基于改进粒子群优化算法的永磁球形电机驱动策略研究

周嗣理 李国丽 王群京 郑常宝 文 彦

基于改进粒子群优化算法的永磁球形电机驱动策略研究

周嗣理1,2李国丽2,3王群京2,4郑常宝2,3文 彦2,5

(1. 安徽大学计算机科学与技术学院 合肥 230601 2. 安徽大学高节能电机及控制技术国家地方联合实验室 合肥 230601 3. 安徽大学电气与自动化工程学院 合肥 230601 4. 安徽大学工业节电与电能质量控制安徽省级协同创新中心 合肥 230601 5.安徽大学互联网学院 合肥 230601)

永磁球形电机(PMSpM)是一种结构紧凑、可多自由运动的单关节传动装置。该文提出一种适用于PMSpM驱动策略优化的改进粒子群优化(IPSO)算法,该算法可实时计算PMSpM期望转矩所对应的线圈驱动电流。首先,通过圆环函数建立PMSpM转矩解析模型,并构建转矩Map图;然后,在确定种群数量后为标准粒子群优化(PSO)算法引入自适应动态惯性权重和自适应学习因子,将所提IPSO算法与PSO算法进行仿真对比,仿真结果表明,在同样的精度下采用IPSO算法计算驱动电流比采用PSO算法有更快的计算速度;最后,通过PMSpM控制试验进一步证明了该仿真结论的正确性。

永磁球形电机 改进粒子群优化 自适应动态惯性权重 自适应学习因子 驱动电流

0 引言

永磁球形电机(Permanent Magnet Spherical Motor, PMSpM)是一种结构紧凑的单关节多自由度电机[1-2],有广泛的应用前景[3]。PMSpM的闭环控制需要计算驱动电流,驱动电流计算需要建立电磁转矩模型。国内外学者在PMSpM转矩建模领域经多年研究提出了很多方法,主要有麦克斯韦张量法[4]、虚位移法[5-6]和洛伦兹力法[7-9]。以上方法的计算速度都因计算量大而无法满足PMSpM实时控制的需求。而PMSpM驱动电流计算需利用转矩模型逆运算,且关系到控制的实时性,国内外学者提出了多种驱动电流计算方法。

用解析法[10-11]或有限元法[12-13]计算一个线圈和一个磁极的转矩位置关系,通过叠加定理计算转子总转矩,再使用伪逆矩阵求解驱动电流。该方法解的非唯一性无法支持后续PMSpM通电策略的优化研究。

采用支持向量机[14]、高斯过程[15]等数据驱动方法将PMSpM作为黑盒,绕过复杂的三维电磁建模机理,精度也足够,但数据集采集工作很有挑战性。

采用智能优化算法的方法[16-17],假定转子不动,一个线圈沿转子表面在三维空间运动建立转矩Map图,再通过智能算法计算PMSpM的驱动电流,避免了伪逆矩阵的问题,但往往计算速度不够。

本文以文献[18]所提的台阶式永磁球形电机为研究对象,计及电机控制对算法的实时性要求,基于圆环函数建立PMSpM转矩解析模型,进而构建转矩Map图。线圈驱动电流可基于该转矩Map图上快速插值计算得出对应的转矩,避免了解析模型中大量的积分计算。为进一步提升PMSpM驱动电流的计算速度,本文提出改进粒子群优化(Improved Particle Swarm Optimization, IPSO)算法,以线圈电流为粒子,在转矩Map图上快速寻找到最优的驱动电流,提高了控制的实时性。

1 PMSpM结构原理及转矩Map的构建

1.1 PMSpM的结构及工作原理

1.1.1 PMSpM结构

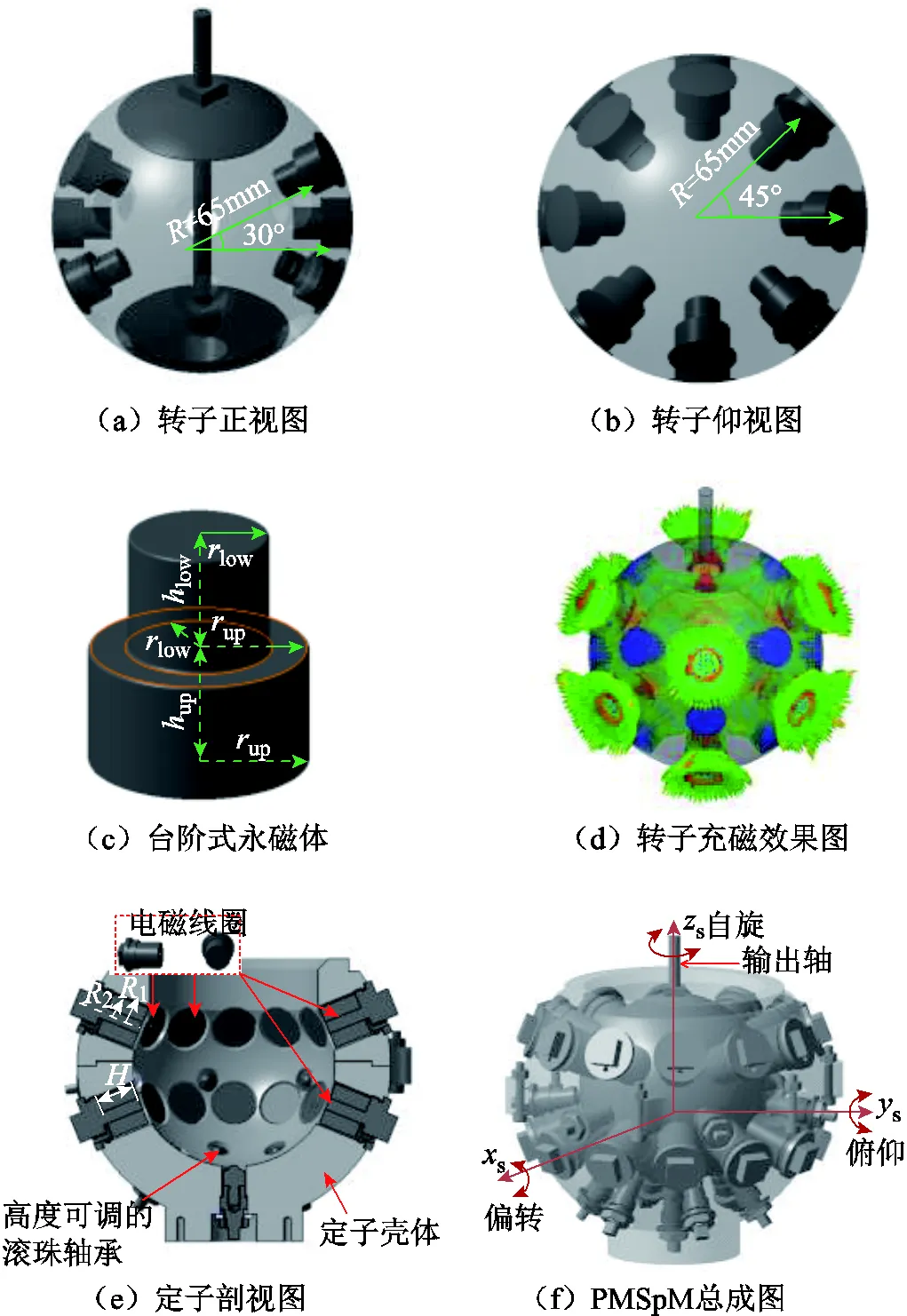

本文所研究的PMSpM转子有三层24个NdFe35的台阶式圆柱永磁体(Permanent Magnet, PM),如图1a~图1c所示。转子磁极阵列N、S交替排布,充磁效果如图1d所示。为避免复杂的磁耦合因素影响并降低转子的转动惯量,转子本体采用空心的铝制球形结构,输出轴从转子顶端接出。图1e展示了球壳状定子的剖面图,24个集中绕制的圆柱形空心线圈均匀对称地排布在定子球壳体的两层上,这两层所在极角与赤道面的角度差均为22.5°。为避免复杂的磁耦合问题,满足轻量化需求,定子壳体采用聚碳酸酯材料。

