Advances in Research of Characteristics and Removal of Microplastics in Sewage Treatment Plants

Shasha LIU, Jianping FU, Yue YANG

1. School of Environmental and Chemical Engineering, Zhaoqing University, Zhaoqing 526061, China; 2. South China Institute of Environmental Sciences, Ministry of Ecology and Environment, Guangzhou 510655, China

Abstract Microplastic pollution has become a worldwide issue. The discharge of sewage treatment plants (STPs) or wastewater treatment plant (WWTPs) is an important way for microplastics to enter the environment. This study reviewed the sources and occurrence characteristics (type, size, color and components) of microplastics in domestic and foreign sewage plants. It elaborated the removal principles of microplastics by primary, secondary and tertiary treatments. In addition, the removal effects of various treatment units and different processes on microplastics were summarized. In the future, the removal mechanism of microplastics in sewage treatment plants should be discussed in more depth, so as to further improve the removal rate of microplastics by optimizing and transforming traditional sewage treatment processes. Therefore, it is necessary to develop new technologies/processes specifically for the removal of microplastics and promote them to practical applications.

Key words Microplastics, Sewage treatment plant (STP), Wastewater treatment plant (WWTP), Occurrence characteristics, Removal

1 Introduction

Microplastics generally refer to plastic particles with a particle size less than 5 mm. As an emerging pollutant, it has attracted widespread attention. It has been confirmed that microplastics exist in the atmosphere[1], oceans[2], rivers[3], lakes[4], soils[5]and sediments[3], seriously polluting the ecological environment. Sewage treatment plant (STP) or wastewater treatment plant (WWTP) is an important gathering place for microplastics. Most microplastics can be effectively removed in the sewage treatment process. However, due to its large effluent, some microplastics still entered the environment and become an important source. Therefore, analysis of the occurrence characteristics and removal of microplastics in sewage treatment plants is an important approach to control their environmental pollution. In this study, we outlined the sources and occurrence characteristics (type, size, color and components) of microplastics in domestic and foreign sewage plants, summarized the removal principles of microplastics, and summarized the removal effects of various treatment units and different processes on microplastics. Finally, we came up with recommendations for improving microplastics removal process and the research and development of new technologies in sewage treatment plants. This study could provide references for the prevention and control of microplastics pollution.

