Formation of ceramic-metal composite layers on die steels by electron beam irradiation

Takahiro Akao, Yuki Sakurai, Tetsuhiko Onda, Kazutake Uehara, Zhongchun Chen

(1.Department of Mechanical and Aerospace Engineering, Graduate School of Engineering, Tottori University, Koyama-minami 4-101, Tottori 680-8552, Japan 2.Next Generation Advanced Medical Promotion Center, Tottori University Hospital, Nishi-cho 36-1 Yonago, Tottori 683-8504, Japan)

The durability of tools and dies for machining processes is becoming increasingly important due to growing demands for processing high strength materials. For such purpose, surface modification aimed to enhance wear resistance and fatigue strength has been intensively explored by means of diverse technologies. In particular, the formation of a hard layer such as CrN, TiN, TiCN etc. on tool surfaces has been widely utilized mainly in machining tools. However, since the hard layer has clear interface with the matrix, the delamination between the hard layer and matrix often occurs because of mismatches of the thermal expansion coefficients and other physical properties. A composite layer with complicated interfaces between hard material and matrix is desired to avoid such a delamination.

Cemented carbide has been investigated as a candidate for the composite coatings. So far many attempts have been made for WC-Co coatings by high-velocity oxygen fuel (HVOF) thermal spray technique, and the detailed microstructure of the coat was studied[1]. Later, a warm spray technique was newly proposed by reducing the temperature in comparison with conventional HVOF technique[2]. More recently, a better performance has been obtained using near-nano crystalline powders[3]. However, in these HVOF related techniques, the workpiece subjected to high temperature for rather long time, accordingly, the thermal deformations often cause a trouble for high precision tools. Moreover, the WC-Co coating by HVOF still has a flat and sharp interface between the coat and substrate. Niino et al. have proposed a concept of functionally graded materials (FGMs) in which no clear interface existed between workpiece and coating materials[4]. The composite of WC-Co alloy and steel with the FGM structure has been accomplished by spark plasma sintering (SPS) technique[5]. The SPS technique, however, cannot apply to the cold-working dies with large-scale and complicated geometries due to the instrumental limits.

EB irradiation has attracted much attention in welding of machine parts with high accuracy such as automotive parts. It can also be used in surface treatment (e.g., surface finishing[6]) of metallic materials. Recently, further developments have been achieved to apply EB irradiation to large-scale treatment for metal mold[7], tool steels[8], and WC-Co tools[9]. In addition, wear resistance of high-speed tool steels[10]and for gear materials[11]can also be improved by EB irradiation.

In this study, the influence of EB irradiation on cold- and hot-working die steel substrates as well as the formation of ceramic-metal composite layer on surfaces of a cold-working die steel by EB irradiation have been investigated. The concept of formation of the composite layer by EB irradiation is schematically illustrated in

Fig.1. Firstly, hard ceramic particles are supplied onto a metal substrate, and then the irradiation results in formation of a melting zone, where the hard particles are involved. Finally, a composite layer consisting of the hard phase and substrate metal is formed on the substrate surface without significant oxidation and thermal deformation.

Fig.1 Schematic drawing of the formation of a composite layer on the substrate surface by EB irradiation

1 Experimental

A cold-working die steel (JIS SKD11) and a hot-working die steel (JIS SKD61) were employed as the substrates. Table 1 shows the chemical com-

positions of SKD11 and SKD61 die steels. In order to assess the effect of chemical compositions of steels, a pure iron (JIS SUY1) was also used as a reference material. Commercially available rolled steel plates with 3mm thickness were cut into 10 mm×10 mm sized substrates.

A rolling plane of the substrates was polished to mirror surface. For fabrication of the ceramic-metal composite layer, the starting ceramic powders, SiC (99.5% purity and 2~3 μm in diameter), TiN (99% purity and 1~2 μm in diameter) and WC-17Co ( 99% purity and ca. 5 μm in diameter, Kojundo Chemical Lab. Co. Ltd., Japan) were chosen as the filler hard material. These powders were mixed in an ethanol medium. The mixed slurry was embrocated onto the substrate surfaces by brush. After drying, the samples were subjected to the EB irradiation experiments. The irradiation was carried out by an electron beam multi-surface processing machine (e-flash, e-FM-1LB-1VL-C5050; Mitsubishi Electric Corp., Japan) with operating power of 40 kV, 1~4 mA and scanning rate of 10 kHz for 0.04 mm pitch (i.e. 0.4 m/s). In the whole operations, the diameter of electron beam was estimated as ca. 0.2 mm.