图1 PMSpM结构

PMSpM的气隙长度是1mm。PMSpM总成如图1f所示,其详细尺寸参数见表1。

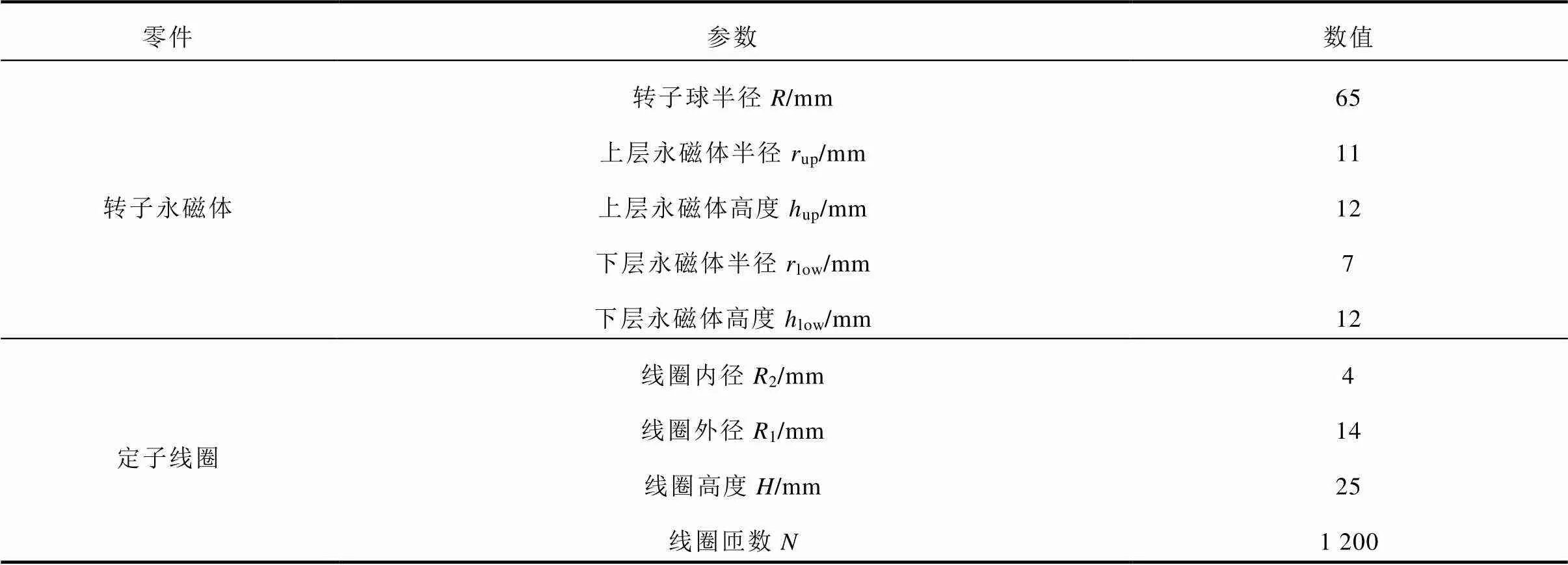

表1 PMSpM定转子关键参数

Tab.1 Key parameters of the PMSpM rotor and stator

1.1.2 PMSpM工作原理

该PMSpM可实现偏转、俯仰和自旋三自由度运动。图1f展示了转子绕s、s和s对应的三自由度运动模式,其中sss是定子坐标系。为便于分析,将所有永磁体和线圈沿方位角方向(赤道方向)展开成图2所示平面图。沿方位角方向给各线圈依次通电,因定转子极数不同形成步进角,电机可实现自旋运动。若在同一方位角下给沿极角方向的两个线圈通电,则转子可实现俯仰或偏转运动。

