On the critical particle size of soil with clogging potential in shield tunneling

Shuying Wng ,Ziho Zhou ,Pengfei Liu ,Zho Yng ,Qiujing Pn ,Weizhong Chen

a School of Civil Engineering,Central South University,Changsha,410075,China

b CCCC Second Harbor Engineering Company Ltd.,Wuhan,430040,China

c Institute of Rock and Soil Mechanics,Chinese Academy of Sciences,Wuhan,430071,China

Keywords:Shield tunneling Soil clogging Adhesion Critical particle size

ABSTRACT Shield tunneling is easily obstructed by clogging in clayey strata with small soil particles.However,soil clogging rarely occurs in strata with coarse-grained soils.Theoretically,a critical particle size of soils should exist,below which there is a high risk of soil clogging in shield tunneling.To determine the critical particle size,a series of laboratory tests was carried out with a large-scale rotary shear apparatus to measure the tangential adhesion strength of soils with different particle sizes and water contents.It was found that the tangential adhesion strength at the soil-steel interface gradually increased linearly with applied normal pressure.When the particle size of the soil specimen was less than 0.15 mm,the interfacial adhesion force first increased and then decreased as the water content gradually increased;otherwise,the soil specimens did not manifest any interfacial adhesion force.The amount of soil mass adhering to the steel disc was positively correlated with the interfacial adhesion force,thus the interfacial adhesion force was adopted to characterize the soil clogging risk in shield tunneling.The critical particle size of soils causing clogging was determined to be 0.15 mm.Finally,the generation mechanism of interfacial adhesion force was explored for soils with different particle sizes to explain the critical particle size of soil with clogging risk in shield tunneling.

1.Introduction

When a shield machine passes through a clayey stratum,the excavated soil grains easily adhere to the cutterhead,cutters and chamber bulkhead,resulting in the phenomenon of soil clogging.This phenomenon reduces the tunneling speed and seriously aggravates cutterhead abrasion (Thewes and Hollmann,2016;Liu et al.,2018).This is mainly induced by high adhesion strength at the interface between excavated soils and the steel plate in both the normal and tangential directions.Normal adhesion strength is always measured by tension tests,in which a steel block is pulled out from the soil after a period of compression (Thewes and Burger,2005;Sass and Burbaum,2009;Azadegan and Massah,2012).However,the loading condition in tension tests is probably different from that in real shield excavations.The soil movement along the steel surface appears in the tangential direction during shield tunneling.Therefore,the tangential adhesion strength plays a more important role in soil clogging than the normal adhesion strength,which is the main viewpoint in the original work of Zumsteg and Puzrin (2012) and Liu et al.(2019).

Tangential adhesion strength,also referred to as the shear strength between clay and steel,has been studied by many researchers (e.g.Zumsteg and Puzrin,2012;Birch et al.,2016;Peila et al.,2016).However,these existing studies only focus on the soil clogging problem in clay strata.It has been reported in engineering practice that soil clogging also occurs in coarse-grained soils containing particles with diameters larger than 0.075 mm and even in rock strata(Thewes and Hollmann,2014,2016;Ye et al.,2017).In addition,when an earth pressure balance (EPB) shield tunnels in coarse-grained soils such as sands and gravels,it is necessary to inject bentonite slurry into the excavated soils to ensure its workability.The soil conditioning of the bentonite slurry on the excavated coarse soils may also cause shield clogging(Jiang et al.,2011).

Few studies have been carried out on soil clogging for shield tunneling in coarse-grained soils.Thewes and Hollmann (2016)determined the possibility of soil clogging by analyzing the mineral composition of decomposed clay in the rock and the associated plasticity index.However,as stated by Thewes and Hollmann(2016),there is a debate over the issue of whether this method is accurate enough,which was not well explained in their study.Based on the Chamshir water conveyance tunnel project in Iran,the clogging risk in soft marlstone and mudstone strata was evaluated by Hassanpour et al.(2019),who reported that a shield machine had a high clogging risk when the consistency index of soils was in the range of 0.4-0.5.Engineering experience has shown that larger soil particles are less likely to induce soil clogging (Ye et al.,2017;Hassanpour et al.,2019).There exists a critical particle size of soil grains below which soil clogging probably occurs.It is assumed that the critical particle size of soils for evaluating soil clogging risk is possibly different from that for soil classification in soil mechanics,which normally adopts 0.075 mm and 0.06 mm in particle diameters to classify fine-and coarse-grained soils,respectively.To date,there have been no studies on the critical particle size of soils for soil clogging in shield tunneling.In addition,the consistency index is applied to evaluate the soil clogging risk;however,it is calculated according to the Atterberg limits and water content.The Atterberg limits are only applicable to soils with particles less than 0.5 mm or 0.425 mm in diameter according to the Chinese standard(GB/T 50123-2019,2019) and American standard (ASTM D4318-10,2010),respectively,and are not suitable for soils with larger particles.

In this study,a new large-scale rotary shear apparatus is developed to determine the tangential adhesion strength of soils with different particle sizes and water contents.The variations in the interface friction coefficient and the interfacial adhesion force for soil specimens with different particle sizes and water contents are investigated.Then,a new criterion for judging soil clogging for shield tunneling is established based on the interfacial adhesion force.The critical particle size of soils is proposed to judge whether there is a risk of clogging.Finally,the generation mechanism of the interfacial adhesion force is explored from a mesoscopic-level perspective.

2.Testing program

2.1.Testing materials

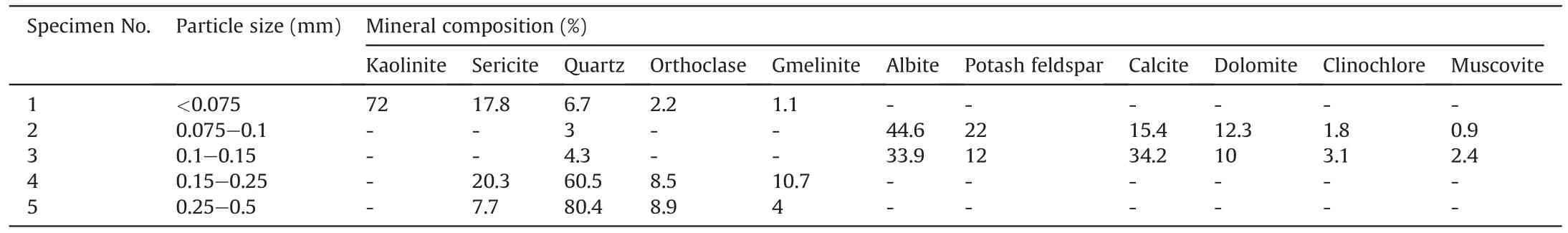

Fully weathered granite,medium sands and sandy pebbles were used as testing materials.These materials were dried at 105ºC for 24 h before sieving.The agglomerated soils were crushed using a rubber hammer.It was very important to ensure that the soil grains were not damaged during the crushing process.Then,the soils were mixed together,and the soil specimens with different ranges of particle sizes were obtained after sieving.Five soil specimens were selected for testing,whose particle sizes were less than 0.075 mm,0.075-0.1 mm,0.1-0.15 mm,0.15-0.25 mm and 0.25-0.5 mm,respectively.X-ray diffraction(XRD)tests were carried out to determine the mineral composition of each soil specimen.Table 1 shows the mineral compositions of the five groups of soil specimens.There were no clay minerals in the soil specimens except for the specimen with a particle size less than 0.075 mm.

