热处理温度对针刺C/C复合材料热力学性能的影响

白 侠,嵇阿琳,崔 红,程 文

(1.西安航天复合材料研究所,西安 710025;2.高性能碳纤维制造及应用国家地方联合工程研究中心,西安 710089)

0 Introduction

Needling carbon/carbon(C/C)composite has superior characteristics of low density,high specific strength,high thermal conductivity,low thermal expansion coefficient and excellent anti-ablation.These excellent properties make it become the essential candidates for aeronautical and aerospace applications as high-temperature structural material,which is especially used for large thin-walled nozzle extension of rocket engine,such as the engines of the DeltaⅣand Ariane 5 upper stage equipped with very large needling C/C extendable nozzle extension[1-2].

C/C composite dominated by C-C covalent bonds is of brittle nature relatively,which restrict their application consequently.Thereby,much attention has been focused on improving toughness of C/C composite.High temperature treatment(HTT)is an efficient method for increasing the thermal shock resistance and eliminating the thermal stress of the composite,further improving fracture toughness of C/C composite[3].This paper concern the effect of heat treatment on the performance of needling C/C composites with density of 1.6 g/cm3treated at 1 800 ℃,2 000℃,2 200℃ and 2 500℃,respectively.The objectives are to improve the toughness of needling C/C composite and to provide an optimally treatment temperature for heat structural of thin-walled C/C components.Furthermore the bending fracture surfaces of composites are observed by scanning electron microscopy(SEM)to understand the failure mechanisms.

1 Experimental

1.1 Material preparation

C/C composites,whose needling preform with fiber volume fraction of 24% was fabricated using T300-3K PAN-based twill carbon-cloth,were deposited with a flowing mixture of propylene and nitrogen by means of chemical vapor infiltration(CVI)at 1 050℃under reduced pressure of 8 kPa firstly,followed by polymer infiltration and pyrolysis(PIP)deposition process with furfural acetone resin.The density of composite is about 1.4 g/cm3and the microstructure of the pyrocarbon is smooth layer after CVI process.As prepared C/C composites with density of 1.6 g/cm3,are treated at 1 800 ℃,2 000 ℃,2 200℃and 2 500℃,respectively.

1.2 Measurement

1.2.1 Thermal property

The coefficient of thermal expansion(CTE)was tested from room-temperature to 1 000℃ at a rate of 5 ℃ /min by using RPZ-1 dilatometer.The shape of specimen is a right circular cylinder with size of φ6 mm ×25 mm.

The thermal conductivity was measured by laser conductometer at a heating rate of 30 ℃/min,and specimen is a circular disk,3 mm thick and 12.7 mm in diameter.

X-ray diffraction(XRD)was used to analyze the crystallinity structure parameters of needling C/C composite using D8 advance X-ray diffractometer.The interplanar spacing(d002)of the material was tested and calculated by Bragg'equation.The graphitization degree(g)was calculated by using equationThe crystallite height(Lc)was calculated by using the Scherrer equation.

1.2.2 Mechanical property

The three-point bending test was carried out to measure flexural property and the specimen size was 55 mm×10 mm×4 mm.The specimens were loaded at a rate of 1 mm/min by means of a mechanical testing machine(CMT5105).The morphology and microstructure of fracture surfaces were observed by SEM(JSM-6460LV).

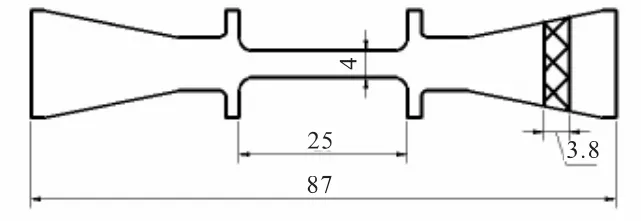

The tensile specimens(its detailed configuration shown in Fig.1)were prepared from C/C composite plate.Specimen thickness paralleled to the needling direction.The mean tensile strength and elastic modulus of specimens were measured by means of testing machine with 70 N load and displacement speed of 0.595 mm/min.

