Common Emulsifier Combination Skin Feeling Research and Recommendation

Wang Yiyu,Lan Fangyi,Zha Jinqi

Ingenuity Biotechnology (Shanghai) Co.,Ltd.,China

Abstract Emulsifier is an important component of emulsified skin care BASE (matrix),and the commoninfluencing factors affecting the skin feel of BASE are: emollient,thickeners,and emulsifier.The choice of emulsifier is crucial to the skin feel of cosmetics.In this paper,12 classical emulsifiers were selected and 13 combinations of them were made.Thirteen creams were designed using the same formulation structure,their physicochemical indexes were determined,and their skin feel was tested and evaluated using five expert panel scores,with the test site being the hand.Physicochemical parameters included pH and viscosity.Skin feel indicators include: stickiness,silkiness,whiteheads,greasiness at the end of application,absorption,softness after use,etc.The BASE formulations of the creams were tested and evaluated by five experts.Recommendations were also made for the selection of emulsifier combinations in the design of cream BASE formulations.

Key words face cream;skin feel;emulsifier;skin feel index

The year 2021 is the first year of skincare efficacy.There is a saying in the market,called: no efficacy,no skincare.Looking back at the development of China’s skincare products,we can see that from the 1980s,the emphasis was on stability,to the early 2000s,when the emphasis began to be on skin feel,and to the 2020s,when the emphasis began to be on efficacy.For formulators who have just entered the skincare industry or are not very experienced,thanks to the progress and rapid development of efficacy skincare,the summarization of the efficacy of the active ingredients,relevant information,data can be “at hand”.Perhapsit is the formulator’s “self-preservation”,or perhaps itis regarded as a “housekeeping skill”,but there is still a lack of information on “skin feel”,especially on the performance of the more classic emulsifiers and their combinations.This article starts from this perspective to summarize and classify recommendations for skin feel performance of classic emulsifiers and their combinations on the market to strengthen information sharing within the industry and reduce repetitive work.

Cosmetics can be divided into surface-active system,aqueous system,oil (cream) system,loose powder system,emulsification system.Among them,the emulsification system is a common dosage form in skin care products,which can be applied to emulsions,lowviscosity lotions,oil-containing essences,face creams,eye creams,hand creams,etc.The common factors affecting the skin feel of BASE (base) are: emollients,thickeners,and emulsifiers[1].There are many studies and summaries of emollients,thickeners,and new emulsifiers(such as sucrose ester type emulsifiers and polyglycerol type emulsifiers) suppliers,but such summaries are not common for classic emulsifiers due to the lack of relevantinterest drivers.Nevertheless,the emulsifier combination of the current common face creams is still dominated by classic emulsifiers.

Emulsifiers belong to the category of surfactants,common emulsifiers are divided into oil-in-water (O/W) and water-in-oil (W/O),with HLB values often ranging from 5~16.Thanks to the development of emulsifiers and thickeners,the current oil-in-water system has less consideration for the HLB value,and the HLB value of a single or a combination of emulsifiers is usually set at around 12 when the formulation is designed based on experience.

Sensory evaluation is the only analytical technique that closely links people with products,factories with markets,products with brands,and survival with enjoyment,and it is mainly a technique to judge cosmetics through people’s visual,olfactory,auditory and tactile senses[2].The evaluation of skin feeling is mainly based on the sense of touch,and is carried out by means of scoring by an expert group.Skin feel is divided in detail into pre-application(viscosity,glossiness,pick-up),pre-application(texture,spreadability,freshness,creaminess),midapplication (spreadability,stickiness,layering),end-application (greasiness,absorption),afterapplication (residual film,final oiliness,final softness,smoothness,luminosity),etc.[3].

