An Overview of Condition Monitoring and Fault Diagnostic for Wind Energy Conversion System

(1. School of Electrical Engineering Southeast University Nanjing 210096 China 2. Nanjing Electric Power Company Nangjing 210096 China)

1 Introduction

With serious energy crisis and increased environmental concern, wind energy has become one of the fastest-growing renewable energy sources in the world, which is still required to continue because many countries need to implement urgent targets for sustainability and pollutant emissions reduction. The US intends to generate 20% of the country’s electricity from wind power generation, i.e. over 300GW, by 2030[1]. Danish plans for 25GW of wind generation over the coming four years[2]. China aims for 15%renewable power generation by 2020[3]. Wind power is growing towards a major utility source, nowadays the reliability and power quality of WECS is emphasized for the cost-effective utilization.

Therefore wind energy conversion system(WECS)with low reliability where many faults often occur will need high costs of operation and maintenance(OM). For a wind turbine (WT) with over 20 years of operating life, the OM and part costs are estimated to be 10%~5% of the total income of a wind farm[4].According to General Electric (GE) energy, a $5,000 bearing replacement can easily become into a$250,000 project involving cranes, service crew,gearbox replacements, and generator rewinds, not to mention the downtime loss of power generation[5].

Larger WT may reduce the OM cost per unit power, but the cost per failure is increased. These not only increase the OM cost, but also reduce the efficiency of WECS[6].

There are mainly two ways to reduce the costs of WECS.One way is to reduce manufacturing and installation cost, and another important way is to reduce the OM costs. However, the more effective and practical method is condition monitoring and fault diagnosis(CMFD) because it achieves the costeffective utilization compared with the other way[7].

CMFD system with integrated fault detection algorithms can allow early warnings of faults to prevent major component failures. Many faults can be detected while the defective component is still in operation, necessary repair actions can be planned in time. Furthermore, condition monitoring can also observe the operating state of WT under extreme conditions, such as icing or tower oscillation, and then take appropriate measures to prevent damage to WT.In this way, overall OM costs and downtimes of WECS can be greatly reduced, so the security,reliability and competitiveness of WECS can be greatly improved[8-11].

Because of the importance of CMFD for WECS,it is very necessary to know the research achievements and the latest progresses. This paper briefly introduces the development trends of wind power generation, the main fault components of WECS and the existing CMFD methods, as well as some problems need to be researched.

2 WT and Fault Type

The WT is composed of many subsystems, such as rotor blades and pitch system, hub, structure (tower,foundation and nacelle), drive train, gearbox,generator, electrical system, control system, sensors,mechanical brakes hydraulic system, yaw system, etc,as showed in Fig.1 and each subsystem is constituted of several components.

Fig.1 Structure of WT

The function of WT is to transform the kinetic energy in the wind into electric energy. During the working process of WT, the wind speed is constantly changing, where there is strong gusty wind, wind wheel and blades will be impacted by impulsive load.The time-varying load will transfer to each component of the transmission chain, causing great influence to its working life, and make many sorts of fault appear in the WT[12].

WT is subjected to different sorts of failures.Some of them occur more frequently than others and WT failures statistics might be studied by considering both failure frequencies and downtimes. Therefore, it is not always easy to obtain WT failures statistics. This paper refers to the latest available data of WT[12,13]. Tab.1 shows annual frequencies of failure and downtimes between 2000 and 2004 for Swedish wind power plants. It shows the percentage breakdown of the number of failures that occurred between 2000 and 2004 for Swedish wind power plants and it is also shown that most failure components are the electric system, sensors, and blades/pitch. And the most troublesome components are the gearbox, the control system and the electric system.