Fig.1 of tensile specimen(all dimension are in mm)

2 Results and discussion

2.1 Thermal property

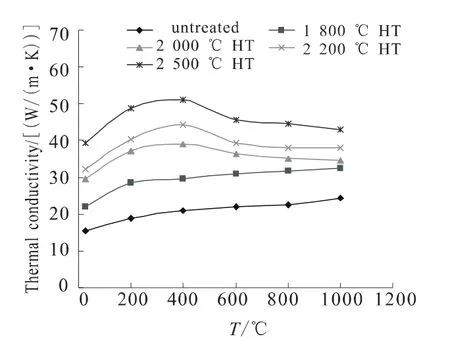

Thermal conductivity is a key physical parameter to estimate heat-transfer capability.Compared with other traditional composites,C/C composites have higher thermal conductivity.The higher the thermal conductivity of C/C composites,the more beneficial to the heat transfer in material internally.Thereby,the temperature gradient and thermal stress in materials can be readily eliminated,and the performance of thermal shock resistance is improved.

Fig.2 shows thermal conductivities of samples heat treated under different temperatures in the test temperature range from room-temperature to 1 000℃.Some phenomena can be got from Fig.2 and is described as follows:(1)Thermal conductivity of needling C/C composite rise with the increasing heat treatment temperature;(2)Thermal conductivity of needling C/C composites untreated or treated at 1 800℃increase during the whole test temperature ascending process,while the corresponding curve of composites treated at 2 000℃or higher temperatures rise first and then fall down when test temperature is up to 400℃.It can be seen that higher the treatment temperature is,the bigger the amplitude is.

The vibration of the crystal lattice is the mechanism of thermal conduction to C/C composites.The crystal lattice vibration can be described as outcome of the phonon interaction,which is called phonon thermal conduction too.So,thermal conductivity can be calculated by debye equation as follow[4]:

where k is thermal conductivity;c is specific heat capacity;v is the velocity of phonon movement;l is the mean free path of phonon.

Fig.2 Thermal conductivity of C/C composite as a function oftest temperature and heat treatment temperature

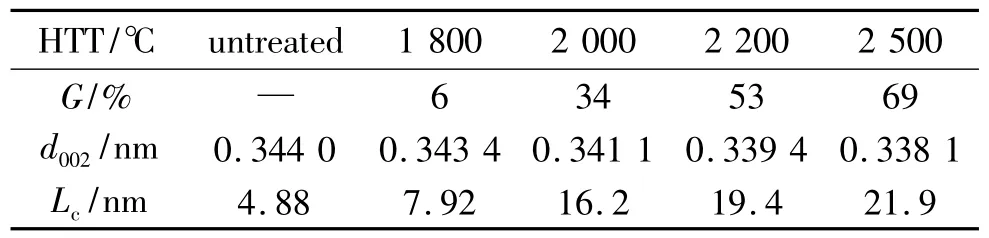

According to equation above mentioned,the growth of crystallites can decrease the opportunities of phonon collision and scatter,and increase the mean free path of phonon.As a result,the phonon mean free path is gradually dominated by the phonon-phonon interaction,and the thermal conductivity of C/C composite can be enhanced observably.Therefore,the thermal conductivity of C/C composite is in connection with crystalline parameters which have always been reflected by graphitization degree characterized by means of XRD.The test results of crystallite parameter of C/C composites are listed in Table 1.It can be seen that the crystallite height of needling C/C composites gradually increase from 4.88 nm to 21.9 nm with increasing heat treatment temperature,and the graphitization degree add at the same time.Needling C/C composite treated at 1 800℃ had been partically graphitized,but its graphitization degree of amorphous carbon calculated is very low,only 6%.When heat treatment is temperature is elevated to 2 000℃,the graphitization degree appear translation markedly,the graphitization degree add and crystallinity is improved continuously with increasing heat treatment temperature.