1 Experimental part

1.1 Experimental materials

1.1.1 Cream base formulation design

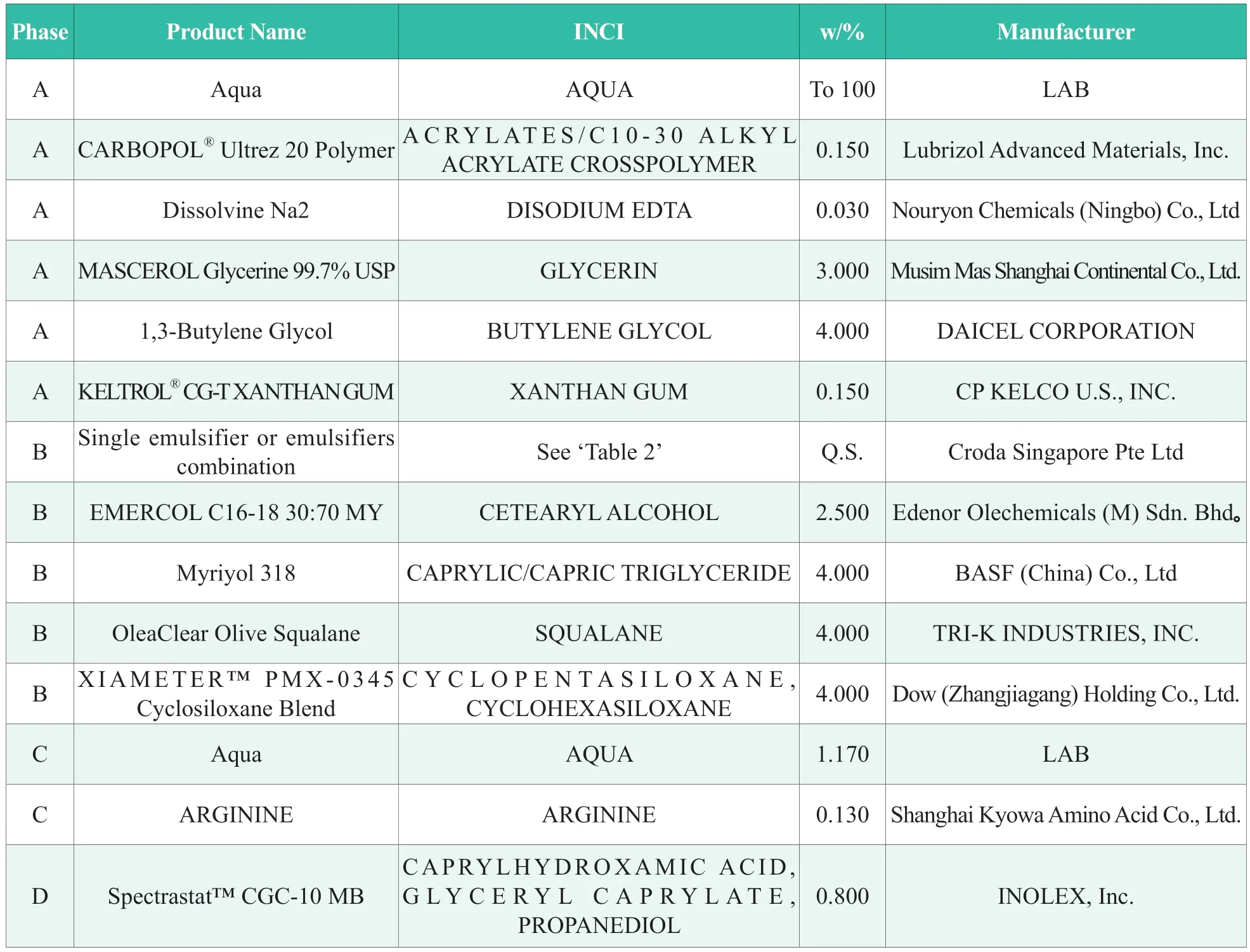

The cream base formulation and ingredients are shown in Table 1.Emollients were selected from 3 common combinations (silicone-derived silicone oils+synthetic-derived oils+vegetable-derived oils) of refreshing (cyclopentadimethylsiloxane and cyclohexasiloxane),medium-textured (caprylic/capric triglycerides),and slightly moisturizing (squalane).Thickeners choose the common combination of polyacrylates+xanthan gum.Polyols choose the common combination of glycerin+butylene glycol.