The phase composition of the processed surfaces was determined by X-ray diffraction (XRD). The microstructure of the surfaces and cross-sections was observed by scanning electron microscopy (SEM). With regard to the elemental distributions in the processed layers, elemental maps were observed by electron probe micro analyzer (EPMA). Since the surface hardness is known to influence predominately the wear resistance of dies and tools, the depth profiles of hardness were evaluated for the processed samples. The Vickers hardness was determined using a Vickers micro-indentation tester with a load of 10 g for 15 s; 10 indentation tests were performed for each depth.

Table 1 Chemical compositionsof the cold- and hot-working die steels(mass fraction) %

2 Results and discussion

2.1InfluenceofEBirradiationonmicrostructureandpropertiesofthesubstratesurfaces

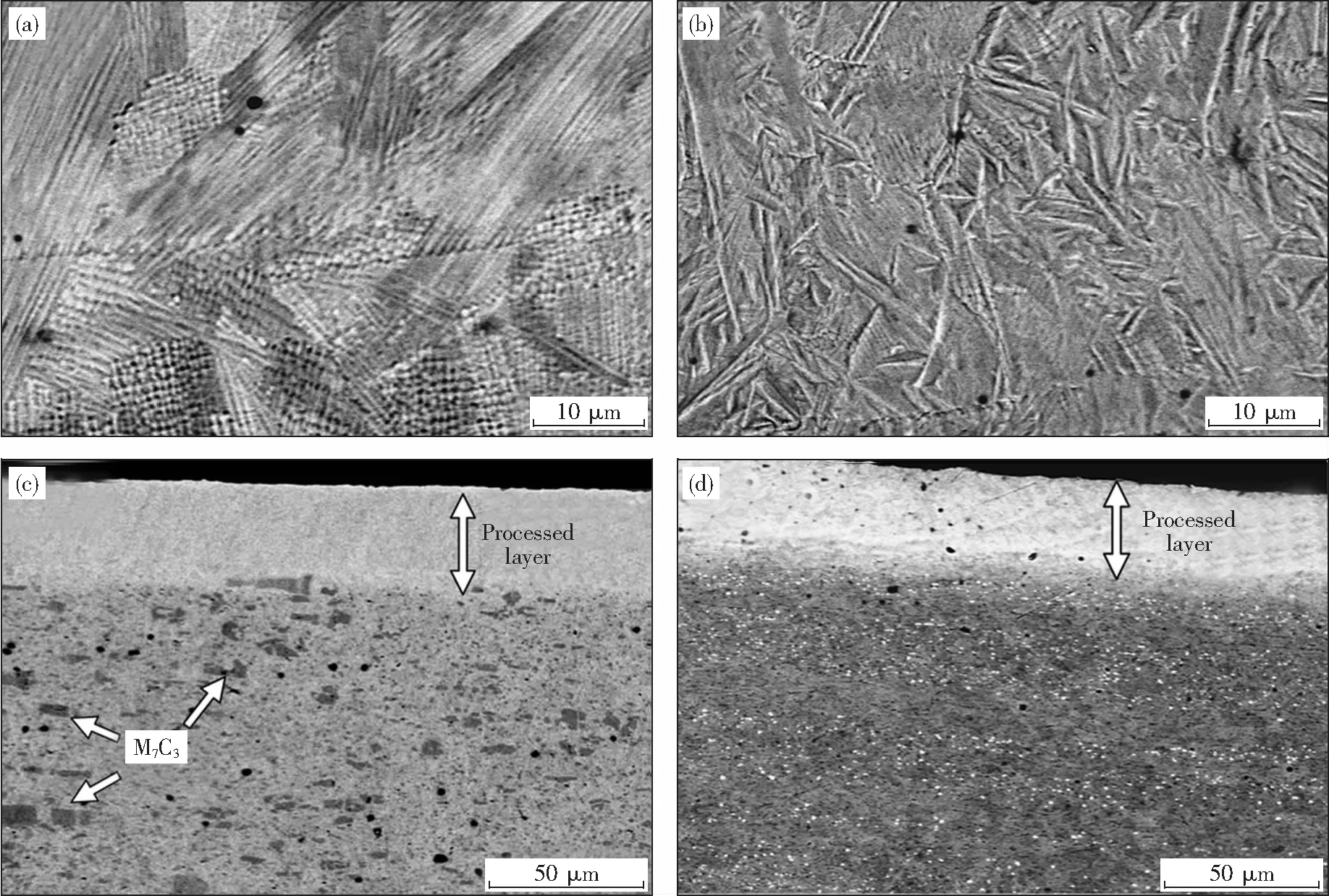

Prior to fabrication of ceramic-metal composite layer on the surfaces of die steels, the influence of the EB irradiation on microstructure and mechanical properties of the die steel substrates was investigated. After EB irradiation, the microstructure on the surfaces of both SKD11 and SKD61 samples were changed as shown in Figs.2(a) and (b). SKD11 is designed to be hardened by martensitic transformation and carbide precipitations of iron and chromium, mainly M7C3(M=Fe, Cr, etc). In

Fig. 2(c), the initial microstructure of SKD11 can be observed in the lower part of the image which is far enough away from the EB processed layer. The dispersed carbide precipitations are observed with a dark gray contrast. After the irradiation, on the other hand, the precipitations disappeared and much smaller dendritic structure with domains of different growth directions formed instead, as shown in

Fig.2(a). With regard to the cross section of the irradiated sample, a homogeneous processed layer with a thickness of ~40 μm was formed near the surface layer of the sample as shown in

Fig.2(c), where the processed layer has a light gray contrast and includes no M7C3precipitations at all. Such microstructural changes are similar to those results found in SKD11 treated by large-area EB irradiation[12]. As for SKD61, as shown in

Fig.2(b), the EB irradiated surface has massive reliefs provoked by the martensitic transformation during cooling after the irradiation. The cross sectional view of the EB irradiated SKD61 sample shows a light contrast layer of ~40 μm thickness as seen in

Fig.2(d). The processed layer has no VC precipitations which often exist in the SKD61 matrix as bright contrasted small particles seen in the lower region of

Fig.2(d).

Fig.2 SEM images of the EB irradiated (4 mA) samples; surfaces of (a) SKD11, (b) SKD61 and cross-sections of (c) SKD11 and (d) SKD61