Tab.1 Downtimes and failure frequencies for Swedish wind power plants 2000~2004

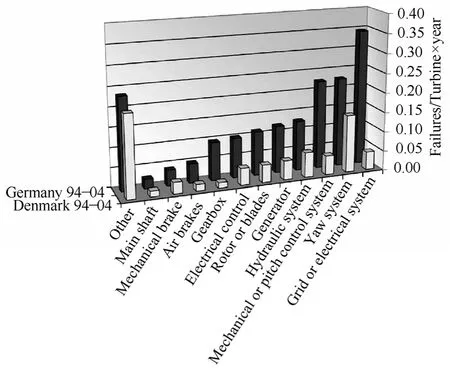

There is another study concerning Danish and German wind power plants[14], which shows the same tendency as the above. Fig.2 shows the failure rate in the two power plants during the period 1994~2004,where principal components with the higher failure rate are the electrical control or system subassemblies(grid or electrical system, yaw system and mechanical or pitch control system).

According to the above statistics and analysis,the following review will be focused on the failures occurring in WT and its subsystem.

Fig.2 Failure rates for danish and german wind power plants

3 CMFD of WT

As the wind power generation develops very quickly, which gains more and more attention recently,this paper aims to review the recent condition monitoring and fault diagnostic techniques with the focus on WT. This section summarizes the monitoring and diagnostic methods for the major subsystems in WT which are reported in recent works.

3.1 The process of CMFD

In order to implement CMFD technology, it is important to know the general process of CMFD. Fig.3 shows the general steps involved in a CMFD process for a WECS. The signal-measurement block measures physical quantities which reflect the observers/estimators. After the signals are obtained,fault features present in these signals are extracted in the feature extraction block. The extracted information is then fed to a fault-decision algorithm that compares it with prerecorded information about the signals at a fault decision step. Finally, the faults are detected.

Fig.3 General process of CMFD for WECS

3.2 Generator

A generator is the core component of wind power system and it is responsible for transforming rotating mechanical energy into electrical energy. In the actual application, two main kinds of generator are often used, doubly fed induction generator(DFIG) and permanent magnet synchronous generator(PMSG).The WT generator may easily subject to failures in bearing, stator, and rotor. It is reported that percentage failure by components in induction machines is typically: bearing related(40%), stator related(38%), rotor related(10%), and others(12%)[15].

There are many techniques available, which are used to observe the condition of induction generator or synchronous generator. Some of the technologies used for monitoring include sensors, which are used to measure speed, current, voltage, torque, vibration,temperature, fl ux density and so on. These sensors are together coupled with algorithms and architectures,which are applied to monitor of the machine conditions[16]. The most popular methods for condition monitoring of induction generator or synchronous generator utilize the spectral components of the stator or rotor quantities. The stator, rotor or rotor modulating signals include voltage and current.They are used to detect turn faults, broken rotor bars,bearing failures and air gap eccentricities for DFIG and PMSG[15,17-22].

For a WT, one of main issues is variable-speed operation as put forward in[23]. Therefore, many condition monitoring techniques, which are being applied to generators, based on steady-state analysis are not suitable for WT generators under such situation. So it prompts the use of non-stationary techniques for fault detection, such as wavelet, state observer and so on.

For turn faults, a transient technique that is a combination of extended Parks vector, wavelet analysis and statistics or adaptive algorithm, is applied to the detection of turn faults occurring in a DFIG through the analysis of current signatures. This technique is not affected by variation of DFIG speed[23,24]. In Ref.[25], a CMFD scheme based on a state observer is developed to detect stator inter-turn fault of a DFIG, which can detect the time of faults and gives an accurate diagnosis of the fault position and level. And the applied exponential adaptive observer with a time varying gain is also able to provide a good estimation of level under a wide range of speed variation. In Ref.[26], a real-time inter-turn fault diagnostic system based on the so-called floating-space-vector method is introduced and used for a variable speed PMSG, the calculated results show the robustness, accuracy, and proper speed response of the technique.

Short circuit of coils is a critical electrical fault. In order to rule out interference of speed change, spectral methods are used to detect shorted coil for PMSG Ref.[27], where a CMFD signal(Sdet) is derived by taking the energy in band around the drive train’s torsional natural frequency and normalizing for the variable energy input from the wind. The authors in Ref.[28] propose two methods applied to diagnosis of short coil. The first one is that the criterion, based on the torque-speed characteristic of the synchronous machine, is proposed to detect the shorted coil. The second approach is that discrete wavelet transform (DWT) is used to reduce the noise of the stator winding current signal, power signal and continuous wavelet transform(CWT) is used to extract fault features correctly from the highly variable wind turbine signals,finally the experiments are carried out to verify the effectiveness of the proposed methods.

