Prevention and treatment technologies of railway tunnel water inrush and mud gushing in China

Yong Zho, Pengfei Li, Siming Tin

aProjectDesignandApprovalCenterofMinistryofRailways,Beijing100844,China

bCollegeofArchitectureandCivilEngineering,BeijingUniversityofTechnology,Beijing100022,China

Prevention and treatment technologies of railway tunnel water inrush and mud gushing in China

Yong Zhaoa,∗, Pengfei Lib, Siming Tiana

aProjectDesignandApprovalCenterofMinistryofRailways,Beijing100844,China

bCollegeofArchitectureandCivilEngineering,BeijingUniversityofTechnology,Beijing100022,China

A R T I C L E I N F O

Articlehistory:

Received 31 December 2012

Received in revised form 20 June 2013

Accepted 24 July 2013

Tunnel engineering

Unfavorable geological regions

Water inrush and mud gushing

Pressure relief technology

Advance grouting technology

Advance jet grouting

Water inrush and mud gushing are one of the biggest hazards in tunnel construction. Unfavorable geological sections can be observed in almost all railway tunnels under construction or to be constructed, and vary in extent. Furthermore, due to the different heights of mountains and the lengths of tunnels, the locations of the unfavorable geological sections cannot be fully determined before construction, which increases the risk of water inrush and mud gushing. Based on numerous cases of water inrush and mud gushing in railway tunnels, the paper tries to classify water inrush and mud gushing in railway tunnels in view of the conditions of the surrounding rocks and meteorological factors associated with tunnel excavation. In addition, the causes of water inrush and mud gushing in combination of macro- and micromechanisms are summarized, and site-specific treatment method is put forward. The treatment methods include choosing a method of advance geological forecast according to risk degrees of different sections in the tunnel, determining the items of predictions, and choosing the appropriate methods, i.e. draining-oriented method, blocking-oriented method or draining-and-blocking method. The treatment technologies of railway water inrush and mud gushing are also summarized, including energy relief and pressure relief technology, advance grouting technology, and advance jet grouting technology associated with their key technical features and applicable conditions. The results in terms of treatment methods can provide reference to the prevention and treatment of tunnel water inrush and mud gushing.

© 2013 Institute of Rock and Soil Mechanics, Chinese Academy of Sciences. Production and hosting by Elsevier B.V. All rights reserved.

1. Introduction

Up to now, nearly ten thousand kilometers of railway tunnels have been built under a variety of complex geological conditions in China. In tunnel construction, water inrush and mud gushing are the challenging issues. They are characterized by the largest geological hazards and the potential risks (see Fig. 1). In this paper, water inrush and mud gushing in underground projects basically refer to the dynamic destruction of structure in unfavorable geological sections. The hydrodynamic system and the dynamic equilibrium of surrounding rocks undergo drastic changes due to the excavation of underground projects, which causes instant release of the energy stored in underground water carrying mud and sand that gush to the tunnel face at a high speed (Lin and Song, 2012).

In recent years, more than 100 cases of water inrush and mud gushing have been observed in China, causing serious losses of human life and economics and deterioration of construction conditions. Accordingly, the quality and the long-term safety of underground construction are involved. For drainage in large quantity over a long period of time is costly, the ecological environments can seriously be undermined, leading to the depletion of water resources, death of vegetation and destruction of farmlands.

Water inrush seriously threatens construction when the tunnel goes through water-rich area, which frequently occurs in unfavorable geological sections. For examples, serious water inrush and mud gushing occurred in the Yuanliang mountain tunnel of Chongqing-Huaihua Railway. The peak duration of the water inrush lasted for roughly 0.5 h, with water discharge of 1.1 × 105m3; the mud in the tunnel was 1.2–4.5 m deep, and the value of mud was approximately 1.5 × 104m3. Large-scale events of water inrush and mud gushing of this kind occurred ten times in Wulong mountain tunnel, accounting for economic losses over RMB 20 million. In the Malujing tunnel of Yichang-Wanzhou Railway, water inrushand mud gushing occurred in the “DK255 + 978” karst tunnels on 21 January 2006, with the value of water inrush of approximately 7.2 × 105m3and the mud of about 7.0 × 104m3. The water inrush and mud gushing flooded the 3152 m parallel heading and 2508 m main tunnel in vicinity of exit, and caused the damages of a large number of equipment and machinery with economic losses over RMB 10 million. After that, the treatments of this accident took for 3 years. In the Yesanguan tunnel of Yichang-Wanzhou Railway, water inrush and mud gushing were observed in “DK124 + 602”karst tunnels on 5 August 2007, and the peak flow rate reached 1.5 × 105m3/h. The volume of mud and broken stones gushing was around 5.0 × 104m3, causing the equipment and machinery in the tunnel to be seriously deformed and/or damaged, flooded about 500 m away from their positions. The economic losses were huge and subsequent treatments took 2 years. In the Baiyun tunnel of Nanning-Guangzhou Railway, water inrush and mud gushing occurred at the stake DK334 + 733 on 16 January 2010, lasting for about 30 s. The length of mud gushing area is 167 m, and the value of mud and sand gushing is over 2500 m3, also leading to serious damages to construction equipment and machinery. The Guanjiao tunnel of Xining-Lhasa Railway, located at the northeast edge of Qinghai-Tibet Plateau with strong geological activities, goes through 19 fault zones with the total length of 2.8 km. The peak water inrush rate reaches 3.2 × 105m3/d with water loss of 1.5 × 105m3/d, inducing the cost of electricity output RMB 5 million monthly.