图2 二维展平的定转子磁极分布图

1.2 PMSpM转矩Map图的构建

1.2.1 PMSpM转矩解析模型

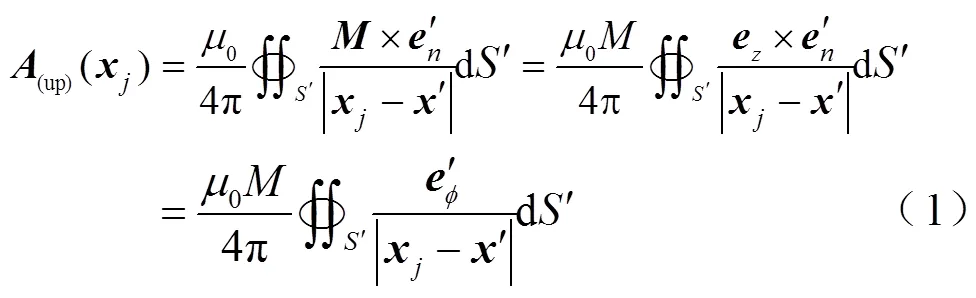

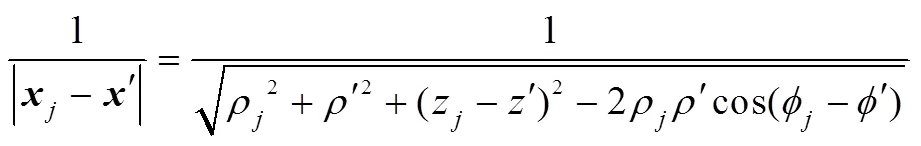

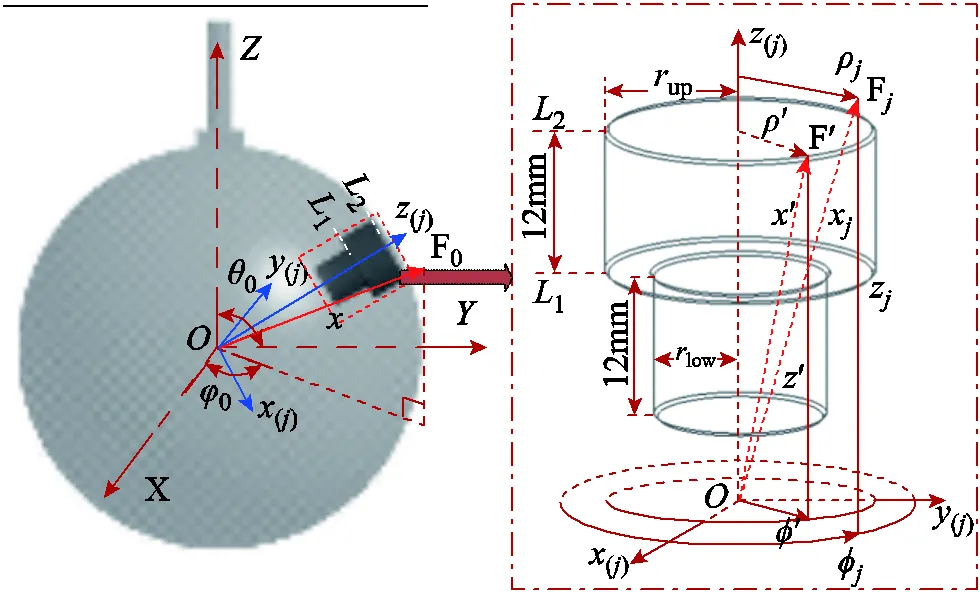

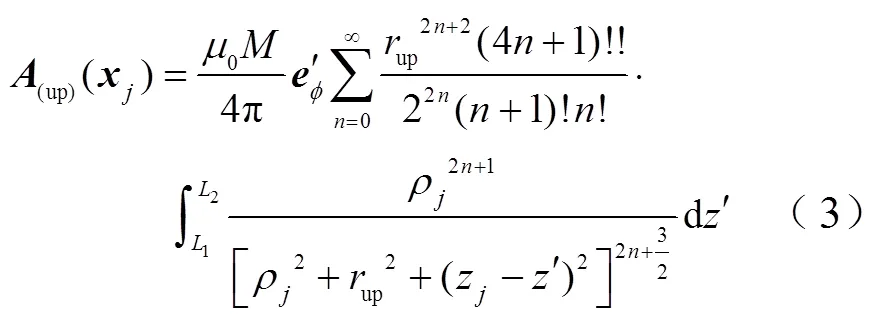

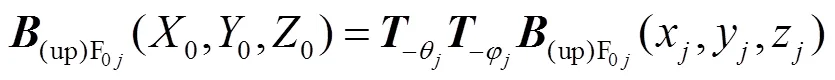

根据电磁场电流等效模型理论,图3所示台阶式圆柱永磁体的上层外部矢量磁位可以表示为

图3 局部坐标系下的第j个永磁体

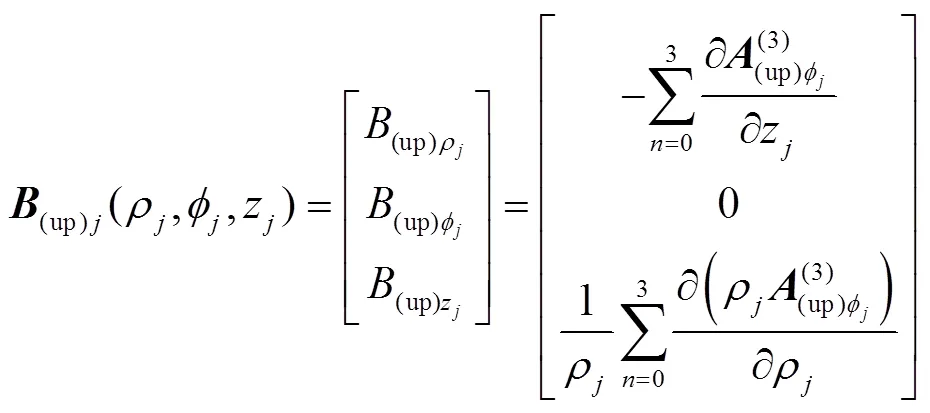

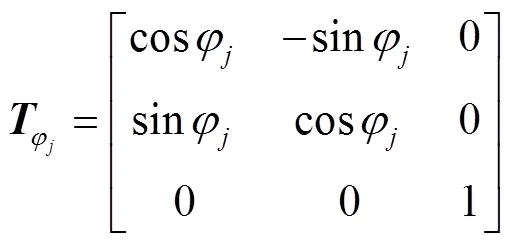

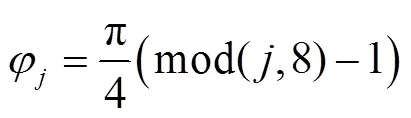

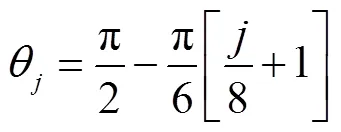

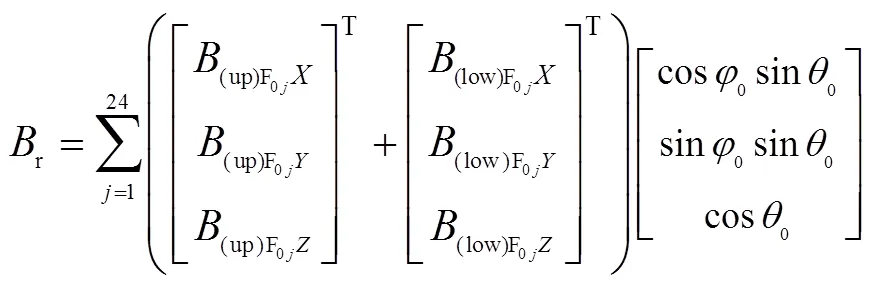

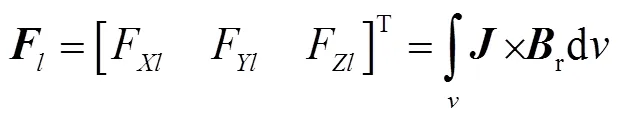

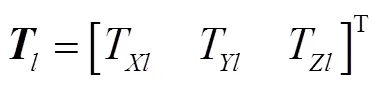

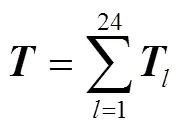

将电流密度矢量变换到转子坐标系下,根据洛伦兹力法可得

最终可得转子的总转矩解析模型为

1.2.2 PMSpM转矩Map图的构建

PMSpM转矩模型因计算量大而无法满足电机实时控制需求。为此,本文在第1.2.1节所提转矩解析模型基础上构建转矩Map图,使计算量前置。

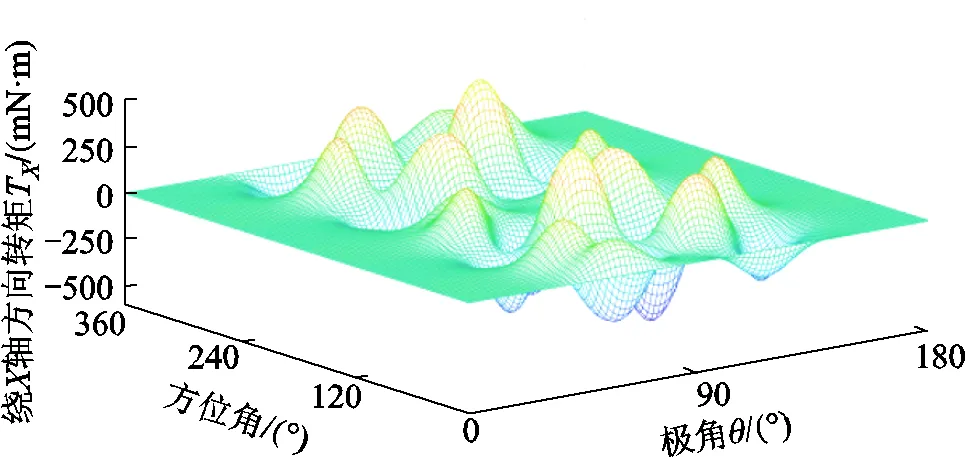

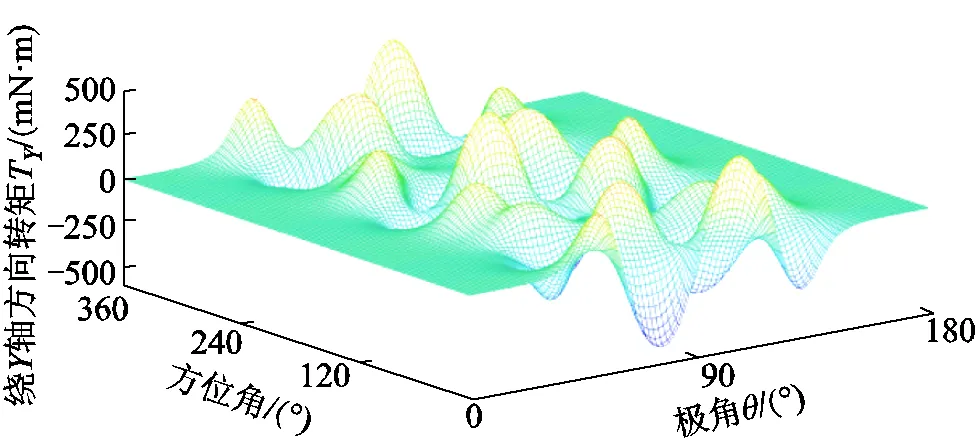

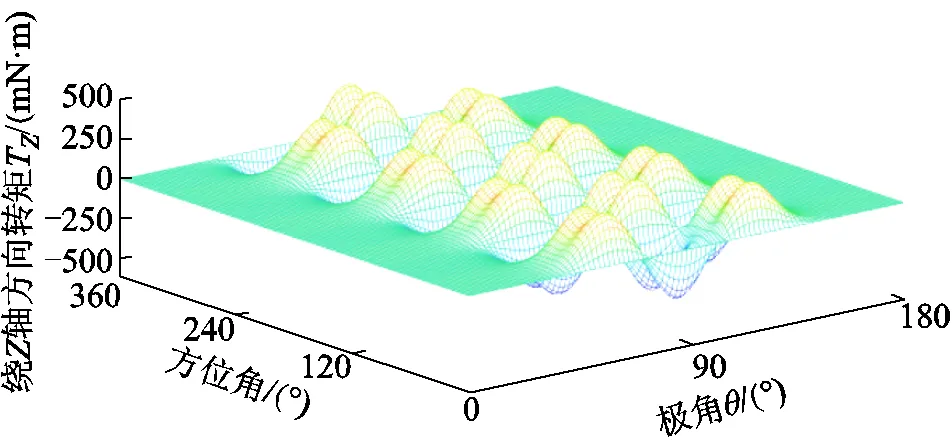

假设转子固定,一个线圈沿方位角和极角依次遍历整个转子气隙球面,利用式(13)计算出每个遍历点的对应转矩,可得到、、三个自由度方向上的转矩Map图,分别如图4、图5和图6所示。其中,构建转矩Map时转矩解析模型所对应的PMSpM几何参数见图1和表1,所选在整个转子气隙球面上遍历的线圈电流设定为1A。

