Design of special fixture for automatic measurement of resistance of auto ignition wire*

Hua-ru YAN,Fang CHEN,Wei DU

1Department of Mechanical Engineering,Henan Mechanical and Electrical Engineering College, Xinxiang 453003, China;2Henan University of Science and Technology, Luoyang 471003, China

Design of special fixture for automatic measurement of resistance of auto ignition wire*

Hua-ru YAN†1,Fang CHEN1,Wei DU2

1DepartmentofMechanicalEngineering,HenanMechanicalandElectricalEngineeringCollege,Xinxiang453003,China;2HenanUniversityofScienceandTechnology,Luoyang471003,China

Resistance of auto ignition wire, which is an important parameter of the factory inspection, affects the performance of engine ignition directly. For meeting the demand of large scale production and automatic measurement, a special fixture to measure the resistance value of auto ignition wire is designed from join shape of auto ignition wire in the paper. With easy operation, it can rapidly assemble and disassemble, and is centralized outcome of optical-mechanic- pneumatic. Through practical operation, it reduces labor intensity of operator, saves unnecessary labor, and improves measuring efficiency and automation level. It is very good for popularization.

Special fixture, Auto ignition wire, Resistance, Automatic measurement

1.Introduction

Generally, there are four auto ignition wires with different length in electronic spark control system of auto engine, whose resistance value is also different from each other, and generally 2~10 kΩ. The value affects the performance of engine ignition directly, so it is a very important parameter and has to pass strict inspection before it leaves factory. Nowadays, automatic measurement system of resistance of automotive ignition wire is largely absent at home, and the general way is to use a multimeter and a buzzer for manual measurement, which is very inefficient. With the rapid development of automatic measurement technology and the increasing enlargement of production[1-2], it is urgent to meet the demand of effective and automatic measurement. According to join shape of auto ignition wire and operation requirements of automation system[3-5], a special fixture,which can coordinate with automation system to realize rapid measurement in a cooperation project with enterprise in 2012,is designed, and which has passed provincial-level projects appraisement now.

2.The basic situation of the special fixture in automatic measurement system of resistance

2.1.The configuration of the special fixture in system

The external configuration of the whole system is shown in Figure 1. The special fixture consists of distributor module 4, clip module 3 and spark plug module 1. According to different length of four auto ignition wires, the modules are fixed on workbench 6 that is made from aluminium plate. Inside distributor module and spark plug module, there are copper probes to connect auto ignition wire to measuring circuit. Between distributor module 4 and spark plug module 1, clip module 3 is a set, which contains photoelectric mechanism and pneumatic mechanism. The control button 5 can control start and stop of the measuring. The measuring and controlling device 8 is installed in the wall box of the back of LCD 9, which contains the main hardware circuit and a single chip microcomputer as core. The small keyboard 7 is used to set basic parameters of the measuring system.

1.spark plug module; 2.auto ignition wire; 3.clip module; 4.distributor modules; 5.control button; 6.workbench; 7.small keyboard; 8.measuring and controlling device; 9.LCD

Figure 1. External configuration of system

The major role of clip module 3 is to create automatic signal for automatic measuring system, which is the core of the special fixture. Pressure clamp, used in the clip module 3, a high elasticity of rubber product, is obtained by direct buying. The four arc grooves are good for pressing 4 auto ignition wires.

2.2.The workflow of the special fixture in system

The workflow of the special fixture in system is:first, the two ends of four auto ignition wires are respectively connected to measuring circuit:one end is connected with distributor module, the other end is connected with spark plug module. Secondly, using pressure clamp, the middle of four auto ignition wires can be pushed into the clip module, which can be detected by photoelectric mechanism of clip module, and a position signal (INPOS signal) is generated and transferred to controlling system. Thirdly, when the single chip microcomputer of control system receives the INPOS signal, the electromagnetic valve is opened and pneumatic mechanism is drived to lock wire harness, then a locking signal is generated to control system. Fourthly, when the single chip microcomputer receives the locking signal and the start button is pressed, the measuring programs is started to measure resistance value, then the measuring results, four groups of wire numbers and the respective resistance value are displayed on the LCD panel. Lastly, after pressing stop button, the electromagnetic valve is switched and pneumatic mechanism is reset to loosened locked wire harness. Thus, the measuring is end.