Fig. 1. Types of geological disasters in tunnels excavated by drill-and-blast method and their percentages.

In unfavorable geological sections, it is critically important to figure out the mechanism of water inrush for safe tunnel construction, and effective water inrush risk assessment method and appropriate measures should be adopted. At present, researches on the mechanism of water inrush in tunnel construction in mountainous regions, such as the analysis of water inrush mechanism in unfavorable geological sections (especially in fault zones and karst stratum), determination of critical condition of water inrush, the quantity calculation of inrush water, are fruitful, providing solid supports to tunnel construction (Guan, 2003; Cui, 2005; Jiang, 2006; Zhang, 2010; Guan and Zhao, 2011). However, most researches on water inrush in tunnels are experienced from coal mining industry (Gao et al., 1999; Li, 2010; Guo, 2011). For extra-long tunnels in mountains, the locations of the unfavorable geological sections cannot be fully understood before construction. We still do not have very effective method for advance geological forecast. We need to have better understanding of the disastercausing mechanism and dynamic evolution of the disasters, and correct theories for the early warning and prevention of water inrush and mud gushing.

Based on the characteristics of long tunnels, this paper summarizes different types of water inrush and mud gushing accidents and tries to understand the influential factors and propose preventive measures and treatment technologies which have been successfully applied to many railway tunnels in China.

Table 1 Types of water inrush and mud gushing.

2. The mechanisms and influential factors of water inrush and mud gushing in tunnels

2.1.Typesofwaterinrushandmudgushing

Water inrush and mud gushing in tunnels can be classified into different types according to various criteria. Based on the results (Gao et al., 1999; Zhao et al., 2009; Li, 2010; Guo, 2011), theclassification of water inrush and mud gushing is shown in Table 1 and Fig. 2.

Fig. 2. Types of water inrush and mud gushing in tunnels and their percentages.

2.2.Influentialfactorsofwaterinrushandmudgushing

Through site investigation and available studies of water inrush and mud gushing accidents, it is observed that the tunnels with water inrush and mud gushing are basically characterized by high water pressure, large quantity of water storage, loose filling materials, rich water supply, and known geological conditions. The main factors, related to water inrush and mud gushing, are the sources of water supply, water pressure, confining bed, geological structure, tunnel excavation and meteorological impacts. Source of water supply is the dominant factor; water pressure is the main factor, a driving force determining whether water inrush occurs and the quantity thereafter; the unbroken rock stratum above the vault can be regarded as the confining bed to ensure safe tunnel excavation; geological structure determines the passage of the water inrush in tunnels (most water inrush cases especially that of large scale are related to geological structure); tunnel excavation is the inducing factor of water inrush; temperature, raining and other meteorological factors contribute to water inrush and mud gushing. The first four factors are associated with the conditions of surrounding rocks.

2.2.1.Conditionsofsurroundingrocks

The environmental conditions of tunnel excavation, such as the rock types and lithology, conditions of underground water and other geological factors, are the basic conditions for water inrush and mud gushing. Tunnel water inrush and mud gushing usually occur at the structural plane of the rocks, fault zone, intensively fissured zone, weathered trough, karst cavity and other unfavorable geological areas. In terms of rock lithology, water inrush and mud gushing are usually observed at dolomite, limestone and other dissolvable rock strata. The vertical zonation of water and mud is closely related to water inrush. The possibility of tunnel water inrush emergence from low to upper is karst water aeration zone, deep slow flow zone, seasonal change zone, shallow water-rich zone, and water-rich zone with pressure.