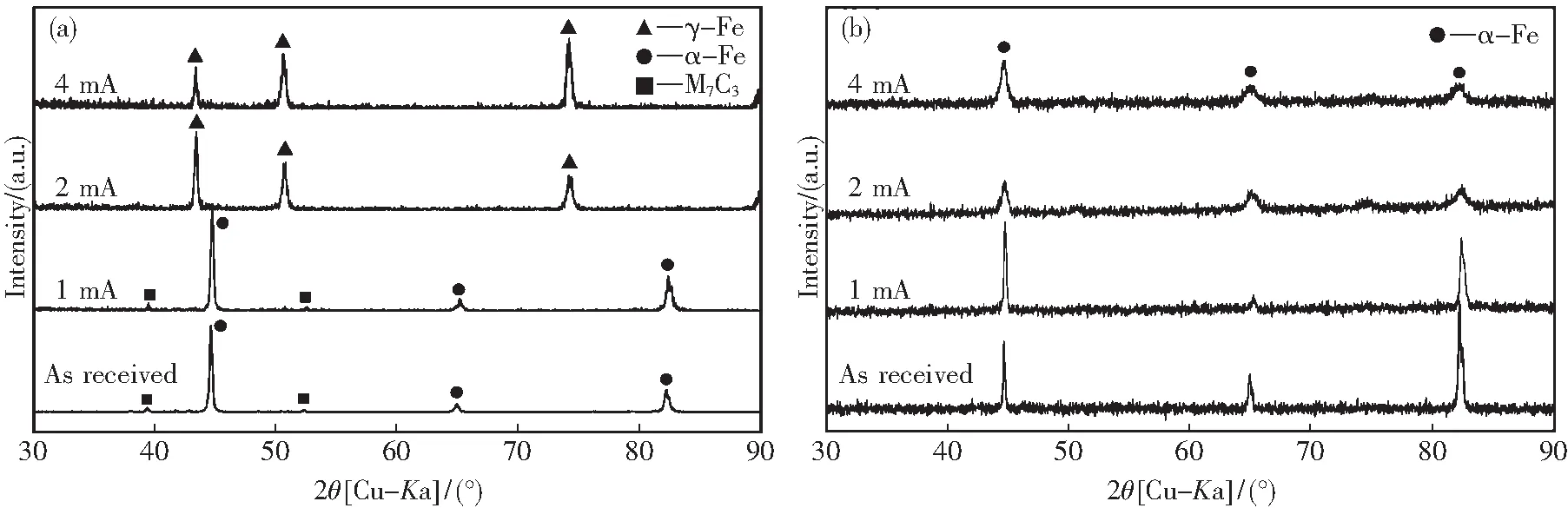

Fig.3 XRD patterns of the electron beam irradiated samples of (a) SKD11 and (b) SKD61 with various current conditions

Figure 3 shows the XRD patterns of the EB irradiated SKD11 and SKD61 samples under various current conditions. In the case of SKD11 (

Fig.3(a)), the surface irradiated with ≥2 mA shows only an austenite (γ) phase, while the as-rolled SKD11 sample shows ferrite (α) main phase with small trace of the M7C3phase. In the Fe-Cr-C phase diagram, theγphase is a high-temperature phase for the corresponding composition and it should exist in the form of α solid solution and M7C3phases at room temperature. The lattice constant of the retainedγphase is 0.361nm (Space group: Fm-3m), this value is higher than that of pure iron (γ-Fe) estimated as if it exists at room temperature. This strongly suggests that the whole carbide precipitations as well as the matrix are melted during the irradiation as evidenced in the SEM observation, then the melt undergoes a subsequent rapid solidification after the irradiation. Thus, theγphase as high-temperature phase should be retained by the quench process and the small dendritic structure concurrently grows. On the other hand, the SKD61 samples do not show such phase change after the irradiations even with the current up to 4mA as shown in

Fig.3(b). However, the SKD61 samples irradiated with ≥2mA show apparently broadened peaks with different intensity ratio, which must be related to the changes in microstructure as observed in the SEM image (

Fig.2(b)). In such case, the grain refinement is most likely to be induced by the martensitic transformation.

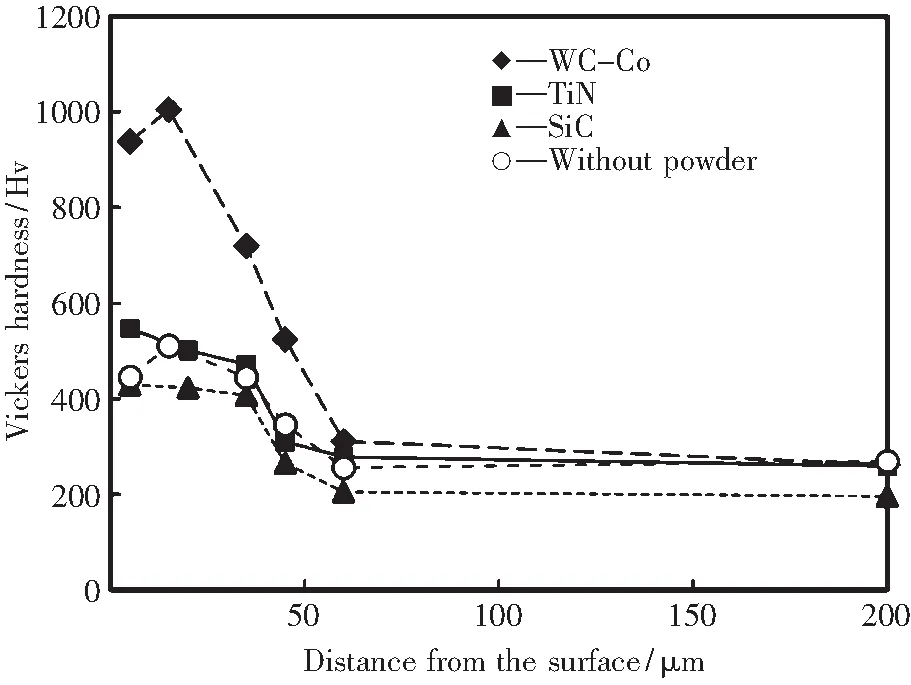

Fig.4 Hardness profiles of the electron beam irradiated (4 mA) SKD11, SKD61 and pure iron substrates