图4 PMSpM转矩Map图()

图5 PMSpM转矩Map图()

图6 PMSpM转矩Map图()

在PMSpM控制过程中,已知当前位置期望转矩,利用智能算法在Map图上可快速地寻找到最优的PMSpM驱动电流。显然,所采用算法的收敛速度直接影响PMSpM控制的实时性。粒子群优化(Particle Swarm Optimization, PSO)算法因为计算量小、收敛速度快而广泛应用于实时控制领域[21]。本文以标准PSO算法为基础,提出改进的IPSO算法用于PMSpM驱动策略研究,进一步提升了驱动电流计算速度。

2 PMSpM驱动策略优化的IPSO算法

2.1 标准粒子群优化算法

早期的粒子群优化算法是1995年由美国R. Eberhart和J. Kennedy根据模仿鸟类觅食行为而提出的。1998年Y. Shi和R. Eberhart又引入惯性权重以提高粒子的搜索能力,进而得到标准PSO算法。标准PSO算法收敛速度快,代码简洁高效,近年来在供配电[22-23]、光伏与微电网[24]、参数辨识[25]、电机设计优化[26-27]等领域得到广泛应用。

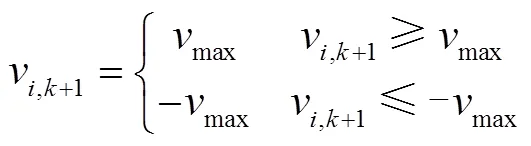

PSO算法通过式(15)和式(16)对所有粒子的位置和速度进行更新[28-29]。

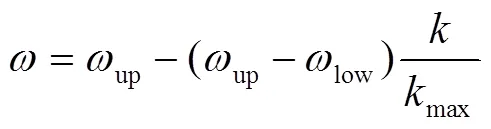

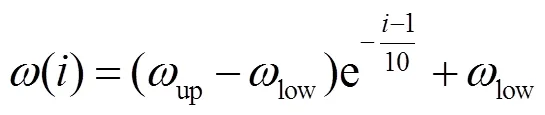

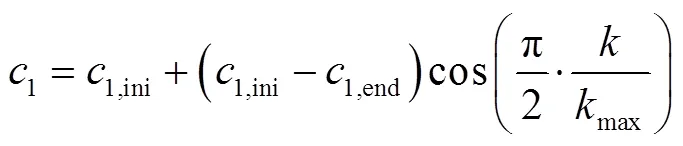

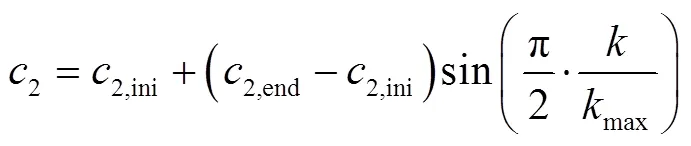

2.2 标准PSO算法的改进

2.2.1 惯性权重的改进

2.2.2 学习因子改进

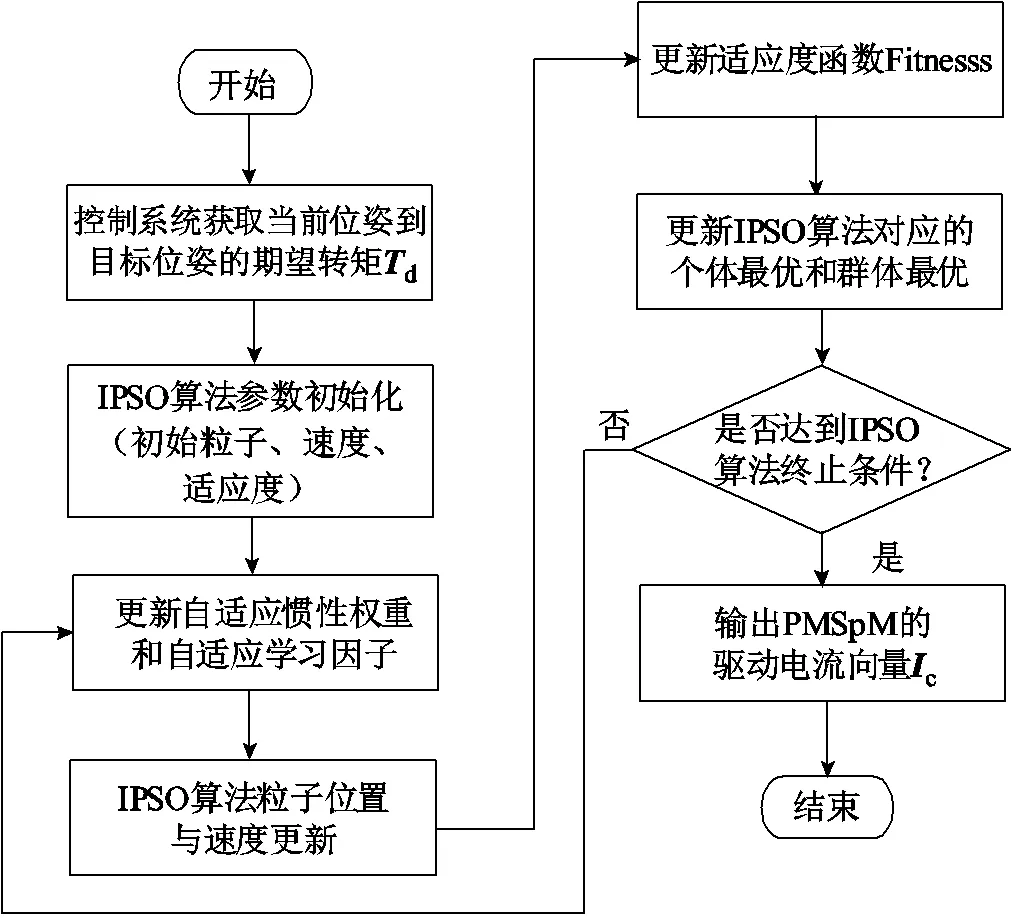

2.3 PMSpM驱动策略优化的算法流程

图7 驱动电流计算的IPSO算法流程

3 IPSO算法改进的仿真对比研究

3.1 仿真环境

本文在相同仿真条件下将IPSO算法与PSO算法进行仿真对比,通过比较改进前后算法的收敛速度证明IPSO算法改进的有效性。

本文所采用仿真设备为DELL移动工作站Precision 3541,配备处理器的型号是Intel(R) Core(TM) i7-9750H CPU@2.60GHz (12 CPUs)~ 2.59GHz,运行内存是8.00G,操作系统是Windows 10,仿真软件版本为Matlab 2018b。