Table 1.Basic Formula and Ingredient List for Face Cream

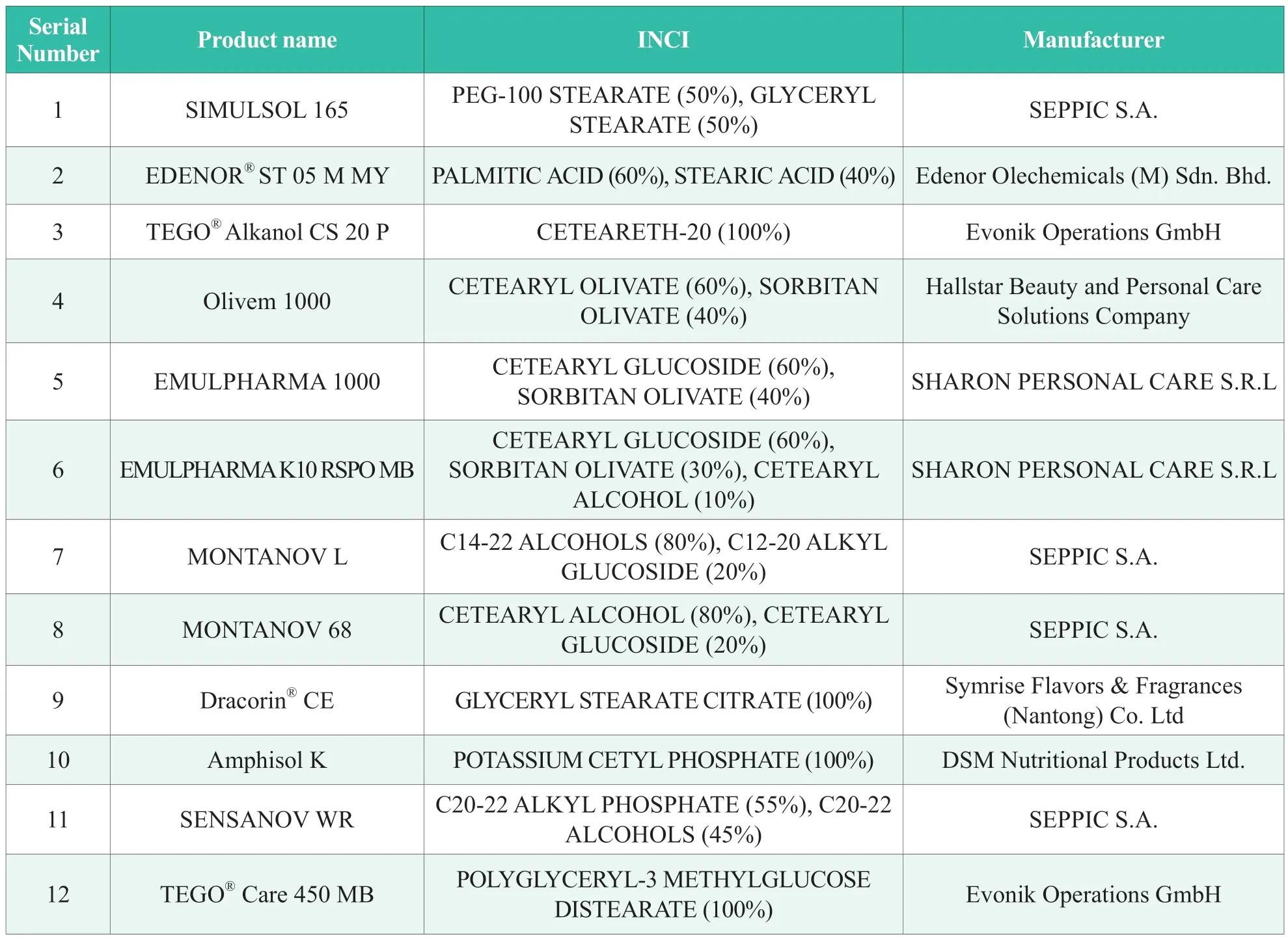

1.1.2 Emulsifier and emulsifier combination description

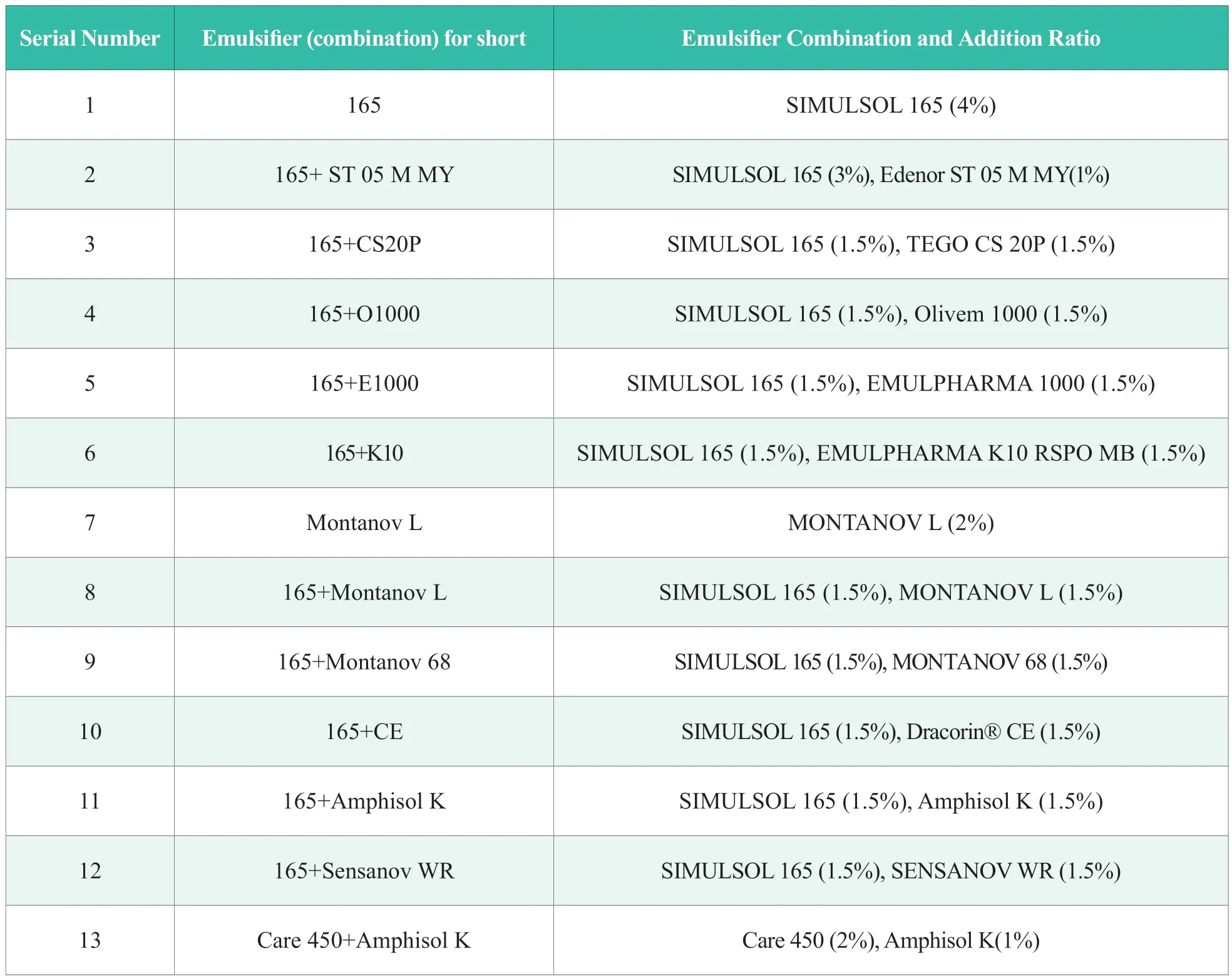

The details of 12 emulsifiers are shown in Table 2,and the more classic emulsifiers are selected in this paper.13 creams and emulsifier combinations,and the amount of additives are shown in Table 3,and SIMULSOL 165 is selected because it is very classic,and it is widely used in creams,and the combination of 165+other emulsifiers is selected to facilitate the comparison of the skin feel and the analysis of the skin feel on the basis of 165,in order to demonstrate the characteristics of the other emulsifiers.

Table 2.Emulsifier details

Table 3.Cream numbers and emulsifier combinations,additions

1.2 Experimental equipment

1.2.1 Instrumentation for cream preparation and testing

IKA (RW20 digital) emulsification homogenizer,Aika (Guangzhou) Instrument Equipment Co.,Ltd.;IKA RW20 mixer,Aika (Guangzhou) Instrument Equipment Co.,Ltd.;NDJ-1 rotary viscometer,Shanghai Yueping Scientific Instrument Co.,Ltd.Company;ME precision balance ME802E,ME4002E,Mettler Toledo Technology (China) Co.,Ltd.;Lei Magnetic PHS-3C pH meter,ShanghaiYidian Scientific Instrument Co.,Ltd.;Yiheng HWS-24 (double row four hole) water bath Pot ShanghaiYiheng Scientific Instrument Co.,Ltd.;beakers,label paper,and medicine spoons.

The process of cream preparation is as follows:

1) Weigh water in a beaker first,then add CARBOPOL®Ultrez 20 Polymer,wait until it is completely moistened (no small white spots on the surface of the water),add the other ingredients of phase A,start stirring,heat up to 80~85 ℃ in a water bath,stir evenly(stirring speed 350~400 r/min),keep warm for 20~30 min.Note that KELTROL®CG-T XANTHAN GUM (Xanthan Gum) is pre-dispersed with 1,3-Butylene Glycol (Butylene Glycol) before addition.

2) In another beaker of suitable size,weigh the raw material of phase B (oil phase) and heat it to 80~85 °C in a water bath with moderate stirring untilit is dissolved evenly.

3) In a suitable size beaker weigh the C-phase raw materials,stirring to dissolve,set aside.

4) Add phase B to phase A,turn on the homogenizer,homogenize at a speed of 8 000~10 000 r/min,and homogenize for 3~5 min.Stir to cool down.Cool down to 60~65 ℃,add phase C,continue to stir evenly (stirring speed 350~400 r/min),and continue to cool down.

5) Cool down to 40~45 °C,add phase D,and stir evenly (stirring speed is about 350 r/min).

6) Stop stirring when the temperature drops to about room temperature,and measure the pH and viscosity.

