The Application of Seedling Nursing on Moist Trays and Fermentation Heating Using Farmyard Manure Methods in High-altitude Tobacco Areas of Fenggang County

Yuke WANG,Xiaozhong PENG,Hongjiang ZHOU,Weijun ZHANG,Yuying LUO*,Junqi WANG,Kemin WANG

1.Fenggang County Branch of Zunyi Tobacco Company in Guizhou Province,Fenggang 564200,China;

2.Hunan Agricultural University,Changsha 410128,China

Responsible editor:Nanling WANG Responsible proofreader:Xiaoyan WU

In recent years,seedling-raising techniques of flue-cured tobacco have developed quickly in China,moreover,the techniques of floating breeding and seedling production in seedbeds have already been widely popularized,achieving the greater reform of breeding technique.After improving many times,the quality of tobacco plants bred by floating breeding technique improved a lot[1-6].The nursery stage of flue-cured tobacco in Fenggang County is often in low-temperature and sunlight shortage weather,thus the effective accumulative temperature of flue-cured tobacco during nursery stage is insufficient and the illumination is also inadequate,generating underdeveloped root system of tobacco seedlings,long seedling time and low rate of strong seedlings.At present,shortening the seedling culture time has mainly focused on heating water body of nursery pond using warming devices,making water temperature suitable for the growth of tobacco seedlings,increasing accumulated temperature during seedling stage,and finally shortening seedling time[7-10],however,the research is mainly suitable for large-scale tobacco seedling workshop with convenient transportation,good water conditions and guaranteed electricity,but most tobacco-growing areas of Fenggang County are mainly concentrated in remote and high-altitude localities,which can not guarantee the use of warming facilities.Therefore,the paper mainly explored the shortening of the seedling culture time using seedling nursing on moist trays and fermentation heating using farmyard manure methods,the aim was to explore new approaches for shortening the seedling culture time in high-altitude tobacco areas[11-12].

Materials and Methods

Experimental materials

The experimental variety was K326,and the experimental materials were floating tray (each polystyrene tray has 160 holes and the specification is 600 mm×350 mm×60 mm ),matrix,straw,strain,oil cake fertilizer and urea,etc.

General situation of experimental field

In the experiment,medium houses were made of steel frame,and the experiment was carried out in Shishan Group of Tianqiao Village,Tianqiao Town,Fenggang County,the altitude is 1 155 m.

Experimental design and methods

The sowing time was on February 6,2013.And the seedling management was performed by the

Technical Regulations of Flue-cured Tobacco Floating Breeding of Fenggang County.

Four treatments without repetition were set for the experiment,each treatment had one nursery pond and 220 trays seeds.

A:Seedling nursing on moist trays.2-3 d after sowing,after absorbing enough water of seeds,1-2 cm water level of seedbed should be maintained until later cross-seedling stage to keep trays moist.Other management measures should obey the Technical Regulations of Fluecured Tobacco Floating Breeding of Fenggang County.

B:Fermentation warming using farmyard manure.10 d before sowing,farmyard manure with the thickness of 30 cm was evenly paved in the bottom of seedbed (≤2 cm chopping straw,strain,urea and water were mixed thoroughly),then compacting,after that,about 5 cm holes were punched evenly for three rows from straw surface to the bottom of nutrition pool,and each row had two holes,followed by plastic film mulch,watering and sowing.Other management measures should obey the Technical Regulations of Flue-c ured Tobacco Floating Breeding of Fenggang County.

C:Fermentation heating using farmyard manure+seedling nursing on moist trays.Before seedling,farmyard manure with the thickness of 30 cm was evenly paved in the seedbed(≤2cmchopping straw,strain,urea and water were mixed thoroughly),then compacting,after that,about 5 cm holes were punched evenly for three rows from straw surface to the bottom of nutrition pool,and each row had two holes,followed by agricultural film and a little water.2-3 d after sowing,after absorbing enough water of seeds,1-2 cm water level of seedbed should be maintained until later cross-seedling stage to keep trays moist.Other management measures should obey the Technical Regulations of Flue-c ured Tobacco Floating Breeding of Fenggang County.

CK:The CK group should be operated by the Technical Regulations of Flue-cured Tobacco Floating Breeding of Fenggang County.

Measuring items

Greenhouse temperature and matrix temperature should be measured at 9:00,13:00 and 18:00 every day.Sowing time,seeding stage,early cross-seedling stage,later crossseedling stage,the first leaf-cutting stage,seedling stage and seedling age should all be recorded.