Table 1 Soil mineral composition.

2.2.Testing apparatus

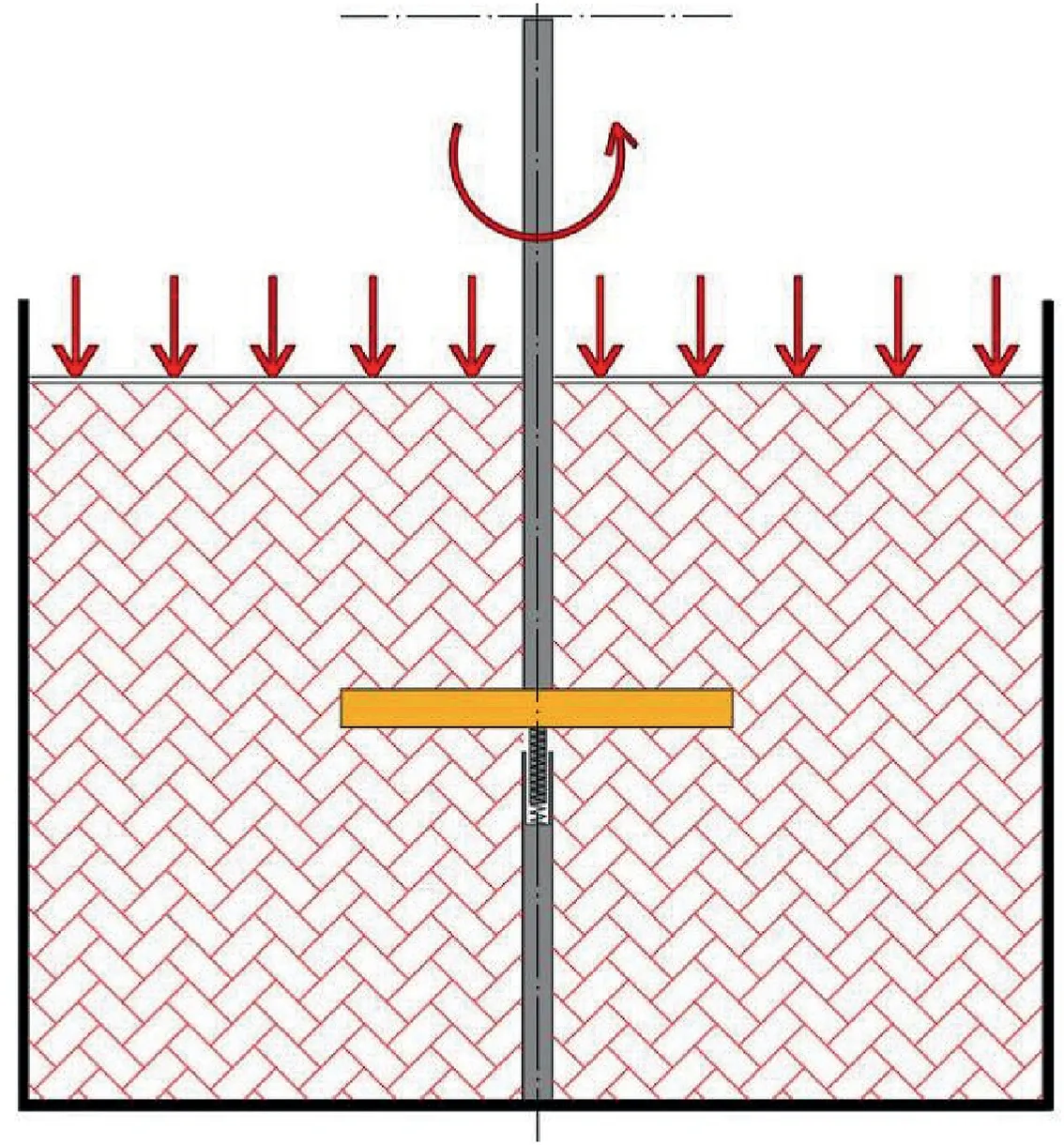

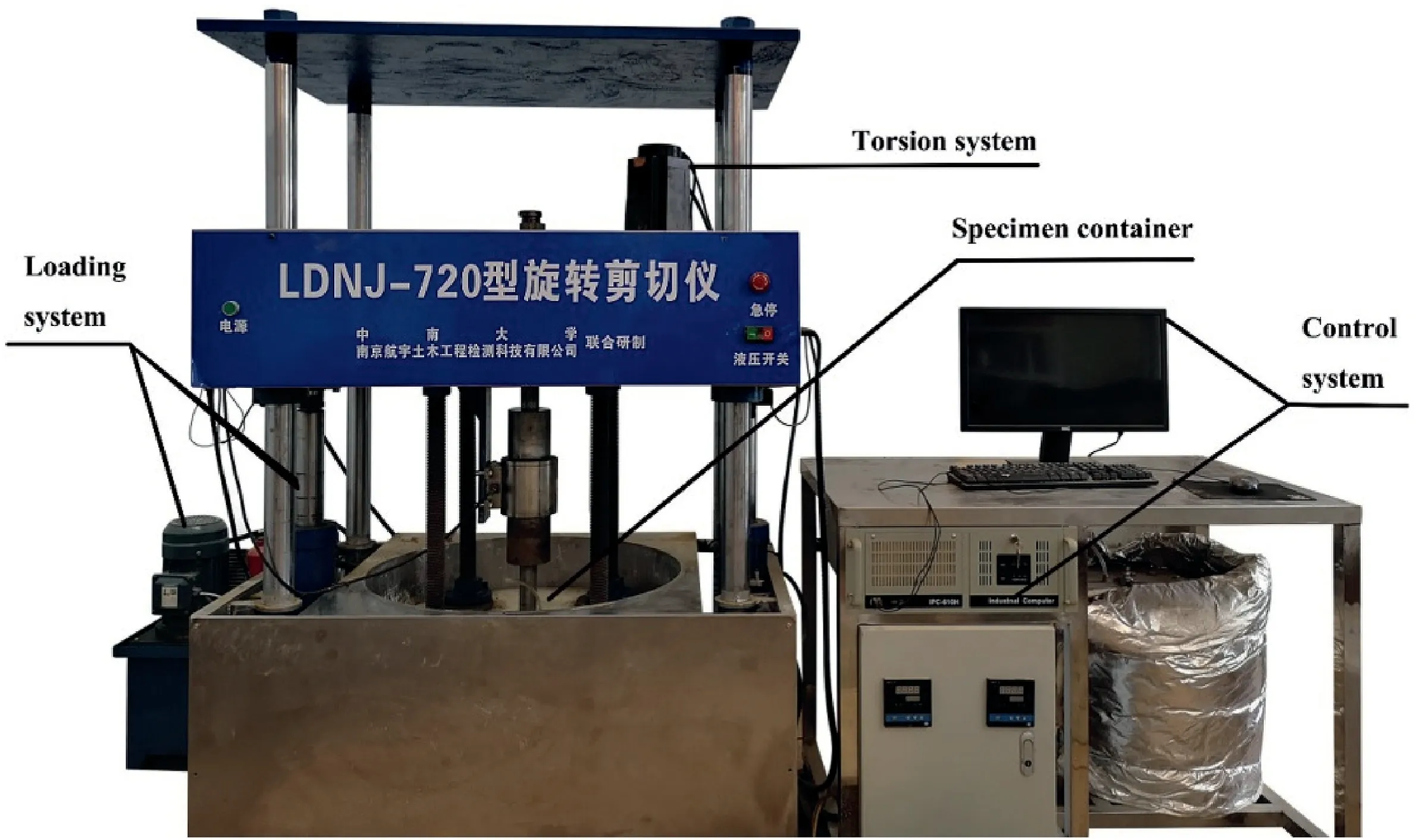

Several methods for determining the tangential adhesion strength between soil and steel exist,such as the direct shear test,soil-metal adapter test,static lateral adhesion test and shear plate test (Zumsteg and Puzrin,2012;Basmenj et al.,2016;Birch et al.,2016;Peila et al.,2016).The soil will be easily squeezed out of the shear box if the soil specimen appears in a soft state for the direct shear test and soil-metal adapter test.It is difficult for these methods to measure the tangential adhesion strength of the soil with a consistency index of 0.4-0.75,which is the ideal state for EPB shield tunneling.The tangential adhesion strength cannot be obtained directly for the static lateral adhesion test,and the test can only be conducted under atmospheric pressure,not corresponding to the stress state of the soil in the chamber(Wang et al.,2020).To overcome these shortcomings,a small-scale rotary shear apparatus similar to the shear plate apparatus presented by Zumsteg and Puzrin (2012) was designed and built by Liu et al.(2019) to perform laboratory tests on soil with different particle sizes.Compared with other testing apparatus,this apparatus can be used to determine the tangential adhesion strength at the interface between clay and steel under different normal pressures.The tangential adhesion strength can also be measured at soft consistencies of soil.However,the small-scale rotary shear apparatus cannot be used for specimens with coarse particles.Therefore,a large-scale rotary shear apparatus was designed and built.Fig.1 shows the schematic diagram of the apparatus,and Fig.2 presents a photograph of the large-scale rotary shear apparatus.The apparatus is mainly composed of a specimen container,a loading system,a torsion system and a control system.

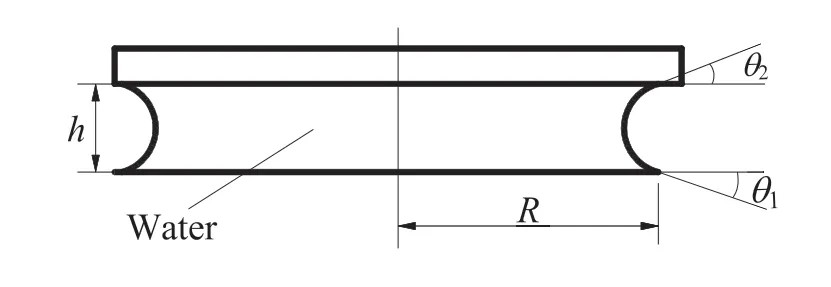

