PP/回收PET共混物的动态流变行为*

陶友季,章自寿,麦堪成

(1.中山大学化学与化学化学工程学院//教育部聚合物基复合材料及功能材料重点实验室,新型聚合物材料设计合成与应用广东省高校重点实验室,广东广州510275; 2.中国电器科学研究院工业产品环境适应性国家重点实验室,广东广州510663)

PP/回收PET共混物的动态流变行为*

陶友季1,2,章自寿1,麦堪成1

(1.中山大学化学与化学化学工程学院//教育部聚合物基复合材料及功能材料重点实验室,新型聚合物材料设计合成与应用广东省高校重点实验室,广东广州510275; 2.中国电器科学研究院工业产品环境适应性国家重点实验室,广东广州510663)

为了研究回收PET对PP流变行为的影响,用双螺杆挤出机制备了PP/回收PET和增容PP/回收PET共混物,研究了回收PET用量、不同相容剂对PP/回收PET共混物的动态流变行为的影响。结果表明,PP/回收PET共混物的复数黏度随回收PET含量增加而降低,具有明显的剪切变稀特性。PP-g-MA提高回收PET复数黏度,但PP-g-G MA降低共混物的复数黏度,表明回收PET与PP-g-MA的化学作用较PP-g-G MA强。PP-g-MA提高PP/回收PET共混物的动态弹性模量,但PP-g-G MA使共混物的动态弹性模量和动态黏性模量降低。PP-g-MA加入使PP/回收PET共混物tanδ降低,但PP-g-MA用量过高,tanδ反而提高;PP-g-G MA使共混物的tanδ提高,归结于相容剂的增容和增塑作用。

回收PET;聚丙烯;复数黏度;动态弹性模量;力学损耗

PET广泛地用于吹料瓶,大量使用导致许多废弃PET产生。由于PET为工程塑料,具有比聚烯烃高的强度和模量,用回收PET与聚烯烃共混可望提高聚烯烃的力学性能和降低成本,而且是废弃PET回收利用的重要方法。然而,PET和PP作为结晶性聚合物,其熔点、熔体黏度不同。为得到良好性能的PP/回收PET共混物,回收PET对PP的加工特性和流变行为有待于研究。

PP/PET共混物流变行为已有研究。Hausnerova等[1-2]研究了未增容和PP-g-MA增容PP/PET共混物的稳态流变和动态流变行为,观察到共混物在不同温度下剪切黏度受PET含量影响而呈现不同的流变行为。在265℃,剪切黏度随PET含量增加而降低;在245℃,剪切黏度随PET含量增加而提高,具有粒子填充体系的流变行为特征,PP-g-MA增容提高共混物的剪切黏度和黏弹性。Chiu等[3]也发现POE-g-MA增容可提高PP/PET共混物的剪切黏度,SEBS-g-MA和SEBS-g-G MA等增容提高PP/PET共混物的熔体黏度[4]。但Cheung等[5]发现相容剂Epolene E-43(马来酸酐改性PP)使PP/PET共混物的剪切黏度降低,剪切变稀特性变得不明显。

近几年用回收PET制备高分子共混物已有研究[6-10]。虽然PP/回收PET共混物的力学性能与其加工特性有关,但PP/回收PET共混物的动态流变行为至今未见有报道。本文在PP/回收PET共混物结晶行为与熔融特性研究[11-13]基础上,为深入了解PP/回收PET共混物的加工特性,本文研究了不同回收PET用量、相容剂及其含量等对PP/回收PET共混物的动态流变行为的影响。

1 实验部分

1.1 样品的制备

PP:牌号EPS30R,MFI=3.4 g/10 min(230℃,2.16 kg),新疆独山子石化公司产品;r-PET为回收瓶料;PP-g-MA和PP-g-G MA为广州鹿山化工材料有限公司产品,接枝率分别为1.0%和1.1%。原材料真空干燥后,SJSH-Z-35型双螺杆挤出机制备共混物,Y-350型立式注塑机制备标准样条。

