Application of New-type Soil Stabilizer Q2 in Subgrade Construction

Peng TIAN,Cunlian TANG,Qiang CHEN,Huifang LU

1.Shanghai Hengfeng Fluorocarbon Material Co.,Ltd,Shanghai 200092,China;

2.Beijing Vocational College of Agriculture,Beijing 102442,China;

3.Yituobang (Beijing) Agri-tech Co.,Ltd.,Beijing 100017,China;

4.Binxian County Water Conservancy Bureau,Shaanxi 713500,China

Responsible editor:Xiaoxue WANG Responsible proofreader:Xiaoyan WU

Wanna be rich? Build roads first! Asmooth road is a guarantee for economy development.With China economy evolvement,national road network is increasingly dense and wide.However,for roads available,whatever road grade,the structure always keeps the same,including subbase,base course,paver base and pavers.Specifically,the pavers are dominated by pitch and subbase is the bottom layer,playing a decisive role in guaranteeing the whole road,with consideration of gravity of soils and pavers undertaken by subbase.Therefore,it is of significance to research construction of subgrade.

Currently,road destruction is mostly caused by the destruction on subgrade.In constructing subgrade in China,subgrades of traditional cement road and lime-ash soil are popular.With good performance of high strength in early stage,however,the subgrades have problems in durability and freezing tolerance under influence of season,climate,construction conditions and experience[1].Meanwhile,because of ill treatment at construction,the phenomena of "spring" and sinking usually occur,which is actually caused by weak soil layer or high water content in mixed materials.Such problem would worsen pavement destruction in Northeast China.

In order to resolve the problems above,the research,based on construction experience of foreign roads,made analysis on soil solidification and constructed a road of 1 000 m2in Beijing Vocational College of Agriculture with new-type soil stabilizer Q2.After 3 months,it is proved that the road performed well,which resolved the difficulties of road sinking,crack,or apophysis,and reinforce the strength and durability of subgrade.What’s more,due to rapid construction technique,road maintenance and construction cycle are reduced,saving cost and improving efficiency,and the soil solidification technology should be widely applied in subgrade construction.

Soil Solidification

Asoil stabilizer is a construction material consisting of organic and inorganic materials to stabilize soils.It is added to soils to improve soil physical,chemical and mechanical properties in order to meet construction demands.

In the early 1990s,limes and cements were used for fixing subgrade in constructing subgrades in wharf,road,port and house in developed countries,such as America,France and Germany and soil stabilizer rose as a subject until the end of the 1950s to save resources and resolve soil fixing and widely researched in foreign countries in the 1960s.In the 1980s,it was considered as a new type material applied in road construction in Europe,America,Japan and Taiwan (China),with progress made on environment and economy[2-7].

After introduction of soil stabilizer in China in the 1990s,domestic research started on the change and development of property of soil stabilizer and soil solidification technology advanced fast in the following 30 years.With consideration of application target of subgrade project,scholars,at home and abroad,researched and developed a series of soil solidification materials,changing simple and single inorganic materials into complex and comprehensive chemical compounds.

Soil stabilizer and its roles

In the research,the road used Q2 produced by Shanghai Hengfeng Fluorocarbon Material Co.,Ltd as a soil stabilizer.It is baby blue powders,with lime,zeolite and slag as dominant curing agents and calcium carbonate,sodium fluoride,aluminium potassium sulfate,triethanolamine and sulfamate as supplement curing agents(Fig.1).

Specifically,of the soil stabilizer,A plays the role of cementing soil particles and forming net structure to obtain early strength of soils.B is to react chemically with minerals to make up the weak strength of net structure and improve the final strength of solidified soils.D would react with humus of soils,increasing volume of the product,separate out gels,and fill holes of solidified soils,resulting in swelling of soils and improving soil tolerance to permeation,shrinkage and freezing.Furthermore,B also plays the role of surfactant action and delayed coagulation,making it easier for D components into soils,so that ion exchange reaction proceeds fast and completely.When solidified soils are immersed longer in water,E would react with water to form a balance material,avoiding erosion of solidified soils and keep soil strength.