2.2.2.Impactofraining

Raining, temperature changes and other meteorological phenomena can also affect water inrush and mud gushing, i.e. magnitude varying in different seasons. For example, in summer with strong rainfall, the construction-induced disturbance in combination of high water pressure and temperature, water scouring effect and other relatively actives (i.e. physico-chemical reactions) can easily induce large-scale water inrush and mud gushing.

2.2.3.Construction-induceddisturbance

Tunnel excavation can inevitably disturb the original strata. Excavation method and excavation extent are two important factors. The former is reflected in whether drill-and-blast method or partial excavation method is adopted and in the design of support parameters; the latter is involved in cross-sectional area and excavation span.

2.3.Mechanismofwaterinrushandmudgushing

The macro-mechanism of tunnel water inrush and mud gushing is basically concentrated on the analysis of different types of tunnel water inrush and mud gushing, and the micro-mechanism on the analysis of the minor physico-mechanical effect of underground water exerted on the strata. Thus, analysis of macro-mechanism can explain different types of water inrush and mud gushing, and that of micro-mechanism can provide theoretical basis (Lin and Song, 2012) for an in-depth study on the causes of water inrush and mud gushing and the mechanism.

Fig. 3. The erosion-expansion effect of groundwater.

In karst strata, engineering geology, hydro-geological conditions, in situ stress level, and physico-mechanical characteristics of rocks as well as different tunnel locations, lead to different mechanisms of tunnel water inrush and mud gushing. Thus, the mechanism of emergence of tunnel water inrush and mud gushing is different due to complex geological conditions. In terms of macro-mechanical mechanism, tunnel water inrush and mud gushing can be classified into 4 types according to the storage environments of water and mud: karst cave (hole) water inrush, high-pressure geological interface water inrush, and underground karst channel (or underground river) water inrush, and fault (fractured) zone water inrush. According to analysis of formation of mud passage, the mechanism of tunnel water inrush can be roughly classified into 4 types: the fracture of watertight layer through stretching, the shear-yielding of geological interface, the hydraulic impact of discontinuous geological interface and the instability and slipping of the controlling rocks (Lin and Song,

2012).

The essence of micro-mechanism of tunnel water inrush is the continuous physico-chemical impact of water and mud on geological interface and the impact of the accumulated micro-damages, including the softening and dissolving effect of water and mud on the strata of the geological interface, the effect on cavity expansion, the water wedge effect, and the erosion-expansion effect on the water inrush passage. Therefore, tunnel water inrush is a process evolution in which the continuous physico-chemical impact of water and mud on geological interface leads to its progressive damage. The erosion-expansion effect of groundwater is shown in Fig. 3.

