Tailored martensitic transformation and enhanced magnetocaloric effect in all-d-metal Ni35Co15Mn33Fe2Ti15 alloy ribbons

Yong Li(李勇) Liang Qin(覃亮) Hongguo Zhang(张红国) and Lingwei Li(李领伟)

1Key Laboratory of Novel Materials for Sensor of Zhejiang Province,College of Materials&Environmental Engineering,Hangzhou Dianzi University,Hangzhou 310018,China

2Faculty of Materials and Manufacturing,Key Laboratory of Advanced Functional Materials,Ministry of Education of China,Beijing University of Technology,Beijing 100124,China

Keywords: martensitic transformation,magnetocaloric effect,wheel speeds,all-d-metal Heusler ribbons

1. Introduction

Magnetic materials with outstanding magnetoresponsive performances have been attracted researchers’ interest in recent years.[1–5]Among them,compared to conventional refrigeration technologies based on vapor compression which have caused the environmental pollution and greenhouse effect,the solid-state magnetic refrigeration(MR)technologies,[6–18]based on the magnetocaloric effect (MCE), have been shown as high efficiency alternative and environmentally friendly method that we seek in sustainable society. Until now, several materials based on first-order magnetostructural transitions (FOMSTs) with large MCE have been reported, including rare earth(RE)-based compounds,[12,14,19]Hexagonal MM’X alloys,[20,21]and Heusler alloys,[22,23]etc.Searching and designing novel magnetic materials with outstanding magnetocaloric performance is one of the topic issues at present stage.

In 2015, Weiet al.[24]reported a new alloy system with FOMSTs named all-d-metal Heusler alloys, substitutingp–dorbital hybridization between main-group element and transition group element(Al,Ga,In,etc.) byd–dorbital hybridization between transition group elements(Ni with high valenceelectrons and Ti with low valence-electrons), which has accelerated the exploration of new multifunctional materials.Thed–dorbital hybridization can also stabilize parent phase structure and introduced Co atoms make the establishment of ferromagnetism.[25]Subsequently, Bezet al.[26]reported that solidified ribbons exhibit magnetic entropy change (∆Sm) as high as 27 J/kg·K with magnetic field change of 20 kOe in Ni37.5Co12.5Mn35Ti15. Using digital image correlation and infrared thermography technologies, Weiet al.[27]observed irreversible(reversible)∆Tadof 10.7 K(9.0 K)at a strain level of 3.9%(4.6%)for Ni50Mn32Ti18and Ni35Co15Mn35Ti15,respectively. At the same time, the prediction of crystal and electronic behaviors, phase stability, magnetic state, and possible martensitic transformation (MT) have also been calculated by the first principle calculations based on density functional theory (DFT) to explore the more all-d-metal Heusler alloys.[28,29]Most of them are focused on the modification of chemical composition, thermal treatment, and pressure in the all-d-metal alloys.For ribbon samples,little attention has been focused on the effect of linear wheel speed on MT and MCE.