Solidification process of soil stabilizer

The process of soil stabilizer reaction with soils can be divided into following stages:

Physical processWhen soil stabilizer is added to soils and stones,soils would be compacted closely by mixer and road roller,reducing soil porosity,increasing compactness and decreasing water permeability.It is a physical process.

Chemical processIt is a process of chemical reaction of soil stabilizer components and the reaction of soil and soil stabilizer in soil solidification,of which the former mainly refers to hydrolysis reaction and hydration reaction of inorganic materials,carbonation reaction with CO2in airs,and polymerization reaction and polycondensation with organic materials,and the latter includes pozzolanic reaction between soil stabilizer and soil and complexation between organic polymer and soil particles.

Physiochemical processIt is a process of adsorption process of soil stabilizer and soil components,involving physical absorption,chemical absorption,and physiochemical absorption.Specifically,physical absorption refers to soils absorb some components of soil stabilizer under influence of molecular force to reduce surface energy.Chemical adsorption is a chemical reaction between adsorbent and adsorbate,producing chemical bond and insoluble matter.Physiochemical absorption is a process of ion exchange and adsorption of soil stabilizer and soils.

It is notable that reactions above are not isolated,but closely connected with each other.Nevertheless,only chemical and physical reactions would improve soil mechanical property,and tolerance to permeability and durability and physical and mechanical processes is a guarantee of chemical and physiochemical processes.

Solidification mechanism of soil stabilizer

With diversified formulae of soil stabilizer,the solidification process keeps the same.As shown in Fig.2,soil stabilizer is firstly dissolved in water and added to water after physical or chemical reactions.Then,high-valence ion of dissolved soil stabilizer reduces repulsive force among soil particles by changing electric charges,destroys capillary film and improve adsorption capacity among soil particles.Subsequently,exchange reaction occurs of calcium ion and magnesium ion with sodion,increasing agglomeration of soil particles.Furthermore,lots of acicular crystals containing crystal water would form in water and the formed framework of acicular crystals is filled with silicate hydrate,compacting soils.Finally,with excitant effect,soils are of irreversibility and perform well in durability.Hence,with compacted soils,soil bearing capacity and permeability tolerance can be enhanced(Fig.2).