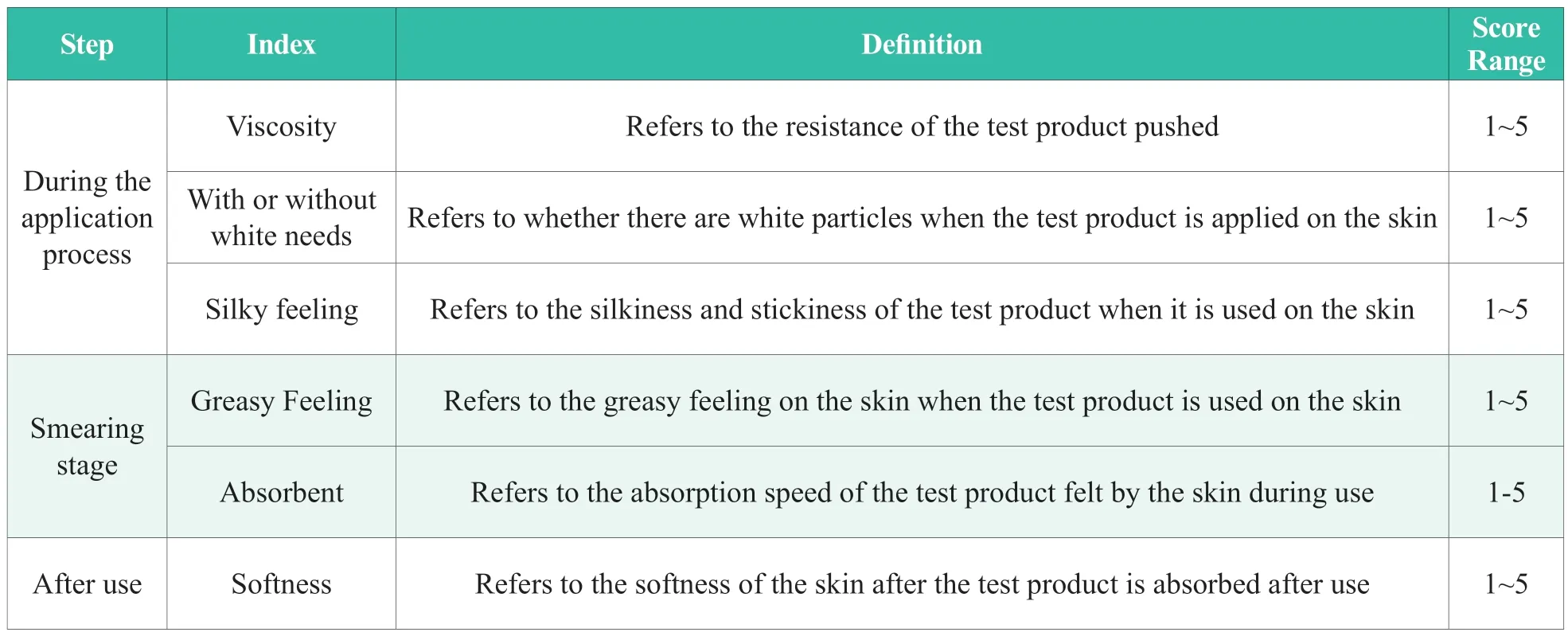

1.3 Skin feel test

From the perspective of consumers and formulators,this paper selects 6 indicators for evaluation,as shown in Table 4.They are: stickinessin application,silky feeling,presence or absence of whiteheads,greasiness at the end of application,absorbability,and softness after use.From the consumer’s point of view,among these 6 indicators,whiteheads and greasiness,which are skin sensations that most consumers do not like,are minus points.Silky feeling,absorbency,and softness are skin sensations that most consumers like,and are plus points.The indicator of stickiness in application is neutral.For a better distinction,we set a resolution of 0.5 points.

Table 4.Definition and scoring of skin sensitivity test indicators

2 Results and analysis

2.1 Physical and chemical test results

The physicochemical indexes of the 13 creams are shown in Table 5.The pH was measured by the dilution method with reference to the 2015 edition of the Technical Specification for Cosmetic Safety[4],and the indexes ranged from 4.60~6.88,which conformed to the requirements of the People's Republic of China light industry standard QB/T 1857,Emollient Creams and Creams,regarding pH[5].Viscosity is an instantaneous measurement,index between 21,000~59,000.The combination of 165+O1000 or 165+E1000 has the highest viscosity and is a suitable emulsifier combination for thick textured creams,while the combination of 165+Montanov L or 165+Sensanov WR has the lowest viscosity and is a suitable emulsifier combination for light textured creams.