The interface between the clay and steel plate can be simplified as a plate-water-plate model(Ren et al.,1990;Liu et al.,2019),as illustrated in Fig.3.The adhesion strength is affected by the thickness of the water film,radius of the water film,and contact angles of the clay and steel.Wang et al.(2022)found that there was a small difference in contact angle between the stainless steel and the alloy steel,which are the materials making cutterheads or cutters.Thus,stainless steel was used to make the rotational disc.The surface roughness of the disc was 0.34 μm.The diameter of the rotating steel disc was as large as 360 mm.The inner diameter and the height of the specimen container were designed as 720 mm and 560 mm,respectively.The steel disc was fixed at the central rotation shaft.It was found that the large size of the disc and misalignment of the rotation shaft caused the disc to swing during their rotations.To solve this problem,a support slot was installed at the bottom of the specimen chamber to ensure the centering accuracy of the disc.A spring was installed on the support shaft to ensure that the disc could move vertically during the loading process.The loading system was composed of a jack and a hydraulic pump.The hydraulic pump pressurized the hydraulic oil to the jack to move it vertically.Then,normal loading was applied to the soilspecimen.The pressure of a shield chamber generally does not exceed 300 kPa in reality.Thus,the maximum normally applied pressures were set to 500 kPa with an accuracy of 0.1 kPa.The torsion system was mainly composed of a servo motor,a torque sensor and a transmission device.The torque sensor was fixed on the motor and connected to the rotary disc shaft through the transmission device.Thus,the motor could drive the disc to rotate.The step-less speed regulation was realized in the range of 0-4.5 rpm.The range of the torque sensor with an accuracy of 0.1 N m was 0-3000 N m.The control system consisted of a computer and software that controlled the normal pressures and rotation speeds and displayed and recorded the torque and rotation angle in real time.

Fig.1.Schematic diagram of the large rotary shear apparatus.

2.3.Testing procedures

Each large-scale rotary shear test was carried out step by step as follows:

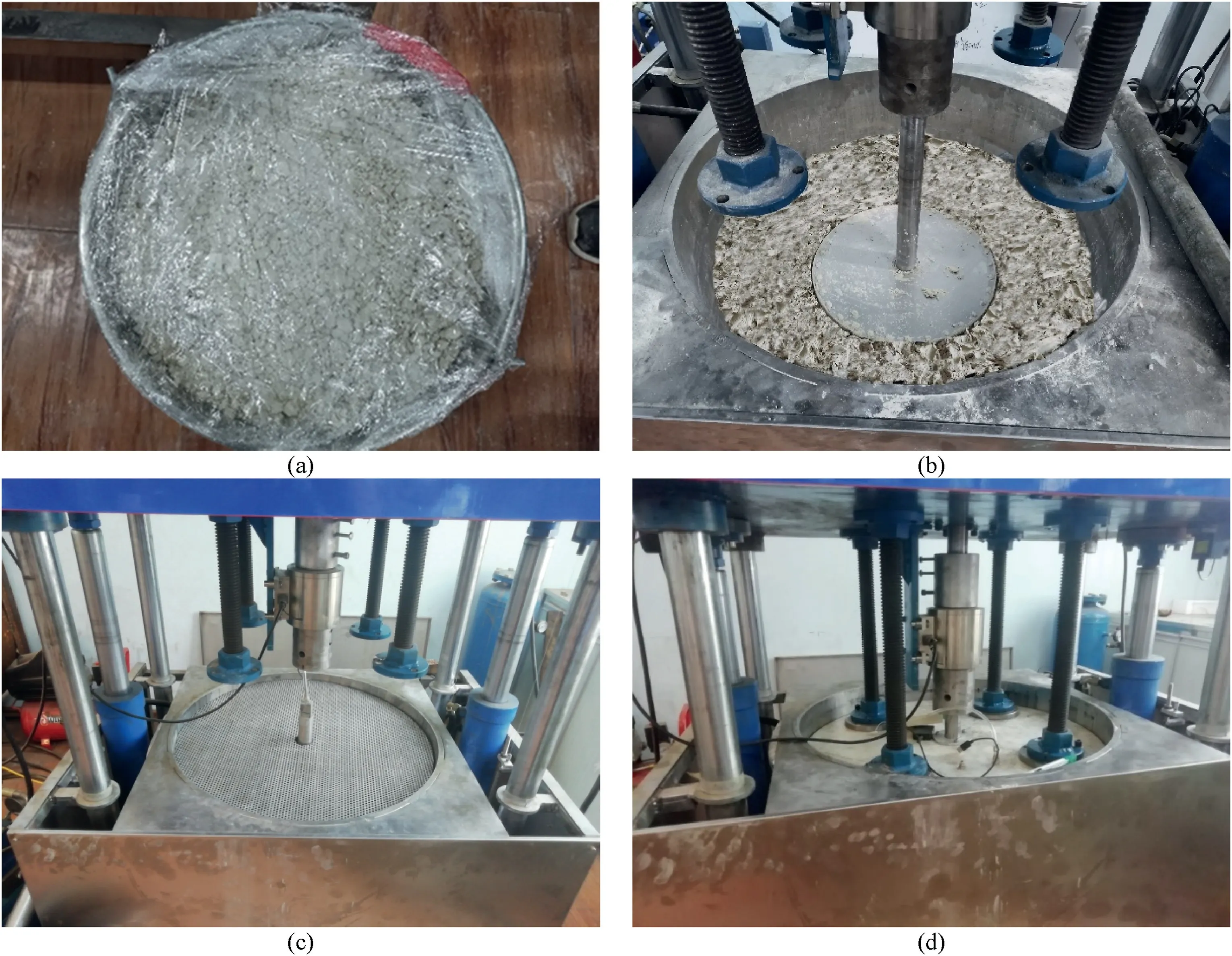

(1) A predetermined amount of water was stirred with the soil in a container.The well-mixed soil was then covered for 24 h for complete wetting (Fig.4a).

Fig.2.Large rotary shear apparatus.

Fig.3.Plate-water-plate model. h is the thickness of water film, R is the radius of water film,θ1 is the contact angle of clay,and θ2 is the contact angle of steel.

(2) The soil specimen was prepared with six layers in total.The upper surface of the specimen was scraped before filling the next layer.The bottom of the rotation shaft of the disc was connected to the bottom slot in the specimen container after placing 3 layers of soils.Notably,the disc was cleaned with a dry cotton cloth to absorb the liquid attached to the disc surface.Then,the loading system was lowered to check whether the top of the rotation shaft was in the vertical line with the rotation system(Fig.4b).

(3) The remaining three layers of soils were filled continuously in the container.Then,the rotation loading system was raised to separate it from the rotary disc shaft.The height of the specimen was measured and recorded.The soil specimen surface was covered with a permeable plate (Fig.4c),followed by the normal loading plate.

(4) The exhaust valve was opened,and the normal loading system was lowered.A normal pressure of 10 kPa was applied to expel the air between the loading plate and the soil.The excavated soil in the chamber of the EPB shield is generally discharged in a short time;therefore,it is thought that the excavated soil is not drained and consolidated during shield tunneling (Wang et al.,2020).Thus,the exhaust valve was closed to prevent water drainage and consolidation of the specimen after the initial small loading of 10 kPa.Then,the desired normal pressure was applied to the soil specimen via the top plate.The soil specimen is in an undrained and unconsolidated state.The height of the specimen was measured after the vertical displacement of the loading plate stabilized.

(5) Rotary shearing was initiated (Fig.4d).The disc was rotated at a velocity of 20ºper minute according to ASTM D4648-00(2000).The total rotation angle was set to 360º.The torque during the rotation of the disc was recorded.The water content of the soil specimen around the disc was measured once the test was finished.

Fig.4.Large-scale rotary shear test process: (a) Wetting specimen;(b) Layered soil addition;(c) Placing the permeable board;and (d) Loading and shearing specimen.

The shear stress might vary across the plate surface due to the normal stress,and the linear velocity of each point on the circular disc was not uniform.Thus,the average shear stress was the focus of the study and was determined from the tests.The average shear stress is called the shear stress in the following text.The tangential adhesion strength was determined based on the shear stress.The shear stress during the test was calculated by

whereais the shear stress between the clay and steel,Tis the torque measured by the torque sensor,andDis the diameter of the steel plate.

The degree of saturation of the soil can be calculated by

whereSris the degree of soil saturation,msis the mass of dry soil in the container,wis the water content of the soil,ρwis the water density,His the height of the soil specimen,andGsis the specific gravity of the soil.