Measuring the quality of tobacco seedlings should follow the following methods:5-point sampling method should be obeyed during the first leafcutting stage and seedling stage,25 plants from each treatment should be chosen to measure the number of leaves,stem height,the maximum leaf area,stem girth and the dry and fresh weights of root,stem and leaf.

Results and Analyses

Effects of different treatments on matrix and pool water temperature

As seen in Table1,the differences on matrix temperature of 4 treatments were not obvious at 9:00,and they were all among 12-13 ℃; at 13:00,treatment C had the highest matrix temperature,namely 21.05 ℃,and treatment A had the lowest matrix temperature,namely 19.35 ℃;at 18:00,treatment C and treatment A respectively had the highest and the lowest matrix temperature,which were 17.07 and 15.89 ℃,respectively.In the morning,the highest pool water temperature was treatment C,and reached 14.26 ℃,treatment A had lower temperature; at 13:00,the highest pool water temperature was treatment C,and reached 18.81 ℃,which was higher than CK by 4.85 ℃; at 18:00,the highest pool water temperature was treatment C,and reached 18.49 ℃,which was higher than CK by 4.43 ℃.From this,we drew that pool water temperature of treatment C was improved obviously.

Effects of different treatments on growth period

From Table2,it can be inferred that seeding stage,early crossseedling stage,later cross-seedling stage and seedling stage of treatment C were all earlier than other treatments; compared with CK,treatment C had the shortest seedling age,namely,67 d,which was 8 d shorterthan CK,followed by treatment B and treatment A,all these indicated that treatment C can promote the growth of tobacco seedlings,shorten seedling culture time,thereby helping ensure timely transplanting of high-altitude tobacco areas.

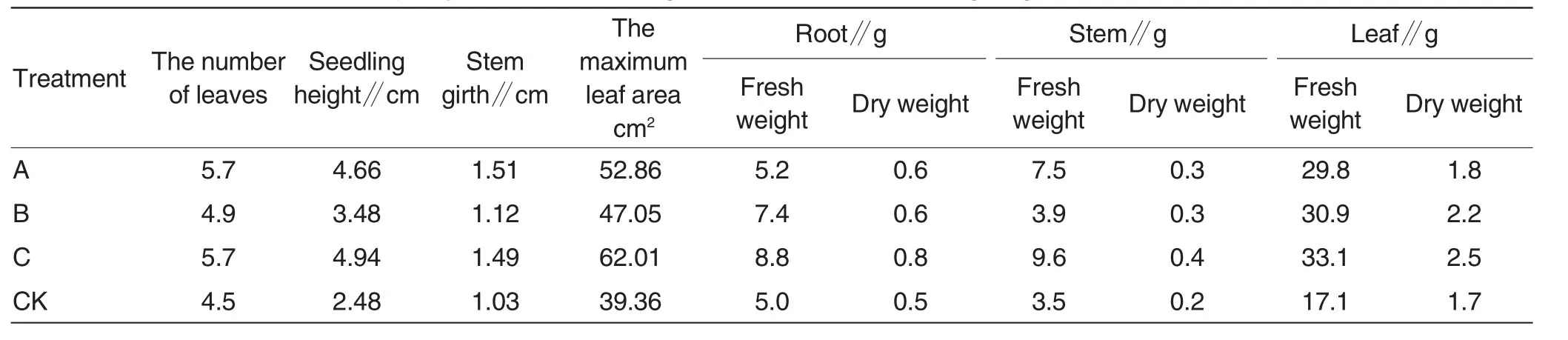

Table3 The measurement of the quality of tobacco seedlings before the first leaf-cutting stage