When comparing Emulsifier Combinations 1~3,monoglycerides (glyceryl stearate) do not have a significant impact on viscosity.In emulsifier combinations 1-3,the monoglyceride content is 2%,1.5%,and 0.75%,respectively.Comparing emulsifier combinations 4~6,sorbitan olivate has a greater effect on viscosity than cetearyl alcohol,which has a better thickening effect.In combinations 4~6,the contents of sorbitan olivate and cetearyl alcohol were 0.6%,0%;0.6%,0%;0.45%,0.15%,respectively.In addition,comparing the emulsifier combinations 2,3 and 10,it can be found that,as far as 165 compounding single emulsifier (without fatty alcohol and sorbitan olive oil ester),there is not much difference between their viscosities,which are 55,000 mPa·s,57,000 mPa·s,and 53,000 mPa·s,respectively.From the above,it can be deduced that,as far as the effect on thickening of the cream is concerned: sorbitan olive oil ester >cetearyl stearol>glycerol Stearate.

Table 5 Physical and chemical test results of face cream

2.2 Skin feel test results

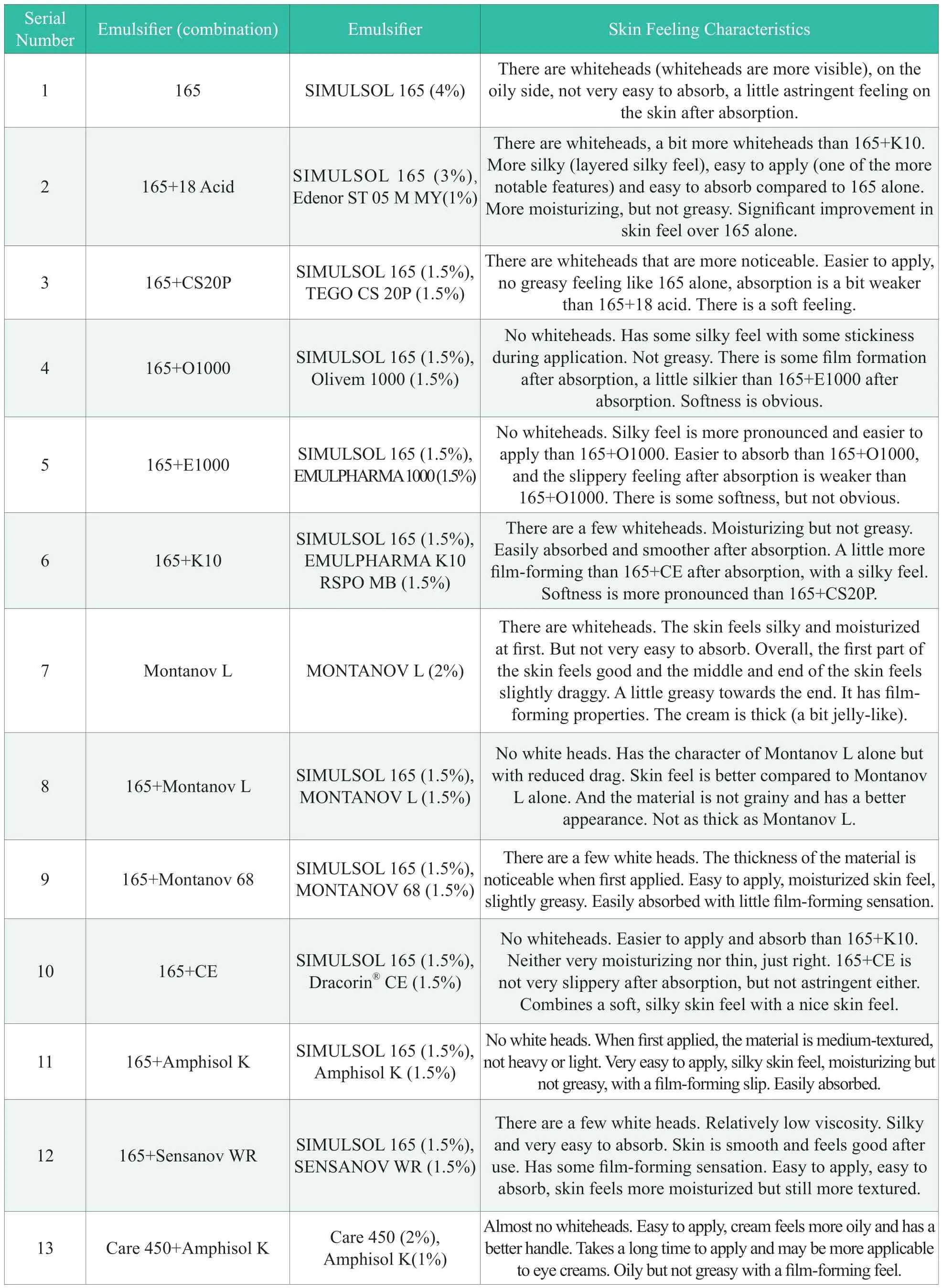

In this paper,the skin feel of the cream was scored and statistically evaluated using expert panel scoring,and the results are shown in Table 6.