Application of Soil Stabilizer in Subgrade

Standard mixing ratio of soil stabilizer in construction

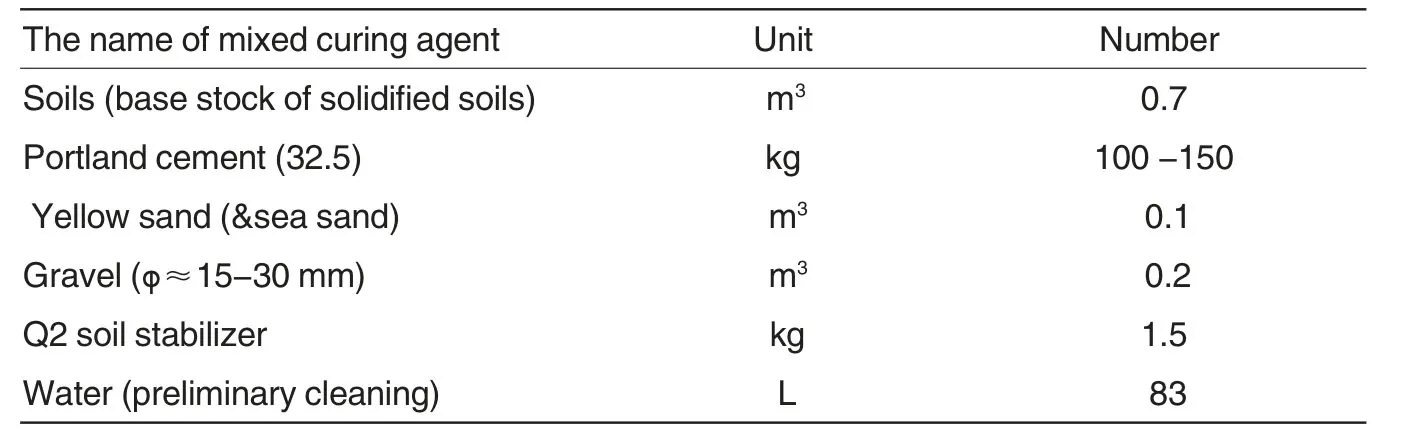

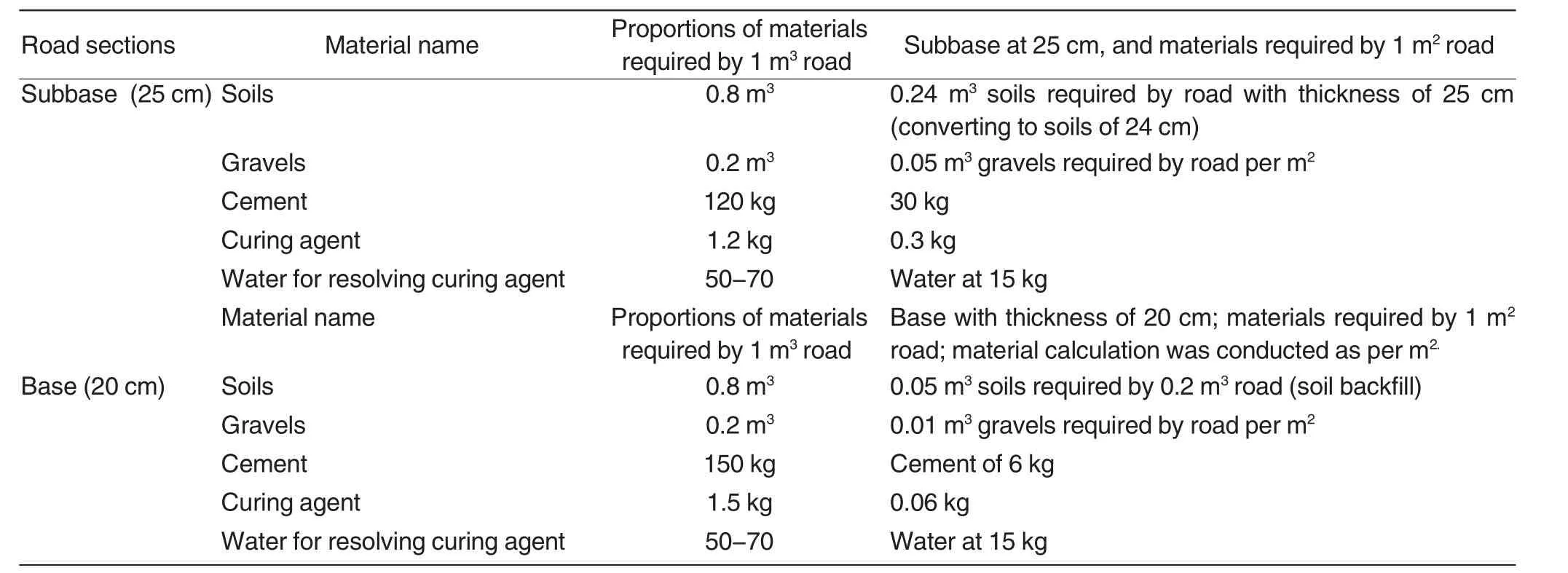

On basis of lots of soil testing,analyzing and construction,standard mixing ratio of the soil stabilizer was concluded(Table1).

(1) Before use of the soil stabilizer,soils ready for solidification should be tested,involving soil particle analysis,liquid limit,plasticity index,organic matter content,moisture rate,pH and crushing value.

(2) Common Portland cement,portland blast furnace slag cement and portland-pozzolana cement are all available for reinforcing pavement,subgrade and subbase.However,cement strength should be higher than 32.5,and the cement should meet construction in terms of final setting time.It is notable that rapid hardening cement and high-early-strength cement are not suitable.

(3) Use introduction of different components.Dinas and yellow sands are optimal choice in the component,which would improve strength of solidified soil; cement is a necessary component and the amount is related to soil samples of mixed curing agent.For example,alkaline soil and stony soil have less demands on cements,which is contrary to humus and black soil,with the range of 6%-12%.Additionally,soil stabilizer is of insignificant relation with soil texture,which is con-trolled of 1%of cement.

