Effect of chloride salt concentration on unconfined compression strength of cement-treated Lianyungang soft marine clay

Zhang Dingwen Cao Zhiguo Fan Libin Deng Yongfeng

(School of Transportation, Southeast University, Nanjing 210096, China)

Soft marine clay deposits around the coast of Lianyungang and Yancheng regions in Jiangsu province. Its natural water content varies from 50% to 110% and the liquidity indices of the marine clay are in the range of close to or more than one. In particular, the salt concentration is high in pore water of marine soft soil. Due to its very high water content, low shear strength and high salt concentration, the disposal of marine clay at construction sites is a challenge encountered by engineers. An improvement of the super soft soil within a short period to serve as a geomaterial is necessary in ocean and geotechnical engineering practise.

The deep mixing method is an attractive ground improvement technique for high water content soft clay. In the deep mixing method, powder cement or slurry cement is injected into the natural soil at the required depth and a blade is pushed into the ground to mix the soil and cement. This technique has been increasingly used worldwide, especially in Europe, North America and Asia since its development in Sweden and Japan in 1970s[1]. The deep mixing method was introduced to China in the early 1980s. Because this technique can effectively reduce the compressibility and permeability and increase the strength of soft ground, it rapidly spread throughout China in the 1990s, especially for controlling seepage and as a cut-off barrier, reduction of settlement, prevention of sliding failure and increasing the bearing capacity of the ground[2-5].The bond strength of cement-treated soil is controlled by many factors such as soil gradation, types of clay minerals, organic matter, pH, slat concentration, mixing energy and so on. Numerous researchers have performed experimental studies on the fundamental mechanical properties and engineering behaviour of soil-cement in the past four decades[6-9].

This study, therefore, aims to quantify the influence of the sodium chloride salt concentration on the strength of cement stabilized Lianyungang soft marine clays. Clay with various sodium chloride salt concentrations was prepared artificially and stabilized by ordinary Portland cement with different contents. A series of UCS tests were performed on cement stabilized clay specimens after desired curing periods. Based on the experimental results, a new parameter, termed as porosity-salt concentration/cement content (PSC) ratio, is found to be appropriate to describe the effect of salt on the strength of cement-treated soil.