2 Sources and occurrence characteristics of microplastics in sewage

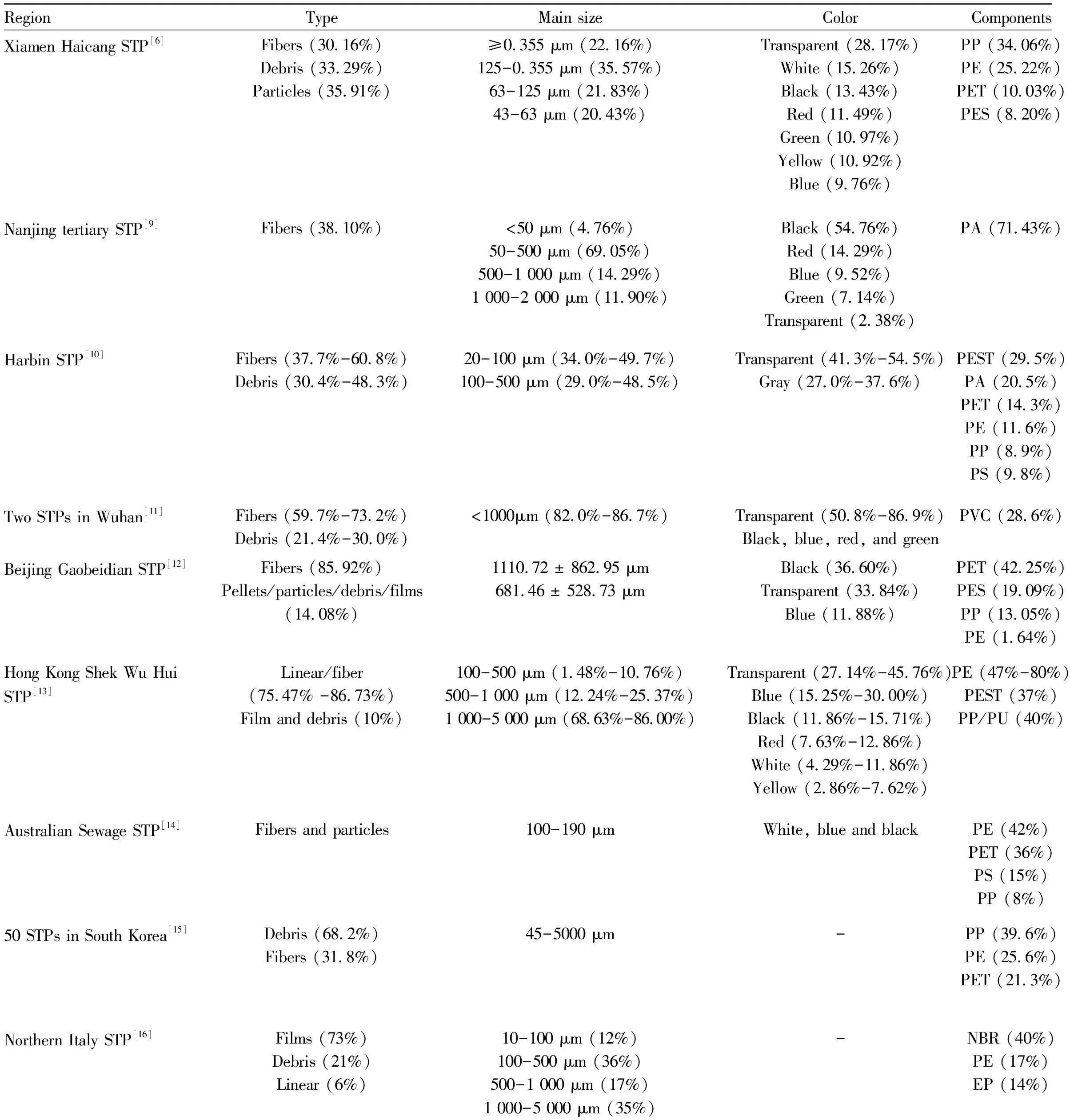

Microplastics in sewage treatment plants come from various sources, mainly including plastic microbeads in personal care products (e.g., facial cleanser, toothpaste and shower gel), microfibers released from washing clothes, particles generated during the use of packaging products (e.g., plastic bags, plastic bottles, food packaging films and toys.), wear debris of rubber tire washed by rain, and wastewater of textile mills and garment manufacturing factories[6-8]. Besides, there are many types of microplastics, mainly including fibers, foams, particles, fragments and films. The components of microplastic samples were polyethylene (PE), polypropylene (PP), polystyrene (PS), polyvinyl chloride (PVC), polyethylene terephthalate (PET), polyamide (PA, also called nylon), polyurethane (PU), polyethersulfone (PES), polyester (PEST), polyacrylonitrile (PAN), acrylonitrile-butadiene rubber (NBR) and ethylene-propylene (EP) copolymer. Microplastics in sewage treatment plants in different regions vary in type, size, color and components, as indicated in Table 1.

Table 1 indicates that fibers are the main type of microplastics in both domestic and foreign sewage treatment plants. For the sewage treatment plants we surveyed, most of the influent water was domestic sewage, and the washing process of textiles would cause a large amount of synthetic fibers to fall off and enter the sewage. Natural fibers (e.g., cotton thread and linen) accounted for more than 50% of the fibers in some sewage samples. It is difficult to distinguish natural fibers from synthetic fibers using the existing quantitative analysis methods, and it may also lead to the detection of high fiber content in WWTPs. Quantities of micro-plastics (i.e., debris, films, foams and particles) are different among WWTPs. Daily plastic products will break into pieces of microplastics, which may also come from personal care products (e.g., toothpaste). After corrosion, plastic bags and packaging products will turn into films and foam-like microplastics. Granular microplastics released directly from personal items. The diverse types of microplastics may result from the differences of the population, economic development level and climatic conditions in the areas served by STPs. The various particle size distribution of microplastics was related to the sieve size of the sampling device. Microplastics with a particle size of less than 100 μm in the effluent of the STP accounted for about 60%, the removal of small-sized microplastics in the sewage treatment process should be of great concern. PE and PP are widely used to make plastic bags/bottles, toys, food/cosmetics containers, building materials and automotive decorative parts. They were worn and broken in the process of application and then entered the wastewater, so that PE and PP became the components of microplastics in most WWTPs. In terms of color distribution of microplastics, there was no certain rule.