3.3 Gearbox

Gearbox is one of the most important units in the drive train of WT and is composed of shaft, cabinet,gear and so on. It transforms low-speed revolutions from the rotor to high-speed revolutions. Because gearbox operates under the harsh environment, speed variation and load variation, it is very prone to get faults in long term, mainly including gear fault and bearing fault. The common gear faults are broken teeth, tooth surface fatigue, plywood, etc; bearing faults are wear, crack, flake surface etc. Tab.2 shows distribution of fault type of gearbox for Swedish wind power plants according to the statistical data in Ref.[12].

Tab.2 The fault type of gearbox

There are many researchers concern on detection of WT gearbox fault in recent years, where vibration measurement and spectrum analysis have been a prominent prevalent technique. In Ref.[29], a vibration condition monitoring system about gearbox is put forward, and fast fourier transform(FFT)and power spectrum are used for diagnosis for fixed-speed operation. The document[30]presents a study on vibration spectrum analysis based gearbox fault classification using wavelet neural network. For variable-speed wind turbine operation, a neural network based diagnostic framework for gearbox is developed based on the wavelet analysis of vibration signals in Ref.[31].

For CMFD of gearbox, the signals of WT generator electrical terminals have been investigated.In Ref.[32] the authors dealt with the demodulation of the current signal of an induction machine driving a multistage gearbox for its fault detection. Amplitude demodulation and frequency demodulation are applied to the current for detecting the rotating shaft frequencies and gear mesh frequencies(GMFs),respectively. DWT is applied to the demodulated current signal for denoising and removing the intervening neighboring features. Spectrum of a particular level, which comprises the GMFs, is used for gear fault detect. In Ref.[28], diagnosis of gear eccentricity is studied using current and power signals,where wavelet transforms is applied to deal with the variable-speed operation, the DWT is employed to deal with the noise-rich signals from WT measurements and CWT is used to extract time-frequency fault features. These techniques are very useful to monitor gearbox as it involves a non-stationary technique.

In Ref.[33], the stator current is analyzed via wavelet packet decomposition to detect bearing defects. The proposed method can accommodate the rotational speed dependence of the bearing defect frequencies. The wavelet packet decomposition also provides a good treatment of non-stationary stator current. In Ref.[34], amplitude demodulation of three phase stator currents is adopted, such as Hilbert transform(HT), Concordia transform(CT), to detect bearing fault. The results show that HT method is well suite for non-stationary performance. A free parameter approach for bearing CMFD is discussed in Ref.[35], which extracts the amplitude and frequency modulations of faulty vibration signals. The amplitude demodulation is inherent, and the fault frequency can be detected from the spectrums of the vibration signals.

3.4 Blade

WT blade is a vital component. Due to external conditions, internal stress and fatigue, the crack and damage may gradually take place as time goes by,thus resulting in deterioration of WT, which lead to loss in energy capture efficiency. In other words, it is important to monitor the WT blades so that operation can be better ensured.

There are a few works about the problem. In Ref.[36], four different algorithms, transmittance function, resonant comparison, operational detection shape and wave propagation, are used for detecting damage on WT blades. The methods are all based on measuring the vibration response of the blade when it is excited using piezoceramic actuator patches bonded to the blade, or a scanning laser doppler vibrometer.In Ref.[37], the wind wheel unbalance fault due to mass unbalance of the blades is studied on the test WT.Power output and vibration signals obtained are processed by spectrum and time-frequency analysis,and the faults features are obtained to detect unbalance fault of the blade.

Blade fault diagnostics have been studied based on strain measurement techniques such as fiber-optic Bragg grating (FBG) and Acoustic emission (AE)[36,38-41]. For the blades of small WT, a piezoelectric impact sensor is used[42], as well as AE sensor for fault detection is used[43].

