading points and then expands to the center of the disc.Since the cracking of the BD initiates from the loading ends,not from somewhere near the center of the disc,the working principle of a BD test is violated and the standard equation(Eq.(10))is invalid for reducing the tensile strength from the tensile stress history at the disc center.With pulse shaping,the BD sample achieves force balance.In sharp contrast to the images from the non-pulse shaped BD tests,this disc cracks near the center,then the fracture propagates bilaterally to the loading ends.The next two frames illustrate the splitting trajectory of the sample;and the disc specimen is split completely into two fragments approximately along the center line of the sample(Fig.30).Because the splitting of the disc initiates near the center,the tensile strength can be determined as long as we can accurately determine the tensile stress of the disc at failure.

Moreover,for conventional dynamic compression tests with SHPB or direct tension tests with SHTB,the samples are cylindrical and thus the force balance at the ends ensures the stress equilibrium throughout the sample.However,the disc is 2D;the force balance on the boundaries does not necessarily ensure dynamic equilibrium within the entire sample.A further comparison of the stress history at a point of interest from full dynamic analysis with that from quasi-static analysis is necessary.The histories of the stress components,σx(in tension)andσy(in compression),at the disc center(potential failure spot)for dynamic and quasi-static fnite element analyses are compared in Fig.31a and b,respectively.The stress states at the disc center from both quasi-static and dynamic data reductions match with each other.Hence the quasistatic analysis with the far-feld loading measured as input can accurately represent the stress history in the sample provided the force balance on the sample ends,and the standard BD equation (Eq.(10))can be used to reduce the tensile strength.

In quasi-static BD tests,although the BD sample may fracture before the peak load is reached,the difference between the peak load and the failure load may be smaller if a servo-controlled material testing machine is used and the transverse expansion of the disc is used as the controlling variable(Shewmon and Zackay,1961; Hudson et al.,1972).In dynamic BD tests using SHPB,there is no way to control the load using a feedback system,thus the mismatch of the measured peak load and the failure load can be signifcant. Fig.32 shows the signal of the strain gauge mounted on the position at 10 mm distance from the center of the BD sample,compared with the transmitted force for a test featuring high loading rate.It can be concluded that the tensile stress at the fracture onset(namely tensile strength)is much lower than the peak stress determined from the far-feld loading.The reason for this phenomenon lies in the sample test confguration.For an ideal BD test, the fracture will initiate at the center of the sample along the loading axis.At the fracture onset,the sample is still in contact with the two loading platens.The load can thus still increase until the sample is completely split into two halves.From part of the strain energy release from the fracture,the two halves will get transverse velocities to separate from each other.The two halves may rotate and lose contact with the platen during the separation process, resulting in unloading.

Fig.28.Schematics of Brazilian disc and fattened Brazilian disc.

Fig.29.Dynamic forces on both ends of disc specimen tested using a modifed SHPB:(a)without pulse shaping and(b)with careful pulse shaping(after Dai et al.,2010b).

The post-mortem failure patterns of BD samples in SHPB tests generally consist of two types:shear failure and tensile failure (Zhang and Zhao,2013a;Zhou et al.,2013).The tensile failure is the main axial crack parallel to the impact direction,dividing the sample into two pieces.The shear failure zones are at the contact points of BD,which are more signifcant with the increase of loading rate.As shown above,for a valid dynamic BD test,the failure should start from the center of the disc.The shear failure is then a result of secondary fractures due to further compression between the bar and the cracked disc as demonstrated by the highspeed camera snapshots.However,due to misunderstanding of the failure process,fattened BD method was proposed to prevent the shear failure zone as shown in Fig.28b(Wang et al.,2009).The principle of the fattened BD method is similar as that of BD method.However,as discussed,there is no need to prevent the shear failure as long as the initial failure starts from the center of the disc,and this approach has also other limitations(Yu et al., 2009).