3.Specific structure of the special fixture

3.1.Specific structure of the spark plug module

According to structure dimensions of spark-plug terminal of auto ignition wire, the spark plug module is designed, which consists of four same spark plug units. As shown in Figure 2, each of them consists of 16 parts. As a main part, copper probe 9 is installed in insulated sleeve 5 to achieve insulation. Because spring 7 is placed around the left-hand side of probe 9, probe 9 can keep a trend of a movement to the right, which can make reliable connection between probe 9 and spark-plug terminal of measured wire. There is an aperture on the left end of probe 9, which is designed to connect probe 9 to measuring circuit.

1.base; 2.end cover; 3.sunk screw 1; 4.sunk screw 2; 5 insulated sleeve; 6.gland; 7.spring; 8.column sleeve; 9.probe; 10.supporting body1; 11.supporting body 2; 12.supporting body 3; 13.sunk screw 3; 14.sunk screw 4; 15.frame body; 16.sunk screw 5

Figure 2. Structural drawing of spark plug unit

3.2.Specific structure of the distributor module

According to structure dimensions of distributor terminal of auto ignition wire, the distributor module is designed, which consists of four same distributor units. As shown in Figure 3, each of them consists of 8 parts. Like internal structure of spark plug unit, copper probe 2 is installed in insulated sleeve 3 to achieve insulation. Because spring 5 is placed around the lower part of probe, probe 2 can keep an upward trend, which can make reliable connection between probe 2 and distributor terminal of measured wire. There is an aperture on the lower end of probe, which is designed to connect probe 2 to measuring circuit. Screw nut 7 is to fix distributor unit to workbench.

1.housing; 2.probe; 3.insulated sleeve; 4.column sleeve; 5.spring; 6.gland; 7.screw nut

Figure 3. Structural drawing of distributor unit

3.3.Specific structure of the clip module

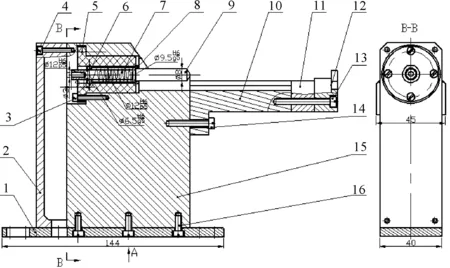

According to the signal demand of system and the structure dimensions of bought pressure clamp, clip module is designed. As shown in Figure 4, it consists of 19 parts, and contains photoelectric mechanism and pneumatic mechanism.

1.cylinder; 2.base; 3.clamping arm; 4.nutM3; 5.screwM3; 6.gland; 7.screw; 8.compression spring; 9.copper base; 10.photoconductive rod; 11.V-shaped part; 12.cylindrical-pin axis 1; 13.cylindrical-pin axis 2; 14.cylindrical-pin axis 3; 15.tension spring; 16.trundle; 17.cylindrical-pin axis 4; 18.support cap; 19.screw nut;