In the practical application, a condition-monitoring package onto existing WT without requiring additional sensors is preferred. In Ref.[44], unbalance and defects in the blades of a small WT are detected by measuring the power spectrum density at the generator terminals. In this case, bicoherence, a normalized bispectrum, is used. It is able to monitor small physical changes in the machine. The technique overcomes problems of the bispectrum which is not convenient for detection purposes[18]. In Ref. [39], a continuous wavelet transform-based approach is used to detect blade damage; its advantage is that it requires no additional sensors. However, WT blades experience some faults and damages that could not be monitored by using the WT generator terminals, and they are particularly exposed to lightning strikes. So,a lightning protection system is equipped[45]. However,lightning is a stochastic phenomenon in nature, a complete protection against its damage is not achievable. In Ref.[46], a method for lightning impact localization and classification using a fi ber optic current sensor network that helps to detect damages caused by lightning and to monitor the blades is presented.

3.5 Drive train

Drive train basically consists of a shaft and bearings and occasionally a clutch between the gearbox and the generator. The shaft goes into the nacelle from the hub, where the blades are connected, and connects to the gearbox. The shaft rotates with low speed and needs to be geared up,by the gearbox. In reality, the probability of this failure is quiet small, as shown in Tab. 2. There are radial or axial vibrations of shaft excited by other faults such as imbalance, misalignment and the time-varying load from the rotor. Therefore, it is necessary to monitor the shaft, and help to diagnose the faults of other components.

In Ref.[47], rotor eccentricity is detected through the analysis of the power output of a DFIG by the use of wavelet in variable-speed operation. In Ref.[48],the power signal is used to detect generator rotor misalignment based upon both FFT and wavelet analysis, where wavelet analysis is used to produce time-frequency representation of non-stationary signals and FFT analysis is used to determine the amplitude of the harmonic components more accurately, and thus to help find the peak amplitude spectrum of the wavelet coefficients during the given time period, which is used as the fault indicator. The results show success in identifying early stage of failures.

Some researchers discuss the detection of a rotor mechanical unbalance fault in the WT[21,49-51].In Ref.[21], the authors point out that a torsional oscillation or a shift in the torque-speed ratio can be used to detect a rotor mechanical unbalance fault.Nevertheless the method is still not feasible, on one hand, torque sensors are usually highly expensive and difficult to be installed and on the other hand, load fluctuation has great influence on shaft torque. In Ref.[49], a developed wavelet-based ‘energy tracking’technique is utilized to diagnose the fault by using the generator output and rotational speed, where the fault detection signals are derived and a CWT-based adaptive filter detection algorithm is used to track the energy in the prescribed time-varying fault related frequency bands in the power signal. Empirical mode decomposition(EMD) and bivariate empirical mode decomposition(BEMD) are applied to detecting a rotor mechanical unbalance fault occurring in the WT[50,51]. Fault characteristics are extracted by processing the power output of generator. The experiment results demonstrate that the techniques have a great ability in detecting the faults occurring in variable speed WT.

3.6 Other parts

At present, control system, pitch system, yaw system, heating system and cooling system are all equipment with several sensors which can be applied to monitor their own working condition and external environment. The electrical parameters, such as voltages, currents, power and so on are applied to judge each component states. In Ref.[2], power curve copula modeling is applied to recognition of incipient faults of yaw system and pitch system, where operational data of WT are used to estimate bivariate probability distribution functions representing the power curve of existing turbines so that deviations from expected behavior can be detected. Because of the complex form of dependency between active power and wind speed, the application of empirical copulas is proposed to detect the faults.

4 CMFD System

WECS and even its subsystems include many components. CMFD requires systematic analysis,so it is necessary to establish a system about CMFD of WECS. The systems about this research have been mentioned in some literatures, as described below.