1.2 流变性能测试

样品的动态流变行为采用先进流变扩展系统(ARES)测试,采用平行板夹具,平行板间距为1 mm,测试温度为260℃,频率扫描采用从低频到高频的方式,频率范围200~0.08 rad·s-1,应变固定为5%。

2 结果与讨论

2.1 动态复数黏度与组成的关系

图1是未增容PP/回收PET共混物的动态复数黏度(η*)与频率(ω)的对数关系曲线。PP和PP/回收PET共混物的复数黏度都随着剪切频率增大而减少,具有明显的剪切变稀特性。回收PET的复数黏度明显低于PP和PP/回收PET共混物,并且随剪切频率变化不大。PP/回收PET共混物的复数黏度随回收PET含量增加而降低。但在低频区,回收PET加入使PP复数黏度提高,表明回收PET与PP分子链存在相互缠结作用。但在高频区, PP/回收PET共混物复数黏度低于PP,表明回收PET加入有利于PP熔体黏度降低。

图1 PP/回收PET共混物的η*与ω的对数关系曲线Fig.1 Relationship ofη*withωfor PP/r-PET blends

为了研究相容剂对PP/回收PET共混物流变行为的影响,本文先研究相容剂/回收PET共混物的流变行为。图2是回收PET与PP-g-MA、PP-g-G MA共混物的η*-ω关系曲线。可见,在低频区PP-g-MA或PP-g-G MA加入提高回收PET复数黏度,尤其PP-g-MA;认为PP-g-MA与回收PET作用生成大分子接枝物PP-g-PET,提高了回收PET的复数黏度。但在高频区相反,尤其PP-g-G MA。回收PET/PP-g-MA共混物出现转变的频率高于回收PET/PP-g-G MA共混物,也表明回收PET与PP-g-MA间的化学作用较PP-g-G MA的强[11-13]。