3. Prevention measures and treatment technologies of tunnel water inrush and mud gushing

3.1.Preventionmeasures

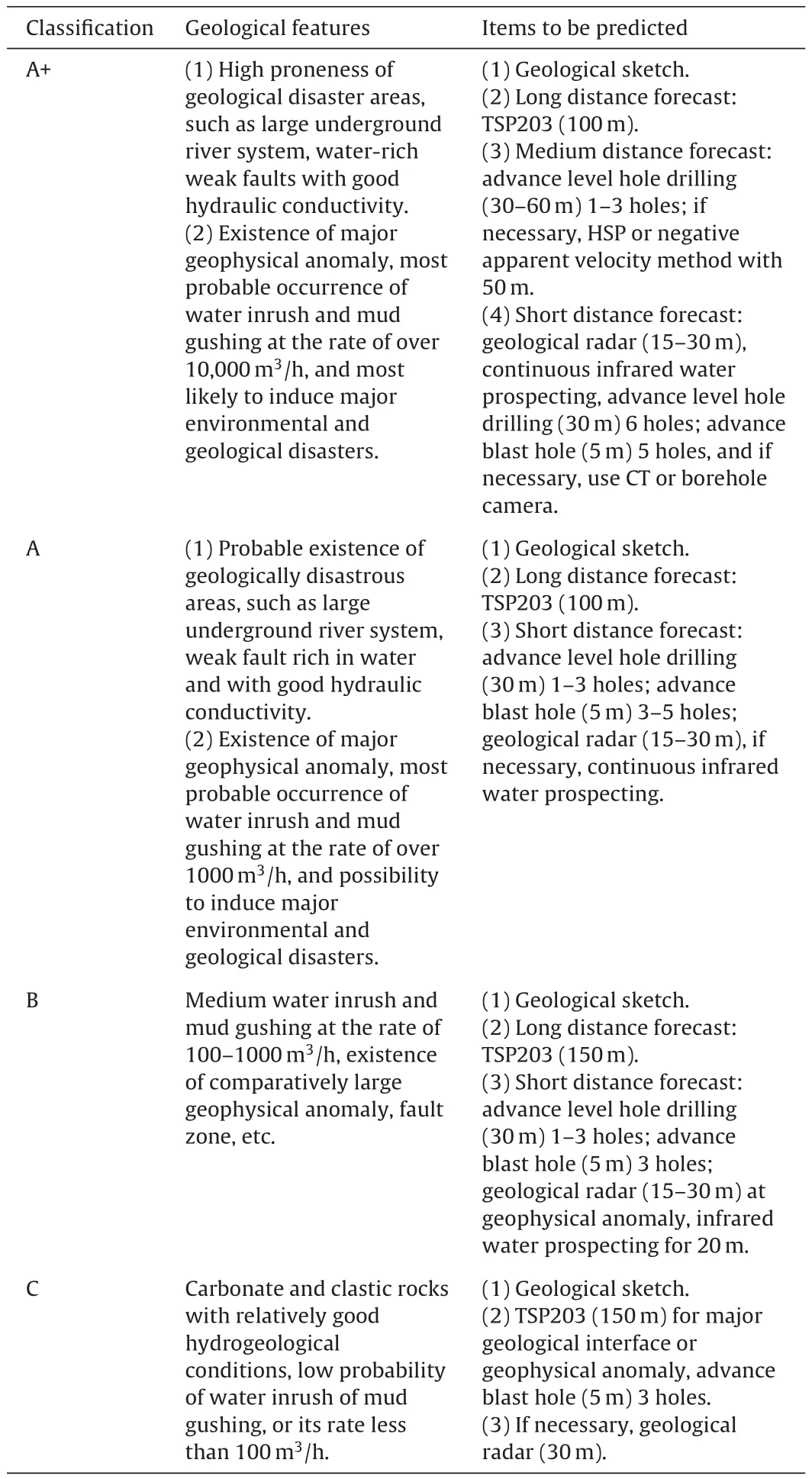

Comprehensive advance geological forecast is the principal measure for the prevention of railway tunnel water inrush and mud gushing. Currently, it has been widely used in railway tunnel construction in China. The measures include geophysical prospecting and prospecting by drilling. Advance geological forecast shall be determined according to the risks of different sections in the tunnel, and the prediction items shall be considered subsequently. The classification of advance geological forecast and the items are shown in Table 2 (Zhao et al., 2009). According to the researches of Shandong University (group of Prof. Li Shucai), advance geological forecast technology (Li, 2009; Zhang et al., 2010; Li et al., 2011) for progressive water-bearing structures is shown in Fig. 4.

Table 2 The classification of advance geological forecast and items to be forecasted.

3.2.Treatmentprincipleandtechnology

3.2.1.Treatmentprinciple

According to the site-speci fic groundwater environments, the treatment principles are draining-oriented, blocking-oriented or draining-and-blocking.

(1) Draining-oriented: such as energy relief and pressure reduction method. It is mainly applied to large-scale high-pressure water-rich karst, high-pressure and water-rich karst channel, and regional water-rich cystic weathering cavities.

(2) Blocking-oriented: such as advance curtain grouting method. It is mainly applied to the cases that groundwater environment requirement is strict, the faults where water pressure is less than 0.5 MPa, and the water leakage from bedrock fissure.

(3) Draining-and-blocking: such as pressure relief through water diversion tunnels, and grouting. It is mainly applied to water-rich faults where water pressure is over 0.5 MPa and water leakage from bedrock fissure, or karst deposits after energy relief and pressure reduction.

3.2.2.Treatmenttechnology

(1) Energy relief and pressure reduction method

Energy relief and pressure reduction method (Zhang, 2010) means in karst cavity with high pressure and rich water during tunnel construction, accurate blasting or advance drilling is applied to drain water, release mud, and reduce water pressure in the cavity for the purpose of energy relief. During excavation, structural support and treatment after energy relief and pressure reduction can take a certain period of time. Energy relief and pressure reduction method shall be considered in dry season; if it is used in rainy season, the constant supply of rainwater can pose risk to tunnel construction. The work procedure and detailed items of energy relief and pressure reduction method are shown in Fig. 5.

(2) Advance grouting technology

Advance grouting means filling proper grouting materials into karst cavity, fault (fractured) zone, bedrock fissure and other construction bodies through reasonable grouting process by equipment and machinery, so as to achieve filling, reinforcement, water-blocking to ensure the safe tunnel excavation and its long-term operation (Mo and Zhou, 2008; Dai, 2009; Zhuang and Mu, 2009).