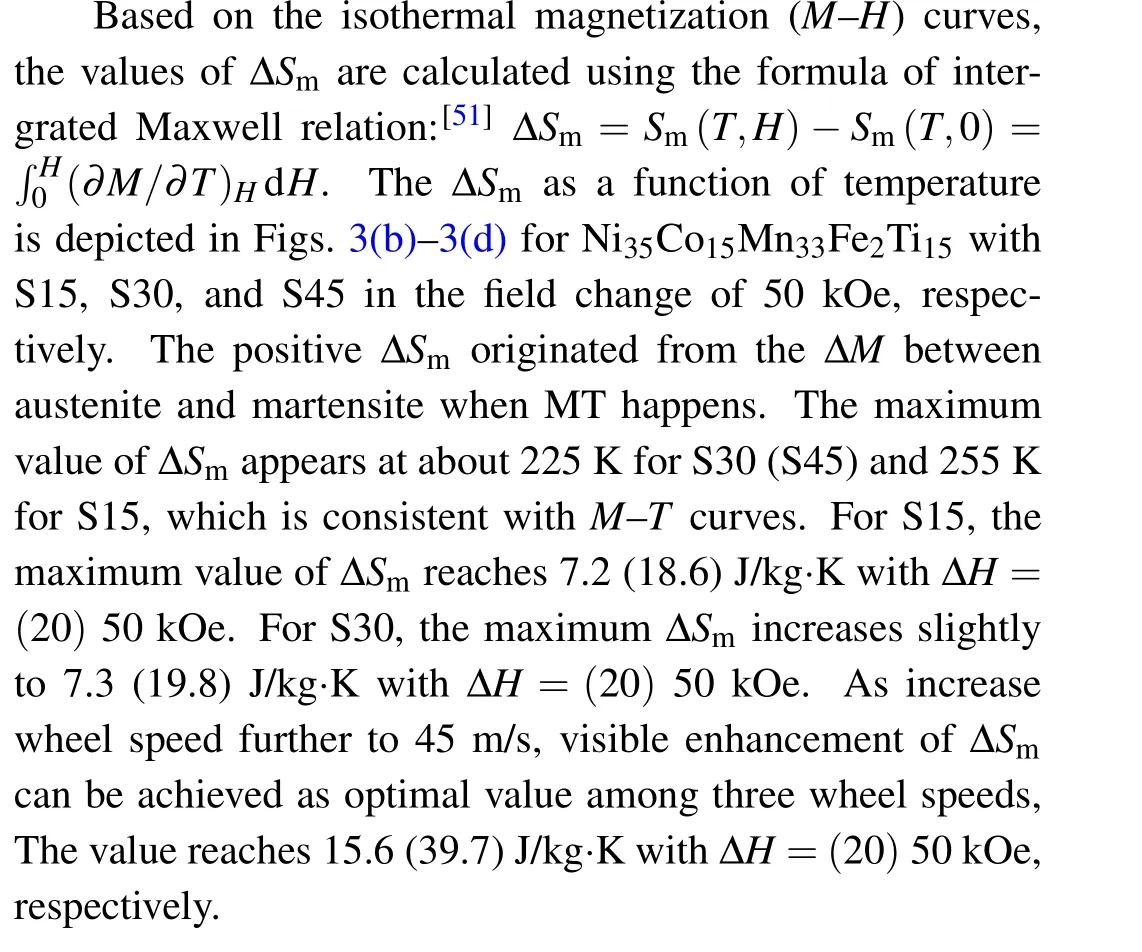

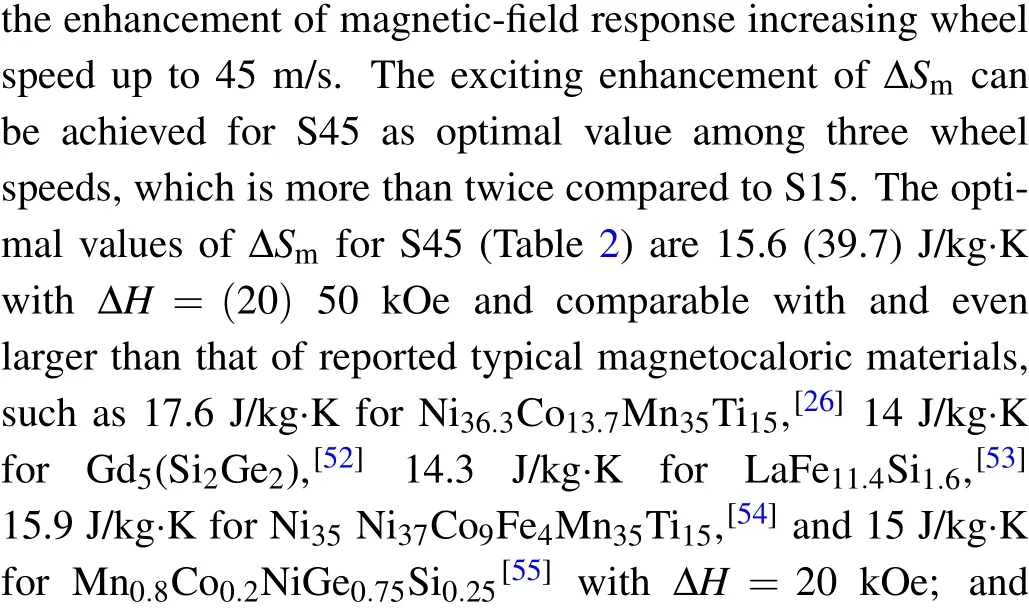

Improving phase compatibility and minimizing thermal hysteresis between the martensite and the austenite through hydrostatic pressure and/or chemical substitutions (such as Fe element) have been reported.[5,26,30]In this work, the effect of wheel speeds (15 m/s, 30 m/s, and 45 m/s) on the crystal structure, MT and mangetocaloric properties in Ni35Co15Mn33Fe2Ti15ribbons are systematically investigated.With the increase of wheel speed, the grain size becomes smaller resulting in the decrease of martensitic transformation temperature (Tt) from 230 K to 210 K,i.e., the austenite is stabilized. Meanwhile, Curie temperature of martensite (TAC)slightly increases from 371 K to 378 K.It is worth noting that the enhancement of ∆Smof 15.6 (39.7) J/kg·K and refrigeration capacity (RC) of 85.5 (212.7) J/kg with magnetic field change of 20(50)kOe can be obviously obtained for S45,the values are comparable or even larger than some reported magnetocaloric materials.

2. Experimental details

With high purity metals (≥99.9%), the polycrystalline Ni35Co15Mn33Fe2Ti15alloy ingot was fabricated by arcmelting method under the argon atmosphere. The alloy ingot was turned and re-melted for 4-times to ensure homogeneity and then cut into three pieces. The Mn losses were compensated for by adding the excess of Mn elements. The three ribbons,ejecting(ejection pressure of∼0.1 MPa)the ingots onto a rotating copper wheel with a surface speed of 15 m/s(S15),30 m/s(S30),and 45 m/s(S45),were prepared by using meltspinning techniques as studied samples. The scanning electron microscope(SEM,Sigma 300,Zeiss)with x-ray energydispersive spectroscopy (EDS) was carried out to investigate the microstructure and composition of melt-spun ribbons. The crystal structures were investigated by room temperature(RT)x-ray diffiraction(XRD,SmartLab-9 kW,Rigaku)with Cu-Kαradiation. The differential scanning calorimeter (DSC, Discovery DSC 25, TA) was used to measure thermal property.The microstructure was measured by using scanning electron microscope(SEM,Sigma-300,Zeiss).The magnetization data(thermomagnetic(M–T)curves and isothermal magnetization(M–H)curves)were obtained by magnetic property measurement system(MPMS3,Quantum Design).