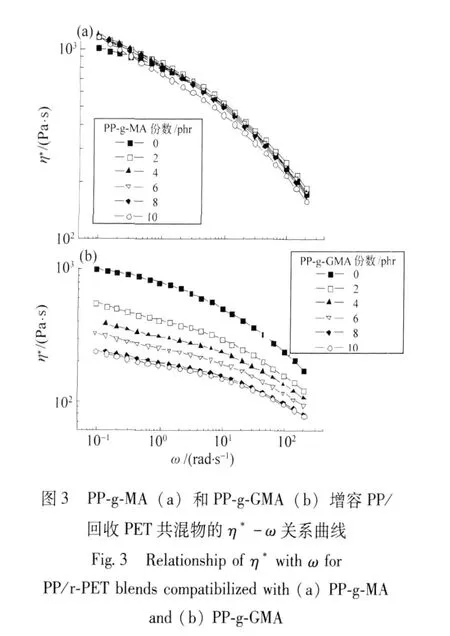

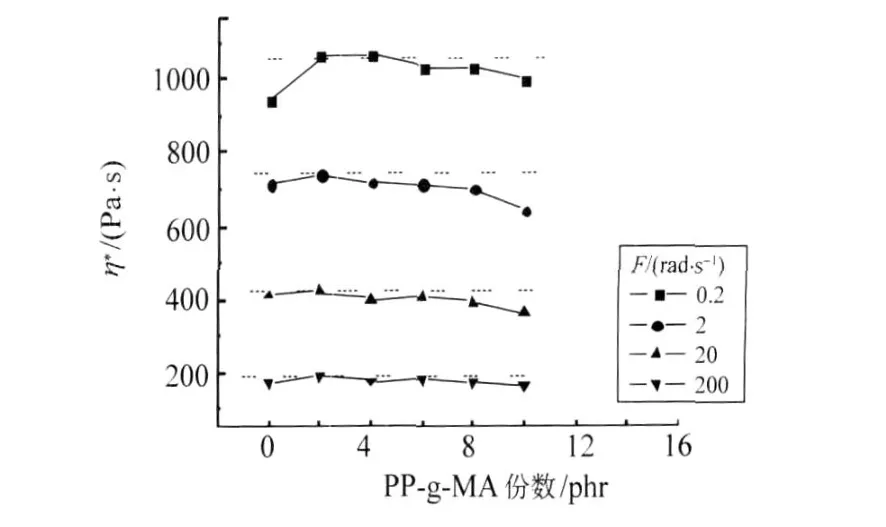

图3是PP-g-MA和PP-g-G MA增容PP/回收PET共混物的η*-ω关系曲线。不同用量PP-g-MA的加入对共混物复数黏度影响不大,但PP-g-G MA加入降低了共混物的复数黏度,且随PP-g-G MA含量增加而降低。由图4可见,当PP-g-MA的分量为2 phr时,共混物在各频率下的复数黏度都提高,归结于PP-g-MA与回收PET的化学作用生成大分子接枝物PP-g-PET的影响。PP-g-MA用量继续增加,共混物的复数黏度下降,归结于过多的PP-g-MA起到增塑作用。

图4 增容PP/回收PET共混物在不同ω的η*与PP-g-MA含量的关系曲线Fig.4 Relationship ofη*with PP-g-MA content for P/r-PET blends compatibilized with PP-g-MA at differentω

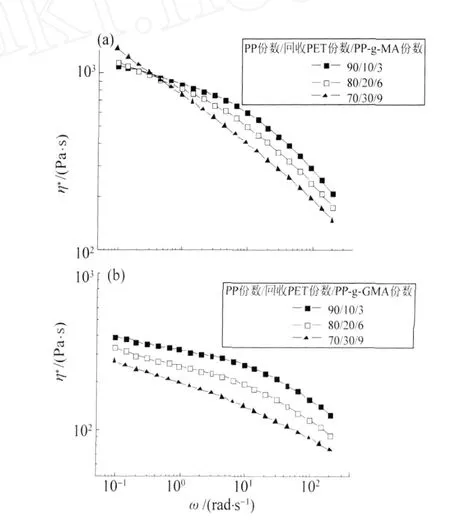

图5是具有相同回收PET/相容剂质量比的增容共混物的η*-ω关系曲线。同样可见,在低频区,PP-g-MA增容共混物具有高的复数黏度;在高频区,相反。而PP-g-G MA增容共混物复数黏度随PP-g-G MA用量增加而降低。

图5 在相同回收PET/相容剂下PP-g-MA(a)和PP-g-G MA(b)增容PP/回收PET共混物的η*与ω的关系曲线Fig.5 Relationship ofη*withωfor(a)PP-g-MA and (b)PP-g-G MA compatibilized PP/r-PET blendswith the same r-PET/compatibilizerweight ratios