3.2 IPSO算法参数改进的仿真对比

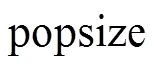

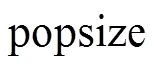

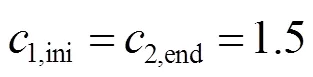

3.2.1 种群数量分析与仿真对比

图8 PSO算法种群数量仿真对比

表2 不同种群数量下PSO算法收敛性能对比

Tab.2 PSO performance comparison for different popsize

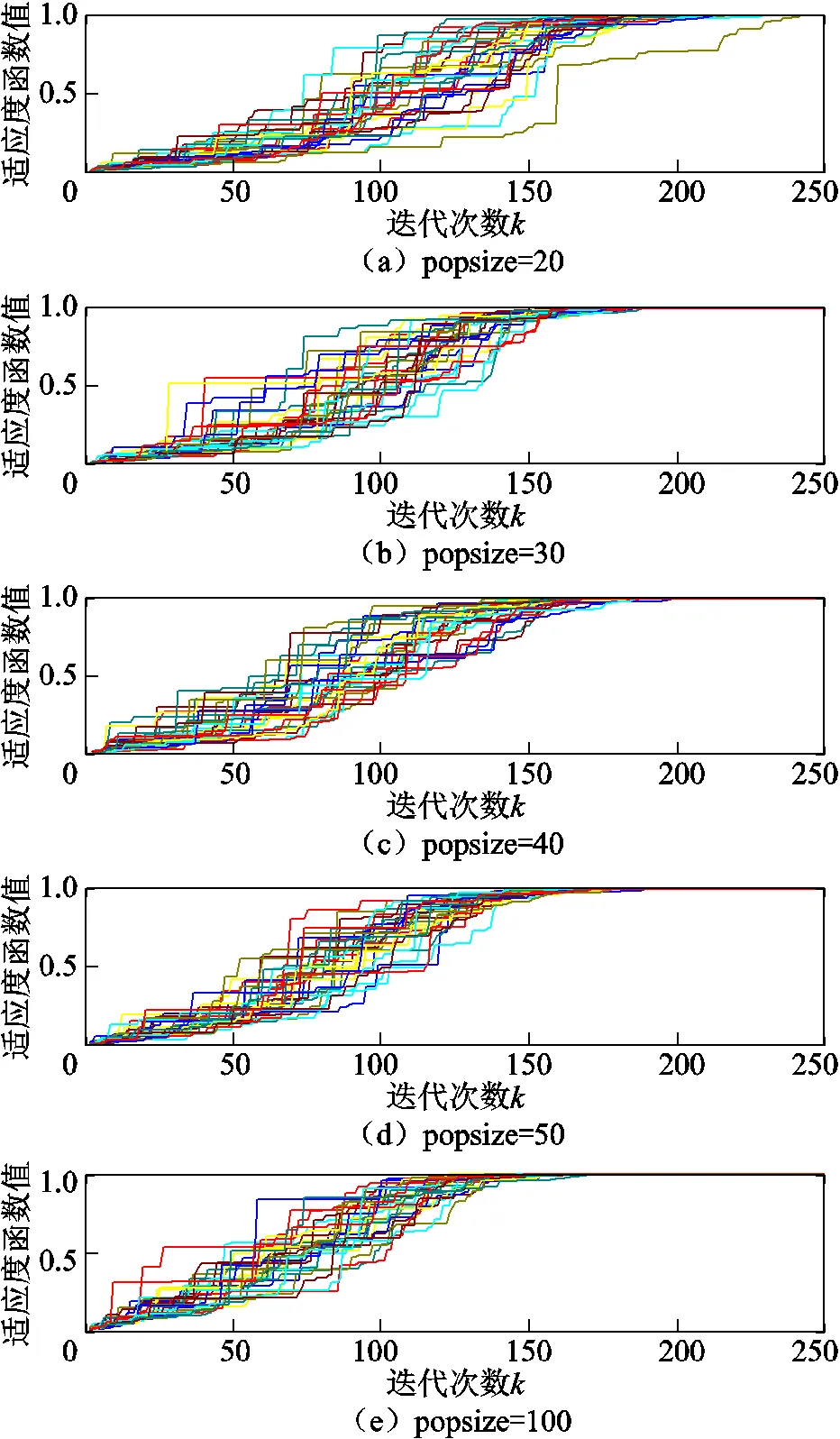

3.2.2 自适应动态惯性权重改进的仿真对比

图9 惯性权重改进仿真对比

可以看出,在同样的收敛精度下,PSO算法配备改进的自适应动态惯性权重能有效提高运行效率,在第50代左右就能完成收敛。而当算法配备传统惯性权重时需要在近200代才能彻底收敛。通过表3对比可以看出,改进为自适应动态惯性权重后,PSO算法平均运行时间只有改进前的22.3%,收敛速度从800ms级降低到200ms级,证明了采用自适应动态惯性权重的有效性。

表3 惯性权重改进前后收敛性能对比

Tab.3 Inertia weight improvement impact comparison

3.2.3 自适应学习因子改进的仿真对比

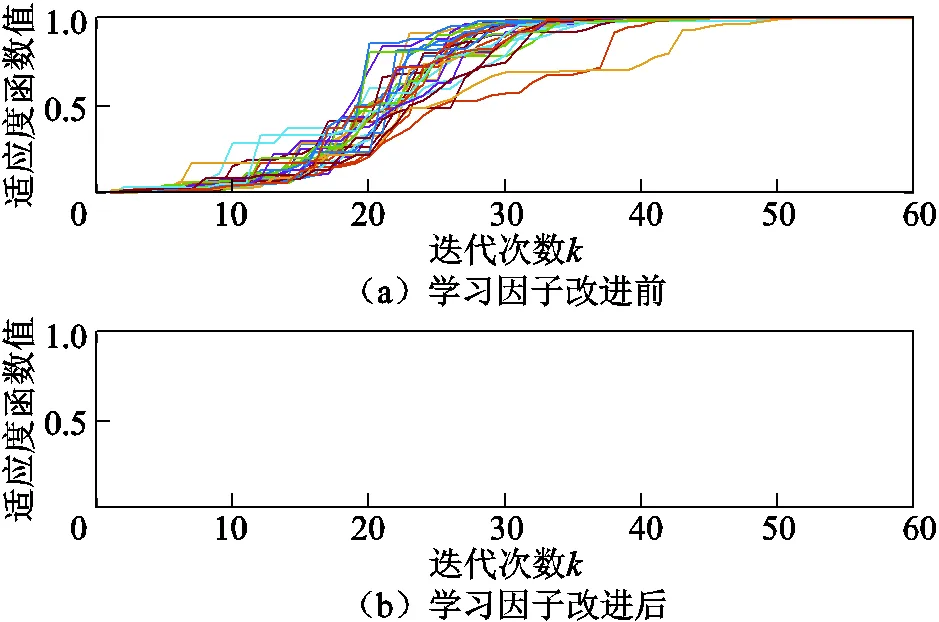

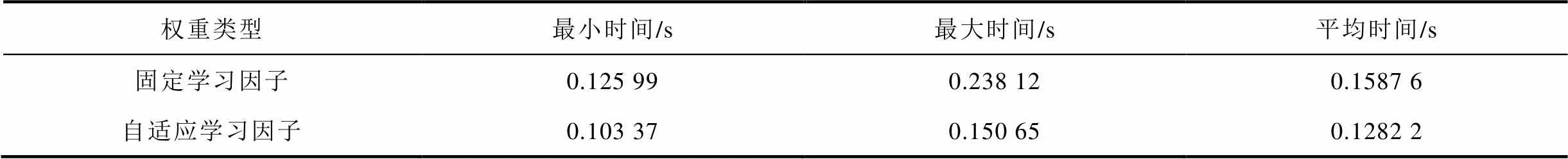

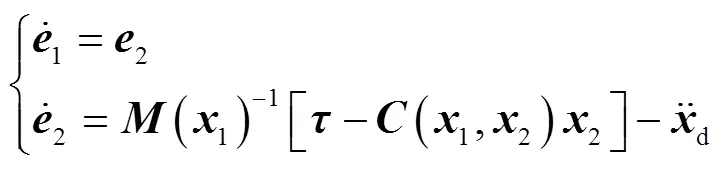

由图10a可以发现,PSO算法在仅配备自适应动态惯性权重时能在50代左右稳定收敛。如果进一步引入自适应学习因子,算法可以在40代以内稳定收敛,如图10b所示。学习因子改进前后收敛性能对比见表4。