(2)Semi-circular bend(SCB)method

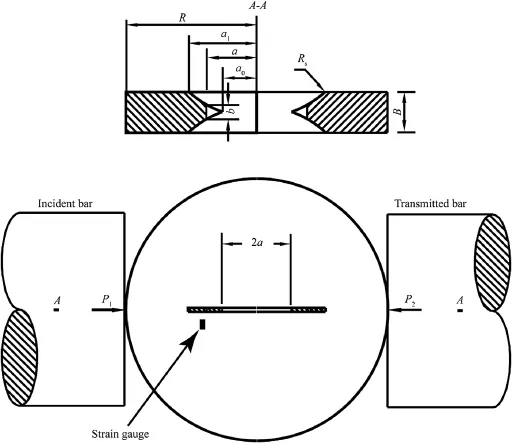

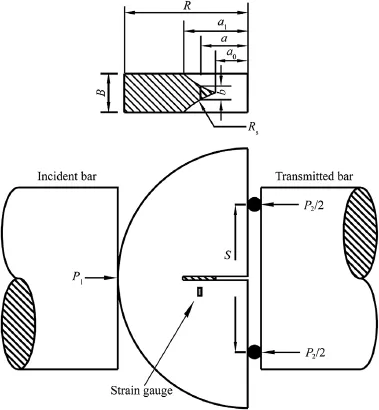

SCB was also used in SHPB to measure the tensile strength of Laurentian granite(Dai et al.,2008,2010a)The SCB specimen in the SHPB system is shown schematically in Fig.33 and the insert of Fig.34.The pulse shaping technique was employed to achievedynamic force balance and momentum-trap technique was used to attain single-pulse loading.

Fig.30.High-speed video images of two typical dynamic Brazilian tests.Top four images:Brazilian test without pulse shaping;Bottom four images:Brazilian test with careful pulse shaping(after Xia et al.,2011).

Fig.31.(a)Tensile stressσxand(b)compressive stressσyhistories at the Brazilian disc center from both dynamic and quasi-static fnite element analyses in a typical SHPB Brazilian test with pulse shaping(after Xia et al.,2011).

Provided a quasi-static state has been achieved in the sample during the test,using a dimensional argument,the equation for calculating the tensile stress atOis(Dai et al.,2010a):

whereP(t)is the time-varying load recorded in the test,Sis the span of the supporting pins,andRis the radius of the disc.The dimensionless stressY(S/(2R))can be calibrated using fnite element analysis.The dynamic tensile strength measured by the SCB method is also called fexural strength,and the fexural tensile strengthσfis taken as the maximum tensile stress in the history of σ(t)and the corresponding loading rate is measured from the slope of the pre-peak linear portion of the curve.The reason why strengths measured using the SCB method are higher than those by the BD is initially explained using a non-local failure model(Dai et al.,2010a).Since the dynamic force equilibrium is satisfed in all SCB tests,the non-local failure approach should work for dynamic SCB and BD tests.This theory states that the material fails when the local stress averaged over a distanceδalong the prospective fracture path,σ,reaches the tensile strength,σt(Lajtai,

Fig.32.Tensile stress history with the strain gauge singal for detecting failure onset (after Xia et al.,2011).

1972;Car∫ter,1992;Van de Steen and Vervoort,2001): σ=(1/δσdl,where l0is a characteristic material length σ δ scale,andis the tensile stress distributing over.Numerical methods were applied to calculate σfor a given sample geometry. The tensile stress gradient(the ratio of the tensile stress along the prospective fracture path,σ,to the tensile stress at the failure spot, σm(also the maximum tensile stress in the sample)along the prospective fracture path of SCB sample was calculated numerically with fnite element analysis,and then the relation between σand σmcan be found.Thus,at the critical state,the fexural tensile strength,σf,is equal toσmand the tensile strength,σt,from BD test is equal to σ.The relation betweenσfandσtcan be established. Using this relation and non-local failure theory,the tensile strength σtcan be derived from the measured dynamic fexural strengthσf(Dai et al.,2010a).Dai et al.(2010a)demonstrated that the corrected dynamic tensile strengths from fexural strengths have a good agreement with those measured from the dynamic BD tests (shown in Fig.34).The rate dependence of dynamic tensile strength for Laurentian granite is demonstrated in Fig.34(Dai et al.,2010a). Besides,the simulated fracture pattern from fnite-discrete element method agreed well with that from the recovered specimen(Dai et al.,2010a).However,the results obtained from the SCB test is the fexural strength,which is different from the tensile strength from the BD method(Zhang and Zhao,2014).

(3)Spalling method

The spalling method on SHPB is based on the refection of elastic wave in a cylindrical bar(Fig.35).A compressive wave propagates into a cylindrical specimen and is refected as a tension wave at the free end of specimen.Since the tensile strength of rock is muchlower than its compressive strength,the refected tension wave causes the failure of rock specimen.

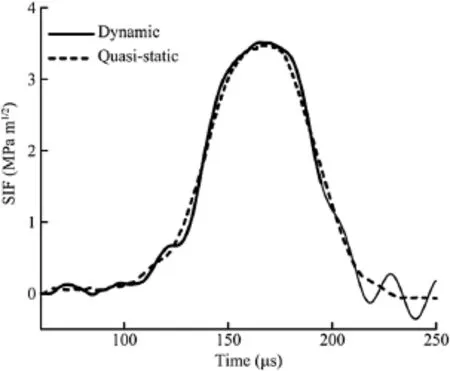

Fig.33.Schematics of the SCB method.