1 Materials and Method

1.1 Materials

1.1.1 Soil sample

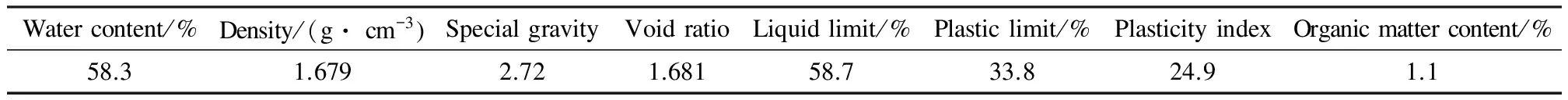

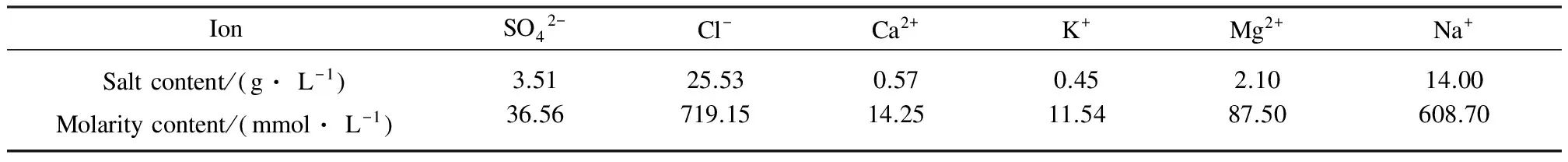

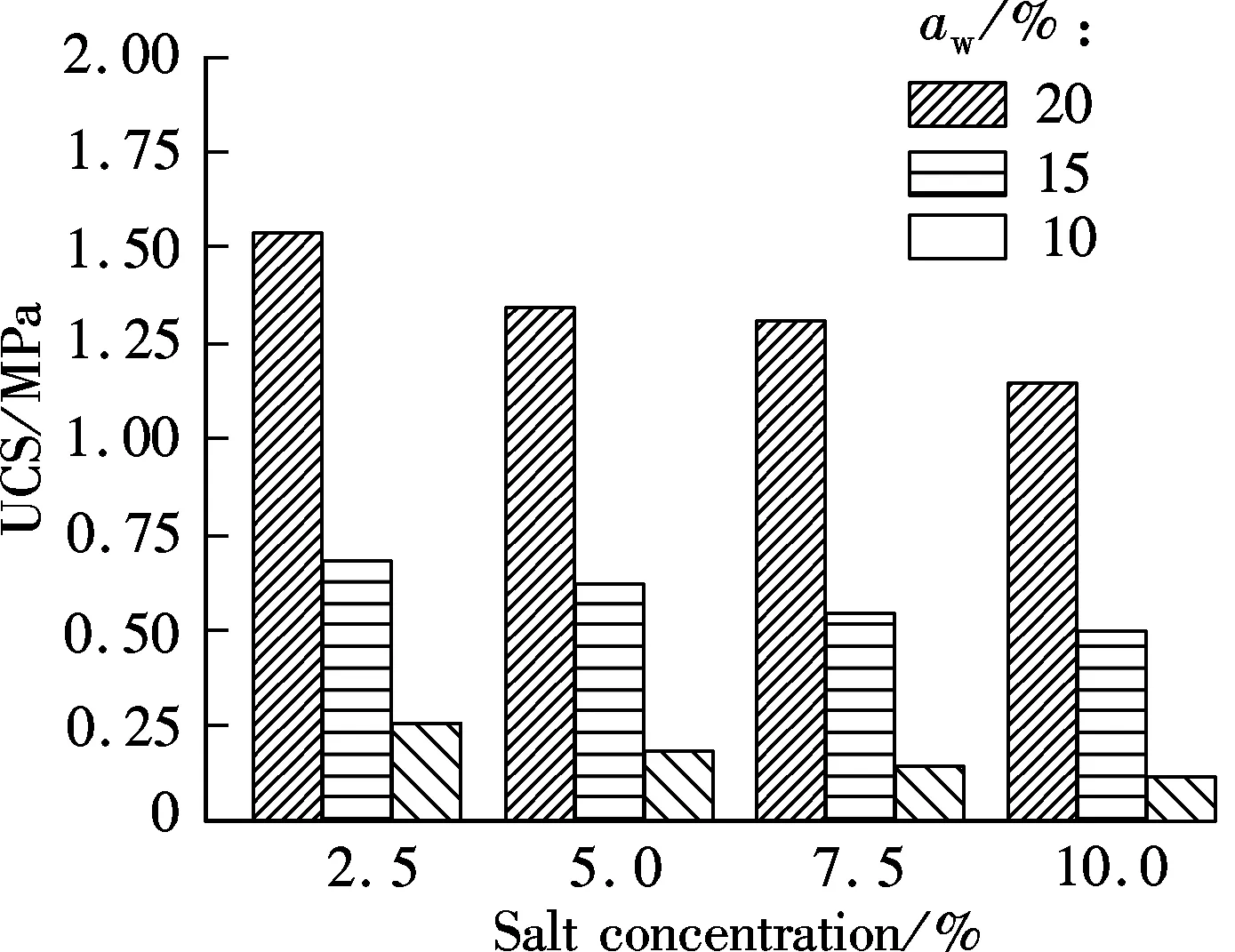

The Lianyungang marine clay used in this investigation was obtained from the Liezikou bridge construction field, Guannan County, Jiangsu Province, China. Clay was sampled at 2.0 m depth under the ground surface. The properties of Lianyungang marine clay samples are shown in Tab.1. The clay has a high plasticity with a liquid limit of 58.7% and a plastic limit of 33.8%. The total salt concentration is quite high, with a value of 46.16 g/L. Tab.2 presents the chemical analysis results of the pore water of Lianyungang marine clay. The results show that the dominant salt composition in the pore water is sodium chloride. Based on the sieving and hydrometer analysis (see Fig.1), the soil used in this research consists of 2.8% sand and 97.2% fines (53.5% silt and 43.7% clay), indicating that the Lianyungang marine clay is composed of silt and clay fractions. The pH value of the pore water of natural clay is about 7.8, which is close to neutrality. Liu et al.[15]reported that the most predominant clay minerals in Lianyungang marine deposits were illite-smectite mixed-layer mineral and illite. These results indicate that the Lianyungang marine clay has not only high water content, high void ratio, high compressibility, but also contains a much higher content of sodium chloride salt.