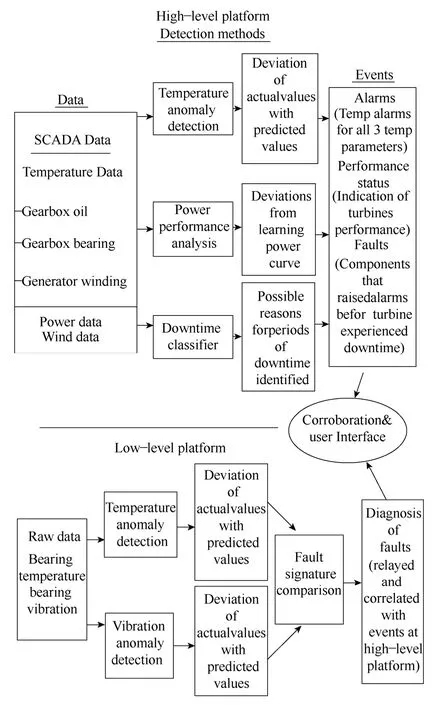

In Ref.[52], a multi-agent fault detection system for WECS is put forward, as shown in Fig.4, low-level platform and high-level platform are included. The fault diagnostics system(FDS) utilizes both the sources of data obtained through supervisor control and data acquisition(SCADA) system connected to WECS and other sensors for processing and analysis.FDS is partially distributed over the two platforms,corroborating events that are identified in the low-level platform with those identified in the high-level platform via the messages that can be sent between them. This corroboration can offer a more robust and accurate fault detection since similar faults that are identified in both data sources can offer greater confirmation and reassurance that the fault detected is genuine.

In Ref.[53], the author puts forward the intelligent system for predictive maintenance application to condition monitoring of WECS. It is organized in a modular architecture presented in Fig.5 around the following six main modules:

Fig.4 Overall system architecture

Fig.5 Architecture of intelligent CMFD system

(1)Normal behavior models: these models are used to predict on-line the normal behavior (or reference behavior) expected for each WECS component, according to its current working and environmental conditions.

(2)Anomalies detection module: its main goal is to detect possible anomalies in components by means of the results given by the normal behavior models.

(3)Health condition assessment module: its function is to evaluate on-line the health condition of each WECS component as well as the general WECS health condition.

(4)Diagnosis expert module: its main goal is to identify the possible failure modes that are present or developing in a WECS component before this component faults in an irreversible way.

(5)Predictive maintenance scheduling module:its main goal is to optimally schedule WECS maintenance actions, suitable to avoid or mitigate the detected incipient failures as well as the measured component degradation.

(6)Maintenance effectiveness assessment module:its main function is to obtain an effectiveness measurement for each maintenance action applied.

For wind power plant, a network-based CMFD system is necessary and network architecture is influencing the function and operation of WECS. A typical architecture of CMFD system in wind power plant is shown in Fig.6. The signal acquisition and pre-processing system will collect and pre-process the measurement data, then transfer the data to auto-diagnostics server, which can extract the fault feature and generate the alarm information. The user and remote experts can browse the monitoring information of WECS through Internet or Intranet[54].

Furthermore, a summary of a number of widely available and popular condition monitoring systems for WECS are provided in Ref.[55].

5 Conclusions

Fig.6 Architecture of CMFD system in wind power station

An overview of fault detection techniques of WECS is proposed. The main faults are listed and fault detection techniques are discussed. Many kinds of CMFD methods have been put forward and applied to WECS. However most of them are still in an experiment stage. The following directions will be focused on in the future:

(1)The main issues of WT are variable-speed operation and the stochastic characteristics of aerodynamic load, which prevent the usage of traditional frequency domain techniques (e.g. FFT).Advanced signal processing techniques such as wavelet, HT and EMD, have a powerful capability in processing non-stationary or nonlinear signals, and have been widely used in such situations. The remaining problem is that how to analyze the obtained signals correctly using a valid signal processing technique.

(2)It can be thought that wherever the mechanical faults occur (either in blades, shaft,bearings or gearbox), the energy generated because of the fault travels along the drive train and arrive at the generator of the WT in the end. It will have an effect upon the air-gap between the rotor and the stator of the generator and give response in the output (e.g.current and voltage) of the generator. Likewise, when an electrical fault occurs either in generator (e.g.stator/rotor winding fault) and converter, the output of the generator will be disturbed as well. This suggests that a globally effective way for detecting both mechanical and electrical WT failures may be achieved through monitoring the electrical signals of the generator terminal. Obviously, this will be a simple and cheap way.