Table 1 Microplastics in sewage treatment plants of different regions

3 Microplastics removal principles of the sewage treatment process

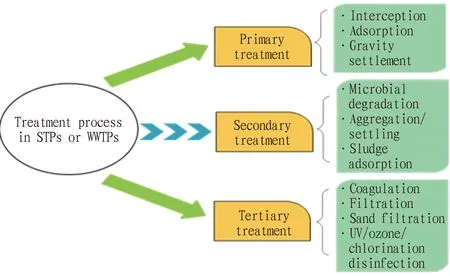

The treatment process of the STP can be divided into primary treatment (i.e., grid, regulating tank, grit chamber, and primary sedimentation tank), secondary treatment (i.e., activated sludge process, biofilm method) and tertiary treatment (i.e., coagulation, advanced filtration, UV/ozone/ chlorination disinfection), as shown in Fig.1. However, the existing sewage treatment systems are mainly targeted at the removal of pollutants (e.g., organic matter, nitrogen, and phosphorus), and there is no specific process for removing microplastics.

The primary treatment removes the suspended particulate matter in the sewage through interception filtration, adsorption and gravity sedimentation[18]. The grid has a certain interception effect on the microplastics with large particle size or adsorbed in the suspension, and transfers them into the grid slag. The lighter microplastics will float in the sewage[19], heavy microplastics can be removed by sedimentation. Due to the large specific surface area and strong hydrophobicity, microplastics can absorb other suspended particulate matters and then form larger pellets, which can be precipitated and removed in the grit chamber and primary sedimentation tank[20].