3. Results and discussion

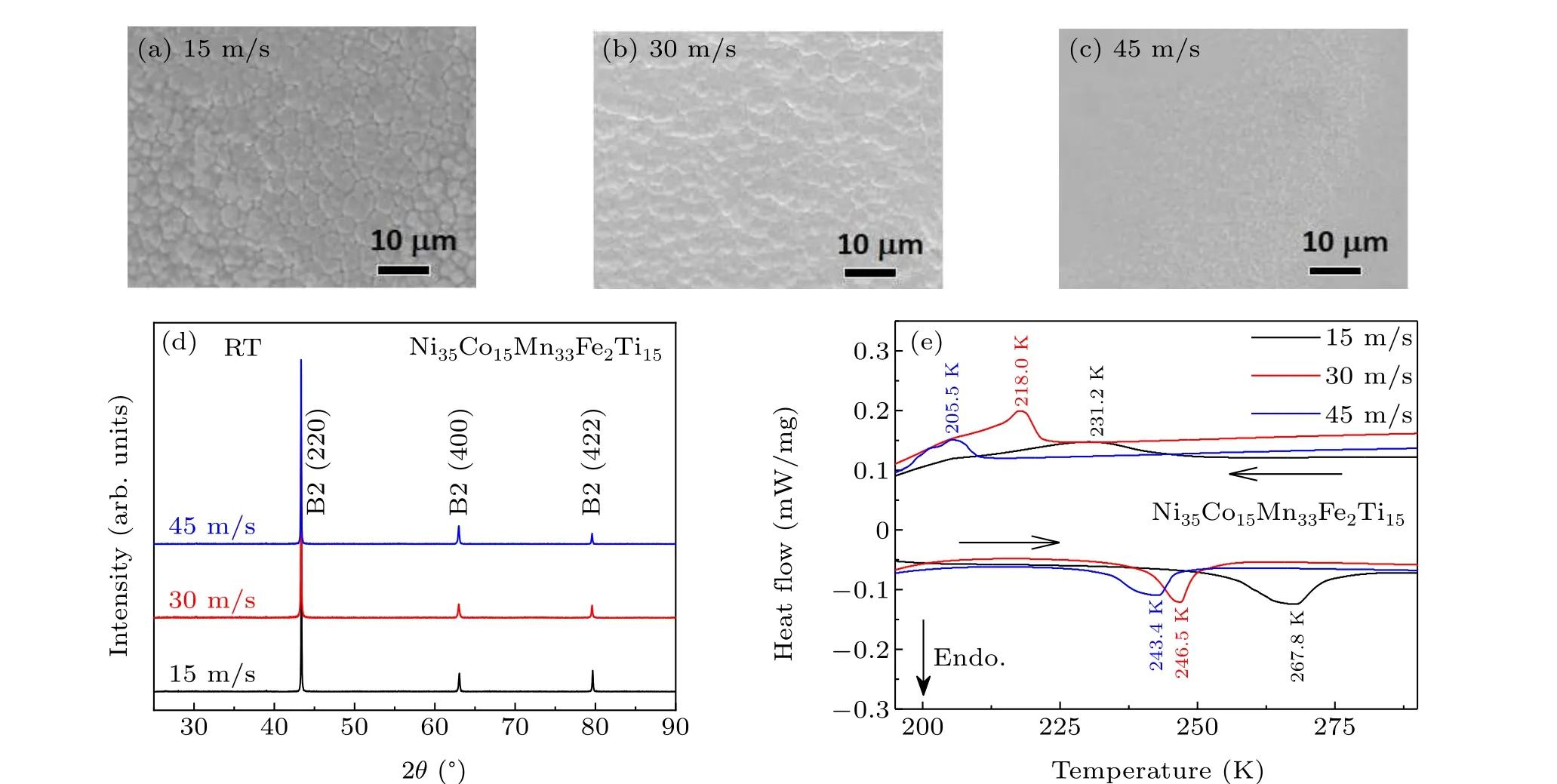

The microstructure of free surface using SEM at room temperature (RT) is depicted in Figs. 1(a)–1(c) for Ni35Co15Mn33Fe2Ti15with S15, S30, and S45, respectively.The visible equiaxed-grain-like austenite without the appearance of plat-like martensite can be clearly seen. The average grain size obviously declines from 3.5 µm (S15) to 2.8 µm(S30)and further to 1.0µm(S45)with increasing wheel speed,i.e., lower grain size with higher cooling rate. RT XRD patterns of Ni35Co15Mn33Fe2Ti15with different wheel speeds are shown in Fig. 1(d). The similar phenomenon can be seen for all ribbons. Due to absence of the superlattice diffraction peaks of L21structure,all three ribbons crystalize in B2-ordered structure which is similar to other reported all-d-metal Heusler alloys,[24,31]meaning that the ribbons prefer to form B2 rather than L21structure during melt spun process. It also indicates that the martensitic transformation temperature (Tt)is below RT,which is conformed to SEM analysis. The miller indexes of (220), (400), (422) are signed in the corresponding peaks. The characteristic peaks move slightly towards to small angle with increasing wheel speed,the crystal constant,5.893(2) ˚A for S15, 5.898(4) ˚A for S30, and 5.898(6) ˚A for S45(see Table 1),monotonically increases. Another is worth noting is that the more intensive intensity of the diffraction of(220) plane, showing that the〈110〉direction is closely parallel to the solidification direction, is the preferred direction during melt spun process.[32,33]

The DSC curves with different wheel speeds were measured upon heating and cooling rates of 10 K/min under nitrogen atmosphere,which are displayed in Fig.1(e). The obviously exothermic and endothermic peaks (below RT) with thermal hysteresis appear for three ribbons, which show that the type of transition belongs to first order nature.Tt(T′t)monotonously decreases with the increase of wheel speed(Table 1), meaning that MT is sensitive to wheel speed. TheTt(T′t) of 231 (268) K for S15 decreases to 218 (246) K for S30 and further to 206(243)K for S45.

Fig.1. (a)–(c)Microstructure of free surface using SEM,(d)room-temperature XRD patterns,and(e)DSC curves for Ni35Co15Mn33Fe2Ti15 with wheel speed of 15 m/s,30 m/s,and 45 m/s,respectively.