Commonly used advance grouting technology includes fullface curtain grouting technology and informationized grouting technology. Full-face curtain grouting technology is based on the assumption that the outer strata of the tunnel are uniform, thus the loose area can be reinforced by full-face grouting. In practical engineering, grouting parameters can be determined according to water pressure as shown in Fig. 6. For informationized grouting technology, according to different damages of the strata, sectional division, water blockage from outside and reinforcement inside, local strengthening is used as shown in Fig. 7. Compared with the full-face curtain grouting technology, informationized grouting technology involves few drilling holes and thus is less time-consuming.

(3) Advance jet grouting technology

Advance jet grouting technology (Yang and Zhang, 2008; Zhao, 2012) is basically employed for the purpose of deformation control of surrounding rocks. Through measuring core rock and soil samples, the physico-mechanical properties of surrounding rocks can be determined; accordingly, the states of the surrounding rocks, i.e. stable, temporary stable, unstable after excavation, can be predicted. Then, the informationized design and construction method can be considered to control the geological deformation and to ensure safe passing of tunnel’s full-section in various strata, in especially complex and unfavorable geological regions. Presently, the technology is introduced to the treatment of railway tunnel water inrush and mud gushing (see Fig. 8).

4. Applications of treatment technologies

4.1.Applicationofenergyreliefandpressurereductionmethod toYesanguantunnel

After the occurrence of water inrush and mud gushing in Yesanguan tunnel of Yichang-Wanzhou Railway, it is suggested that the energy relief and pressure reduction method and grouting method be adopted. A drainage hole of 5250 m long is considered on the left side of the tunnel, and a branch drainage hole at ahigh position, 7.5 m above the main tunnel vault, is dug to release energy and reduce water pressure (see Fig. 9). Accordingly, the mixture of water and mud in the cave was released to mitigate the construction risks. After that, advance pipe-shed and other measures are adopted, and finally the tunnel construction is successfully completed. Three years’ monitoring results show that the tunnel structure is safe and reliable.

Fig. 4. Advance geological forecast technology system for progressive water-bearing structures.

4.2.ApplicationofcurtaingroutingmethodtoQiyueMountain tunnel

Qiyue Mountain tunnel is located at the junction of soluble rock and insoluble rock, passing through the fault F11 characterized by high water pressure. The fault F11 is large-scale stretching about 250 m along the tunnel direction, composed of limestone, tectonic breccia, fault gouges. The rock is broken and poor in agglutination. Water inrush rate of a single hole disclosed by advance geological drilling reaches 790 m3/h. The water pressure is observed up to 2.5 MPa. Before tunnel construction, the fault F11 is carefully investigated by comprehensive advance geological forecast methods, such as geological sketches, advance geophysical prospecting, 60 m long advance hole drilling, 30 m long advance hole drilling, and blast hole. As a result, large-scale water inrush and mud gushing are successfully prevented.

The principle and method of “pressure relief through draining + reinforcement by grouting” are adopted according to the obtained information by the advance geological forecast method and field grouting and draining tests. Drainage holes are considered in the parallel heading and branch drainage areas to relieve water pressure of the surrounding areas in the tunnel, thus water pressure on the surrounding rocks of the tunnel is reduced, and consequently the dif ficulties in tunnel grouting and excavation are reduced (see Fig. 10). With those measures, the scopes of the parallel heading and the main tunnel by advance grouting are determined at 5 m and 8 m outside the excavation contour line, respectively (see Fig. 11). Additional site-speci fic grouting holes shall also be considered in water-rich regions. In this project, the advance pipe shed and tunnel face fiberglass bolt and other advance-supporting measures are taken for consideration of safe and quick tunnel excavation. After 3 years of monitoring, it shows that the tunnel structure remains safe and reliable.

4.3.ApplicationofinformationizedgroutingmethodtoGuanjiao tunnel

Guanjiao tunnel in the Qinghai-Tibet Railway is located between Tianpeng station (the existing line) and Chahannuo station. There are two parallel tracks in the tunnel with length of 32.6 km (currently the longest railway tunnel in Asia). The tunnel passes through many water-rich fault zones and serious water inrush disasters occurred during construction. In order to reduce the quantity of water inrush and the costs of water drainage, the informationized grouting technology is adopted. The number of necessary grouting holes is determined considering the results of advance geological forecast, damage extent of surrounding rocks at the tunnel face, water inrush quantity and forms of water inrush. The principle of water inrush control is applied from outside to inside, step by step, through drilling at suitable intervals. Addition of holes and local strengthening are also considered to achieve the targeted number of grouting holes and the effective grouting. The informationized grouting technology adopted in the construction of Guanjiao tunnel is shown in Table 3, and good results are achieved (see Fig. 12).