All results show that heat treatment temperature is in favor of the thermal conductivity of C/C composite.As to the needling C/C composite untreated or treated at 1 800℃,their matrix microstructures has rather low orientation which could be described as a kind of disorder layer structure,and this results in low graphitization degree and thermal conductivity.When test temperature elevate,the combine action including increase of phonon number and augment of specific heat resulted in raise of thermal conductivity.

Table 1 Test results of crystallite parameter of C/C composites

When the C/C composites were graphitized obviously,such as treated at 2 000℃,2 200℃ and 2 500℃,the defects such as dislocation,interlinkage and disordering layer of crystallite were eliminated gradually,which made crystal structure perfect and let the mean free path of phonon to augment[5].All of these were available to improve the thermal conductivity.As thermal conductivity rise at the beginning and then fall off we analyze that graphitizing should lead to increment of the quantity and size of micro-crack and pore of C/C composites matrix[6].But the micro-crack and pore have scattering effect on phonon which is in favor of thermal conductivity.Therefore,the thermal conductivity increase with increasing test temperature from low to intermediate temperature test stage(RT~400℃).But from intermediate to high temperature test stage(400~1 000℃),the micro-crack form at heat treatment process close again and eliminate gradually,which make the mean free path of phonon shorten or altered direction.As a result,when test temperature is over 400℃,the thermal conductivity of C/C composites fall off with increasing test temperature.

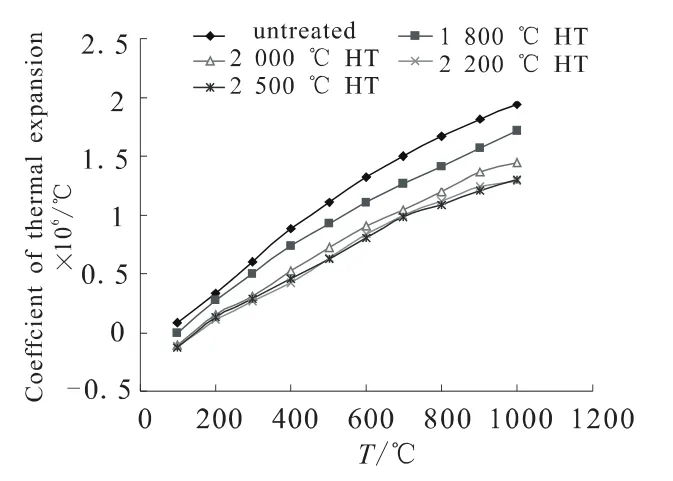

CET reflects the dimensional stability of C/C composite at high temperature[7].Fig.3 illustrates the test results of CET tested from room-emperature to 1 000℃.It can be seen that the CET reduce with increasing heat treatment temperature.The result shows that the quantity and size of micro-rack and pore of C/C composites increase with increasing heat treatment temperature,when test temperature is elevated,the micro-crack and pore could absorb a part of expansion generated owing to vibration of atom.CET of C/C composites graphitization treated at 2 000 ℃,2 200 ℃,2 500℃ approach stabilization.

Fig.3 Temperature dependence of thermal expansion of C/C composites heat treatedat different temperature

2.2 Mechanical behavior of composites

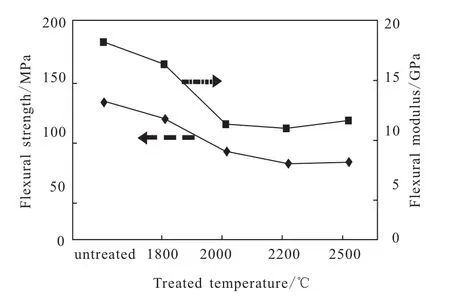

Fig.4 shows the relationship between flexural strength(flexural modulus)of needling carbon/carbon composites and heat treatment temperature.It can be seen that the flexural strength of these samples decrease from 126 MPa to 72 MPa with increasing heat treatment temperature.When treated under 2 000℃ or higher temperature,the samples flexural strength and modulus decrease relaxedly and approach almost 72 MPa and 11 GPa,respectively.