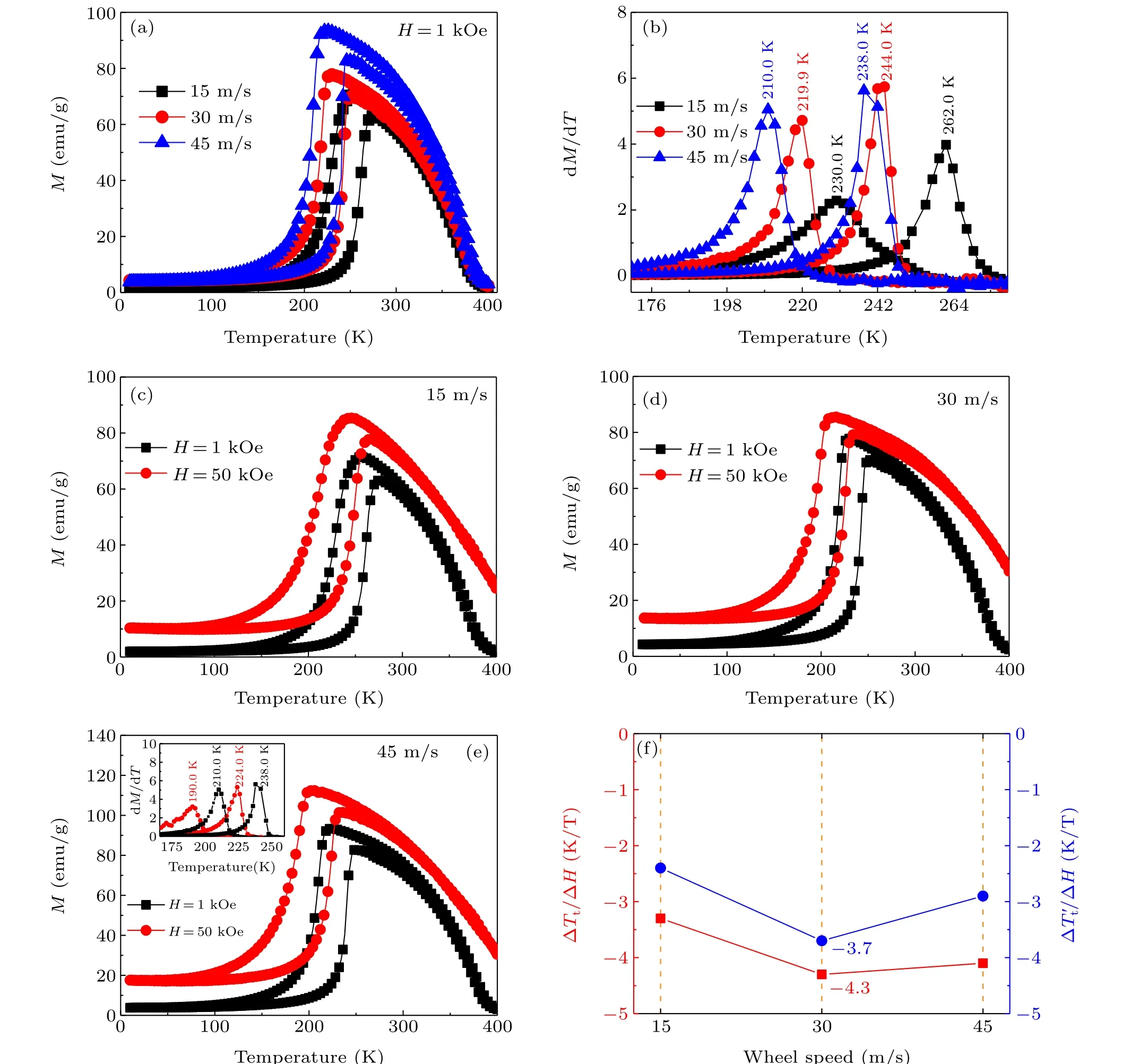

Fig. 2. (a) Thermomagnetic (M–T) curves under 1 kOe. (b) The derivative of M–T (dM/dT) curves as a function of temperature. (c)–(e)Temperature dependence of magnetization (M–T) curves under 1 kOe and 50 kOe. (f) The driving rate by magnetic field (∆Tt/∆H, normal MT,circle;∆T′t/∆H,reverse MT,square)for Ni35Co15Mn33Fe2Ti15 with wheel speed of 15 m/s,30 m/s,and 45 m/s,respectively.