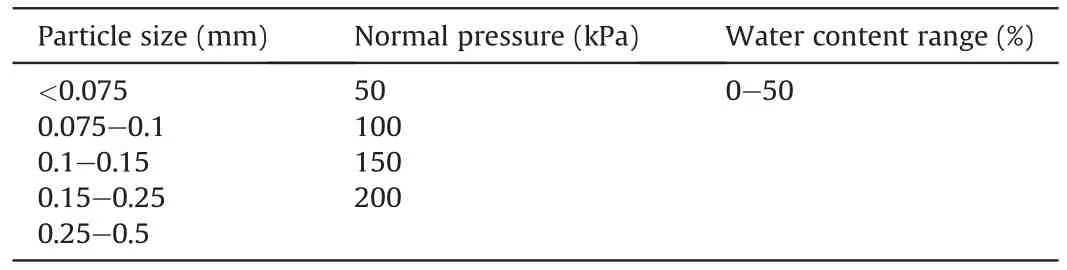

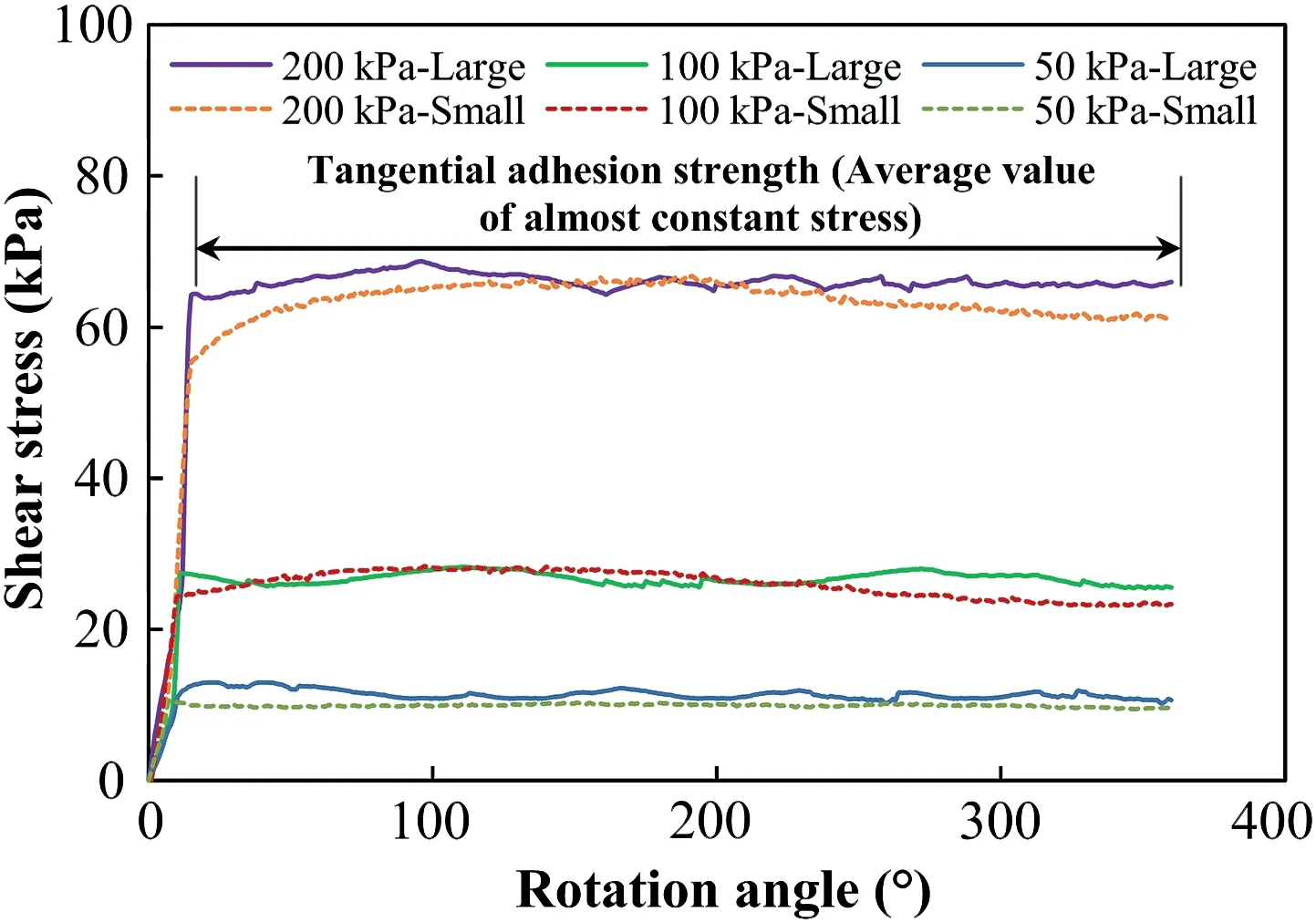

To explore the critical particle size of the soil that might cause soil clogging,a series of large-scale rotary shear tests was conducted under different normal pressures,as shown in Table 2.To verify the reliability of the test results using the large-scale rotary shear apparatus,rotary shear tests using the large-and small-scale rotary shear apparatus were performed on soil specimens with a particle size less than 0.075 mm.The box of the small-scale rotary shear apparatus had a diameter of 200 mm and a height of 250 mm.The diameter of the steel plate was 75 mm.This apparatus was adopted to study the tangential adhesion strength between clay and steel by Wang et al.(2020)and Liu et al.(2019).Fig.5 shows the shear curves obtained from the large-and small-scale rotary shear apparatus.The legends of‘50 kPa’,‘100 kPa’and‘200 kPa’represent the applied normal pressures,while‘large’and‘small’represent the large-and small-scale rotary shear apparatus,respectively.The testing results showed that the shear curves measured by the two kinds of apparatus agreed reasonably well with each other.This validated the reliability of the large-scale apparatus used in the current study.The shear stress first increased and then basically stabilized as the rotation angle increased.When the difference between any two consecutive interval readings remained lower than 0.1 kPa,the shear stress was considered to be constant.Thetangential adhesion strength was determined by averaging the slightly fluctuating shear stress values.Fig.5 shows the determination of tangential adhesion strength measured by the large-scale apparatus under a normal pressure of 200 kPa.

Table 2 Large-scale rotary shear test conditions.

Fig.5.Shear curves obtained from shear tests of different scales.