2.2 动态模量与组成的关系

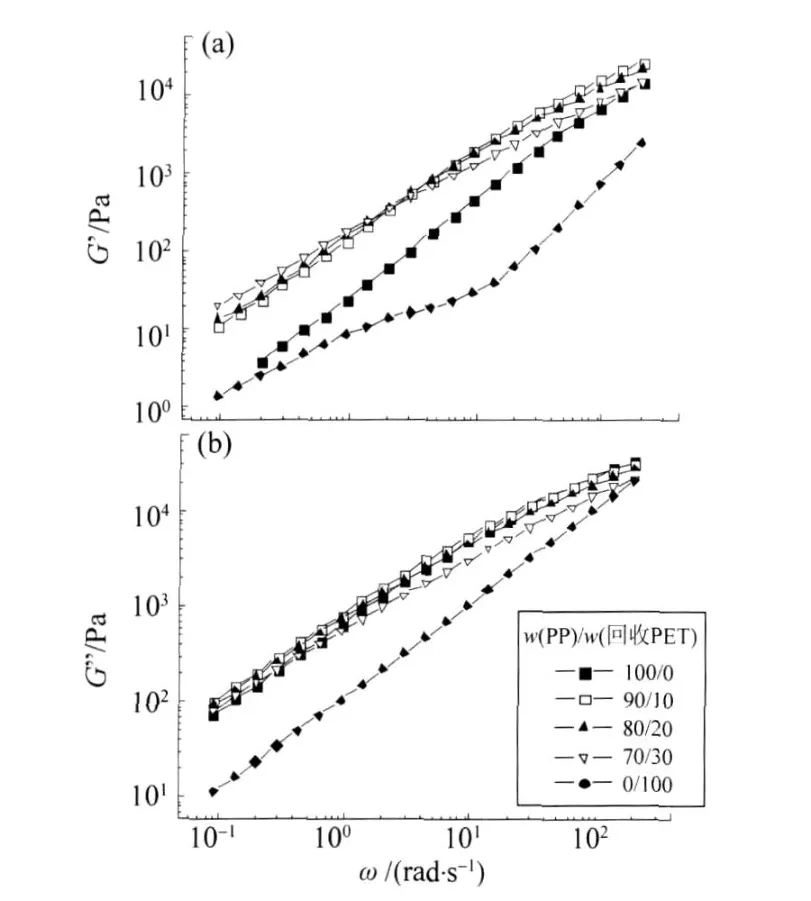

图6是PP/回收PET共混物的动态弹性模量(G′)、动态黏性模量(G″)与ω关系曲线。共混物的G′高于PP和回收PET,但随组成比变化不大,归结于回收PET与PP分子链存在相互缠结作用[14]。回收PET增加,PP的G″降低,与回收PET的G″和熔体黏度低有关。