Tab.1 Properties of Lianyungang marine clay

Tab.2 Chemical analysis results of pore water of Lianyungang marine clay

Fig.1 Soil particle distribution curve

1.1.2 Cement

Ordinary Portland cement type I is used to investigate the effect of the cement content (the ratio of cement weight to weight of the dry soil, termed asaw) on the strength of stabilized clay.

1.2 Test method

In order to investigate the effect of the salt concentration, the clays were treated to eliminate the salt by the wash method first. The wash method was applied as follows: the Lianyungang marine clay from the construction field was air-dried, crushed down, sieved, and dipped in distilled water for 24 h. Salt in the soft soil was removed after repeating this process 5 times. After that, the desired content of sodium chloride salt was added into the washed soil and mixed thoroughly for 10 min by a miniature mixing machine. Their sodium chloride salt concentrations (ratios of the sodium chloride salt weight to the dry soil weight, termed asCs), were 2.5%, 5.0%, 7.5% and 10.0%.

The clay was then mixed with 10%, 15% and 20% cement by mass of dry soil. In order to eliminate the effects of differences in water content, the samples were prepared to contain the same water content of 70% (i.e. 1.2 times liquid limit) by adding the distilled water into the clay. Kitchen stand mixers were used to mix the cement into the clay for a total mixing time of 10 min until a homogenous clay-water-cement paste was attained. To ensure thorough mixing, the sides of the bowl were continuously scraped and the mixer was stopped as often as needed to scrape off any materials packed onto the bottom of the bowl. Upon completion of mixing, the soil was compacted into plastic tubes with an internal diameter of 50 mm and a height of 100 mm (see Fig.2). All the samples were compacted by hand vibrating to eliminate the entrapped air. The samples were cured at a temperature of about 20 ℃ and a humidity of 95% for the desired curing periods. The samples were removed and carefully extruded from the plastic molds after curing the desired periods. The UCS tests were run on specimens after curing periods of 7, 14 and 28 d according to the procedure of ASTM D2166-06 at a strain rate of 1% per minute. Before the UCS test, the diameter, height and weight of the specimens were measured with accuracies of about 0.1 mm and 0.01 g.