3.Study of the soil adhesion due to variation of normal pressures

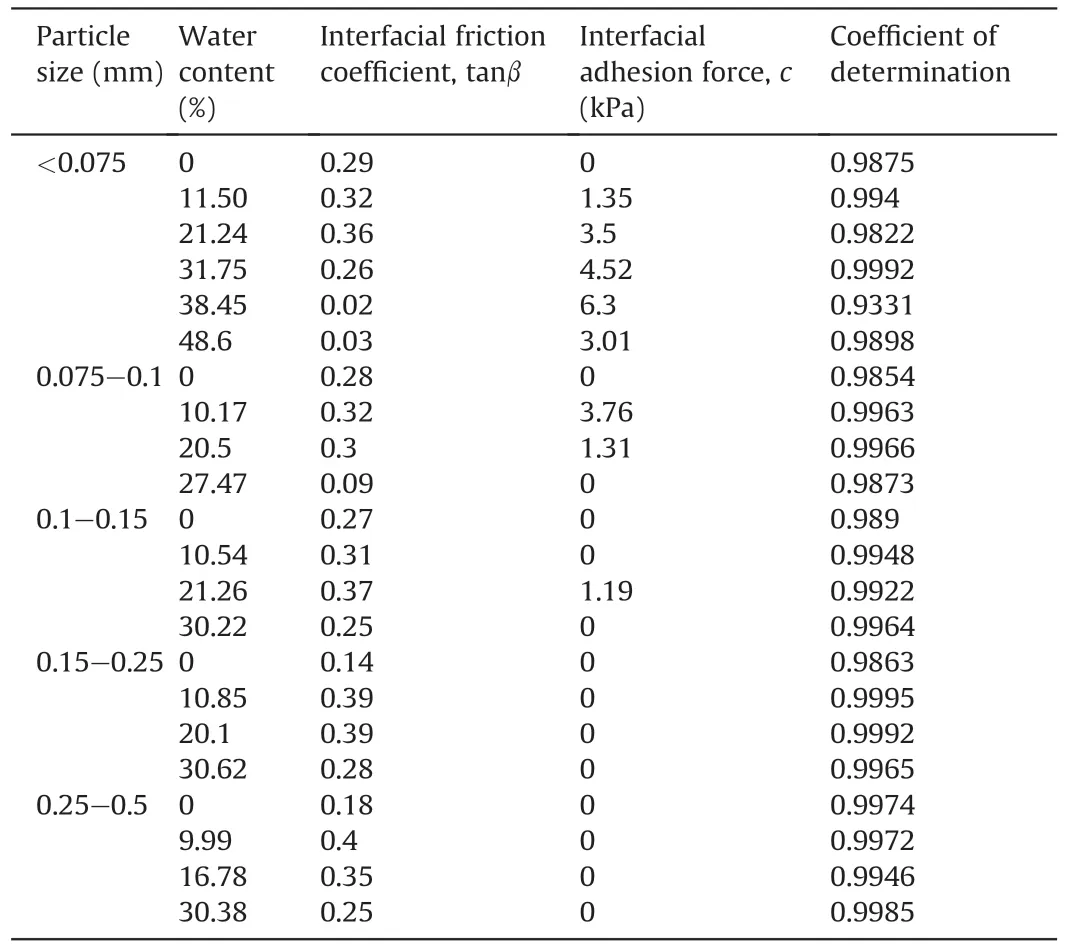

Fig.6 shows the variation in the tangential adhesion strength against the applied normal pressures for the soil specimens with different ranges of particle sizes under various water contents.It can be clearly observed that the measured tangential adhesion strength gradually increased as the applied normal pressures increased,exhibiting a good linear relationship under different water contents.

The relationship between the tangential adhesion strength of the soils and the applied normal pressures can be established as follows:

where σ is the normal pressure applied at the soil-steel interface,β is the apparent internal friction angle at the soil-steel interface,andcis the interfacial adhesion force between the soil and the steel.The total normal stress at the interface was controlled during the test.However,no pore water pressures were measured.Hence,the effective normal stress was unknown.β was determined based on the total normal stress rather than the effective normal stress.Thus,β and tanβ are called the apparent internal friction angle and apparent internal friction coefficient,respectively.The apparent interfacial friction coefficient tanβ and the interfacial adhesion forceccan be obtained by fitting the relationship between the tangential adhesion strength and the normal pressures.Table 3 shows the results of the apparent interfacial friction coefficients,interfacial adhesion forces and coefficients of determination under different testing conditions.Most of the coefficients of determination for all fitting results exceeded 0.95 at different water contents,reconfirming the linear relationship between the tangential adhesion strength and the normal pressures.

Table 3 Fitting results of tangential adhesion strength and normal pressure for different testing conditions.

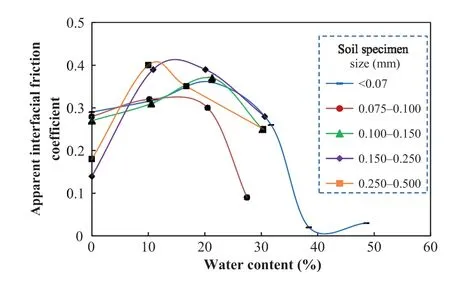

Fig.7 shows the variations in the apparent interfacial friction coefficient against water content for different ranges of particle sizes.The apparent interfacial friction coefficient first increased and then decreased sharply as the water content increased.The maximum apparent interfacial friction coefficients were 0.4.In particular,the apparent interfacial friction coefficient increased from 0.14 to 0.4 when the water content increased from 0%to 15%,and then continued to decrease to 0.28 when the water content reached 30.6%.It is interesting to observe that the critical water content of a soil specimen at which the apparent interfacial friction coefficient reached its maximum value increased with the reduction of soil particle sizes.

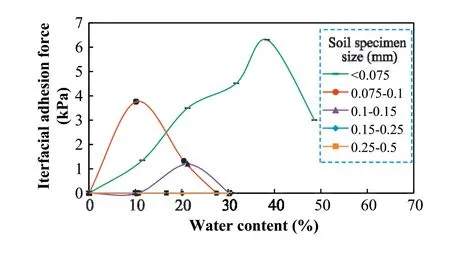

Fig.8 shows the variations in the interfacial adhesion force against water content for the specimens with different ranges of particle sizes.For the specimen with a particle size less than 0.075 mm,the measured interfacial adhesion force increased from zero at the dry state to the maximum value of 6.3 kPa when the water content was approximately 40%,beyond which the measured interfacial adhesion force started to decline to approximately 3 kPa when the water content reached 48%.When the particle sizes of the soil specimens were in the ranges of 0.075-0.1 mm and 0.1-0.15 mm,the interfacial adhesion force first increased and then decreased to zero with increasing water content.This finding is reasonable since the soil showed a certain interfacial adhesion force only when the water content was neither too low nor too high.The maximum interfacial adhesion forces for the two cases were 3.76 kPa and 1.19 kPa,respectively.When the particle size was greater than 0.15 mm,the specimens showed no interfacial adhesion force,no matter how much water was contained in the specimens.Interestingly,the results showed that the maximum interfacial adhesion force gradually decreased as the particle size increased.

Since the soil adhesion was closely related to the consistency index,the consistency index can be used to evaluate the soil tangential adhesion strength (Wang et al.,2020).The consistency index is calculated using the Atterberg limits and the water content of the soil specimens.However,the method of the Atterberg limits only works well when the soil particle size is less than 0.5 mm according to the Chinese standard (GB/T 50123-2019,2019).This means that the method using the consistency index for evaluating the soil tangential adhesion strength is only applicable to soils with a particle size less than 0.5 mm.A method is therefore required to evaluate the tangential adhesion strength for soils with a particle size greater than 0.5 mm and the risk of soil clogging in shield tunneling.