The hardness profiles of the EB irradiated (4 mA) substrates are depicted in

Fig.4. The pure iron shows no significant enhancement in hardness after the EB irradiation, only near the surface (~10 μm) is slightly hardened by the refined microstructure induced by the rapid solidification. In contrast, both the SKD11 and SKD61 surfaces show a remarkable hardening with a thickness of ~50 μm after the EB irradiation. Generally, the hardening of SKD11 is achieved by the martensitic transformation during a conventional quenching process. However, based on the phase analysis, the EB irradiated SKD11 surface evidently shows no martensitic phase. Accordingly, the hardening in the irradiated surface layer is due to the grain refinement as well as the solution hardening induced by carbon and chromium atoms, being in good agreement with the aforementioned SEM and XRD results. As for SKD61, the surface hardening is achieved by the grain refinement as well as the martensitic transformation.

2.2Formationoftheceramic-metalcompositelayerbyEBirradiation

In order to further enhance the surface hardness, ceramic-metal composite layers have been incorporated on the SKD11 surfaces. Here, the SKD61 was excluded to substrate candidates for the composite layers because of the high surface roughness arisen from the martensitic transformation after EB irradiation.

First, SiC was employed as a filler material. The SiC powder was embrocated to the SKD11 surface and then processed by the EB irradiation. The majority of SiC particles were scattered by the electron beam, mainly resulting from charging-up induced repulsive force. Thus a small amount of the residual SiC particles were adhered on the surface as seen in

Fig.5(a). TiN was also employed to form the composite on the SKD11, however, only limited amount of TiN particles was incorporated in the matrix (

Fig.5(b)). Unlike the SiC particles, TiN particles can infiltrate into the matrix, even if the amount of TiN particles is small. This must be mainly because of the relatively high wettability of TiN with steels.

On the other hand, when WC with mass fraction of Co=17% (WC-Co) powder was embrocated onto the substrate surfaces, a composite layer of WC-Co and matrix was formed through solidification after melting by the irradiation as shown in

Fig.6. In the SEM images, WC-rich regions observed as a bright contrast seem to be inhomogeneously distributed. Moreover, the composite layer has a marble-like texture seen in the cross sectional view of the processed layer (

Fig.6(b)). The elemental maps on cross section of the irradiated sample with WC-Co powder embrocation are exhibited in

Fig.7. The distributions of W and Co correspond to the bright area in the SEM image, while the C is rather homogeneously distributed over the processed layer. The distribution of Co evidently indicates its fulfillment of the function as a binder for WC powder. It is noteworthy that the interfaces between WC-rich regions and matrix seem fuzzy and complicated, being considered as an ideal interfacial structure in terms of durability of coatings.

Fig.6 SEM images of (a) surface and (b) cross-section of the EB irradiated SKD11 samples with WC-Co powder embrocation

Fig.8 XRD patterns of the electron beam irradiated samples of SKD11 with and without WC-Co powder embrocation

Fig.9 Hardness profiles of the EB irradiated SKD11 samples with and without various ceramic powder embrocation.

Figure 8 shows the XRD patterns of the EB irradiated SKD11 samples with and without WC-Co powder. The irradiated sample with WC-Co powder consists of WC, W2C, Co andγphases. The W2C is considered to originate from the decomposition of WC during the EB irradiation by following reaction formula.

2WC →W2C+C

(1)

According to the W-C phase diagram[13], the surface temperature during the irradiation process must be over the WC decomposition temperature of 2 750 ℃ at least. The generation of C by the decomposing reaction is also implicated in a rather dispersed distribution of C in the processed layer determined by EPMA analysis. Based on the phase analysis of the irradiated sample with WC-Co powder, the presence of certain content of residualγphase means there must be uncovered areas by the WC-Co coating.

The hardness profiles of the samples processed by the EB irradiation with powder embrocation technique were summarized in

Fig.9. It is reasonable that the hardness profiles have not been changed when both SiC and TiN powders were employed, since less amount of the powders was incorporated into the matrix as seen in

Fig.5. In the meanwhile, by using WC-Co powder, the hardness of surface layer reaches up to 1000 HV as seen in

Fig.9. Conventional WC-Co alloys are known to have the hardness ranging from 1000 to 1800 HV which depends on the Co concentration. Consequently, the surface hardening is reasonably attributed to the formation of the composite layer of WC-Co powder and the substrate material. However, in the composite layer fabricated by EB irradiation, the ratio of WC and Co must be lower than that of the conventional WC-Co alloys due to the dilution with molten matrix, resulting in the reduction of hardness.