图10 学习因子改进仿真对比

表4 学习因子改进前后收敛性能对比

Tab.4 Learning factors improvement impact comparison

从表4可以发现,算法改进前平均运行时间约为0.159s,而改进后算法平均运行时间缩短到约0.128s,速度提升了近20%。结果表明,自适应学习因子的改进对PSO算法收敛性能也有明显的提升。

3.2.4 IPSO算法与标准PSO算法的仿真对比

改进前的标准PSO算法仿真结果如图9a所示,对应的平均运行时间约为0.711s。图10b展示了改进后IPSO算法的仿真结果,对应的平均运行时间约为0.128s。对比两图可发现,标准PSO和IPSO算法的收敛精度均满足应用需求。但在同样的仿真条件下,IPSO算法运行速度远高于PSO算法,IPSO算法的收敛曲线也更密集。对比结果表明改进的IPSO算法对PMSpM驱动策略优化问题不仅能快速得出最优值,算法鲁棒性也足够好,值得进一步挖掘其用于PMSpM实时控制的潜力。

4 IPSO算法的PMSpM控制试验验证

为验证采用IPSO算法计算PMSpM驱动电流在电机实时控制中应用的可行性,本文设计了一个PMSpM闭环控制试验,并在试验中与采用标准PSO算法实时计算驱动电流的工况进行了比较分析。

4.1 PMSpM控制系统的设计

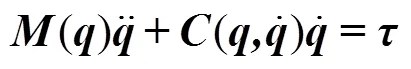

为简化闭环验证试验设计,论文采用比例积分微分(Proportional Integral Differential, PID)控制策略,并忽略PMSpM动力学模型中的不确定因素,PMSpM的动力学方程为

设计PID控制器,则PMSpM控制系统结构如图11所示,其中为控制增益矩阵[34]。

4.2 PMSpM控制试验平台

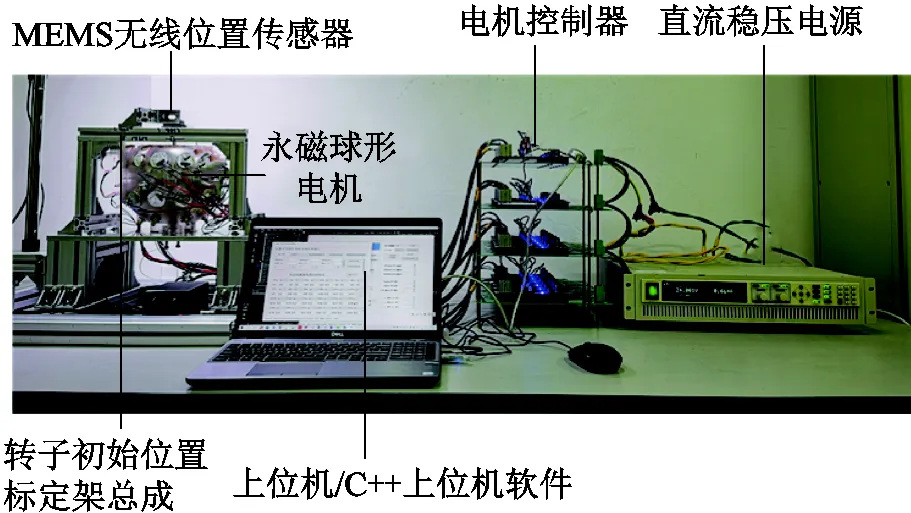

该试验平台由PMSpM样机、电机控制器、上位机、直流稳压电源、微电机系统(Microelectro Mechanical System, MEMS)无线位置传感器(MPU6050)和转子初始位置标定架总成构成,如图12所示。

图12 PMSpM控制试验平台

4.3 IPSO算法的PMSpM控制试验验证

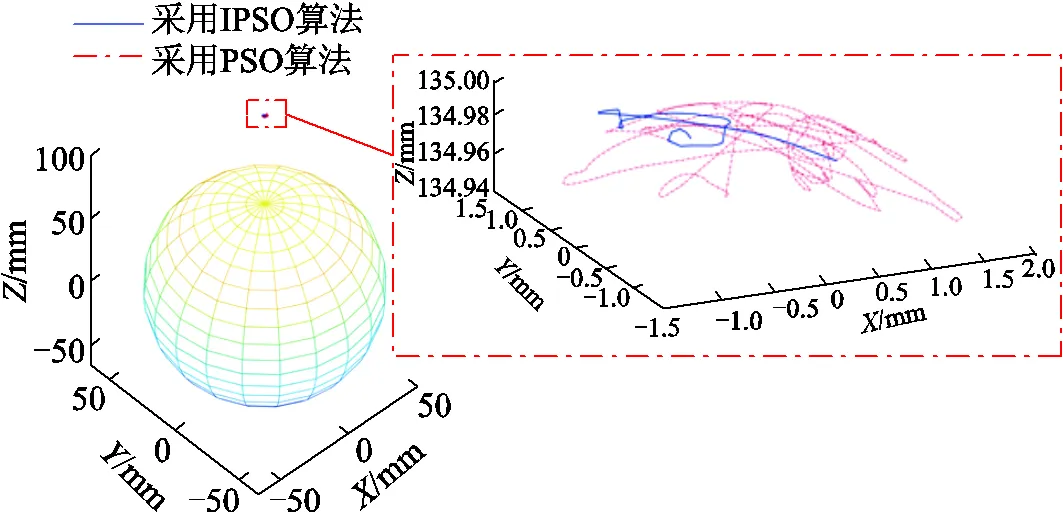

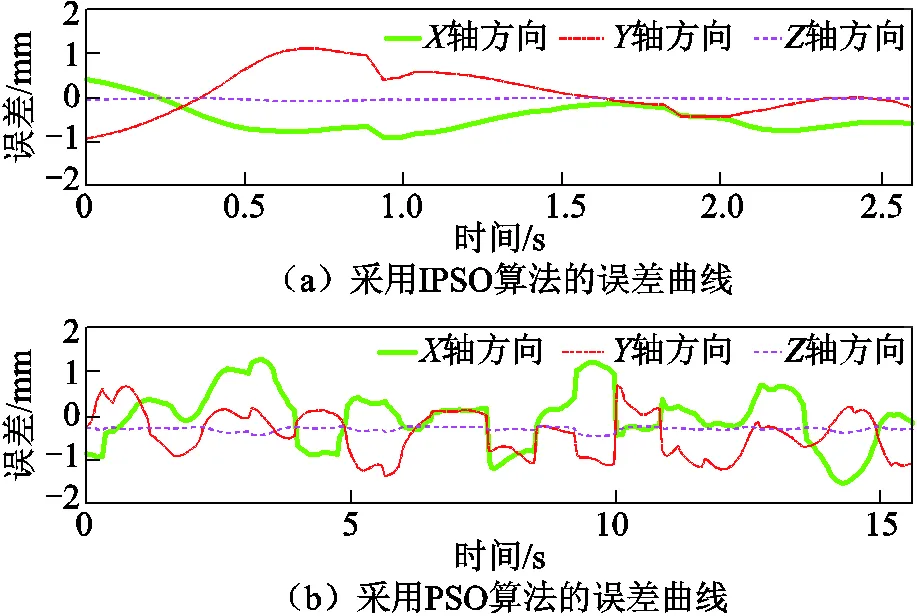

PMSpM闭环控制自旋图如图13所示,其中蓝色实线表示采用IPSO算法时PMSpM自旋运动闭环运动30°的转子轨迹。可以看出,PMSpM闭环自旋运动能够成功运行。此时转子输出轴顶端在定子坐标系、、三个坐标轴方向上的空间运动位移误差曲线如图14a所示,可以发现,该试验自旋运动空间位移误差幅值在、、三个坐标轴方向上均在可接受的范围内,并且从误差波形可发现闭环控制下的转子运自旋动空间位移误差是可控的。该试验采用IPSO算法后PMSpM自旋运动30°的软件执行时间约为2.57s。