(3)Although there are a few CMFD systems for WECS, a great number of sensors installed in single WECS and the cost of sensors is a serious problem.The future work is that the implementation of a new condition monitoring and fault diagnostics system of WECS to make the detection of faults based only on the measurements fed to the control centre through SCADA system and provided by WT without utilization of any other type of sensors.

(4)With the fast development of the technologies of smart grid where one of the main motivations is to absorb more renewable power[56], the CMFD technologies of WECS should be closely integrated with the smart grid technologies, such as the changes of operation modes of grid-connected wind farm may have effects on the CMFD methods of WECS and it is necessary to make further researches on this issue.Furthermore, the smart grid need more smart power apparatus, which will prompt the development of CMFD technologies not only to the substation device but also to the WECS. In the future, both the CMFD technologies will be integrated in the substation level.

[1] 20% wind energy by 2030: increasing wind energy’s contribution to U.S. electricity supply[R]. United States Department of Energy, 2008.

[2] Gill S, Stephen B, Galloway S. Wind turbine condition assessment through power curve Copula modeling[J]. IEEE Transactions on Sustainable Energy, 2012, 3(1): 94-101.

[3] Medium and long-term development plan for renewable energy in China[R]. Chinese Committee for National Development and Reform, 2007.

[4] Walford C A. Wind turbine reliability: understanding and minimizing wind turbine operation and maintenance costs[R]. Sandia National Laboratries,SAND2006-1100, 2006.

[5] Hatch C. Improved wind turbine condition monitoring using acceleration enveloping[J]. Orbit, 2004: 58-61.

[6] Lu B, Li Y, Wu X, et al. A review of recent advances in wind turbine condition monitoring and fault diagnosis[C]. Power Electronics and Machines in Wind Applications (PEMWA), 2009: 1-7.

[7] Xie Y, Jiao B. State of the art of condition monitoring system and fault diagnosis methods of wind turbine[J].Journal of Shanghai Dianji University,2010, 13(6): 328-333.

[8] Amirat Y, Benbouzid M E H, Bensaker B, et al.Condition monitoring and fault diagnosis in wind energy conversion systems[C]. IEEE International Electric Machines and Drive Conference, 2007:1434-1439.

[9] Caselitz P, Giebhardt J, Kruger T, et al. Development of a fault detection system for wind energy converters[C]. Proceedings of EUWEC, 1996:1004-1007.

[10] Caselitz P, Giebhardt J, Mevenkamp M. Application of condition monitoring systems in wind energy converters[C]. European Wind Energy Conference,1997: 579-582.

[11] Nilsson J, Bertling L M. Maintenance management of wind power systems using condition monitoring systems-life cycle cost analysis for two case studies[J]. IEEE Transactions on Energy Conversion,2007, 22(1): 223-229.

[12] Ribrant J. Reliability performance and maintenance- a survey of failures in wind power systems[D]. Sweden:KTH School of Electrical Engineering, 2006.

[13] Nilsson J, Bertling L M. Survey of failures in wind power systems with focus on Swedish wind power plant during 1997-2005[J]. IEEE Transactions on Energy Conversion, 2007, 22(1): 167-173.

[14] Tavner P J, Xiang J, Spinato F. Reliability analysis for wind turbines[J]. Journal of Wind Energy, 2006,10(1): 1-18.

[15] Popa L M, Jensen B B, Ritchie E, et al. Condition monitoring of wind generators[C]. 38th IAS Annual Meeting, 2003: 1839-1846.

[16] Benbouzid M E H. Bibliography on induction motors faults detection and diagnosis[J]. IEEE Transactions on Energy Conversion, 1999, 14(4): 1065-1074.

[17] Benbouzid M E H, Kliman G B. What stator current processing based technique to use for induction motor rotor faults diagnosis?[J]. IEEE Transactions on Energy Conversion, 2003, 18(2): 238-244.