continued

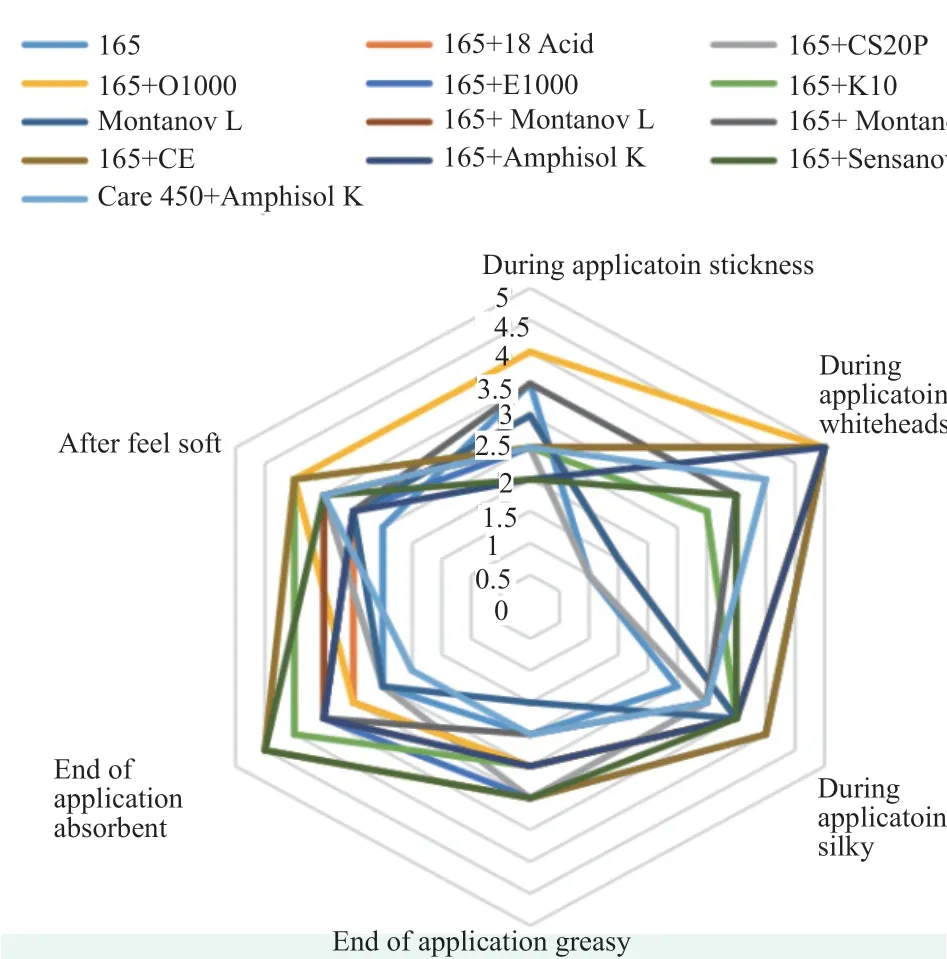

In order to better identify and compare,in the radar chart,we use the method of subtracting points for whiteheads and greasy feeling,that is,use 5-corresponding score value,for example,the whitehead score is 4 points,and the radar map is 1 point,that is,5-4=1;for example,the greasy feeling score is 3 points,and the radar map is 2 points,that is,5-3=2.Different emulsifier combinations of creams skin feel characteristics radar chart is shownin Figure 1.

Based on the evaluation,the selection of emulsifier combinations in the design of the cream BASE formulation was summarized in Table 7.

Figure 1. Radar chart of skinfeel characteristics of creams with different emulsifier combinations

Table 7.Summary of skinfeel characteristics of creams with different emulsifier combinations

Comparing emulsifier combinations 1~3,the differences are very small as far as viscosity is concerned (55,000~57,000 mPa·s),but there are differences in a number of indicators of skin feel,andit can be seen that the influence on skin feel is more strongly affected by differences in the structure of the emulsifiers.Skin feel involves the interaction between the cream and the hand (face),and is affected by the rheological properties of the cream,the microstructure of the cream,and the interaction with skin lipids.Therefore,inferring skinfeel characteristics from the rheological properties of the cream alone is,in our opinion,a very deficient form of linear thinking.

Comparing emulsifier combinations 1,7,and 8,it can be seen that the combination of emulsifiers has a better skinfeel performance than a single emulsifier,which may be related to the diversity of skin lipids and the multiple variability of the cream structure.Consumers prefer a varied,layered skin feel to a monotonous skin feel.

In summary,comparing the emulsifier combinations,we can see that different emulsifier combinations still have a greater impact on skin feel.In addition,emulsifiers containing phosphate ester structure (e.g.,emulsification combinations 10 and 11) have a better performance of silky smoothness of application.As for the relationship between other skinfeel indicators and the structure of emulsifiers,from this experiment,no definite conclusion could be summarized,and further experiments need to be designed to verify the inference.