4.4.ApplicationofadvanceleveljetgroutingtoLiangshantunnel

Liangshan tunnel of Xiamen-Shenzhen Railway is located between Zhangpu Country and Yunxiao County in Fujian Province. The tunnel is 9888 m long, a double-track tunnel with train speed of 250 km/h. During construction, water inrush and mud gushing frequently occurred, resulting in 230 m of main tunnel filled with serious gushed mud. The incident causes a ground subsidence ofabout 20 m in depth in the area of 1500 m2(the overburden depth of tunnel is 270 m). The ground subsidence revealed that the surrounding rocks are located in intensively fissured zone.

Fig. 5. Work procedure and description of energy relief and pressure reduction method.

Table 3 Types of informationized grouting methods employed in Guanjiao tunnel.

Fig. 6. Schematic diagram of full-face curtain grouting.

After the accidents of water inrush and mud gushing, level jet grouting piles were set at the tunnel face in order to (1) ensure the safe construction and long-term operation of the tunnel, (2) to eliminate mud gushing at weak zone in the main tunnel, and (3) to enhance the tunnel stability. Jet grouting piles are 40 m long, over 50 cm in diameter, and 35 cm in spacing between pile centers. The interlocking width of grouting piles is 15 cm and crossdistributed. Four rings of level jet grouting piles are set for the arch wall outside the excavation contour line, and the effective thickness of grouted body is 1.55 m. Two rings of level jet grouting pile are set for the bottom of the inverted arch, and the effective thickness of grouted body is 0.85 m. The compressive strength of grouted body shall be not less than 3 MPa. Advance support of φ159 mm large grouting pipe-shed (40 m long) of two layers at arch wall which is inside the inner ring jet grouting piles should be considered. The pipe-shed shall be embedded into the bedrock with depth not less than 5 m, and circular spacing of 0.3 m. After the jet grouting piles are completed, the effect of reinforcement shall be examined and other related reinforcement works shall becarried out before excavation. Thus, the following criteria should be met:

Fig. 7. Schematic diagram of informationized grouting.

Fig. 8. Diagram of advance level jet grouting in tunnels.

Fig. 9. Plane sketch of the treatment of “+602” karst cavity.

(1) The compressive strength of grouted body should be not less than 3 MPa.

(2) Water stream is not allowed at testing hole, tunnel face and side wall after excavation.

(3) Core sampling rate of jet grouting reinforcement body should be not less than 70%.

Fig. 10. Plane sketch of the geological features and treatment method of fault F11 in Qiyue Mountain tunnel.

If drilling tests results (image borehole tests, core sampling hole and pipe-shed drilling holes) suggest that the jet grouting does not have a targeted effect, additional inspection holes will be drilled in order to determine the potential weak areas; if necessary, supplementary reinforcement measures shall be carried out in the weak areas through supplement pile jet grouting or grouting, or composite grouting to ensure the reinforcement effects of the reinforced rings.

Through the observation in each cycle during excavation, it was observed that the level jet grouting reinforcement ring always keeps its longitudinal continuity in the weak layer. The circular interlocking is good, and the level jet grouting reinforcement rings are visible. Point load test results of level jet grouting reinforced body show that the average strength is 5.7 MPa, with the minimum value of 4.8 MPa; the average compressive strength of the standard grouting samples is 21.7 MPa, with the minimum value of 13 MPa. The values meet the design requirements.

4.5.ApplicationofcombinedmethodtotheBaiyuntunnel

The total length of Baiyun tunnel of Nanning-Guangzhou Railway is 2285 m. The tunnel goes through large regional faults F1, F2. The fault F2 extends more than a dozen of kilometers. The width of fault F2 is 10–40 m, and its deformation in fluential zone even reaches 100 m. Fault F2 and its secondary fault F1 form a closely paralleled combination of reversed fault, thus the stratum is seriously fragmented and vertical penetration between faults is induced. Within the faults, there are mixtures of breccia and clay of very low intensity. So, the mixtures of breccia and clay pose a very high pressure on the stable layer at the top of the tunnel. The inclination angle of the fault is relatively small, only 25◦.

The tunnel construction started from the lower part of the reversed fault. The excavation or blasting unexpectedly disturbed the stratum, and consequently, serious water inrush and mud gushing occurred. As a result, tunnel excavation was stopped as shown in Fig. 13. After the accident of water inrush and mud gushing, many treatment measures were taken (see Fig. 14), including building retaining dam, stabilizing landslide at the tunnel face, draining inrush water, building by-pass heading, jet grouting reinforcement at the top of landslide section in the main tunnel. In addition, curtain grouting was used in the main tunnel. With those measures, the water inrush and mud gushing were successfully stopped.