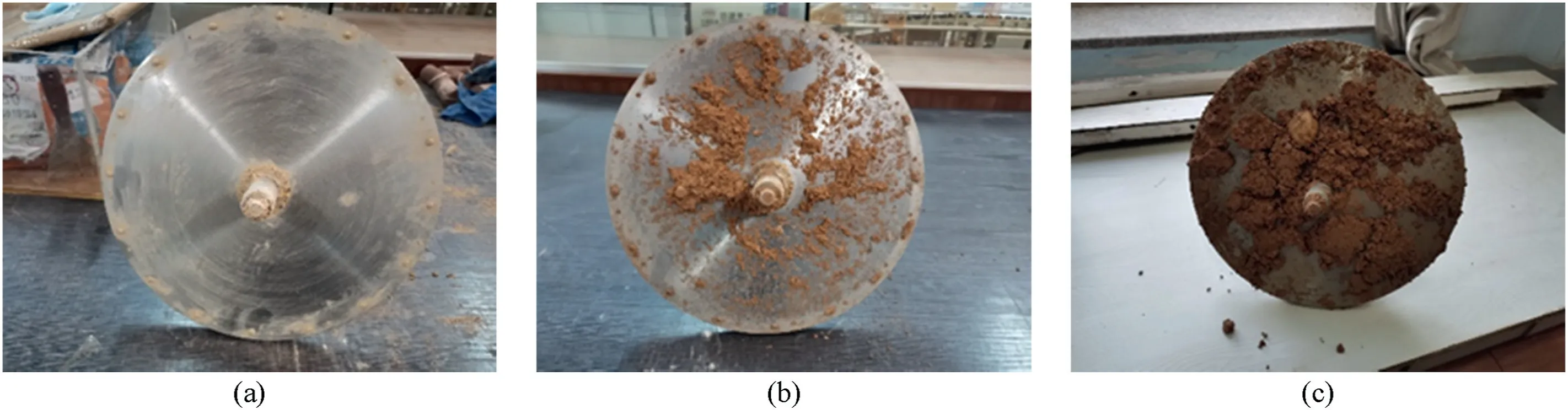

4.Determination of critical particle size for the generation of soil clogging

Soil clogging is a physical phenomenon in which soil particles adhere to the cutterhead or cutters.This phenomenon is due to soil adhesion.Fig.9 shows different amounts of soil mass clinging to the steel disc after the large-scale rotary shear tests were completed.No soil grains adhered to the steel disc when the interfacial adhesion force was 0 kPa(Fig.9a).In contrast,the presence of interfacial adhesion force caused significant soil grains to adhere to the disc.The greater the interfacial adhesion force is,the more the soil grains adhered to the disc are (Fig.9b and c).Notably,the soil grains adhering to the disc were disturbed when removing the surrounding soils and the disc.Thus,the true amount of soil grains adhering to the disc could not be accurately measured.However,the effect of the interfacial adhesion force and the soil stickiness to steel materials could still be qualitatively reflected,which is a main reason for inducing soil clogging in shield tunneling.Therefore,the interfacial adhesion force could be used to characterize the adhesion of grained soils.When the interfacial adhesion force of soils was 0 kPa,the tangential adhesion strength resulted only from the friction at the interface between the soil and steel material.There was no risk of soil clogging when a shield advanced in the strata with an interfacial adhesion force of 0 kPa.In contrast,when the interfacial adhesion force of soils was greater than 0 kPa,there was a high likelihood of soil clogging in shield tunneling.

Fig.6.Variation in the tangential adhesion strength against normal pressures for the specimens with different ranges of particle sizes:(a)<0.075 mm;(b)0.075-0.1 mm;(c)0.1-0.15 mm;(d) 0.15-0.25 mm;and (e) 0.25-0.5 mm.

The interfacial adhesion force was used to characterize whether the soil demonstrates the risk of soil clogging in shield tunneling.When the particle size of the soil was less than 0.15 mm,the soil specimen with a suitable water content manifested a nonzero interfacial adhesion force,resulting in the possibility of soil clogging in shield tunneling.Otherwise,when the particle size of the specimen was greater than 0.15 mm,the interfacial adhesion force of the soil specimen was always 0 kPa,regardless of the water content (see Fig.8).For this kind of soil condition,soil clogging rarely occurs.Thus,the critical particle size of soil with clogging risk in shield tunneling was determined to be 0.15 mm in this study.It is important to realize that the critical particle sizes of soil are different between adhesion and cohesion.In soil mechanics,soil with a particle size less than 0.005 mm or 0.002 mm is classified as clay particles with cohesion(USDA,1938;GB/T 50145-2007,2007).

5.Influence of soil particle sizes on the generation of interfacial adhesion force

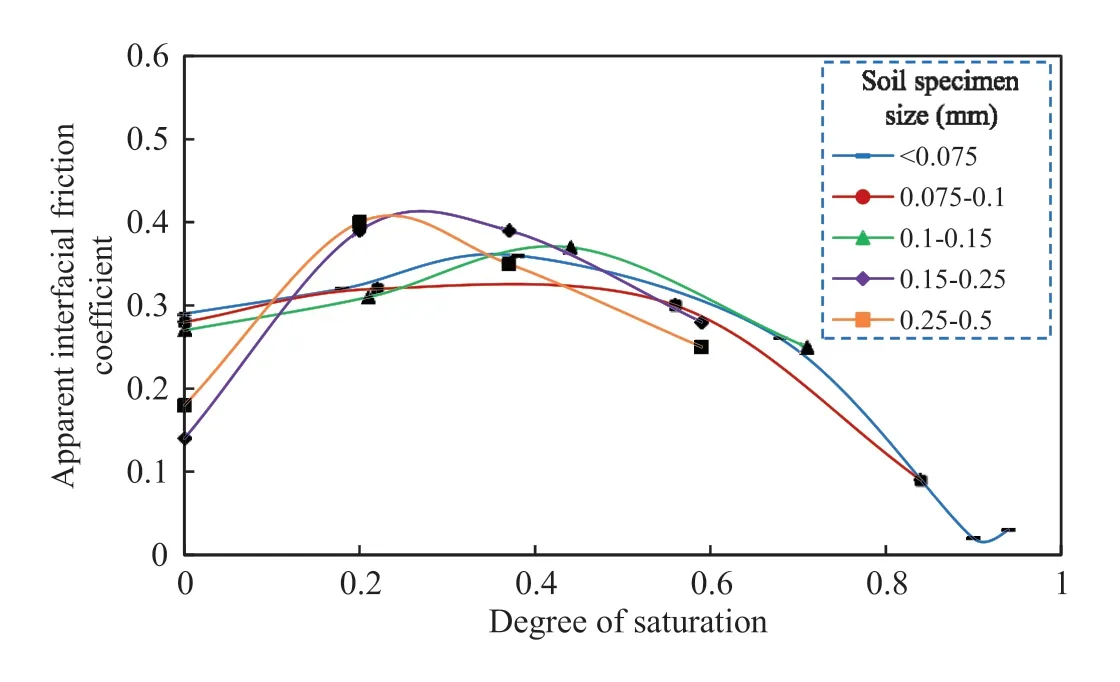

As shown in Eq.(3),the tangential adhesion strength is generated as a result of the apparent interfacial friction under normal stresses and the interfacial adhesion force.To explore thegeneration mechanism of the interfacial adhesion force for different soil particle sizes,the effects of the degree of saturation on the apparent interfacial friction and interfacial adhesion force are discussed.

Fig.7.Variation in the apparent interfacial friction coefficient against water content for the specimens with different ranges of particle sizes.