图6 PP/回收PET共混物的G′、G″与ω关系曲线Fig.6 Relationship ofG′,G″withωfor PP/r-PET blends

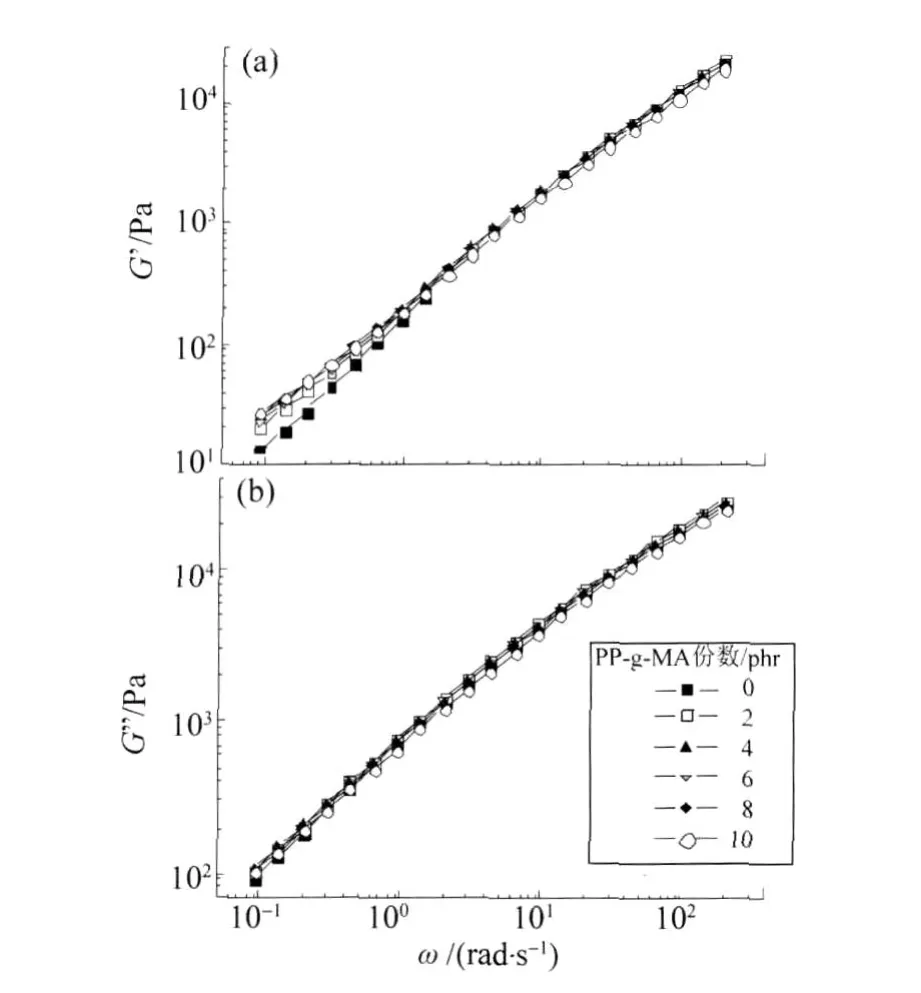

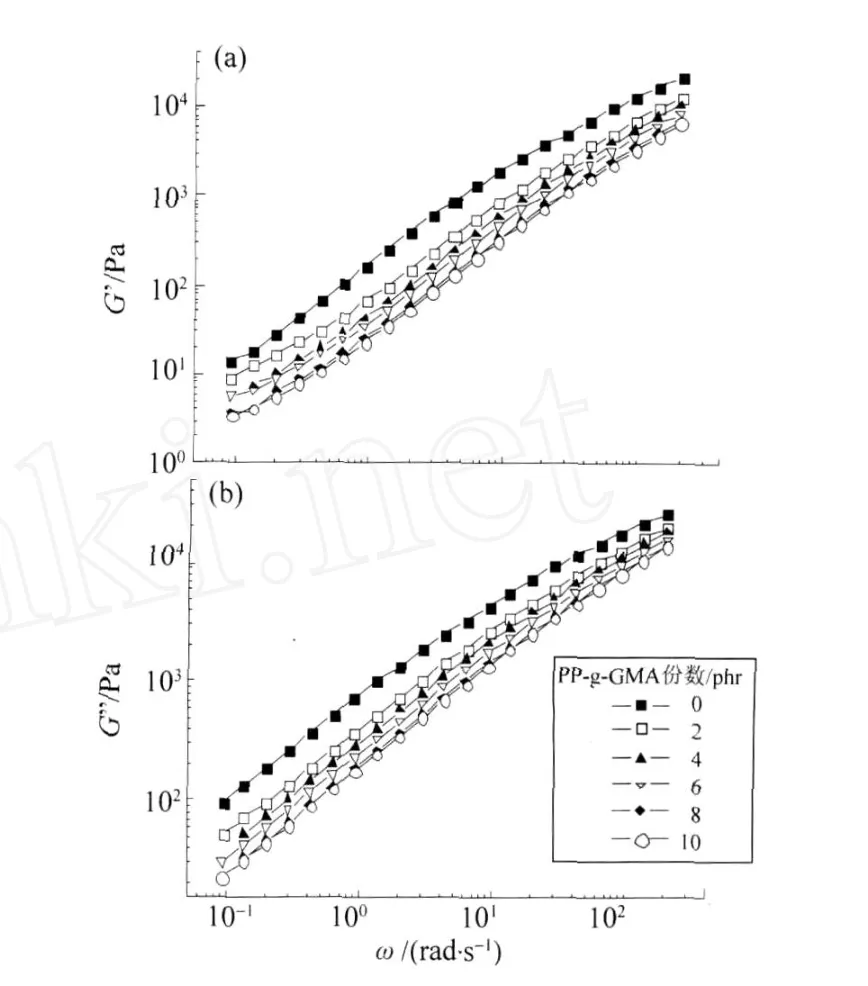

图7是PP-g-MA增容PP/回收PET共混物的G′、G″与ω关系曲线。加入PP-g-MA可提高低频区的G′,但对高频区G′无明显影响。认为PP-g-MA与回收PET作用生成大分子接枝物PP-g-PET,增强界面黏结,导致G′提高[15-16]。表明回收PET加入可以提高PP的动态弹性模量。但在整个剪切频率范围内,PP-g-MA对G″基本无影响。

图7 PP-g-MA增容PP/回收PET共混物的G′、G″与ω关系曲线Fig.7 Relationship ofG′,G″withωfor PP/r-PET 80/20 blends compatibilized with PP-g-MA.