The thermomagnetic (M–T) curves were measured at 5 K/min in a magnetic field of 1 kOe between 10 K and 400 K,as depicted in Fig.2(a). The three ribbons,upon cooling process, firstly undergo the Curie temperature in austenite (TAC)from paramagnetic state to FM state. Subsequently, a magnetostructural transitions happen accompanied by a sudden drop of magnetization from FM austenite to weak-magnetic(WM) martensite. The reverse curves upon heating are not coincided with the curves upon cooling,i.e.,the thermal hysteresis obviously exists, indicating the characteristic of first order transition.[34]Herein,to gain theTt(T′t)andTACvalues,the derivative ofM–Tcurves (dM/dT) was performed and the pattern is shown in Fig.2(b). The results show that theTt(TAC)is sensitive(insensitive)to the wheel speed. With the increase of wheel speed,theTt(T′t)monotonously declines from 230(262)K for S15 to 210(238)K for S45, which are basically in good agreement with the values from DSC. TheTAC(371 K for S15, 374 K for S30, and 378 K for S45) slightly rises simultaneously. The corresponding data are listed in Table 1. The larger wheel speed is used, the more stable the austenite keeps. More importantly, compared with S15 the thermal hysteresis declines for S30 and S45. Smaller hysteresis benefits refrigeration because a reduction in the refrigerant capacity caused by the irreversible behaviors associated with large hysteresis.[35]Furthermore, the magnetization change(∆M)increases from 63.5 emu/g(S15)to 81.9 emu/g(S45)by enhancement of Mn–Co–Mn interaction resulting in the more effective magnetoresponsive performance,which is benefit to the magnetic refrigeration in practice application under low magnetic field.[20]

To find out the fact what affects martensitic transformation, we analyzed possible reasons. For many FOMST alloys,the increase of grain size through heat treatment can tailor MT to high temperature, such as NiMn-based,[36–39]Cubased[40,41]Heulser alloys, and Ni–Co–Mn–Ti.[42]Recently,Maet al.[43]reported that the decline of MT for all-d-metal Heusler ribbons Mn50Ni31.5Co8.5Ti10with increasing wheel speed results in the decrease of grain size. The atomic ratio is not obviously changed for three ribbons (EDS) and the three ribbons show very similar lattice constant with B2 structure (XRD), which give rise to the unchanged valence electron concentration (e/a) and ordering. Thee/avalue and ordering should not be taken into account in the presented case. Therefore, the grain size in three ribbons should play important role. The reason is similar to Mn–Fe–Ni–Ge–Si[44]and Mn50Ni31.5Co8.5Ti10,[43]during the MT the strain energy stored in the material is produced by shearing and by volume change totally, the more produced defects with increasing wheel speed result in the smaller grain size,then the more large driving force was needed to complete MT process.Therefore, the MT shifts to low temperature with increasing wheel speed,i.e.increase of wheel speed can stabilize parent phase.[39]

Table 1. The values of Tt (T′t),Thys,∆Tt (∆T′t),and ∆Tt/∆H (∆T′t/∆H)using DSC under zero magnetic field and MPMS under the fields of 1 kOe and 50 kOe for Ni35Co15Mn33Fe2Ti15 with wheel speed of 15m/s,30 m/s and 45 m/s,respectively.

Figures 2(c)–2(e) display the thermomagnetic (M–T)curves recorded under magnetic fields of 1 kOe and 50 kOe between 10 K and 400 K for Mn50Ni31.5Co8.5Ti10with S15,S30, and S45, respectively. It is worth noting that the ferromagnetism of austenite is stronger than that of martensite,theTt(T′t)calculated from the inset of Fig.2(e)obviously declines with increase of external magnetic field owing to the transformation from FM to WM state. The behaviors result from the magnetic field stabilizing the phase with a higher magnetization by introducing Zeeman energy,i.e., magnetic field stabilizes parent phase in the system. The results are similar to many conventional Heusler shape memory alloys, just like Ni–Mn–In,[45]Ni–Co–Mn–In,[46]Co–V–Ga,[47]and Ni–Mn–Sn.[48]The maximum changes ofTt(T′t)induced by magnetic field(∆Tt/∆H,∆T′t/∆H)can reach−4.3(−3.7)K/T(Fig.2(f),Table 1) for S30, which are compared with and even larger than other materials.[43,49,50]