图13 PMSpM闭环控制自旋图

图14 PMSpM自旋运动误差曲线

为提高闭环试验的可比性,本文在同样的试验条件和运动工况下采用标准PSO算法进行闭环控制试验。图13中的红色点画线表明采用标准PSO算法时PMSpM自旋闭环运动30°同样可以成功运行,但试验所需的软件执行时间约为15.63s,比采用IPSO算法时的软件执行时间约长6倍,证明了前面仿真结果的正确性。采用标准PSO算法时的PMSpM闭环自旋运动所对应的转子空间位移误差曲线如图14b所示。

试验结果表明,在同样的运动工况下,所提IPSO算法用于PMSpM实时驱动电流计算比采用标准PSO算法具有更高的电机驱动电流计算速度,证明了仿真结果的正确性。

5 结论

本文提出了一种适用于PMSpM驱动策略优化的IPSO算法。基于圆环函数建立PMSpM转矩解析模型并构建转矩Map图,IPSO算法通过转矩Map图插值计算可快速地寻找到最优的PMSpM驱动电流。在研究确定PMSpM驱动策略优化问题的粒子群种群数量后,本文在标准PSO算法的基础上重点研究了惯性权重和学习因子在PMSpM驱动策略应用中的改进,仿真和试验结果表明:

1)采用自适应动态惯性权重的PSO算法平均运行速度是采用惯性权重PSO算法的近5.5倍,继续改进学习因子后,算法的平均运行速度又可提升约20%。

2)仿真对比IPSO算法和PSO算法可发现,在同样精度下,采用IPSO算法计算驱动电流比采用标准PSO算法时有更高的计算速度。

3)闭环控制试验表明,在同样的运动工况下,采用IPSO算法应用于PMSpM驱动电流计算比采用标准PSO算法软件执行时间更短,证明了仿真结论的正确性。IPSO算法在PMSpM实时驱动策略上的应用潜力值得进一步研究挖掘。

本文所提IPSO算法方法同样也适用于其他复杂特种电机驱动电流的计算。

[1] 黄声华, 陶醒世, 林金铭. 三自由度球形电机的发展[J]. 电工电能新技术, 1989, 8(1): 6-11.

Huang Shenghua, Tao Xingshi, Lin Jinming. Development of three-dimensional spherical motor[J]. Advanced Technology of Electrical Engineering and Energy, 1989, 8(1): 6-11.

[2] 夏长亮, 李洪凤, 宋鹏, 等. 基于Halbach阵列的永磁球形电动机磁场[J]. 电工技术学报, 2007, 22(7): 126-130.

Xia Changliang, Li Hongfeng, Song Peng, et al. Magnetic field model of a PM spherical motor based on Halbach array[J]. Transactions of China Electrotechnical Society, 2007, 22(7): 126-130.

[3] Chai Feng, Gan Lei, Yu Yanjun. Magnetic field analysis of an iron-cored tiered type permanent magnet spherical motor using modified dynamic reluctance mesh method[J]. IEEE Transactions on Industrial Electronics, 2020, 67(8): 6742-6751.

[4] Wang Qunjing, Li Zheng, Ni Youyuan, et al. 3D magnetic field analysis and torque calculation of a PM spherical motor[C]//2005 International Conference on Electrical Machines and Systems, Nanjing, China, 2005, 3: 2116-2120.

[5] Li Hongfeng, Zhao Yanfen, Li Bin, et al. Torque calculation of permanent magnet spherical motor based on virtual work method[J]. IEEE Transactions on Industrial Electronics, 2020, 67(9): 7736-7745.

[6] 过希文, 李绅, 王群京, 等. 基于三角形(△)组合线圈的永磁球形电机转矩特性与通电策略分析[J]. 电工技术学报, 2019, 34(8): 1607-1615.

Guo Xiwen, Li Shen, Wang Qunjing, et al. Analysis of torque characteristics and electrifying strategy of permanent magnet spherical motor based on triangular combination coils[J]. Transactions of China Electrotechnical Society, 2019, 34(8): 1607-1615.

[7] Yan Liang, Liu Yinghuang, Zhang Lu, et al. Magnetic field modeling and analysis of spherical actuator with two-dimensional longitudinal camber Halbach array[J]. IEEE Transactions on Industrial Electronics, 2019, 66(12): 9112-9121.

[8] Li Zheng, Guo Peng, Wang Zhe, et al. Design and analysis of electromagnetic-piezoelectric hybrid driven three-degree-of-freedom motor[J]. Sensors (Basel, Switzerland), 2020, 20(6): 1621.

[9] Zhou Sili, Li Guoli, Wang Qunjing, et al. Geometrical equivalence principle based modeling and analysis for monolayer Halbach array spherical motor with cubic permanent magnets[J]. IEEE Transactions on Energy Conversion, 2021, 36(4): 3241-3250.

[10] 李洪凤, 林康, 李斌, 等. 基于四元数的永磁动量球位置/电流双闭环控制[J]. 电工技术学报, 2019, 34(增刊2): 484-492.

Li Hongfeng, Lin Kang, Li Bin, et al. Position and current double closed loop control of reaction sphere actuator based on quaternion[J]. Transactions of China Electrotechnical Society, 2019, 34(S2): 484-492.

[11] 李斌, 张硕, 李桂丹, 等. 基于球谐函数的动量球定子磁场分析[J]. 电工技术学报, 2018, 33(23): 5442-5448.

Li Bin, Zhang Shuo, Li Guidan, et al. Stator magnetic field analysis of reaction sphere based on spherical harmonics[J]. Transactions of China Electrotechnical Society, 2018, 33(23): 5442-5448.

[12] Liu Jingmeng, Deng Huiyang, Hu Cungang, et al. Adaptive backstepping sliding mode control for 3-DOF permanent magnet spherical actuator[J]. Aerospace Science and Technology, 2017, 67: 62-71.

[13] Bai Kun, Xu Ruoyu, Lee K M, et al. Design and development of a spherical motor for conformal printing of curved electronics[J]. IEEE Transactions on Industrial Electronics, 2018, 65(11): 9190-9200.

[14] Ju Lufeng, Wang Qunjing, Qian Zhe, et al. Modeling and optimization of spherical motor based on support vector machine and chaos[C]//2009 International Conference on Electrical Machines and Systems, Tokyo, 2009: 1-4.

[15] Wen Yan, Li Guoli, Wang Qunjing, et al. Modeling and analysis of permanent magnet spherical motors by a multitask Gaussian process method and finite element method for output torque[J]. IEEE Transactions on Industrial Electronics, 2021, 68(9): 8540-8549.

[16] Kasashima N, Ashida K, Yano T, et al. Torque control method of an electromagnetic spherical motor using torque map[J]. IEEE/ASME Transactions on Mechatronics, 2016, 21(4): 2050-2060.

[17] Zhou Rui, Li Guoli, Wang Qunjing, et al. Drive Current calculation and analysis of permanent magnet spherical motor based on torque analytical model and particle swarm optimization[J]. IEEE Access, 2020, 8: 54722-54729,.

[18] He Jingxiong, Li Guoli, Zhou Rui, et al. Optimization of permanent-magnet spherical motor based on taguchi method[J]. IEEE Transactions on Magnetics, 2020, 56(2): 1-7.

[19] Selvaggi J P, Salon S J, Chari M V K. Employing toroidal harmonics for computing the magnetic field from axially magnetized multipole cylinders[J]. IEEE Transactions on Magnetics, 2010, 46(10): 3715-3723.

[20] Qian Zhe, Wang Qunjing, Li Guoli, et al. Design and analysis of permanent magnetic spherical motor with cylindrical poles[C]//2013 International Conference on Electrical Machines and Systems (ICEMS), Busan, Korea (South), 2013: 644-649.

[21] Parsopoulos K E, Vrahatis M N. Particle swarm optimization and intelligence advances and applications[M]. Hershey: Information Science Reference, 2010

[22] 李骥, 张慧媛, 程杰慧, 等. 基于源荷状态的跨区互联系统协调优化调度[J]. 电力系统自动化, 2020, 44(17): 26-33.

Li Ji, Zhang Huiyuan, Cheng Jiehui, et al. Coordinated and optimal scheduling of inter-regional interconnection system based on source and load status[J]. Automation of Electric Power Systems, 2020, 44(17): 26-33.