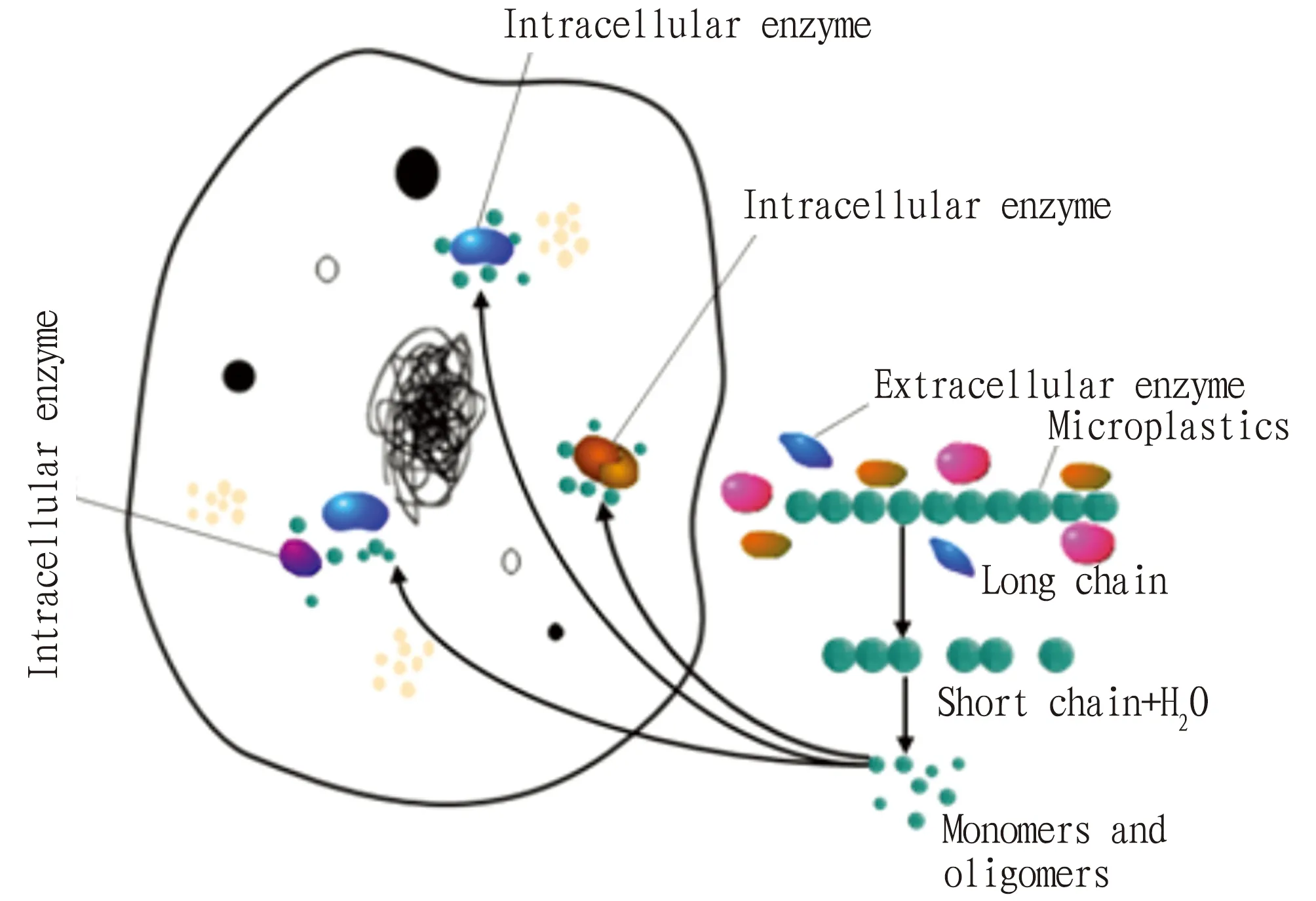

The secondary treatment generally adopts biological methods (e.g., activated sludge process, rotating biological contactors and biological filters) to remove organic pollutants in sewage. Microbial degradation is one of the methods to remove plastics from the environment (Fig.2), the specific process is as follows: (i) microbial attachment to the plastic surfaces; (ii) biofilm formation; (iii) secretion of enzymes and exopolysaccharides (EPS); (iv) biological rupture (i.e., formation of oligomers, dimers and monomers); (v) mineralization (generation of carbon dioxide, methane and water) (Fig.2). Microorganisms secreted hydrolase after contacting with polymers to promote the decomposition of polymers through enzymatic action, and the involved enzymes may include amidase, oxidase, peroxidase, laccase, urease, protease and esterase[21-23]. The flora composed ofBacilluscereusandAgromycesmediolanuswas screened from the activated sludge by Torenaetal.[24], which can decompose PET microplastics with the degradation rate of 17% after 180 d. However, there was still controversy about the contribution of microbial degradation to microplastic removal in the secondary treatment of WWTPs. Petroodyetal.[25]found that microorganisms did not decompose microplastics during the aerobic digestion of sludge. While Mahonetal.[26]found that microorganisms could affect microplastics removal to certain extent in the anaerobic digestion system. Therefore, it is necessary to conduct further research in this respect. Also, the degradation efficiency of microplastics can be improved by constructing genetically engineered bacteria. Microplastic-secreted EPS-rich binding sites bridging and entanglement between long backbones can form the backbone on the microplastic surface, which can enhance the adhesion between microorganisms, promote the aggregation and settling properties of microplastics, and subsequently make it easier for microplastics to enter into sludge from sewage or be removed with falling of aging biofilms[21,27]. Sludge flocs can adsorb microplastics to settle in the sedimentation tank and remain in the sludge.