Fig.2 Picture of prepared specimens

2 Test Results and Discussion

2.1 Effect of salt concentration on the UCS

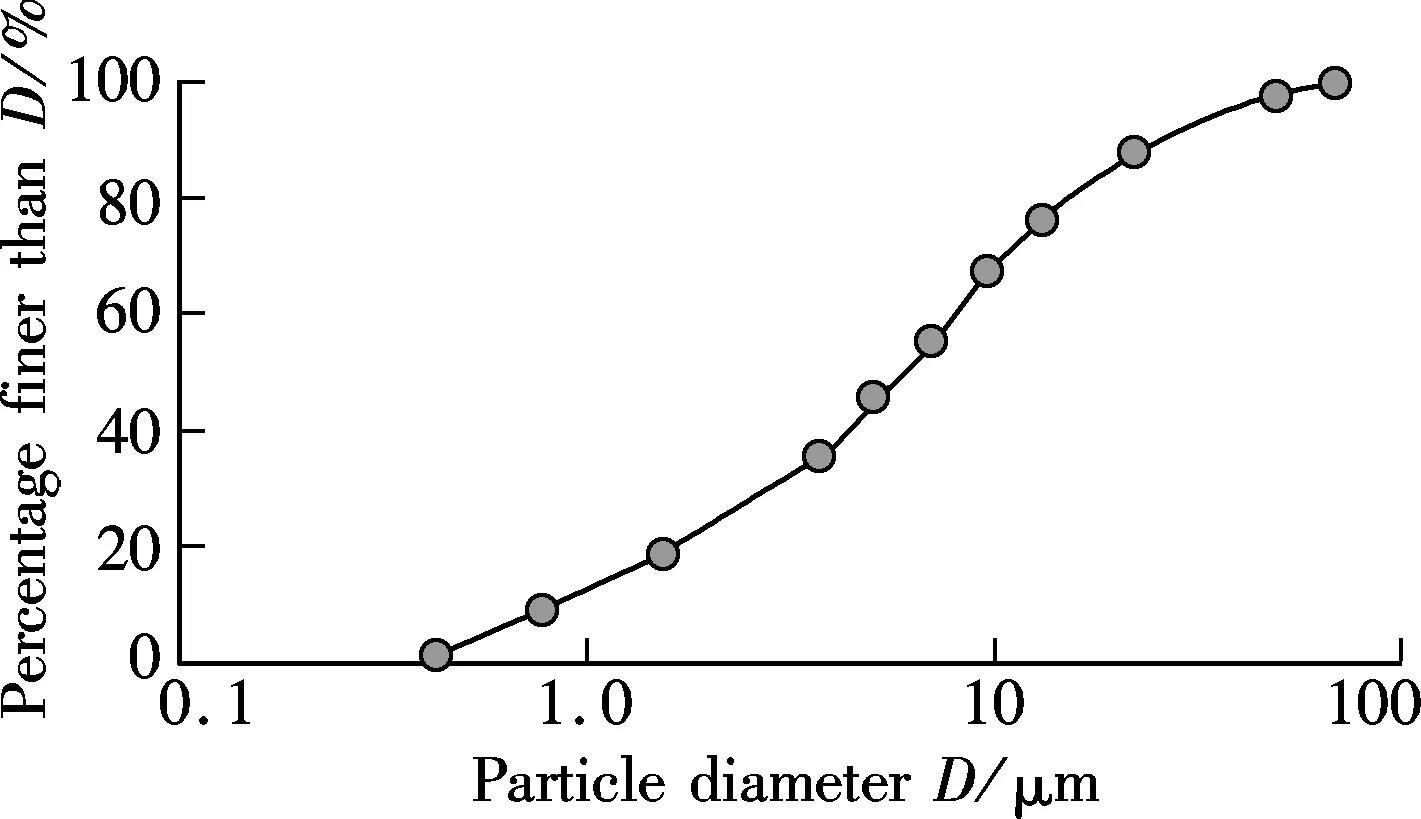

Since the UCS after curing 28 d is usually used as the design value, the UCS after curing 28 d is discussed hereafter. Fig.3 shows the UCS of the cement stabilized clay after curing 28 d vs. salt concentration, where each data point represents the mean of three specimens. The measured UCS of specimens after curing 7 d and 14 d exhibits the same trend as that after curing 28 d. It can be seen that the UCS of the specimens increases with the increase in cement content and curing time, indicating that a great amount of hydration compounds such as calcium silicate hydrate and calcium aluminate hydrate gels is formed. Compared with the UCS of undisturbed natural sample (i.e. 15 kPa), the results indicate that the addition of cement induces a drastic strength improvement of Lianyungang marine clay and cement stabilization is an attractive and successful method to improve the engineering properties of the Lianyungang soft marine clay.

Fig.3 UCS of specimens vs. salt concentration

Fig.3 also indicates that the salt concentration has a great effect on the strength of cement-treated Lianyungang marine clay. It can be seen that the UCS decreases approximately linearly with the increase in the salt concentration. For instance, for specimens with a cement of 20% and a salt concentration of 2.5%, the 28-d UCS is 1.54 MPa. Nevertheless, if the salt concentration is increased to 10.0%, the 28-d UCS is only 1.146 MPa. This leads to the conclusion that the presence of sodium chloride salt in soil has a detrimental effect on the process of the cementation of cement-soil mixtures. This finding agrees with the experimental results of Sinat[16]and Xing et al[12]. However, an increase in strength with salt content in cement-treated clay was reported by Miura et al.[17], Onitsuka et al.[18]and Nor[19]. It should be noted that the strength increase with the increase in the salt concentration was achieved in cement- or lime-treated clay with a high humic acid content. It is generally accepted that the presence of the organic matter in the clay acts to the detriment of the strength of cement or lime stabilized clays. The salt contributes to coagulate with the organic cation, which leaves the clay particles exposed to cement or lime for pozzolanic reaction content, as a result, the strength of cement- or lime-treated soil increases with the increase in salt concentration.