Table1 Standard mixing ratio of soil stabilizer in construction

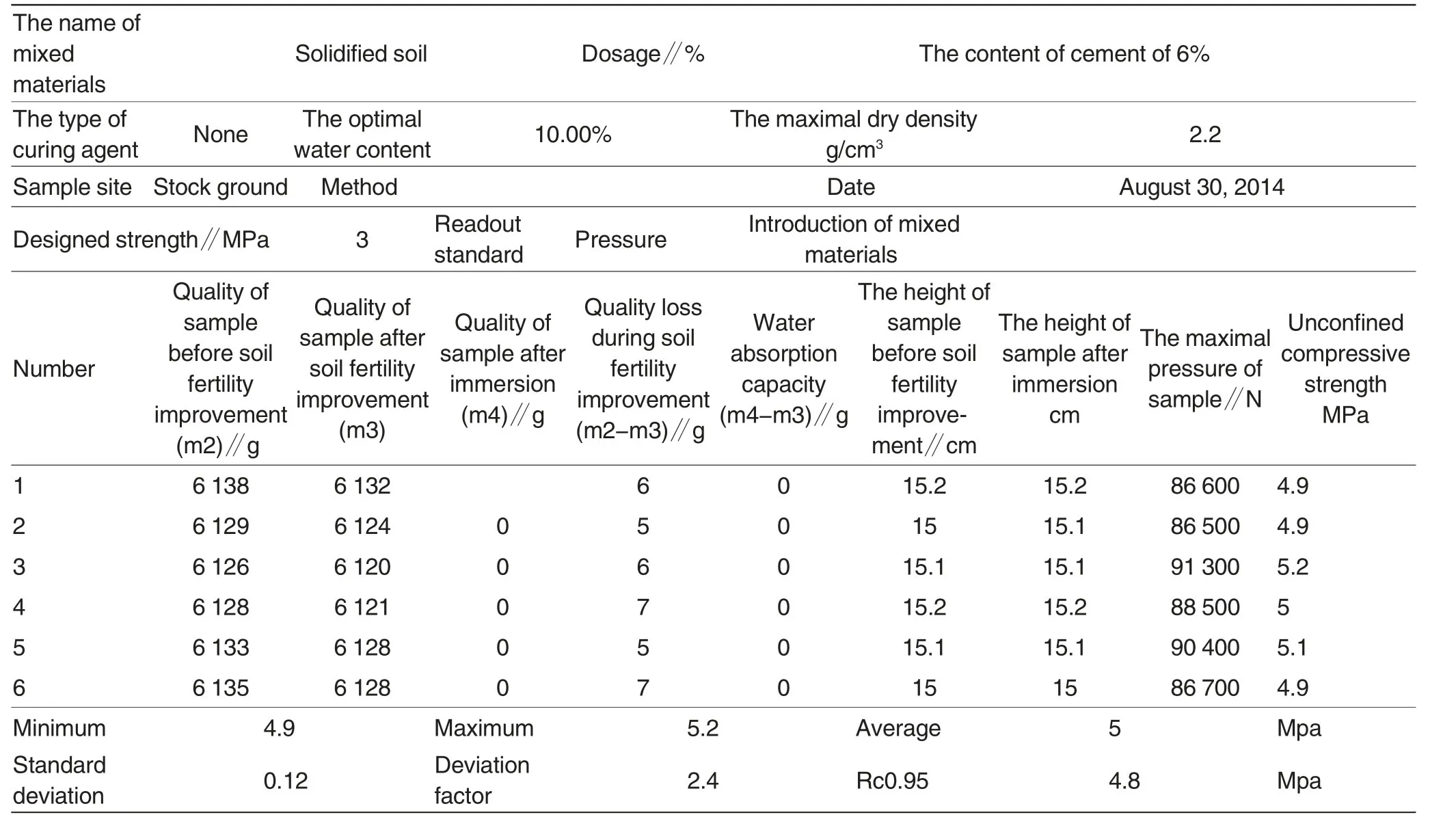

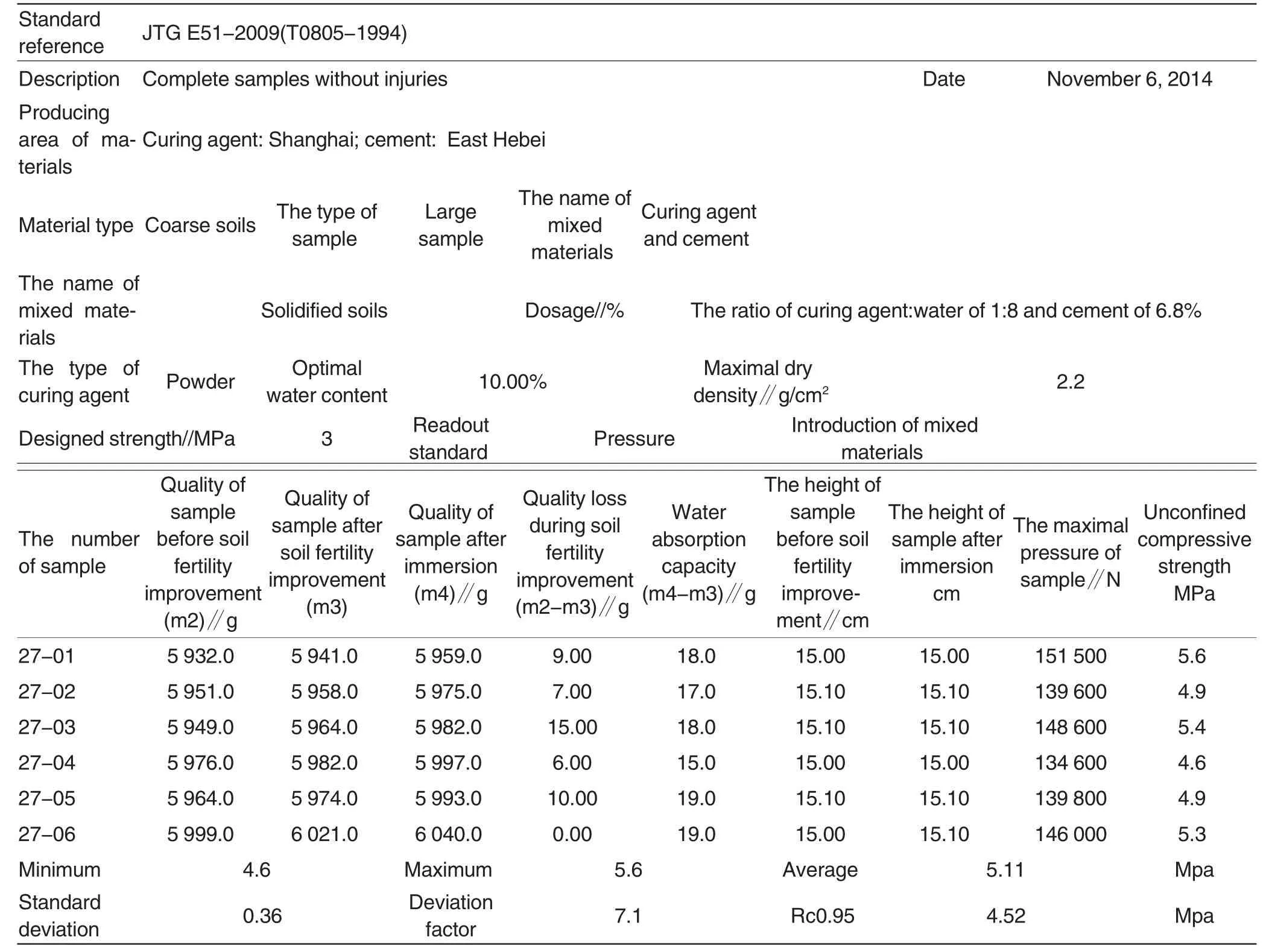

Table2 Inspections of compressive strength of solidified soil

Examination of test data

Soils,yellow and stones were mixed with volume ratio of 70%,10%and 20%,after drying in an oven(Fig.3).Then,cement was added at 120 kg/m3to the mixed soils and soil stabilizer was added at 1.5 kg/m3.Specifically,the soil stabilizer was dissolved in water as per the ratio of 1:80 to prepare stabilizer solution.Subsequently,the stabilizer was sprayed on cement mixtures.Finally,unconfined compressive strength was inspected as per Test Methods of Soils for Highway Engineering(JTJ 051-93)(Table2).