Taking into account the SEM and XRD results of the composite layer, there exists a severe inhomogeneity in the WC phase distribution. Therefore, the reduction of hardness in the composite layer can be explained by the inhomogeneous distribution and low concentration of WC particles on the EB irradiated surface. More amounts of WC particles should be included in the composite layer in order to reduce the inhomogeneous distribution and to enhance hardness as well. Further investigation focusing on interactions such as wettability between the ceramic particles and the molten alloy during the irradiation process is indispensable for enrichment of the particle concentration in the composite layer.

3 Summary

Electron beam (EB) irradiation technique was applied to the surface modification of the cold- and hot-working die steels, SKD11 and SKD61, respectively. The EB irradiation induces microstructural changes on both SKD11 and SKD61 surfaces through melting and subsequent rapid solidification. As a result, microstructural refinement, solution hardening and martensitic transformation occurred, thereby the enhancements in hardness were achieved from 270 to 510 HV for SKD11 and from 190 to 700 HV for SKD61. The formation of ceramic-metal composite layer can be obtained by combination of WC-Co powder embrocation and EB irradiation techniques. The composite layer shows a marble-like texture with WC-rich regions. The hardness of the layer reaches up to 1000 HV, however, it was revealed that there exists highly inhomogeneous distribution of WC particles on the irradiated surface. By using the other ceramic powders such as TiN and SiC, less amount of the particles has incorporated into the composite layer, resulting in a relatively low hardness enhancement after the EB irradiation.

Acknowledgements

The authors greatly appreciate Mr. Takuya Kawamura and Mr. Takaki Oka for their experimental assistances.

[1] Nerz J, Kushner B, Rotolico A. Microstructural evaluation of tungsten carbide-cobalt coatings[J]. Journal of Thermal Spray Technology,1992, 1(2):155-160.

[2] Chivavibul P, Watanabe M, Kuroda S,etal. Development of WC-Co coatings deposited by warm spray process[J]. Journal of Thermal Spray Technology,2008, 17(5-6):751-756.

[3] Saha G C, Khan T I. Comparative abrasive wear study of HVOF coatings obtained by spraying WC-17Co microcrystalline and duplex near-nanocrystalline cermet powders[J]. Journal of Engineering Materials Technology,2011, 133: 2-8.

[4] Niino M, Hirai T, Watanabe R. The functionally gradient materials[J].Journal of Japan Society of Composite Materials,1987, 13:257-264.

[5] Tokita M. Large-size WC/Co functionally graded materials fabricated by spark plasma sintering (SPS) method[J]. Materials Science Forum,2003, 423-425:39-44.

[6] G Lewis B, Strutt P R . Practical implications of electron-beam surface melting[J]. Journal of Metals, 1982,34(11):34-40.

[7] Uno Y, Okada A, Uemura K,etal. High-efficiency finishing process for metal mold by large-area electron beam irradiation[J]. Precision Engineering, 2005, 29: 449-455.

[8] Yu Z, Wang Z, Yamazaki K ,etal. Surface finishing of die and tool steels via plasma-based electron beam irradiation[J]. Journal of Materials Processing Technology,2006, 180:246-252.

[9] Okada A, Kitada R, Okamoto Y,etal. Surface modification of cemented carbide by EB polishing[J]. CIRP Annals-Manufacturing Technology,2011, 60:575-578.

[10] Pakhomova N A, Artinger I, A Bannykh O ,etal. Structural change in steel R6M5 due to surface meting by electron beam[J]. Metal Science and Heat Treatment, 1989,31(10):734-738.

[11] Matossian J N, Wei R, Williams J D. Plasma-based ion implantation and electron-bombardment for large-scale surface modification of materials[J]. Surface and Coatings Technology,1997, 96:58-67.

[12] Okada A, Uno Y, Uemura K. Increases in corrosion resistance and water repellency of metal mold surface by EB polishing[J]. Proc of the 25th Annual Meeting of the American Society for Precision Engineering, 2010:301-304.

[13] Kurlov A S, Gusev A I. Tungsten carbides and W-C phase diagram[J]. Inorganic Materials,2006, 42(2):156-163.