2.2 Prediction model of UCS of cement-treated salt-rich clay

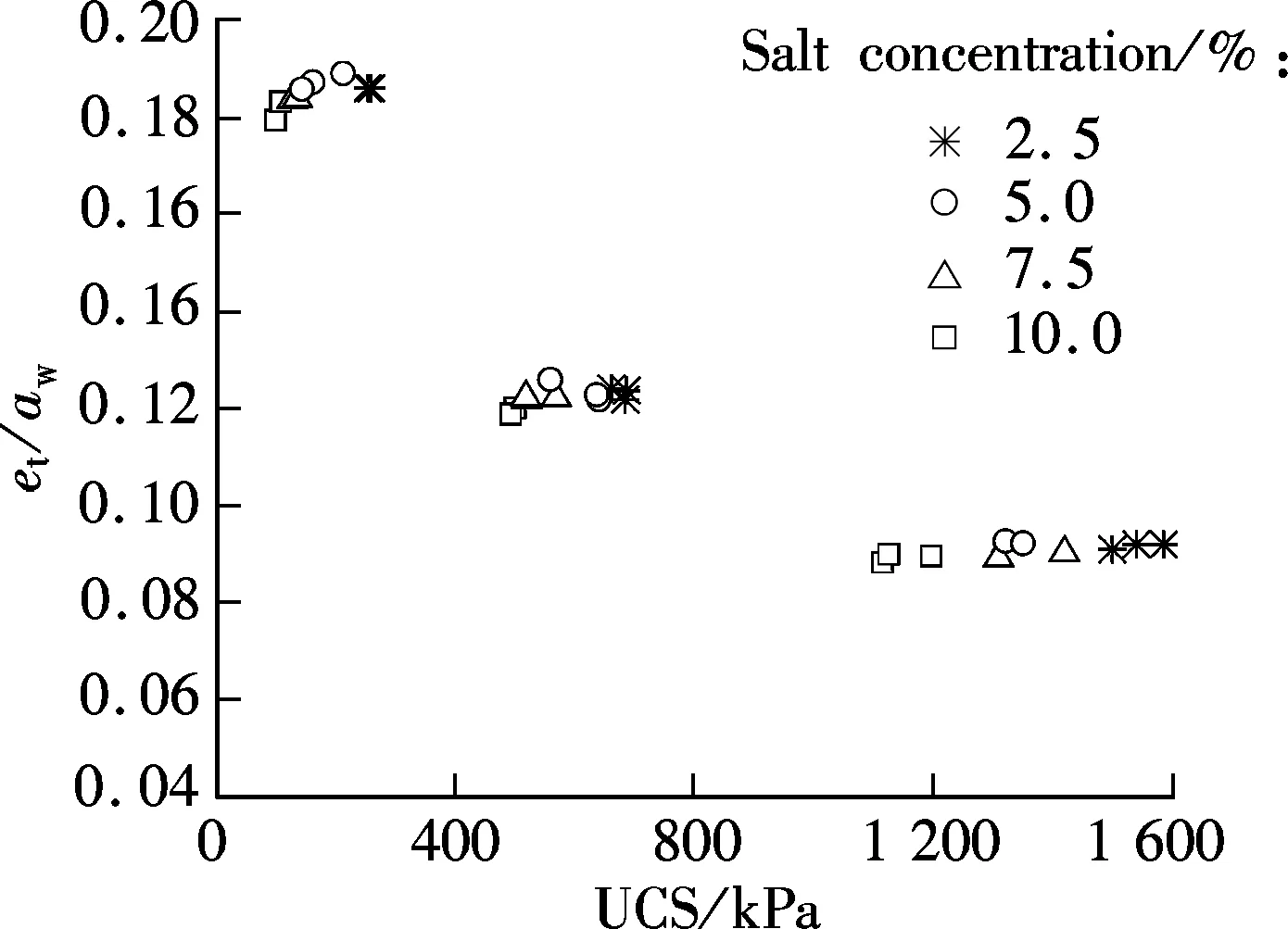

Lorenzo and Bergado[8]reported that the after-curing void ratio (et) and cement content (aw) are the fundamental parameters to characterize the strength and compressibility of cement-admixed clay at high water contents. Fig.4 shows the UCS as a function of the after-curing voids/cement content ratio (et/aw, defined as the after-curing voids divided by the cement content). It can be seen that it is not possible to establish a unique relationship between these two factors. The results differ from those obtained by Lorenzo and Bergado[8]where the after-curing voids/cement content ratio was found to be a useful parameter in the analysis of the strength development of materials that the writers studied. However, in their study the salt concentration of the soil was not reported and constant, so that the after-curing voids/cement content ratio does not reflect the influence of salt concentration.

Fig.4 UCS vs. et/aw ratio

As mentioned above, the UCS of cement-treated soil is dependent on the cement content, the salt concentration, the curing time and the total water content, and so on; therefore, a new parameter, termed as the PSC ratio, is proposed to relate the UCS values and those factors.