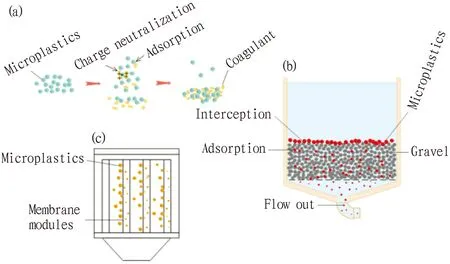

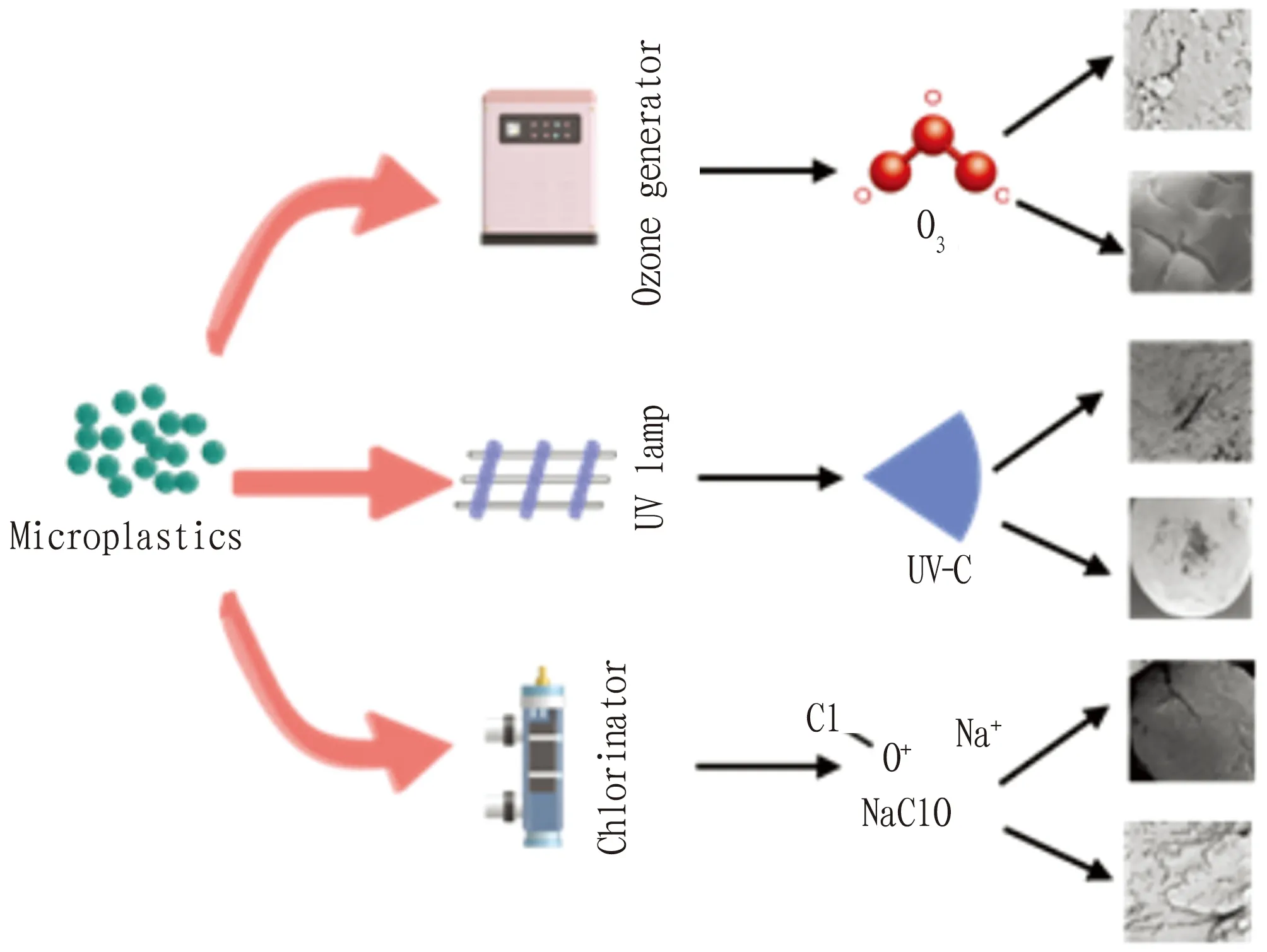

The tertiary treatment can further purify sewage through coagulation, membrane disc filter, rapid sand filter and other processes (Fig.3), and uses the ozone/ultraviolet/chlorination disinfection to remove germs in the sewage. Generally, the coagulation process is taken as the first step in tertiary treatment. After coagulant and sewage are mixed, a hydrolysis reaction occurs to generate cations, which can neutralize the negative charge on the surface of microplastics. This will make microplastics form a compressed double-layer structure and then reduce the repulsive force between the microplastics. Thus, the microplastics are easy to aggregate into flocs and settle to the water bottom[20, 28-29]. The coagulation method has benefits of low investment cost and high removal efficiency, but the entry of coagulant into the environment is harmful. The medium in the membrane disc filter is composed of disc-shaped fibers that can separate plastic particles or act as a barrier for microplastics with a particle size larger than the medium pore size. However, a large number of microplastics may clog the membrane and increase backwash times, enhancing the treatment time and maintenance costs[28]. In addition, the mechanical pressure generated by the filter cloth may lead to mechanical wear of the microplastics. During the sand filtration, the microplastics with large particle size were trapped in the sand particles when passing through the sand filter, while the microplastics with smaller particle sizes were adsorbed on the surface of the sand particles by Van Der Waals force, and the adsorption capacity can be increased by adding flocculant. The microplastics with small particle size entered the environment with the effluent after passing through the medium. Sand filtration technology has the advantages of low cost and high efficiency with the microplastics removal rate of 97%. However, microplastics will be broken into smaller plastic particles after going through the sand filtration process. Ozone can change the microplastics properties (e.g., increase in crystallinity and carbonyl bond strength) and then induce the degradation[30]. Hydroxyl radicals (OH·) generated by ozone decomposition are highly reactive and have high redox potential, which can promote the decomposition of microplastics through hydrolysis[31](Fig.4). The addition of ozone (12.6 mg/L) could remove 90% of the microplastics after 1 min[28]. Nevertheless, ozone technology consumed high energy and easily formed toxic by-products. UV light irradiation could significantly alter the physicochemical properties of microplastics, including increased oxygen-containing groups, specific surface area, number of small pores, hydrophilicity and crystallinity, which led to changes and breaks in the molecular bond structure, resulting in deepening of the surface corrugated structure, shrinkage deformation and even cracks, accompanied by a decrease in particle size and a significant decrease in average molecular weight[32-34](Fig.4). Chlorine addition will promote the formation of new chlorine-carbon bonds (Cl-CH2-C-H) in microplastics and cause the change in the characteristic peaks on its surface, leading to the degradation of microplastics[35].