Fig. 11. Design of curtain grouting in Qiyue Mountain tunnel (unit: cm).

Fig. 12. Comparison of water inrush in the tunnel face before and after curtain grouting in Guanjiao tunnel.

Fig. 13. Layout of faults in Baiyun tunnel of Nanning-Guangzhou Railway and the water inrush and mud gushing disaster.

5. Discussion

Numerous researches on the karst tunnels with engineering problems such as water inrush are achieved, however, with the rapid development of railway construction in karst region in West China, a series of hot issues concerning safe tunnel construction or operation should be addressed. These issues are listed as follows:

Fig. 14. Treatment of water inrush and mud gushing section in Baiyun tunnel of Nanning-Guangzhou Railway.

(1) Karst water outburst is a dynamic evolution of water inrush induced by long-term water–rock interaction and arti ficial interferences during tunnel construction. The reported results merely stress the role of karst water in fractured rocks, ignoring the interaction between water and rocks before and after karst water outburst.

(2) The accuracy of geological forecast data has an important impact on the construction progress and construction safety of karst tunnels. However, various geological prediction methods currently used have their limitations, such as narrow forecast range, qualitative but not quantitative analysis, inconvenient identi fication method, and low accuracy. Comprehensive geological prediction methods should be used to improve the accuracy of karst geological prediction. Also, staff training and field identi fication ability should be improved. We should build up a complete set of applicable karst tunnel geological prediction methods.

(3) In the limestone region, fully understanding karst distribution is dif ficult. Therefore, related geological theory should be focused on to find out the rule of limestone strata distribution in karst regions.

(4) Groundwater, especially karst-connection water, is the principal problem to be addressed during karst tunnel construction. At present, water treatment is still considered in two ways by water discharging and blocking, or in combination. However, we should effectively control groundwater discharge, and protect the valuable groundwater resources and the ecological environments.

(5) Establishing a system of water prevention and control in karst region is not fully comprehended. We should establish an effective expert decision system in the development regulation of karst water inrush, the principles of water inrush classi fication, the model of water inrush, the comprehensive geophysical prospecting technology as well as the early-warning prediction of water inrush.

6. Conclusions

(1) According to the geological conditions and engineering characteristic of the surrounding rocks, water inrush and mud gushing can be classi fied into 4 types as shown in Table 1 and Fig. 2.

(2) The main factors inducing water inrush and mud gushing are associated with the surrounding rock conditions, meteorological impacts and tunnel excavation. Surrounding rock conditions are the basis of potential mud gushing in karst tunnels. Tunnel excavation is the arti ficial trigger of water inrush. The meteorological impacts, including temperature and rainfall, will accelerate the progress of water inrush and mud gushing disasters.

(3) The macro- and micro-mechanisms of tunnel water inrush and mud gushing are discussed. The essence of tunnel water inrush and mud gushing is the continuous softening and dissolving effect, cavity expansion effect, water wedge effect on the geological interface, and the erosion-expansion effect on water inrush passage that leads to the sudden energy release of waterrich body.

(4) Comprehensive advance geological forecast is the principal measure for the prevention of railway tunnel water inrush and mud gushing. Advance geological forecasts are classi fied into different degrees according to the risks of different sections in the tunnel. The items of forecast shall be carefully determined.

(5) The principle of railway tunnel water inrush and mud gushing treatment can be divided into draining- oriented, blocking-oriented or draining-and-blocking. The appropriate method shall be chosen according to the field conditions in practice.

(6) Treatment technologies of water inrush and mud gushing include energy relief and pressure reduction technology, advance grouting technology, and advance jet grouting technology. Each technology has its own benefits and misfits, thus we should consider the suitable technologies based on sitespecific geological conditions.

Cui J. Tunnel and underground project construction technology. Beijing: Science Press; 2005 (in Chinese).

Dai Y. Geological features and treatment of mud rushing in Yunwu Mountain tunnel. Railway Engineering 2009;10:33–5 (in Chinese).

Gao Y, Shi L, Lou H. Law of mining floor water-inrush and its preferred plane. Xuzhou: China University of Mining and Technology Press 1999 (in Chinese).

Guan B, Zhao Y. Construction technology in tunnels with soft and weak surrounding rocks. Beijing: China Communications Press; 2011 (in Chinese).