[23] 王灿, 吴耀文, 孙建军, 等. 基于柔性多状态开关的主动配电网双层负荷均衡方法[J]. 电力系统自动化, 2021, 45(8): 77-85.

Wang Can, Wu Yaowen, Sun Jianjun, et al. Bi-layer load balancing method in active distribution network based on flexible multi-state switch[J]. Automation of Electric Power Systems, 2021, 45(8): 77-85.

[24] 李奇, 赵淑丹, 蒲雨辰, 等. 考虑电氢耦合的混合储能微电网容量配置优化[J]. 电工技术学报, 2021, 36(3): 486-495.

Li Qi, Zhao Shudan, Pu Yuchen, et al. Capacity optimization of hybrid energy storage microgrid considering electricity-hydrogen coupling[J]. Transactions of China Electrotechnical Society, 2021, 36(3): 486-495.

[25] 刘细平, 胡卫平, 丁卫中, 等. 永磁同步电机多参数辨识方法研究[J]. 电工技术学报, 2020, 35(6): 1198-1207.

Liu Xiping, Hu Weiping, Ding Weizhong, et al. Research on multi-parameter identification method of permanent magnet synchronous motor[J]. Transa-ctions of China Electrotechnical Society, 2020, 35(6): 1198-1207.

[26] 李雄松, 崔鹤松, 胡纯福, 等. 平板型永磁直线同步电机推力特性的优化设计[J]. 电工技术学报, 2021, 36(5): 916-923.

Li Xiongsong, Cui Hesong, Hu Chunfu, et al. Optimal design of thrust characteristics of flat-type permanent magnet linear synchronous motor[J]. Transactions of China Electrotechnical Society, 2021, 36(5): 916-923.

[27] 赵玫, 于帅, 邹海林, 等. 聚磁式横向磁通永磁直线电机的多目标优化[J]. 电工技术学报, 2021, 36(17): 3730-3740.

Zhao Mei, Yu Shuai, Zou Hailin, et al. Multi-objective optimization of transverse flux permanent magnet linear machine with the concentrated flux mover[J]. Transactions of China Electrotechnical Society, 2021, 36(17): 3730-3740.

[28] Iqbal A, Singh G K. PSO based controlled six-phase grid connected induction generator for wind energy generation[J]. CES Transactions on Electrical Machines and Systems, 2021, 5(1): 41-49.

[29] Wu Jiangling, Sun Xiaodong, Zhu Jianguo. Accurate torque modeling with PSO-based recursive robust LSSVR for a segmented-rotor switched reluctance motor[J]. CES Transactions on Electrical Machines and Systems, 2020, 4(2): 96-104.

[30] 罗仕华, 胡维昊, 黄琦, 等. 市场机制下光伏/小水电/抽水蓄能电站系统容量优化配置[J]. 电工技术学报, 2020, 35(13): 2792-2804.

Luo Shihua, Hu Weihao, Huang Qi, et al. Optimization of photovoltaic/small hydropower/pumped storage power station system sizing under the market mechanism[J]. Transactions of China Electrotechnical Society, 2020, 35(13): 2792-2804.

[31] 陈龙, 易琼洋, 贲彤, 等. 全局优化算法在Preisach磁滞模型参数辨识问题中的应用与性能对比[J]. 电工技术学报, 2021, 36(12): 2585-2593, 2606.

Chen Long, Yi Qiongyang, Ben Tong, et al. Application and performance comparison of global optimization algorithms in the parameter identification problems of the preisach hysteresis model[J]. Transactions of China Electrotechnical Society, 2021, 36(12): 2585-2593, 2606.

[32] 李家祥, 汪凤翔, 柯栋梁, 等. 基于粒子群算法的永磁同步电机模型预测控制权重系数设计[J]. 电工技术学报, 2021, 36(1): 50-59, 76.

Li Jiaxiang, Wang Fengxiang, Ke Dongliang, et al. Weighting factors design of model predictive control for permanent magnet synchronous machine using particle swarm optimization[J]. Transactions of China Electrotechnical Society, 2021, 36(1): 50-59, 76.

[33] Shi Y, Eberhart R C. Empirical study of particle swarm optimization[C]//Proceedings of the 1999 Congress on Evolutionary Computation-CEC99, Washington, 1999: 1945-1950.

[34] Wen Yan, Li Guoli, Wang Qunjing, et al. Robust adaptive sliding-mode control for permanent magnet spherical actuator with uncertainty using dynamic surface approach[J]. Journal of Electrical Engineering and Technology, 2019, 14(1): 2341-2353.

Improved Particle Swarm Optimization Algorithm Based Driving Strategy Research for Permanent Magnet Spherical Motor

Zhou Sili1,2Li Guoli2,3Wang Qunjing2,4Zheng Changbao2,3Wen Yan2,5

(1. School of Computer Science and Technology Anhui University Hefei 230601 China 2. National Engineering Laboratory of Energy-Saving Motor & Control Technology Anhui University Hefei 230601 China 3. School of Electrical Engineering and Automation Anhui University Hefei 230601 China 4. Anhui Collaborative Innovation Center of Industrial Energy-Saving and Power Quality Control Anhui University Hefei 230601 China 5. School of Internet Anhui University Hefei 230601 China)

A permanent magnet spherical motor (PMSpM) is a compact transmission apparatus that is capable of motion in multiple degrees of freedom. To achieve the close loop control of the PMSpM, the driving current of the stator coils needs to be calculated, and the analytic torque model needs to be built in advance. However, if the geometry of the permanent magnet (PM) is a non-circumferential symmetric one, the pseudo-inverse matrix technique is not applicable. Thus, the research on the fast driving strategy of the universal reverse torque model is an essential prerequisite for the PMSpM close-loop control.

This paper takes the PMSpM with the stepped cylindrical PM as the research object. Firstly, this paper proposes new analytical torque models using the toroidal expansion method. To avoid repeating integrations in magnetic and torque analytic calculation, this paper builds torque maps by moving one 1A energized electromagnetic coil on the overall spherical surface of the airgap along the azimuth angle direction and polar angle direction. Secondly, the classical particle swarm optimization algorithm (PSO) is introduced to build the reverse torque model. The current of the stator electromagnetic coils is considered as the particle swarm, and the desired torques are set as optimization targets. Thus, we can use the reverse torque model to calculate the driving current of the stator electromagnetic coils from the torque maps. Thirdly, this paper proposes an improved particle swarm optimization (IPSO) algorithm for the PMSpM driving strategy optimization, which can be used for calculating the real-time driving current for the desired torques of the PMSpM. After the determination of the population size of the PSO algorithm, the adaptive dynamic inertia weight and adaptive learning factors are introduced for IPSO.

The following conclusions can be drawn from the simulation analysis: ① The driving current calculation speed of the PSO algorithm with adaptive dynamic inertia weight is 5.5 times faster than the classical PSO algorithm; ② The comparison result between the classical PSO algorithm and IPSO algorithm indicates that IPSO has a better convergence rate than PSO on the premise of ensuring the accuracy of convergence. ③ The PMSpM control experimental result shows that the proposed IPSO algorithm is effective in the PMSpM driving strategy, and the PMSpM driving current calculation speed of the proposed IPSO algorithm is significantly faster than using the classical PSO algorithm. In addition, the proposed IPSO algorithm is also applicable for the driving current calculation of other complex special motors.

Permanent magnet spherical motor, improved particle swarm optimization, adaptive dynamic inertia weight, adaptive learning factors, driving current

10.19595/j.cnki.1000-6753.tces.210841

TM351; TP18

周嗣理 男,1984年生,博士,讲师,研究方向为电机设计优化、电机控制及相关算法和新能源汽车电驱动系统等。E-mail:szhou551@gmail.com

王群京 男,1960年生,教授,博士生导师,研究方向为电机、电机控制、新能源汽车电驱动系统和机器人技术等。E-mail:wangqunjing@ahu.edu.cn(通信作者)

国家自然科学基金(51637001)和安徽省自然基金(2008085ME156)资助项目。

2021-06-14

2021-10-07

(编辑 赫蕾)