Application of Soil Solidification in Subgrade Reinforcement

Road design scheme

The test road is located in a basecomputed and paving areas of cement per bag and soil stabilizer can be calculated in accordance with base and subbase thickness of solidified roads,and cement and soil stabilizer quantities.In addition,the line,interval distance and quantity of cement or soil stabilizer can be determined as per width of base and subbase solidified road.

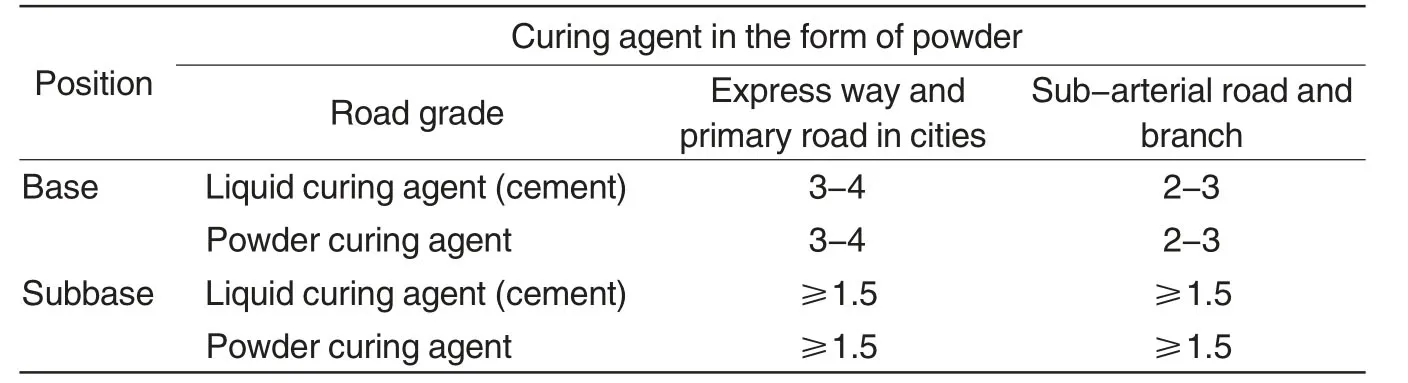

Table3 Standard of strength of mixed curing agents

Table4 Mixing ratio of standard materials of solidified roads(1 m3)

B:Soil movement and leveling.

Surface soils was dug with an excavator and piled on a vacant lot and backfill can be conducted after 20 cm base was prepared.

Paving of loose soilsAs per standard of line setting out,soils was dug with an excavator and bottom soils were turned over to remove stones and weeds.The thickness of uncompacted layer is equal to compacted thickness multiplying coefficient of loose paving material,and every layer should be within 30 cm.Meanwhile,soft base or sludge base should be treated at turning over.For example,if of Beijing Vocational College of Agriculture and analysis was conducted as per design demands and local soil property(Fig.5).

Calculation of materials

The research designed subbase thickness of 25 cm,and base thickness of 5 cm,and calculations were made as per volume,thickness and weight.

Site operation

Surveying and setting outAt first,lines were set out for measurement and central line was redistributed on road subgrade.Specifically,stake was set every 15 -20 cm of the straight line,every 10-15 m of horizontal curve and set every 0.3-0.5 m beyond road shoulder.

MaterialsA:According to road length,width,base thickness,scheduled dry density,and proportion of cement and soil stabilizer,the quantities of cement and soil stabilizer could be water content is higher than 15%,sludge soils should be dried or cement and soil stabilizer should be paved well to meet demands of construction materials(Fig.5).