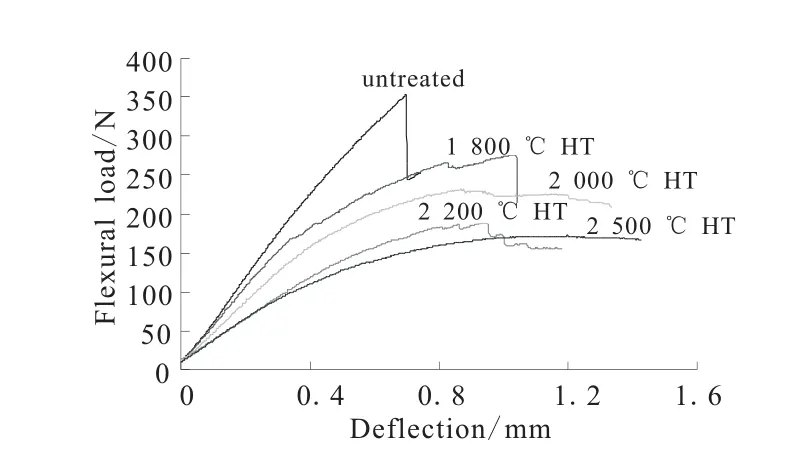

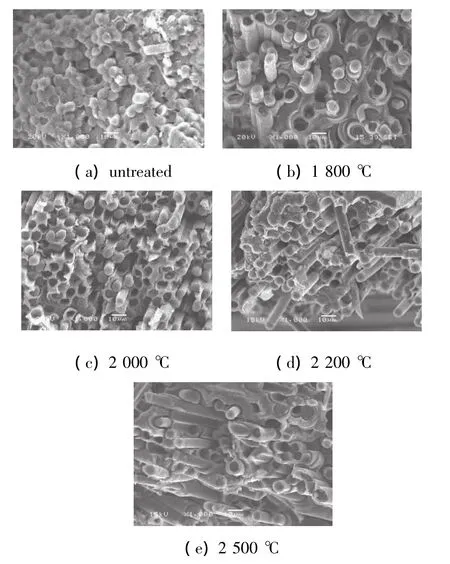

The relationships between flexural loads with deflection are plotted in Fig.5,and fracture morphologies after breakdown are shown in Fig.6.As we can see that the shape of curves up to and following the maximum load were quite different among samples treated under different temperatures.

It indicates that the deflection of untreated C/C composite is linear deformation with flexural load,then the stress dropp rapidly after reaching maximum load,and the curve indicate a typical brittle fracture behavior occurring with small deformation.However,the fracture behavior of needling C/C composites is completely changed after heat treatment,and their curves consist of two load stages,wherein the initial of load exhibit linear,while the following stage become nonlinear up to maximum load and continue distortion until spontaneous fracture happene.The nonlinear stage demonstrate a pseudo-ductile fracture behavior for the interface sticky point,fiber fracture and pullout,bridging,and sliding[8].From the microstructure in Fig.6(a),the fracture surface of C/C composite untreated is smooth relatively and no pullout fiber is observed.But after heat treated,there are long pullout fibers and pores existing on the fracture surface,which is responsible for the toughness failure behavior for C/C composites,demonstrating extensive fiber debonding from the fiber and the matrix.It is apparent that the toughness of C/C composite could be improved by heat treatment.