Guan B. Key points in tunnel designing. Beijing: China Communications Press; 2003 (in Chinese).

Guo J. Study on against-inrush thickness and water burst mechanism of karst tunnel. Ph.D. Thesis. Beijing: Beijing Jiaotong University; 2011 (in Chinese).

Jiang J. Mechanism and countermeasures of water-bursting in railway tunnel engineering. China Railway Science 2006;27(5):76–82 (in Chinese).

Li B. Engineering safety risk analysis and control of subsea tunnel constructed by drill and blast method. Ph.D. Thesis. Beijing: Beijing Jiaotong University; 2010 (in Chinese).

Li L. Study on catastrophe evolution mechanism of karst water inrush and its engineering application of high risk karst tunnel. Ph.D. Thesis. Jinan: Shandong Jiaotong University; 2009 (in Chinese).

Li S, Zhang X, Zhang Q. Research on mechanism of grout diffusion of dynamic grouting and plugging method in water inrush of underground engineering. Chinese Journal of Rock Mechanics and Engineering 2011;30(12):2377–96 (in Chinese).

Lin G, Song R. Research on the mechanism and treatment technology of mud gushing in karst tunnel. Tunnel Construction 2012;32(2):169–74 (in Chinese).

Mo Y, Zhou X. Dynamic monitoring and simulation analysis of surrounding rock deformation of tunnel in karst region. Chinese Journal of Rock Mechanics and Engineering 2008;27(Suppl. 2):3816–20 (in Chinese).

Yang D, Zhang P. Study on the rapid treatment method of mud gushing and landslide at shallowly covered karst section in Yunwu Mountain tunnel. West-China Exploration Engineering 2008(10):192–4 (in Chinese).

Zhang M. Tunnel construction technology in karst fault of Yiwan Railway. Beijing: Science Press; 2010 (in Chinese).

Zhang X, Li S, Zhang Q, Li H, Wu W, Liu R, et al. Filed test of comprehensive treatment for high pressure dynamic grouting. Journal of China Coal Society 2010;35(8):1314–8 (in Chinese).

Zhao Y, Tian S, Cao Z. Geological work method for the construction of the Yichang-Wanzhou Railway tunnel in high-risk karst areas. Journal of Shandong University (Engineering Science) 2009(5):91–5 (in Chinese).

Zhao Y. Study on deformation mechanism and control technology of weak rock surrounding tunnel. Ph.D. Thesis. Beijing: Beijing Jiaotong University; 2012 (in Chinese).

Zhuang H, Mu J. The prevention and treatment of large cross section tunnel mud gushing in karst areas. Railway Engineering 2009(6):49–51 (in Chinese).

Yong Zhao(1969–), male, Ph.D., is the director of bridge and tunnel consultative department in the Engineering Design and Approval Center of the Ministry of Railways. He is also a professional and technical leader in railway engineering, professorate senior engineer. He is mainly engaged in the tunnel and underground engineering fields of scientific research, technical consultation and railway tunnel design review and appraisal work. He has completed many scientific research projects over the past three years, including 1 major project and 2 key projects of the Ministry of Railways. He has published approximately 30 technical papers, co-authored 2 books, i.e.TunnelconstructiontechnologyofsoftrockandLoesstunnelengineering. In recent years, he has been focusing on the stability of tunnel surrounding rocks. He has chaired and participated in many projects, such as “Research on tunnel surrounding rock stability and its control technology”, “Study on whole set technology of high-speed railway construction in loess tunnel with large section”,“Rock cuttings and shallow-buried tunnel safety control blasting technology in the urban district”, and “Previous study on the key technology for channel tunnels”. He is well experienced in the design and research of tunnels in loess, urban tunnels, and channel tunnels.

∗Corresponding author. Tel.: +86 13601107599.

E-mail address: jdzxzhaoyong@sina.com (Y. Zhao).

Peer review under responsibility of Institute of Rock and Soil Mechanics, Chinese Academy of Sciences.

1674-7755 © 2013 Institute of Rock and Soil Mechanics, Chinese Academy of Sciences. Production and hosting by Elsevier B.V. All rights reserved.

http://dx.doi.org/10.1016/j.jrmge.2013.07.009

Journal of Rock Mechanics and Geotechnical Engineering2013年6期

Journal of Rock Mechanics and Geotechnical Engineering2013年6期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Numerical evaluation of strength and deformability of fractured rocks

- Feasibility evaluation for excavation of Naghshe Jahan Square subway station by underground methods

- Dam foundation excavation techniques in China: A review

- Afteruse development of former landfill sites in Hong Kong