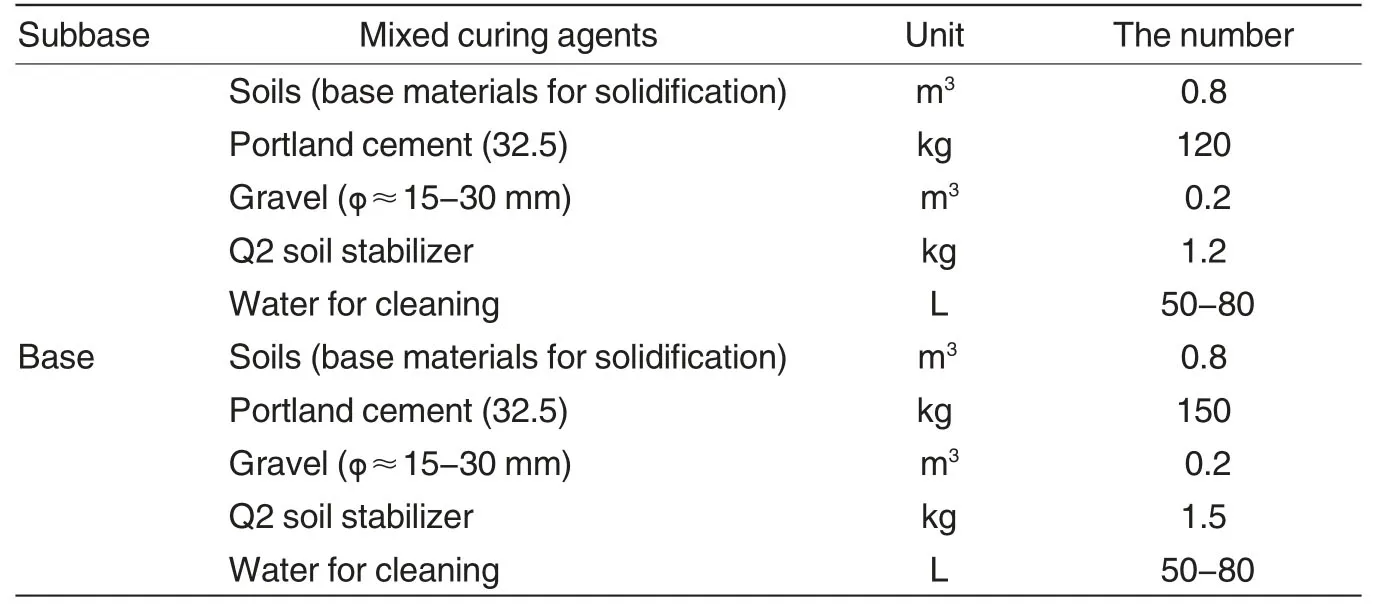

Table5 Proportions of road subgrade

Mixed stonesStones and sands were paved on soil surface with forklifts and excavators.

Paved cementsAs per proportion of rammed earth,cements were paved on soil surface where stones were paved as per crossing method at 30 kg/m2(Fig.7).

Material stirringThe materials were well stirred with an excavator to guarantee full mixture of soils,stones and cements in bottom layer(Fig.8).

To stir materials with a road-mixing machine after curing agents sprayedThe number of curing agent can be weighed and collected as per rammed earth proportion at 0.3 kg/m2and curing agents per kg were dissolved in water of 50-70 kg.After well mixing,curing agents were sprayed uniformly on materials with a sprayer.It is notable that water quantity should be well controlled to guarantee water content below 15%.What’s more,material mixing and curing agent liquid were stirred well on site with a roadmixing machine.(Fig.9)

Before spraying Q2,water content of mixed materials should be measured and soil stabilizer liquid can be prepared as per water quantity 1%-2%over optimal water content.

Water liquid directly permeated to the mixed materials can be sprayed twice.Specifically,40% was sprayed,followed by multiple mixing with a machine,followed by twice mixing after 40%liquid spraying.