翠姨越来越瘦了,哥哥去到外祖母家看了她两次,也不过是吃饭,喝酒,应酬了一番。而且说是去看外祖母的。在这里年青的男子,去拜访年青的女子,是不可以的。哥哥回来也并不带回什么欢喜或是什么新的忧郁,还是一样和大家打牌下棋。

(1)

wherenis the porosity.

Since the structure of the cement-treated soil is dependent on cement content, soil mineral, curing time and water content in the cement-water-soil mixture, it is logical to utilize a parameter that combines the effects of these factors. The porositynis adopted in this study to take into account the effect of water content primarily. The porosity can be determined by void ratioeusing Eq.(2), which can be determined by the solid-liquid-air phase concept using Eq. (3) with the predetermined indices of specific gravity, water contentw, and bulk density. The bulk density is calculated according to the dimensions of the specimen measured before the UCS test. For convenience of use by engineers in practise, water content here refers to the water in the soil before the mix of cement (i.e. 70% in this study). A composite specific gravity, based on the soil, cement and sodium chloride salt mass percentages in the specimen, is used. The specific gravity values of the soil, the cement, and the sodium chloride salt are 2.72, 3.10 and 2.165, respectively. Sodium chloride salt is simply assumed as a solid phase, although it would react with hydrated products and form complicated forms. Such an assumption is useful to derive the values of the specific gravity of mixed soils.

(2)

(3)

whereGsis the composite specific gravity of the treated soil (dimensionless);γis the unit weight of the treated soil (kN/m3);γwis the unit weight of water (kN/m3).