图8是PP-g-G MA增容PP/回收PET共混物的G′、G″与ω关系曲线。加入PP-g-G MA使w(PP/r-PET)/w(PP/r-G MA)为80/20的共混物的G′和G″降低,并且G′和G″随PP-g-G MA含量增加而降低,这与PP-g-MA增容体系明显不同。反映PP-g-G MA与r-PET的化学作用比PP-g-MA与r-PET的弱,G′和G″的降低归结于PP-g-G MA的增塑作用。

图8 PP-g-G MA增容PP/回收PET共混物的G′、G″与ω关系曲线Fig.8 Relationship ofG′,G″withωfor PP/r-PET 80/20 blends compatibilized with PP-g-G MA.

2.3 力学损耗与组成的关系

力学损耗tanδ=G″/G′的大小与大分子链段运动能力有关。图9是共混物的tanδ与ω关系曲线。可见,PP/回收PET共混物在低频区的tanδ随回收PET含量增加而减少,与共混物G′较高有关。PP-g-MA增容使PP/回收PET共混物低频区tanδ降低,表明共混物中链段运动变得困难;但PP-g-MA用量过高,tanδ反而提高。这与PP-g-MA的化学增容和增塑双重作用有关,增容降低tanδ,增塑提高tanδ。PP-g-G MA与回收PET化学反应相对较弱,PP-g-G MA加入使共混物的tanδ增加。

3 结 论

图9 增容PP/回收PET(质量比为80/20)共混物的tanδ与ω关系曲线Fig.9 Relationship of tanδwithωfor (a)PP/r-PET 80/20 blends and their blends compatibilized with(b)PP-g-MA and(c)PP-g-G MA

(1)PP/回收PET共混物的复数黏度随回收PET含量增加而降低,具有明显的剪切变稀特性。(2)PP-g-MA提高回收PET复数黏度,但PP-g-G MA降低共混物的复数黏度,表明回收PET与PP-g-MA的化学作用较PP-g-G MA强。(3)PP-g-MA提高PP/回收PET共混物的动态弹性模量,但PP-g-G MA使共混物的动态弹性模量和动态黏性模量降低。(4)PP-g-MA加入使PP/回收PET共混物tanδ降低,但PP-g-MA用量过高,tanδ反而提高; PP-g-G MA使共混物的tanδ提高,归结于相容剂的增容和增塑作用。

[1] ZDRAZI LOVA N,HAUSNEROVA B,KITANO T,et al. Rheological behaviour of PP/PET and modified PP/PET blends.I.Steady state flow properties[J].Polym Polym Compos,2003,11(6):487-503.

[2] ZDRAZI LOVA N,HAUSNEROVA B,KITANO T,et al. Rheological behaviour of PP/PET and modified PP/PET blends.II.Dynamic viscoelastic properties[J].Polym Polym Compos,2004,12(5):433-447.

[3] CH I U H T,HSI AO Y K.Compatibilization of poly(ethylene terephthalate)/polypropylene blends with maleic anhydride grafted polyethylene-octene elastomer[J].J Polym Res,2006,13(2):153-160.

[4] HEI NO K,KI RJAVA J,H IETAOJA P,et al.Compatibilizationofpolyethyleneterephthalate/polypropylene blends with styrene-ethylene/butylene-styrene(SEBS) block copolymers[J].J Appl Polym Sci,1997,65(2): 241-249.

[5] CHEUNGM K,CHAN D.Mechanical and rheological properties of poly(ethylene terephthalate)/polypropylene blends[J].Polym Int,1997,43(3):281-287.

[6] NAVARRO R,FERRAND IZ S,LOPEZ J,et al.The influence of polyethylene in the mechanical recycling of polyethylene terephtalate[J].J Mater Process Technol, 2008,195:110-116.

[7] ZHANG H,GUO W,YU Y,et al.Structure and properties of compatibilized recycled poly(ethylene terephthalate)/linear low density polyethylene blends[J].Eur Polym J,2007,43:3662-3670.