Fig.1 Treatment process in STPs or WWTPs

Fig.2 Biodegradation of microplastics by microorganism

Note: (a) coagulation, (b) membrane disc filter, (c) sand filtration.

Fig.4 Effects on microplastics during ozone, ultraviolet and chlorine disinfection

4 Research status on the removal efficiency of microplastics with sewage treatment process

4.1 Removal effect of microplastics in different process units

The primary treatment unit includes coarse grid, fine grid, membrane grid, grit chamber and primary sedimentation tank,etc.The grid spacing of domestic sewage treatment plants is generally 10-30 mm[36]. Both fine and coarse grids have little ability to intercept microplastics, and only large microplastics can be intercepted by the grids. Different from conventional grids, membrane grids are a fine filter device. Such grids have the mesh gap of about 2 mm and are mainly used to filter fine hairs and fibers, thus they have a certain removal effect on microplastics. Liuetal.[37]indicated that the removal rates of fiber and film microplastics by membrane grids in the primary treatment reached 16.7% and 60.0%, respectively. However, due to the small spacing, the membrane grid holes were easy to block and need to use high-pressure water to flush leads to a high damage rate of the screen, which increased the operating costs. In the existing sewage treatment plants, the utilization rate of membrane grids was still not high, so the primary treatment mainly uses grit chamber and primary sedimentation tank to remove microplastics. The primary treatment units of the four municipal sewage treatment plants in Jinyang, Beijiao, Yangjiabao and Fendong in Taiyuan City of Shanxi Province are aerated grit chamber+advection primary sedimentation tank, swirl grit chamber, aerated grit chamber+vertical primary sedimentation tank, aeratedgrit chamber+rectangular primary sedimentation tank, their removal rates of microplastics reached 42.35%, 49.60%, 46.48% and 50.94%, respectively[38]. Talviteetal.[39]reported that the removal rate of microplastics in a large tertiary sewage treatment plant in Finland reached 66%-72% after coarse screening+sand removal+primary sedimentation tank. The primary treatment of a sewage treatment plant in Harbin using biological aerated filter (BAF) technology is a cyclone grit chamber+advection sedimentation tank, and a high-efficiency coagulation sedimentation tank is set up, which can precipitate microplastics multiple times, thereby increasing the removal rate to 80.28%[40]. These indicated that about 42%-80% of the microplastics can be removed after primary treatment, which mainly relied on the gravity sedimentation of the grit chamber and the primary sedimentation tank. The cyclone grit chamber had the highest removal rate of microplastics. In view of the large fluctuation of the removal capacity of a single treatment unit for microplastics, multiple treatment units can be combined to improve the removal effect of microplastics.