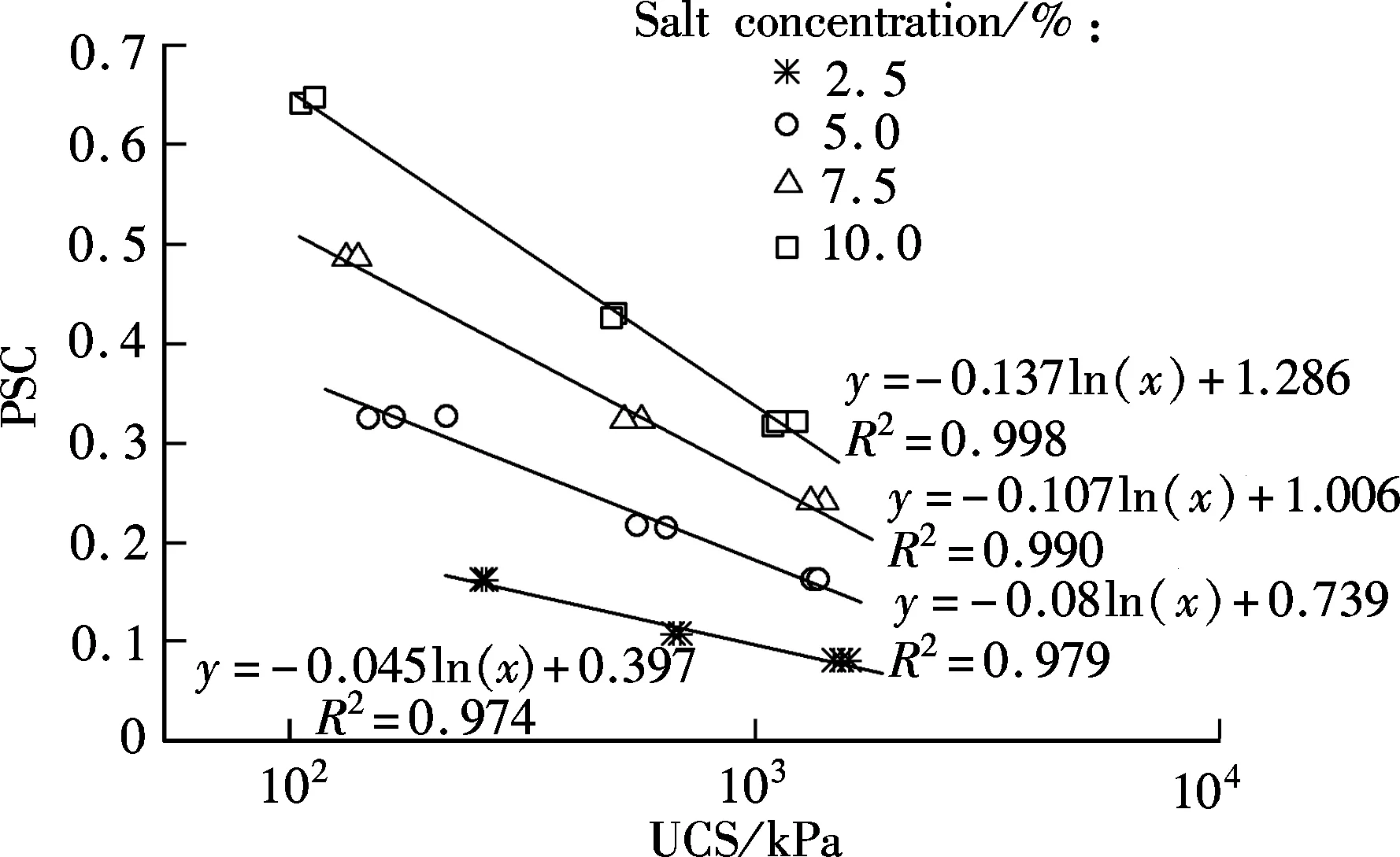

Fig.5 shows the UCS of the cement stabilized clay after curing 28 d vs. the PSC ratio. It can be seen that the unconfined compressive strengths increase with the decrease in the ratio. As expected, the increase in cement content, the reduction of water content and the decrease in salt concentration results in a reduction of the ratio, consequently, yielding an increase of unconfined compressive strength. A good correlation (coefficient of determination,R2>0.97) can be observed between this ratio and the UCS of the soil-cement mixture, which can be expressed as

PSC=Aln(UCS)+B

(4)

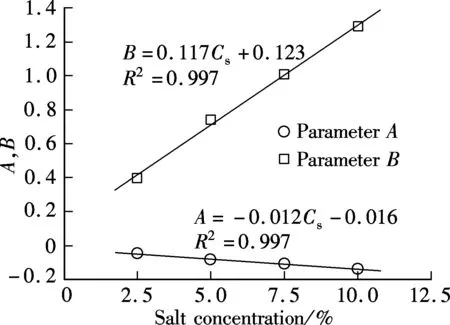

whereAis the slope of the linear regression, andBis the intercept with ordinate. Furthermore, all the fitting curves representing various salt concentrations present a similar format. The parametersAandBare dependent upon the salt concentration, as observed in Fig.6.

Fig.5 UCS vs. PSC ratio

Fig.6 Parameters A and B vs. salt concentration

It is important to point out that the slopes of the fitting lines and the intercepts change linearly with the increase in the salt concentrationCsand the parameters can be fit very well by the following equations:

A=-0.012Cs-0.016

(5)

B=0.117 4Cs+0.123

(6)

Substituting Eqs. (5) and (6) into Eq. (4) gives

PSC=(-0.012Cs-0.016)ln(UCS)+(0.011 74Cs+0.123)

(7)

Eq.(7) relates the UCS of cement-treated soil to the cement content, the salt concentration and the water content of the soil. This equation is very practical for finding the right design parameters. For instance, using Eq.(7), the engineer can choose the amount of cement to provide the soil-cement mixture that meets the strength required by the project for Lianyungang marine clay with a given salt concentration.

It should be pointed out that those parameters in the empirical equation depend on the used materials (soil, cement and salt type). Therefore, one trying to stabilize a different soil has to carry out a similar testing program and develop the relevant equation using this approach.

3 Conclusions

1) The presence of sodium chloride salt in soil has a detrimental effect on the UCS of cement-treated Lianyungang soft marine clay.

2) The PSC ratio is shown to be an appropriate parameter to evaluate the effect of the salt concentration on the UCS of the soil-cement mixture.

3) An empirical equation is proposed to predict the UCS of cement-treated Lianyungang marine clay taking the effect of salt into account. It is possible that those parameters in the empirical equation depend on the used materials (soil, cement and salt type).

Although this study provides information of the UCS of cement-treated Lianyungang marine clay, the microstructure mechanism of adverse effect of salt on the UCS of cement-treated soils requires additional research.

[1]Bruce D A, Bruce M E C, Dimillio A F. Dry mix methods: a brief overview of international practice[C]//ProceedingsofInternationalConferenceonDryMixMethodsforDeepSoilStabilization. Rotterdam, Netherlands, 1999: 15-25.