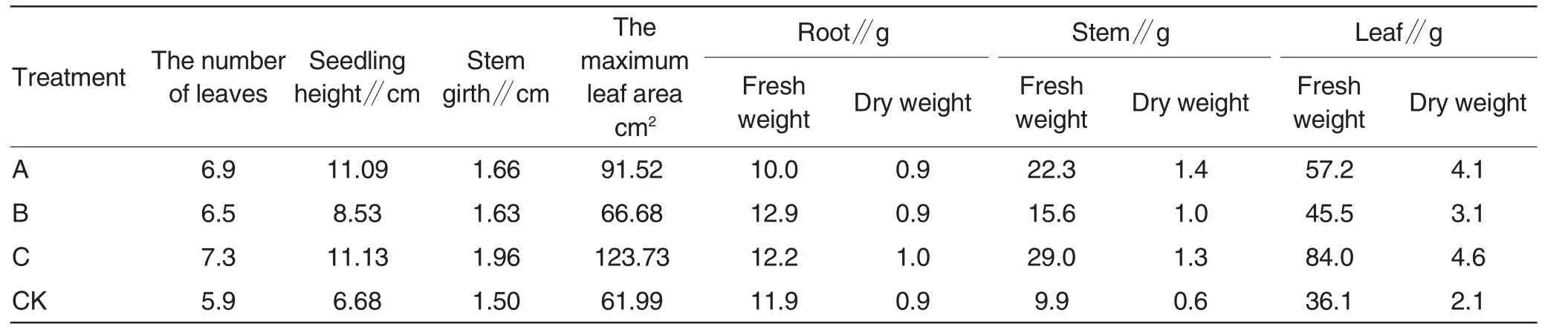

Table4 The measurement of the quality of tobacco seedlings during the seedling stage

Effects of different treatments on the quality of tobacco seedlings

As shown in Table3,through investigating the botanical characters of tobacco seedlings before the first leafcutting stage,it can be demonstrated that the number of leaves,seedling height,stem girth,the maximum leaf area,and the fresh weights of root,stem and leaf were all superior to these of CK,which further indicated that the seedling culture effect of the three treatments were all better than conventional seedbed system of CK,in which treatment C had the best seedling culture effect.

From the testing results of the quality of tobacco seedlings during the seedling stage (Table4),it can be known that stem height of treatment C was higher than CK by 4.45 cm,followed by treatment A and treatment B,which were both higher than CK; stem girth of treatment C was the thickest,which was thicker than CK by 0.46 cm,followed by treatment A and treatment B,but the differences were not obvious; the fresh weights of root,stem and leaf of treatment C were all heavier than other treatments.According to the quality of tobacco seedlings of each treatment,treatment C can not only shorten the seedling time of tobacco seedlings,but also promote the growth of tobacco seedlings and the developed growth of root system.

Conclusions and Discussions

(1) The techniques of seedling nursing on moist trays and fermentation heating using farmyard manure had certain influence on the temperature of matrix,but the effect was not obvious,however,they had obvious influence on pool water temperature at low temperature period,especially for fermentation heating using farmyard manure,which can improve pool water temperature by 2-3 ℃comparing with conventional seedbed system,what’s more,fermentation heating using farmyard manure+seedling nursing in shallow water can improve pool water temperature by 4-5 ℃comparing with conventional seedbed system,which was beneficial to the budding and growth of tobacco seedlings in the high-altitude tobacco areas.

(2) The techniques of seedling nursing on moist trays and fermentation heating using farmyard manure can shorten 2 d of seeding stage,and compared with conventional culture of seedlings,fermentation heating using farmyard manure + seedling nursing on moist trays can shorten 3 d of seeding stage and 8 d of seedling stage.These indicated that fermentation heating using farmyard manure +seedling nursing on moist trays can shorten the process of seedling nursing and achieve the effects of transplanting in advance,benefitting to avoiding the phenomenon of "June tobacco" in high-altitude tobacco areas of Fenggang County,meantime,it can make flue-cured tobacco mature in advance,and pick and bake in advance,thus avoiding difficult baking of upper tobacco leaf due to the reduction of air temperature and the insufficient of illumination in later period of pick and bake,finally improving the quality of upper tobacco leaf and increasing the benefit of tobacco growers.

(3) Seedling nursing on moist trays + fermentation heating using farmyard manure can promote the growth of tobacco seedlings.Compared with conventional culture of seedlings,seedling nursing on moist trays + fermentation heating using farmyard manure can make stem height higher than 4.45 cm and stem girth thicker than 0.46 cm of CK,and increase twice of the maximum leaf area,moreover,the fresh weights of root,stem and leaf were all obviously superior to CK.These showed that seedling nursing on moist trays + fermentation heating using farmyard manure can improve the quality of tobacco seedlings,these had positive effect for improving transplanting quality and field growth vigor,enhancing stress resistance of tobacco plants,and improving tobacco quality and whole tobacco quality.

(4) The experiment was carried out in high-altitude tobacco areas of Fenggang County in Guizhou Province,this is only for reference for other areas,at the same time,for the complexity of the experiment,its operation is inconvenient,so it should be further researched.