As the core of the sewage treatment plant, secondary treatment unit mainly plays the role of nitrogen and phosphorus removal. The secondary treatment units of four municipal sewage treatment plants in Jinyang, Beijiao, Yangjiabao and Fendong in Taiyuan City are all activated sludge processes, and the removal rates of non-fibrous microplastics were -16.76%, 37.12%, 47.89% and -5.33%, respectively, and the removal rates of fibrous microplastics were -79.00%, 22.21%, 14.85% and -10.29%, respectively. These indicated that the removal effect of microplastics in the secondary treatment was not obvious, which probably attributed to the most of the fibrous microplastics were removed in the primary treatment[38]. Microplastics could settle down with activated sludge in an advection sedimentation tank in a submerged sewage treatment plant in Beijing[37], and the removal rate was 60.0%. Blairetal.[41]found that the concentration of microplastics decreased by 18% after the secondary treatment in the biochemical tank and the secondary sedimentation tank. The removal of microplastics by the secondary treatment units of different sewage plants has large difference, and the microplastics carried in the return sludge may lead to a negative increase in the removal rate at this stage. Sludge flocs and bacterial extracellular polymers were conducive to the aggregation of microplastics, and the addition of flocculants will also promote the formation of flocs of microplastics, which will promote the sedimentation and removal of microplastics in the secondary sedimentation tank. However, how microorganisms and flocculants interact with microplastics and the extent to which they enhance microplastic removal is still not clear. Microplastics may combine with unstable flocs and fail to complete precipitation, causing them to redisperse in water, which may lead to the poor removal of microplastics. In addition, the formation of biofilms on the surface of microplastics can be promoted by prolonging the residence time of sewage, and then changed the surface properties and relative density of microplastics, significantly strengthening the removal of microplastics through precipitation.

The tertiary treatment further removes the remaining pollutants and disinfects the sewage. The coagulants (e.g., type and dosage) and microplastics (e.g., shape, size and properties) have certain influence on the removal of microplastics. Wangetal.[42]indicated that the removal rate of microplastics by coagulation-precipitation process was related to the type and particle size, the removal efficiency of fibrous microplastics was the best (50.7%-60.6%), almost all microplastics with a particle size larger than 10 μm were removed, and the removal rate of microplastics of 5-10 μm was 44.9%-75.0%. Rajalaetal.[43]used FeCl3and PCA coagulant to treat microplastics in the effluent of a secondary sewage plant in Finland, and the removal rates reached up to 99.4% and 98.2%, respectively. The WWTP-A, WWTP-B and WWTP-C in South Korea used PAC as coagulant, and the removal rates of microplastics were 53.8%, 81.6% and 47.1%, respectively; the higher concentration of microplastics in the sewage contributed to the better removal effect[28]. The coagulation method can quickly and efficiently remove microplastics, but it mainly precipitated microplastics and did not completely remove microplastics. Linetal.[44]reported that the sedimentation characteristics of PS varied with different disinfection methods in sewage treatment plants. After the UV and ozone treatment, hydroxyl functional groups would be formed on the surface of PS, the octanol/water partition coefficient (logKow) was reduced, the hydrophilicity was increased and the surface was smoother, so they were easier to settle. The addition of chlorine could corrode PS and form nano-scale holes, and then the dense air interlayers were generated in nano holes, increasing roughness/hydrophobicity and allowing oil to be easily adsorbed on the surface, so that the density of PS was reduced and tended to float on the water surface and then entered the receiving water body together with the effluent water. Talvitieetal.[45]reported that the removal rate of microplastics by disc filter, rapid sand filter and dissolved air flotation (DAF) was 40%-98.5%, 97% and 95%, respectively. In South Korea, three sewage treatment plants adopted the three-stage treatment technologies of ozone, membrane disc filter and rapid sand filtration, and the removal rates of microplastics were 89.9%, 79.4% and 73.8%, respectively[28]. However, the study of Liuetal.[37]reflected that UV disinfection was difficult to remove microplastics, the plastic media biofilter stage of the sewage treatment plant in the UK only removed 4% of the microplastics[41]. These indicated that there was some controversy about the removal effect of tertiary treatment technology on microplastics. Some researchers believed that the removal rate of microplastics at this stage was almost zero, but some scholars found that the tertiary treatment had a significant removal effect on microplastics, which may be due to the utilization of different treatment processes. It is worth noting that the concentration of microplastics in both the influent and effluent of the tertiary treatment unit was very low. Therefore, the increases of sewage sampling volumes need to be performed to more accurately evaluate the removal rate of microplastics in future research.