[2]Porbaha A, Tanaka H, Kobayashi M. State of the art in deep mixing technology: part Ⅱ. applications[J].GroundImprovement, 1998,2(3): 125-139.

[3]Han J, Zhou H T, Ye F. State-of-practice review of deep soil mixing techniques in China[J].JournalofTransportationResearchRecord, 2002,1808: 49-57.

[4]Liu S Y, Hryciw R D. Evaluation and quality control of dry-jet-mixed clay soil-cement columns by standard penetration test[J].JournalofTransportationResearchRecord, 2003,1849: 47-52.

[5]Xu C, Ye G B. Deformation and bearing capacity of composite foundation with cement-soil mixed pile[J].ChineseJournalofGeotechnicalEngineering, 2005,27(5): 600-604.(in Chinese)

[6]Coastal Development Institute of Technology.Thedeepmixingmethod—principle,designandconstruction[M]. Rotterdam,Netherlands: A. A. Balkema Publishers, 2002.

[7]Horpibulsuk S, Miura N, Nagaraj T S. Assessment of strength development in cement admixed high water content clays with Abram’s law as basis[J].Géotechnique, 2003,53(4): 439-444.

[8]Lorenzo G A, Bergado D T. Fundamental parameters of cement-admixed clay-new approach[J].JournalofGeotechnicalandGeoenvironmentalEngineering,ASCE, 2004,130(10):1042-1050.

[9]Shen S L, Han J, Miura N. Laboratory evaluation of mixing energy consumption and its influence on soil-cement strength[J].JournalofTransportationResearchRecord, 2004,1868: 23-30.

[10]Moh Z C. Soil stabilization with cement and sodium additives[J].JournalofSoilMechanicsandFoundationDivision,ASCE, 1962,88(6): 81-105.

[11]Angelova R. Effect of some chemical additives on the strength development of soil-cement[C]//ProceedingsoftheInternationalConferenceontheImplicationsofGroundChemistryandMicrobiologyforConstruction. Bristol, UK, 1992: 147-159.

[12]Xing H F, Yang X M, Xu C, et al. Strength characteristics and mechanisms of salt-rich soil-cement[J].EngineeringGeology, 2009,103(1/2): 33-38.

[13]Modmoltin C, Voottipruex P. Influence of salts on strength of cement-treated clays[J].GroundImprovement, 2009,162(2):15-26.

[14]Modmoltin C, Lu J M, Onitsuka K. Influence of humic acid and salt concentration on lime stabilised Ariake clays and microstructure research[J].ChineseJournalofGeotechnicalEngineering, 2004,26(2): 281-286.

[15]Liu S Y, Shao G H, Du Y J. Depositional and geotechnical properties of marine clays in Lianyungang, China[J].EngineeringGeology, 2011,121(1): 66-74.

[16]Sinat K. Influence of storage conditions on geotechnical properties of Ariake clay and on its chemical stabilization[D]. Saga, Japan: Saga University, 2006.

[17]Miura N, Taesiri Y, Koga Y, et al. Practical of improvement of Ariake clay by mixing admixtures[C]//ProceedingsoftheInternationalSymposiumonShallowSeaandLowLand. Saga, Japan, 1998: 159-168.

[18]Onitsuka K, Modmoltin M, Kouno M, et al. Effect of organic matter on lime and cement stabilized Ariake clay[J].JournalofGeotechnicalEngineering,JSCE, 2004,729(Ⅲ-62): 1-13.

[19]Nor Z B M Y. Stabilisation of organic clay using lime-added salt[D]. Skudai, Malaysia: Universiti Teknologi Malaysia, 2007.

Journal of Southeast University(English Edition)2013年1期

Journal of Southeast University(English Edition)2013年1期

- Journal of Southeast University(English Edition)的其它文章

- Factors affecting headway regularity on bus routes

- Effects of carbonaceous conductive fillers on electrical and thermal properties of asphalt-matrix conductive composites

- Fatigue behavior of basalt-aramidand basalt-carbon hybrid fiber reinforced polymer sheets

- Effect of chloride salt concentration on unconfined compression strength of cement-treated Lianyungang soft marine clay

- Response mechanism for widened pavement structure subjected to ground differential settlement

- Flexural behaviors of double-reinforced ECC beams