Figure 4.Structural drawing of clip module

Four arc grooves of upper part of copper base 9 fits to four arc grooves of bought pressure clamp, which is good for four wires pressed into clip module. Generating INPOS signal is this: when pressing pressure clamp, photoconductive rod 10 moves downward, which makes photodiode packed here generate INPOS signal to single chip microcomputer of controlling circuit. Clamping arm 3, which is installed on the left and right sides of copper base 9, can revolve round cylindrical-pin axis 14. Convex block on the upper port of clamping arm 3 is designed for pressing pressure clamp. A tension spring 15 and two trundles 16 are installed on the lower port of clamping arm 3. Support cap 18 is installed on the upper port of cylinder 1 by threaded connection. Its locking function is this: when the single chip microcomputer receives INPOS signal and controls the electromagnetic valve powering, cylinder 1 moves upward with support cap 18.When moving to a certain position, the conical head of support cap 18 can pushed two trundles 16 to open by overcoming spring force of tension spring 15, then the convex block of clamping arm 3 can firmly press down pressure clamp with the help of lever principle, in other words, four measured wires are firmly pressed down. When measuring is over, the electromagnetic valve is controlled to be in loss of power, and cylinder 1 moves downward with support cap 18, then the upper port of clamping arm 3 is open under the action of spring restoring force, and pressure clamp is loosened. Screw nut 19, which is installed under base 2, has two roles: one is to fix clip module to workbench, the other is to adjust cylinder 1 position of upper or lower that makes support cap 18 good contacts with two trundles 16.

4.Conclusion

The special fixture is a very important part of the automatic measurement system of resistant. Its application effect has been fine since 2012. It has very obvious advantages such as compact structure, operation easily, low cost, and so on. It can meet the need of large scale production and measurement by coordinating with automation system. So it is very good for popularization.

[1] YU Wei-ping.Current status and development trend of Chinese domestic gasoline-engine Ignition System[J].Journal of Hunan Institute of Engineering,2003,12(2):47-49.

[2] Liu Xialun.Types and structure characteristics of electronic ignition system[J]. Auto electric parts,2002(6):26-27.

[3] ZHU Yao-xiang,Pu Lin-xiang. Modern fixture design handbook[M]. Beijing: China Machine Press, 2010:8-10.

[4] WU Zheng-hua.The principle and structure of special fixture[J]. Machining workers,2006(3):49-50.

[5] WANG Xiao-hua.Machine tool fixture book[M]. Beijing: China Machine Press, 1992.

摘要:以机床主轴为优化设计对象,将优化设计思想与Matlab相结合,利用外惩罚函数法对机床主轴进行建模优化,求解出参数并用分支定界法确定主轴参数。然后运用ANSYS对其进行模态分析,分析了主轴的前6阶固有频率、振型和临界转速,验证了机床主轴结构优化设计的合理性,为机床主轴的结构优化设计提供参考和依据。

关键词:机床主轴;外惩罚函数法;优化设计;模态分析;动态特性

中图分类号:TH133

实现汽车点火线电阻自动测量的专用夹具的设计*

闫花茹†1,陈 芳1,杜 伟2

1.河南机电高等专科学校 机械工程系,河南 新乡 453003;2.河南科技大学,河南 洛阳 471003

汽车点火线的电阻直接影响了发动机的点火性能,是生产厂家出厂检验的一项重要参数指标。为满足大规模生产和自动化测量的需求,根据汽车点火线的接头特征,设计了一种能快速装拆的用于汽车点火线电阻自动测量的专用夹具。它集光、机、气为一体,操作省力方便;经实际应用表明:该夹具明显降低了工人的劳动强度,节约了不必要的劳动力,大大提高了检测效率和自动化水平,具有较大的推广应用价值。

专用夹具;汽车点火线;电阻;自动测量

U270.1+4

机床主轴结构参数优化设计

邓思琪, 马登云, 郑卫刚†

武汉理工大学 智能制造和控制研究所, 武汉 430063

2014-02-20

10.3969/j.issn.1001-3881.2014.12.019

*Project supported by Natural Science Research Project of Henan Province Department of Education(2011B460006)

† Hua-ru YAN, E-mail: huaru6@163.com

- 机床与液压的其它文章

- A Simple time-domain method for bearing performance degradation assessment*

- Structural design and performance testing of the electromagnetic proportional pressure relief valve

- Analysis of magnetic field characteristics for different winding cylinder materials of a new type of magnetorheo-logical damper*

- Impacts of centrifuge errors on calibration accuracy of error model coefficients of gyro accelerometer*

- Interior ballistic simulation and parameter influence analysis of an underwater pneumatic launcher*

- Influence of airflow uniformity over the duct outlet of vehicle air-condition on cooling performance*