Fig.10 shows the variation in the apparent interfacial friction coefficient against the degree of saturation for different ranges of particle sizes.The apparent interfacial friction coefficient first increased and then decreased with increasing degree of saturation.It reached the maximum value at water contents of 10%-30%.Since the apparent interfacial friction coefficient is the slope of the relationship curve between the tangential adhesion strength and the normal pressure,the adhesion strength increases fastest with the normal pressure at water contents of 10%-30%.This was mainly because when the water content was low,adding an appropriate amount of water could increase the density of the soil specimen and increase the contact area between the soil particles and steel.Thus,the apparent interfacial friction coefficient increased with increasing degree of saturation in the low range.However,at a high degree of saturation,the excessive water in the soil voids would fill the soil-steel interface,producing a lubricating contribution (Ren et al.,2001).Thus,the apparent interfacial friction coefficient gradually decreased.

Fig.8.Variation in the interfacial adhesion force against water content for the specimens with different ranges of particle sizes.

The interfacial adhesion force is mainly affected by electrostatic attraction and capillary forces(Qian and Zhang,1984).The water in the soil pores could infiltrate into the soil-steel interface.Once the meniscus on the contact surface formed,a capillary force at the interface was generated in unsaturated soils.For the soil particles with clay minerals,an electric double layer could form around the particles.Under the bridging action of the polar molecules of the water film between the soil particles and the steel,the soil particles could generate electrostatic attraction on the steel surface.Fig.11 shows the variation in the interfacial adhesion force against soil saturation.When the degree of saturation was 0,no water films formed.Neither electrostatic attraction nor capillary force existed at the soil-steel interface,leading to zero interfacial adhesion forces for soils with all particle sizes.The soil specimens with a particle size less than 0.075 mm contained a large amount of kaolinite,a clay mineral.The soil particles were negatively charged.When the degree of saturation was low,the electrostatic attraction and the capillary force existed at the soil-steel interface.However,when the degree of saturation was high,the water film between the soil particles and the steel interface was likely to be saturated,and there was only electrostatic attraction between the soil particles and the steel interface.Therefore,the interfacial adhesion force first increased and then decreased to a certain value as the degree of saturation increased to a high value.For the soil specimens with particle sizes of 0.075-0.1 mm and 0.1-0.15 mm,the soil particles did not contain any clay minerals.There was only a capillary force when the degree of saturation was low.When the degree of saturation increased,the capillary force no longer existed as the water film approached full saturation.Therefore,the interfacial adhesion force first increased and then decreased to 0 kPa as the degree of saturation reached a high value.When the soil particle size was greater than 0.15 mm,a capillary phenomenon could not be easily formed at the interface between the soil particles and steel.The soil specimens without any clay minerals had no electrostatic attraction or capillary force at the interface between the soil particles and the steel,regardless of water content.As a result,the interfacial adhesion force was always 0 kPa.

6.Conclusions

The tangential adhesion strengths of soils with different particle sizes and water contents were measured by a large-scale rotary shear apparatus.The critical particle size of soils with risks of clogging on the cutterhead or cutters in shield tunneling was determined.The generation mechanism of the interfacial adhesion force of soils with different particle sizes and water contents was discussed.The main conclusions are described as follows:

Fig.9.Tangential adhesion of soil under different interfacial adhesion forces: (a) c=0 kPa;(b) c=1.35 kPa;and (c) c=4.52 kPa.

Fig.10.Variation in the apparent interfacial friction coefficient against saturation for the specimens with different ranges of particle sizes.

(1) The tangential adhesion strength between the soil and steel gradually increased as the applied normal pressures increased.The tangential adhesion strength and normal pressures showed a good linear relationship with the water content for all soil specimens with different ranges of particle sizes.

(2) When the particle size of the soils was less than 0.15 mm,the interfacial adhesion force first increased and then decreased as the water content gradually increased.When the particle size of the soil was larger than 0.15 mm,the soil specimens showed no interfacial adhesion force,regardless of the water content.The amount of soil adhering to the steel disc was positively correlated with the interfacial adhesion force.Thus,according to the generation of interfacial adhesion force,the critical particle size of the soils having the potential of clogging was 0.15 mm for shield tunneling.

Fig.11.Variation in the interfacial adhesion against degree of saturation for the specimens with different particle sizes.

(3) The apparent interfacial friction coefficient first increased and then decreased with increasing degree of saturation.When the degree of saturation was low,adding an appropriate amount of water could increase the density of the soil specimens and the contact area between the soil and steel.Moreover,there could be an electrostatic attraction for the soil specimens containing clay minerals and a capillary force in the soil-steel interface for soil specimens with a low degree of saturation.When the degree of saturation increased to a high value,the excessive water in the soil voids would infiltrate into the interface between the soil and steel,reducing the apparent interfacial friction due to the lubrication effect of the excessive water at the interface.

(4) The interfacial adhesion force first increased and then gradually decreased with the degree of saturation under the functions of electrostatic attraction and capillary force.For the soil specimen with particle sizes smaller than 0.15 mm,the interfacial adhesion force increased and then gradually decreased with increasing degree of saturation due to the change in capillary force.For the soil specimen with a particle size larger than 0.15 mm,the interfacial adhesion force was always 0 kPa with any degree of saturation because the large particles did not have any electrostatic attraction (no clay minerals) or capillary force.

In this paper,the critical particle size of soils inducing clogging was investigated,but the effect of soil temperature was not taken into account.The results show that soil particles with sizes less than 0.15 mm are the main contributors to soil clogging.During the rotation of the shield cutterhead,heating produced due to the friction between the soil and cutterhead probably changes the soil adhesion characteristics if the excavated soils are not well conditioned.With the effect of soil temperature,the critical particle size may differ from 0.15 mm.In other words,soil with larger particles probably exhibits a clogging risk due to the friction in shield tunneling.Additionally,most strata in project sites include fully mixed soils with a very wide range of particle sizes.It is necessary to study the adhesion characteristics of fully mixed soils,providing a judgment criterion of the soil clogging risk in shield tunneling.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Acknowledgments

The financial support from the National Natural Science Foundation of China (Grant Nos.52022112 and 51778637) and the Science and Technology Innovation Program of Hunan Province(Grant No.2021RC3015) are acknowledged and appreciated.

Journal of Rock Mechanics and Geotechnical Engineering2023年2期

Journal of Rock Mechanics and Geotechnical Engineering2023年2期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- A multi-purpose prototype test system for mechanical behavior of tunnel supporting structure: Development and application

- Experimental investigations on effects of gas pressure on mechanical behaviors and failure characteristic of coals

- Strength and deformation characteristics of irregular columnar jointed rock mass: A combined experimental and theoretical study

- Spatial distribution and failure mechanism of water-induced landslides in the reservoir areas of Southwest China

- Characteristics of electromagnetic vector field generated from rock fracturing

- Geotechnical investigation of low-plasticity organic soil treated with nano-calcium carbonate