[8] TANG X,GUO W,YI N G,et al.Reactive extrusion of recycled poly(ethylene terephthalate)with polycarbonate by addition of chain extender[J].J Appl Polym Sci, 2007,104:2602-2607.

[9] MBAREK S,JAZIR I M,CARROT C.Recycling poly (ethylene terephtalate)wastes:Properties of poly(ethylene terephtalate)/polycarbonate blends and the effectof a transesterification catalyst[J].Polym Eng Sci,2006, 46:1378-1386.

[10] AV I LA A F,DUARTEM V.A mechanical analysis on recycled PET/HDPE composites[J].Polym Degrad Stab,2003,80:373-382.

[11] TAO Y,MA I K.Non-isother mal crystallization and melting behavior of compatibilized polypropylene/recycled poly(ethylene terephthalate)blends[J].Eur Polym J,2007,43(8):3538-3549.

[12] TAO Y,PAN Y,ZHANG Z,et al.Non-isother mal crystallization,melting behavior and polymorphism of polypropylene inβ-nucleated polypropylene/recycled poly(ethylene terephthalate)blends[J].Eur Polym J, 2008,44:1165-1174.

[13] 陶友季,麦堪成.增容PP/回收PET共混物的非等温结晶和熔融行为研究[J].中山大学学报:自然科学版,2007,46(4):45-49.

[14] PEON J,VEGA J F,DEL A B,et al.Phase morphology andmelt viscoelastic properties in blendsof ethylene/ vinyl acetate copolymer and metallocene-catalysed linear polyethylene[J].Polymer,2004,44(10):2911-2918.

[15] ARANGUREN M I,MORA E,DEGROOT J V,et al. Effect of reinforcing fillers on the rheology of polymer melts[J].J Rheol,1992,36(6):1165-1183.

[16] ROMAN I F,CORR IER IR,BRAGA V,et al.Monitoring the chemical crosslinking of propylene polymers through rheology[J].Polymer,2002,43(4):1115-1131.

Dynam ic Rheological Behaviours of Polypropylene/ Recycled Poly(ethylene terephthalate)Blends

TAO Youji1,2,ZHANG Zishou1,MA I Kancheng1

(1.Materials Science Institute,PCFM Lab,DSAPM Lab,School of Chemistry and Chemical Engineering,Sun Yat-sen University,Guangzhou 510275,China; 2.State Key Laboratory of EnvironmentalAdaptability for Industrial Products, China National Electric Apparatus Research Institute,Guangzhou 510663,China)

In order to investigate the effect of recycled PET(r-PET)on the dynamic rheological behaviour of PP,blends of PP/r-PET and compatibilized blends were prepared on a twin-screw extruder. Effects of compatibilizers and r-PET contents on the dynamic rheological behaviour of PP blendswere investigated.The results showed that the complex viscosity of PP/r-PET blends decreased with increasing the content of r-PET.Addition of PP-g-MA increases the complex viscosity of PET.However,addition of PP-g-G MA decreased the complex viscosity of PET.It indicated that chemical interaction of r-PET with PP-g-MA was higher than thatwith PP-g-G MA.Addition of PP-g-MA increased the dynamic elastic modulus of PP/r-PET blends.However,addition of PP-g-G MA decreased the dynamic elastic modulus and dynamic viscous modulus of PP/r-PET blends.Addition of PP-g-MA decreased the mechanical loss of PP/r-PET blends.However,the mechanical loss of PP/r-PET blends increased at high content of PP-g-MA.Addition of PP-g-G MA increased the mechanical loss of PP/r-PET blends.Itwas explained by the plasticization and compatibilization of PP-g-MA

recycled PET;polypropylene;complex viscosity;dynamic elastic modulus;mechanical loss

O631.2

A

0529-6579(2010)01-0062-05

2009-05-04

广东省自然科学重点基金资助项目(06104925);广东省科技计划资助项目(2008A010500003);中国电器科学研究院工业产品环境适应性国家重点实验室基金项目

陶友季(1981年生),男,博士;通讯作者:麦堪成;E-mail:ces mkc@mail.sysu.edu.cn