3 Conclusion

This article selects 12 classic emulsifiers,and designs 13 creams with the same formula structure.The pH values (dilution method) ranged from 4.60 to 6.88,and the viscosity ranged from 21,000 mPa.s to 65,000 mPa·s.

If you want a face cream without silicone oil and with few or no whiteheads,you can choose 165+O1000 (or E1000,or Montanov L,or CE,or Amphisol K),or Care 450+Amphisol K.

If you want a silky smooth face cream,you can choose 165+CS20P (or O1000,E1000,K10,CE or Amphisol K).

If you want the cream to absorb well,you can choose 165+ST 05 M MY (or E1000,or K10,or CE,or Amphisol K,or Sensanov WR).

If you want a soft feeling in your face cream,you can choose 165+CS20P(or O1000,K10,CE).

For eye cream,you can choose 165+O1000 (or Montanov 68),or Care 450+Amphisol K,which can bring a moisturizing skin feeling.

Thick textured cream emulsifiers are availablein combinations of 165+O1000 or 165+E1000.For light cream emulsifier combinations,choose 165+Montanov L or 165+Sensanov WR.

After comprehensive analysis,we found that the skin feel of emulsifier combinations is more balanced and can take care of multiple aspects compared to a single emulsifier.The optimal combination for skin feel is 165+E1000,which has characteristics such as no whiteheads,silky smoothness,and easy absorption.Another good combination is 165+O1000,which has features like no whiteheads,silky smoothness,softness and moisturizing sensation.Lastly,165+CE also provides benefits such as no whiteheads,silky smoothness and soft skin feel after absorption.

In addition,we also unexpectedly found that in terms of viscosity index,as far as the effect on cream thickening is concerned: sorbitan olivate >cetearyl stearyl alcohol >glyceryl stearate.Of course,it remains to be experimentally verified whether this finding remains the same in combinations that do not contain 165 emulsifiers.

Skin feel involves the interaction between the cream and the hand (face) and is influenced by the rheological properties of the cream,the microstructure of the cream,and the interaction with skin lipids.It is not appropriate or feasible toinfer skin feel characteristics from the rheological properties of the cream alone.

Emulsifiers containing phosphate structures (such as emulsification combinations 10 and 11) have a better silky feeling on application.As for the relationship between other skin feel indicators and the structure of emulsifiers,from this experiment,it failed to summarize the exact conclusion,and further experiments need to be designed to verify the inference.

Cosmetic formulation design is a highly practical work involving the interaction of multiple factors,and it may be more difficult to start from the structure of a single ingredient in the hope of deduction from a theoretical point of view than to generalize from a practical point of view.

Using the key words “emulsifier”,“sensory evaluation” or “skin feel” to search the database“CNKI”,we found that there are very few papers directly discussing the relationship between emulsifiers and skin feel indicators,and only 2 were retrieved.The literatures are “ Research on the sensory properties of common emulsifiers”[6],“The application of the sorting method in the sensory evaluation of cream cosmetics”[7].The former article did not specify the amount of emulsifier in the formulation,but only labeled the unsuitable amount,on the one hand,itis difficult for subsequent researchers to review the sample,on the other hand,as far as the industry perception is concerned,the different amount of the same emulsifier also has a greater impact on the skin feel,and even a greater impact on the viscosityindex.The latter article did not specify the specific emulsifiers,and only used four samples to describe,again,subsequent researchers are difficult to resample,experience can not be accumulated.And in the article,the amount of emulsifier in the formulation is 4% or 6%,such a high amount,in fact,exceeds the amount of emulsifier added in common listed skin care products,and the practicality is not strong.The sensory indicators discussed in the two articles are also excessive,with 14 indicators in the former article and 13 in the latter.However,many of these indicators are of little concern to consumers,i.e.,they are of little value in evaluating the merits of a product.

We hope that more peers will share more experimental results if allowed,and when designing the formula,the types of emulsifiers and the addition ratio should be clear,and the addition ratio should be close to the actual commercially available products,so that the results of the study can be repeated and the experience can be accumulated,so that it is possible to improve the theory of the building.

China Detergent & Cosmetics2023年4期

China Detergent & Cosmetics2023年4期

- China Detergent & Cosmetics的其它文章

- The 2023 (12th) National Sulfonation/Ethoxylation Technology and Market Seminar was Held

- The 3rd Summit Forum on Amino Acid Surfactant was Held

- The 2023 (14th) China Daily Chemical Industry Forum was Held

- The Haircare Efficacy Research of Prinsepia Utilis Oil

- In Vitro Study on the Soothing and Oil Control Efficacy of P-Hydroxyacetophenone

- In Vivo Study of a Natural Whitening Agent