4.2 Removal effects of different treatment processes on microplasticsThere are many types of wastewater treatment processes, including anaerobic-anoxic-oxic (A2/O), anaerobic-oxic method (A/O), sequencing batch reactor (SBR) sludge process, circulating activated sludge technology (CAST), conventional activated sludge (CAS), sequencing batch membrane bioreactor (SBMBR) and membrane bioreactor (MBR) technology. Longetal.[18]simulated the removal of microplastics by the SBR process in the laboratory, results showed that the total removal rate of microplastics was 31.25%, the removal rate for different types was fiber (62.5%)>debris (25%)>particle (18.75%).This study concluded that the longer hydraulic retention time led to the higher retention rate of microplastics in the sludge and the better removal efficiency. Gaoetal.[46]used the SMBR process simulator for treating domestic sewage with PET microplastics (15-50 μm) in the laboratory, results indicated that the small membrane pore size (0.05-0.10 μm) could intercept almost all microplastics and the removal rate reached 99.9%. Due to the longer hydraulic retention time (HRT), A2/O process (92.4%) removed more microplastics than that of CAST (71.7%)[47]. Laresetal.[48]found that the removal rate of microplastics from the municipal sewage treatment plant by MBR (99.4%) was greater than that of CAS (98.3%) process in Mikkeli City of Finland. The best removal effect on microplastics of MBR and SMBR processes arose from their multiple functions (e.g., filtration, retention and capture), which can remove almost all microplastics. However, the membrane breakage and blockage would cause the increased frequency of backwashing and higher operating costs. Microplastics in these processes (e.g., A2/O, A/O, CAS, SBR and CAST) can be adsorbed by activated sludge flocs and then settled down to remove, while the microplastics were embedded in the sludge and did not extract their out. To avoid secondary pollution, the proper disposal of sludge should be performed in the future. Although it is a commonly used sludge stabilization process, anaerobic digestion can’t decompose microplastics. Thus, the pyrolysis techniques (e.g., thermal cracking, microwave pyrolysis and catalytic cracking) should be used to remove microplastics in the pretreatment stage, preventing microplastics from influencing the sludge digestion process[49].

5 Conclusions and prospects

(i) Fibers are the major type of microplastics in sewage treatment plants. The amounts of microplastics (i.e., debris, films, foams and particles) were different among various sewage treatment plants, which was related to the quality, source and quantity of the influent water of the sewage treatment plant. The main components of microplastics were PE and PP, while there was no certain rule for the color distribution of microplastics.

(ii) The removal effect of microplastics varied greatly with different processing units/processes, which may be related to the morphology/properties of microplastics, the structure of constructions, the treatment method selected by each unit and other conditions (e.g., grid pore size, sludge settling performance). The removal mechanism of microplastics by sewage treatment plants still need to be explored in depth. It is necessary to further optimize the operating parameters or process combination schemes of each treatment unit to increase the removal efficiency of microplastics by traditional sewage treatment processes.

(iii) The sewage treatment process could fragmentate microplastics, which will make it harder to clean up microplastics. The existing treatment processes in sewage plants are not specifically designed to remove microplastics. Therefore, it is necessary to develop new processes or technologies (e.g., advanced oxidation, dynamic membrane technology, microbial degradation) for the removal of microplastics. Moreover, these processes and technologies should be extended from laboratory research to practical application.

Asian Agricultural Research2022年11期

Asian Agricultural Research2022年11期

- Asian Agricultural Research的其它文章

- Monitoring and Evaluation of Benefits of Project of Returning Farmland to Forests in Henan Province

- Impact and Policy Implications of Swine Epidemic on Price Fluctuation of Livestock Products in China

- Present Situation of Dictyophora Industry in China and Cultivation Technique of Dictyophora rubrovolvata

- Relationship Between Micromorphological Structure of Leaf Epidermis and Drought Resistance in Callisia repens

- Impacts of ENSO on the Welfare of Rural Residents in China: A Stochastic CGE Model Assessment

- Impacts of Sand and Dust Storms on Regional Economy Based on Stochastic CGE Model: A Case Study in Inner Mongolia, China