The spraying of Q2 should be conducted by a pressure-type watering cart or a nozzle-equipped watering cart.Still,the spraying should be kept uniform,without omission and the cart can not be stopped in midway in case of excessive spraying.

Table6 Test of unconfined compressive strength

After the above procedures finished,soil stabilizer should be well mixed in materials following the watering cart.When slope is over 2%,mixing should proceed closely in case of water loss(Fig.10).

Compaction with a road rollerAfter materials were well mixed,road was compacted with a road roller(18T-22T)according to the principle of sides first and middle later,compaction first,oscillation later,light first,heavy later and slow first,fast later.During the compaction process,if the phenomenon of "spring" occurs,some should be dug and filled with water to re-mix the materials,followed by secondary compaction(Fig.11).

Data inspection

Test method of modulus of resilienceAfter 5 d maintenance of solidified roads,deflection value was tested of subgrade in the road by Construction Quality Monitoring Station Inspection Center and it was concluded the deflection value averaged 40 (0.01 mm),which was lower than that of common cement-based ground of 70 (0.01 mm),indicating that subgrade carrying capacity of solidified cement ground performed well.

Inspection of unconfined compressive strengthSoil samples were collected from local site and maintained in a laboratory for 7 d,including one day immersion for inspection of unconfined compressive strength(Table6).

It can be concluded from data above that both of deflection value and unconfined compressive strength,which can be applied in subgrade construction.

Conclusions

The application of soil stabilizer technology avoids lime and coal ash,lowering environmental pollution and reducing transportation cost of materials.With local soils,stones and cement,standard demands of subgrade can be met,reducing cost of subgrade materials and Q2 is fast in solidification,short in maintenance and high in strength,without pollution.What’s more,secondary argillization can be avoided and rammed earth -based roads can be ground and returned to fields,avoiding construction rubbish.In addition,during construction process,the material is limited and procedure is simple,saving construction time and lowering cost.

[1]XU PH(徐培华).Subgrade maintenance technology of high-grade highways (高等级公路路基路面养护技术).Chang’an University(长安大学公路学院),2002,6.

[2]YANG ZH(杨志宏),ZHANG BH(张炳宏).Application of soil stabilizer(土壤固化剂的应用术)[J].Railway Standard Design(铁道标准设计),2000,20(5):1-4.

[3]HUANG XM(黄晓明),ZHANG SS(张书生),LIAO GY(廖公云).Research of TR soil stabilizer property (TR型土壤固化剂路用性能试验研究)[J].Journal of Highway and Transportation Research and Development(公路交通科技),2002,19(3):23-27.

[4]CAI ZX (蔡志新).Application of ISS soil stabilizer (ISS 土壤固化剂的工程应用)[J].Housing Materials and Application(房材与应用),2002,30(2):32-33.

[5]HUANG WR(黄维蓉),LIU DC(刘大超).Research of physical and mechanical properties of QJ soil stabilizer (QJ型土壤固化剂稳定土物理力学性能研究)[J].Journal of Chongqing Jiaotong University (重庆交通学院学报),2003,22(3):63-67.

[6]Barber,E G.The Utilization of Pulverized Fuel Ash[J].Journal of the Institute of Fuels,1970,43:49.

[7]ZHANG GQ(张国庆),ZHANG QF(张庆富),HUANG YJ (黄玉杰),et al.Development of soil stabilizer (浅谈土壤固化剂的发展现状)[J].Communications Science and Technology Heilongjiang(黑龙江交通科技),1999(2):44.

Agricultural Science & Technology2015年2期

Agricultural Science & Technology2015年2期

- Agricultural Science & Technology的其它文章

- Thoughts and Exploration on Transformation and Upgrading of Tobacco Production Promoted by Lean Management

- Bottleneck of Modern Agricultural Development and Countermeasures in Qinzhou in the Context of Beibu Gulf Economic Zone

- Preliminary Study on Effects of the Model of Community-supported Agriculture(CSA)on Urban-rural Income Gap in China

- Research on Micro-vibration Generator for Powering Tire Pressure Alarm System

- Spices and Food Culture in Native Minorities of Dehong

- Advance in Rice Bacterial Leaf Streak Researches