[18] Benbouzid M E H. A review of induction motors signature analysis as a medium for faults detection[J].IEEE Transactions on Industrial Electronics, 2000,47(5): 984-993.

[19] Ebrahimi B M, Faiz J, Roshtkhari M J. Static-,dynamic-, and mixed-eccentricity fault diagnoses in permanent-magnet synchronous motors[J]. IEEE Transactions on Industrial Electronics, 2009, 56(11):4727-4739.

[20] Blodt M, Granjon P, Raison B, et al. Models for bearing damage detection in induction motors using stator current monitoring[J]. IEEE Transactions on Industrial Electronics, 2008, 55(4): 1813-1822.

[21] Rosero J A, Romeral L, Cusido J, et al. On the short-circuiting fault detection in a PMSM by means of stator current transformations[C].Power Electronics Specialists Conference(PESC), 2007:1936-1941.

[22] Casadei D, Filippetti F, Rossi C, et al. Diagnostic technique based on rotor modulating signals signature analysis for doubly fed induction machines in wind generator systems[C]. 41th IAS Annual Meeting,2006: 1525-1532.

[23] Douglas H, Pillay P, Barendse P. The detection of interturn stator faults in doubly fed induction generators[C]. Fortieth IAS Annual Meeting, 2005:1097-1102.

[24] Barendse P S, Pillay P. A new algorithm for the detection of inter-turn stator faults in doubly-fed wind generators[C]. 32nd Annual Conference on Industrial Electronics Society, 2006: 1235-1240.

[25] Qian L, Breiken T F, Wang H. Modeling and fault diagnosis of inter-turn short circuit in double fed induction generators[C]. 18th IFAC World Congress,2011: 1013-1018.

[26] Sarikhani A, Mirafzal B, Mohammed O. Inter-turn fault diagnosis of PM synchronous generator for variable speed wind applications using Floating-Space-Vector[C]. 36th Annual Conference on Industrial Electronics Society, 2011: 2628-2633.

[27] Wilkinson M R, Spinato, F, Tavner P J. Condition monitoring of generators & other subassemblies in wind turbine drive trains[C]. IEEE International Symposium on Diagnostics for Electric Machines,Power Electronics and Drives (SDEMPED), 2007:388-392.

[28] Yang W, Tavner P J, Wilkinson M R. Condition monitoring and fault diagnosis of a wind turbine synchronous generator drive train[J]. IET Renewable Power Generation, 2009, 3(1): 1-11.

[29] Tang X, Xie Z, WU J. Fault diagnosis of gearbox for wind turbine[J]. Journal of Noise and Vibration Control Noise and Vibration Control, 2007(1):120-124.

[30] Huang Q, Jiang D, Hong L, et al. Application of wavelet neural networks on vibration fault diagnosis for wind turbine gearbox[J]. Lecture Notes in Computer Science. Advances in Neural Networks,2008: 313-320

[31] Yang S, Li W, Wang C. The intelligent fault diagnosis of wind turbine gearbox based on artificial neural network[C]. International Conference on Condition Monitoring and Diagnosis (CMD), 2008: 1327-1330.

[32] Mohanty A R, Kar C. Fault detection in a multistage gearbox by demodulation of motor current waveform[J]. IEEE Transactions on Industrial Electronics, 2006, 53(4): 1285-1297.

[33] Eren L, Devaney M J. Bearing damage detection via wavelet packet decomposition of the stator current[J].IEEE Transactions on instrumentation and measurement, 2004, 53(2): 431-436.

[34] Amirat Y, Choqueuse V, Benbouzid M. Condition monitoring of wind turbines based on amplitude demodulation[C]. Energy Conversion Congress and Exposition (ECCE), 2010: 2417-2421.

[35] Yang S, Li X, Liang M. Bearing Condition Monitoring and Fault Diagnosis of a Wind Turbine Using Parameter Free Detection[J]. Communication Systems and Information Technology, 2011(10):289-294.

[36] Ghoshal A, Sundaresan M J, Schulz M J, et al.Structural health monitoring techniques for wind turbine blades[J]. Journal of Wind Engineering and Industrial Aerodynamics, 2000: 309-324.