Fig.4 Effect of HTT on the flexural strength and modulus

Fig.5 Load-deflection curves for the C/C composites under flexural loading

Fig.6 Fracture morphology of the C/C composites heat treated at different temperature

Bending test describes a phenomenon that flexural samples experience mixed loads which tension,compress and shear force coexist,and then the samples come to fracture under the collective effects of compress on the top of the surface together with tension on the bottom and shear force at middle layer[9].Graphitization is a soften process of matrix,as well as the formation of micro-crack of matrix[10],thus leading to a dramatical decreasing of mechanical property of composites.In addition,the flexural modulus will decrease significantly due to the growth of micro-cracks.After high temperature treatment,the interfacial stress between carbon fiber and matrix is released[11].Interfacial strength become weaker.When the samples suffer from destruction,the force needs to break the bonding between fiber and matrix,and also needs to overcome the friction between them caused by pulling out the fiber.Along with the process,the composite presents better toughness and larger deformation by absorbing considerable quantity of energy.This kind of composite has a forecast before fracture.Thus,it would not destroy suddenly.In view of mechanical point,the domestic and overseas scholars identically agree that the interfacial strength of material would not be much too high,especially for C/C composites.Excessive interfacial strength between fiber and matrix can cause the material very brittle.However,an appropriate interfacial bonding takes the composites on pseudo-ductile[12].From Table 1,C/C composite needs to be treated over 2 000℃where graphitization happens in a deeper scale.But after 2 000℃ or a higher temperature treatment,the composites'flexural strength is reduced greatly relatively.

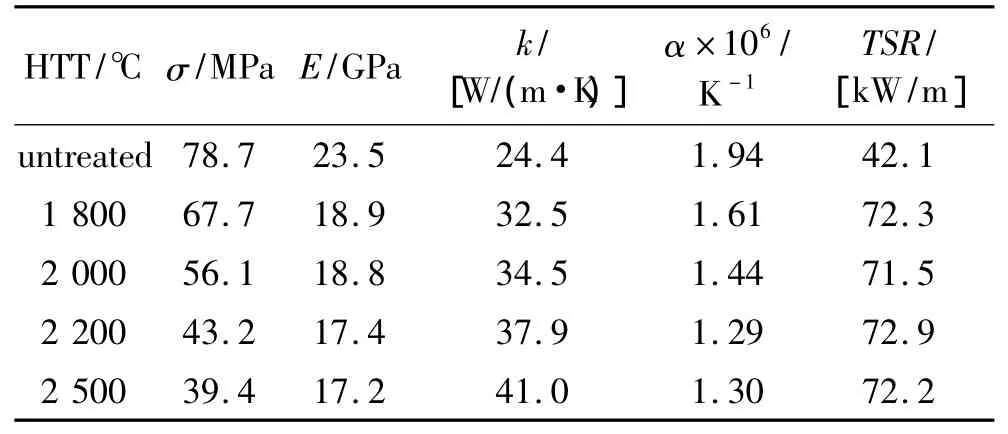

2.3 Thermal stress factor

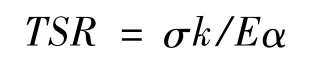

Needling C/C composites are usually used for thinwalled structure and ablation materials under high temperature.Thermal shock resistance is a key indicator to evaluate comprehensive level of structure functional integration,and thermal stress factor is used to denote the material properties about thermal shock resistance[13].According to the thermal stress factor formula,thermal stress factor is proportional to both of the tensile stress and thermal conductivity,and is inversely proportional to elastic modulus and thermal expansion coefficient.This is because high tensile strength can resist bigger thermal stress,thus prevent the material from destruction.Under instantaneous heating-up environment,high thermal conductivity would not let the materials possess large thermal strength because lowering the inside temperature gradient.Small expansion coefficient and low elastic modulus can reduce the stress caused by thermal stain.

where TSR is thermal stress factor;σ is tensile strength;k is coefficient of thermal conductivity;E is elastic modulus;α is thermal expansion coefficient.

The calculation results of thermal shock resistance properties of C/C composites are listed in Table 2.