[1]WAN J(万军),ZHANG WJ(张维军),XIA ZL (夏志林),et al.Preliminary experiment of alternating wet and dry nursery(干湿交替处理对烟苗素质的影响与分析) [J].Guangdong Agricultural Sciences(广东农业科学),2013(2):10-12.

[2]WEN MX ( 温明霞),LI SM (李素明),FENG HP(冯厚平),et al.The technique of tobacco moist tray seedling nursing in shallow water (浅水湿润托盘育苗技术研究初报)[J].Tillage and Cultivation(耕作与栽培),2013(5):16-17.

[3]LIU TY (刘添毅),HUANG YL (黄一兰),PAI LX (赖禄祥),et al.Techniques of flue-cured tobacco seedling production on moist trays(烤烟湿润育苗技术研究)[J].Chinese Tobacco Science(中国烟草科学),2008,29(5):22-26.

[4]WANG SS(王树声),DONG JX(董建新),LIU XM (刘新民),et al.Developmental survey of tobacco intensive seedling production technique (烟草集约化育苗技术发展概况)[J].Tobacco Science &Technology(烟草科技),2003(5):43-45.

[5]LIU JL(刘建利).New technology and development direction of flue-cured tobacco seedlings in China(我国烤烟育苗新技术及发展方向)[J].Chinese Tobacco Science (中国烟草科学),2000,21(2):45-46.

[6]K ONG YL (孔银亮),XIA Y (夏阳),ZHANG XJ(张晓娟).Evaluation of a new seedling production method of fluecured tobacco (烤烟育苗新方式的筛选与研究)[J].Chinese Tobacco Science(中国烟草科学),2010,31(1):28-31.

[7]Bob Pearce,Bill Maksymowicz.Carefull management needed with float plants-Avoid Common Mistakes [M].Burley Tobacco Production Guide,1998:32-33.

[8]HE JH(何建华),QU HF(瞿鸿飛),WANG ZY (王忠宇),et al.Application of straw biological reaction technique in floating culture of flue-cured tobacco seedlings(秸秆生物反应技术在烤烟漂浮育苗上的应用效果)[J].Guizhou Agricultural Sciences(贵州农业科学),2009,37(12):66-68.

[9]LI Q(李奇),CHEN JJ(陈建军),LU JJ(卢静静),et al.Flue-cured tobacco seedling culturing in shallow,higher temperature water(烤烟增温浅水育苗试验)[J].Tobacco Science & Technology (烟草科技),2008(12):61-63.

[10]XIANG PH (向鹏华),SHAN XH (单雪华),YAN CS(颜成生),et al.A preliminary study on strengthening floatingseedlings technology of flue-cured tobacco by heating (烤烟漂浮育苗增温壮苗技术研究初探)[J].Hunan Agricultural Sciences (湖南农业科学),2012(11):24-25.

[11]BO LZ (柏凌志),ZENG HZ (曾惠字),XIANG PH (向鹏华).Experiment on heating in greenhouse for floatingseedlings of flue-cured tobacco in 2012 (2012年烤烟漂浮育苗大棚增温试验)[J].Crop Research (作物研究),2013,27(S1):12-14.

[12]HE JH (何建华),QU H (瞿鸿),WANG ZY (王忠宇),et al.Application of straw biological reaction technique in floating culture of flue-cured tobacco seedlings (秸秆生物反应技术在烤烟漂浮育苗上的应用效果)[J].Guizhou Agricultural Sciences (贵州农业科学),2009,37(12):66-68.

Agricultural Science & Technology2015年5期

Agricultural Science & Technology2015年5期

- Agricultural Science & Technology的其它文章

- Effects of Exogenous Glycine Betaine on Oxidation Metabolism in Cucumbers during Low-temperature Storage

- A Preliminary Study on Genetic Variation of gE Gene of an Epidemic Pseudorabies Virus Strain and Its Pathogenicity to Piglets

- Development and Application of a Quantitative Competitive PCR Assay for Detecting Mycoplasma hyopneumoniae

- A New Rapid and Batch-oriented Crushing Method for DNA Extraction from Maize Leaves

- Effects of Reducing Application Amount of Base Fertilizer and Increasing Application Time of Leaf Fertilizer on Corn Yield

- Screening,Identification and Fermentation Property of a Yeast Strain R6 Accumulating Alpha-ketoglutaric Acid