[37] Jiang D, Huang Q, Hong L. Theoretical and experimental study on wind wheel unbalance for a wind turbine[C]. World Non-Grid-Connected Wind Power and Energy Conference (WNWEC), 2009: 1-5.

[38] Hyers R W, McGowan J G, Sullivan K L, et al.Condition monitoring and prognosis of utility scale wind turbines[J]. Energy Materials, 2006, 1(3):187-203.

[39] Tsai C S, Hsieh C T, Huang S J. Enhancement of damage detection of wind turbine blades via CWT-based approaches[J]. IEEE Transactions on Energy Conversion, 2006, 21(3): 776-781.

[40] Boger L, Wichmann M H G, Meyer L O, et al. Load and health monitoring in glass fibre reinforced composites with an electrically conductive nanocomposite epoxy matrix[J]. Composites Science and Technology, 2008, 68, (7-8): 1886-1894.

[41] Volanthen M. Blade and rotor condition monitoring using blade load measurement data[C]. Proceedings of Non-Grid-Connected Wind Power Systems, 2007:468-473.

[42] Yuji T, Bouno T, Hamada T. Suggestion of temporarily for forecast diagnosis on blade of small wind turbine[J]. IEEJ Transactions on Power and Energy, 2006, 126(7): 710-711.

[43] Bouno T, Yuji T, Hamada T, et al. Failure forecast diagnosis of small wind turbine using acoustic emission sensor[J]. KIEE International Transaction on Electrical Machinery and Energy Conversion Systems,2005, 5-B (1): 78-83.

[44] Jeffries W Q, Chambers J A, In fi eld D G. Experience with bicoherence of electrical power for condition monitoring of wind turbine blades[J].IEE Proceedings Vision Image & Signal Processing, 1998,145(3): 141-148.

[45] Cotton I, Jenkins N, Pandiaraj K. Lightning protection for wind turbine blades and bearings[J]. Wind Energy,2001, 4(1): 23-37.

[46] Kramer S G M, Leon F P, Appert B. Fiber optic sensor network for lightning impact localization and classi fi cation in wind turbines[C]. IEEE International Conference on Multisensor Fusion and Integration for Intelligent Systems, 2006: 173-178.

[47] Watson S J, Xiang B J, Yang W, et al. Condition monitoring of the power output of wind turbine generators using wavelets[J]. IEEE Transactions on Energy Conversion, 2010, 25, (3): 715-721.

[48] Watson S J, Xiang B J. Real-time condition monitoring of offshore wind turbines[C]. European Wind Energy Conference, 2006: 647-654.

[49] Yang W, Tavner P J, Crabtree C J, et al.Cost-effective condition monitoring for wind turbines[J]. IEEE Transactions on Industrial Electronics, 2010,57(1): 263-271.

[50] Yang W, Tavner P J, Crabtee C J. An intelligent approach to the condition monitoring of large scale wind turbines[C]. European Wind Energy Conference,2009: 16-19.

[51] Yang W, Court R, Tavner P J, et al. Bivariate empirical mode decomposition and its contribution to wind turbine condition monitoring[J]. Journal of Sound and Vibration, 2011, 330(15): 3766-3782.

[52] Zaher A S, McArthur S D J. A multi-agent fault detection system for wind turbine defect recognition and diagnosis[C]. IEEE Lausanne Power Tech, 2007: 1-5.

[53] Garcia M C, Sanz Bobia M A, Del Pico J. SIMAP:intelligent system for predictive maintenance application to the health condition monitoring of a wind turbine gearbox[J]. Computers in Industry, 2006,57(6): 552-568.

[54] Lu W, Chu F. Condition monitoring and fault diagnostics of wind turbines[C]. Prognostics and Health Management Conference (PHM), 2010: 1-11.

[55] Christopher J C. Survey of commercially available condition monitoring systems for wind turbines[R].England: Durham University, 2011.

[56] Chen S, Song S, Li L, et al. Survey on smart grid technology[J]. Power System Technology, 2009,33(8): 1-7.