Table 2 Thermal shock resistance properties of C/C composites after HTT

The date in Table 2 shows that high temperature heat treatment could enhance the thermal shock resistance of C/C composite significantly.Although composite without heat treatment has a higher mechanical strength,the thermal conductivity is lower and the thermal expansion coefficient is bigger.Furthermore,the material could easily be caused big stress due to instantaneous thermal gradient,also brittleness of materials and large sensitivity of defect.All of the comprehensive factors lead to lower thermal shock resistance.The C/C composites,which were treated after high temperature,could obtain notable improvement of micro-structure and thermal shock resistance through comprehensive factors of higher thermal conductivity,lower thermal expansion coefficient,and better fracture toughness.From the aspect of thermal stress factor,the thermal shock resistance of C/C composites after HTT was almost as twice as that of the composites without HTT.

The needling C/C composites for thin-walled structure demand higher mechanical properties.Therefore,thermal shock resistance should be enhanced on condition that the mechanical properties are not reduced as far as possible.From Table 2,1 800 ℃ and 2 000 ℃ are the optimum temperature,since the tensile strengths above 55 MPa after these two high temperature treatments;moreo-ver,the remnant ratio of the tensile stress is high and the thermal shock resistance is ideal.

3 Conclusions

(1)With the increasing treatment temperature,graphitization degree and thermal conductivity increase,coefficient of thermal expansion reduce.Furthermore,after treatment at 2 000℃,2 200℃ and 2 500℃,thermal conductivity increase firstly and then decrease,but thermal expansion coefficients are closed to the same.

(2)With the increasing treatment temperature,flexural stress of C/C composites decrease,but flexural deflection increase under flexural load,thus improving the fracture toughness.

(3)Heat treatment could change thermal shock resistance properties of C/C composites.The calculation results of thermal stress factor prove that C/C composites possess excellent thermal shock resistance after HTT.

Reference:

[1] Fitzer E.The Future of Carbon-Carbon Composites[J].Carbon,1987,25(2):163.

[2] Ariane 5 SRM upgrade[R].AIAA 2004-3894.

[3] Heshmat A.The effect of intermediate graphitization on the mechanical and fracture behavior of 2D C/C composites[J].Carbon,1993,31(7):1121-1129.

[4] Chen Wei-ran.Thermodynamic and kinetic analysis of the graphitization process[J].TANSU,1982,29(1):11-16.

[5] QIU Hai-peng,GUO Quan-gui,SONG Yong-zhong,et al.Study of the relationship between thermal conductivity and microcrystalline parameters of bulk graphite[J].New Carbon Materials,2002,17(1):36240.

[6] CHEN Teng-fei,GONG Wei-ping,et al.Influence of heattreatment on crack initiation in smooth laminar pyrolytic carbon matrix[J].Materials Science and Engineering of Powder Metallurgy,2006,11(4):2102213.

[7] Zhang Qing,Cheng Lai-fei,Zhang Li-tong,et al.Influence of high temperature on 3D C/SiC thermal expansion coefficient[J].Acta Materiae Compositae Sinica,2004,21(4):124

[8] WANG Xing-ye.Preparation,nterfaces and performance of fiber reinforced ceramic matrix composites[M].Beijing:Beijing University Publishing House,1998.

[9] BAI Shu-zhen,CUI Sheng-rui.Failure characteristics of carbon fiber composite material using acoustic emission[C]//Composites(First National Composites Conference Papers.1981:289-295.

[10] Guellali M,Oberacker R,Hoffmann M J.Influence of heat treatment on microstructure and properties of highly textured pyro-carbons deposited during CVD at about 1100℃and above 2 000 ℃[J].Composites Science and Technology,2008,68(5):111521121.

[11] ZHAO Jian-guo,LI Ke-zhi,LI He-jun,et al.Effects of heat treatment temperature on the properties of C/C Composites[J].Transactions of Materids and Heat Treatment,2005,26(1):125.

[12] Catherine Ahearn,Brian Rand.Modification of the fiber-matrix bonding in a brittle carbon-carbon composite by controlled oxidation[J].Carbon,1996,34(2):239-249.

[13] Wan E Y.Solid rocket nozzle design summary[R].AIAA 68-655.

- 固体火箭技术的其它文章

- 三基色测量法在S-GAP推进剂火焰温度分布中的应用