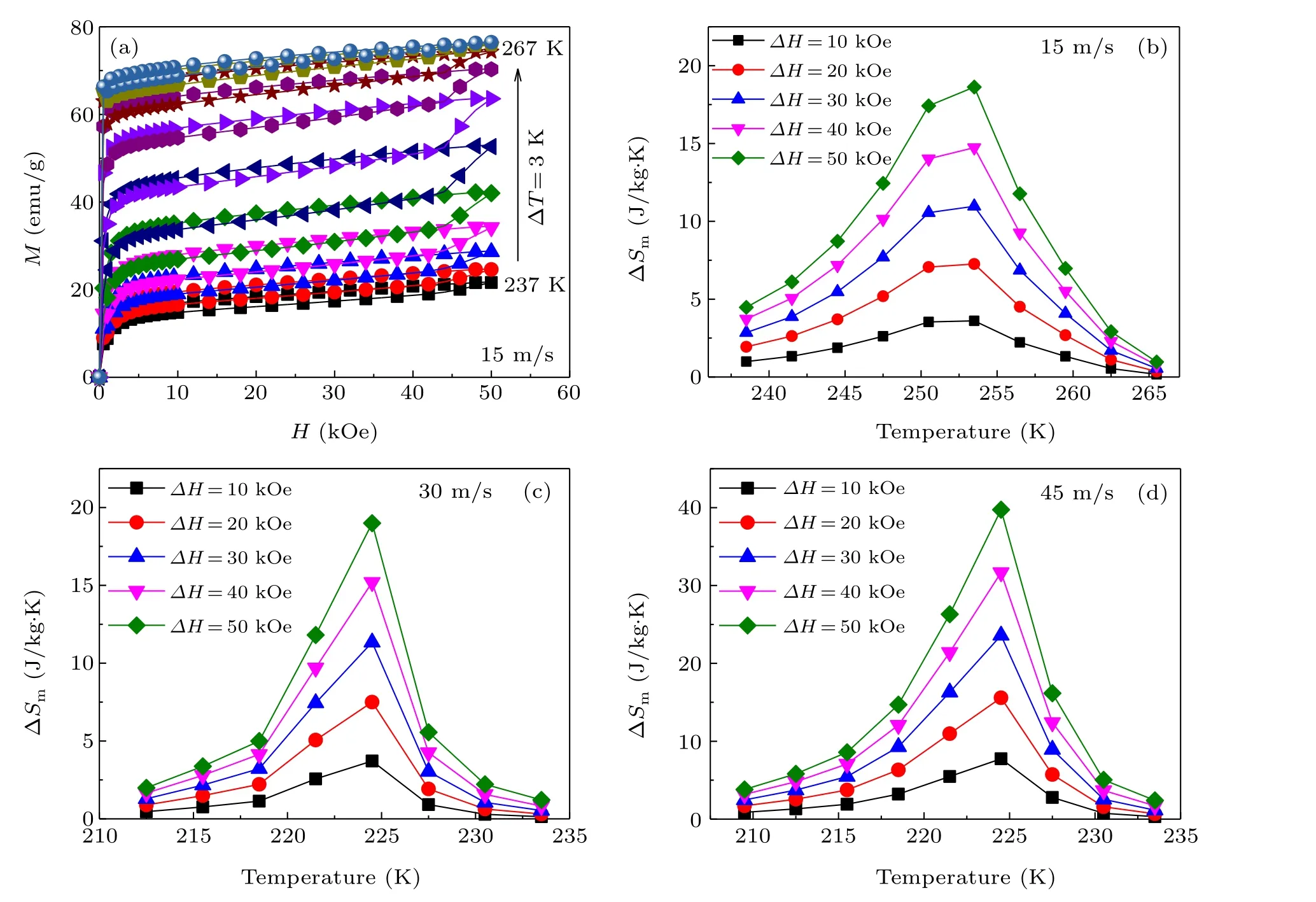

For solid-state magnetic refrigeration materials,the magnetic entropy change(∆Sm)and refrigeration capacity(RC)are important factors to determine refrigeration performance in practical applications.[6]The temperature loop method,[31,51]with the temperature step (∆T) of 3 K, was used in vicinity of MST to eliminate the residual effect generated in previous measurement and avoid overestimating the ∆Sm. Figure 3(a)displays the isothermal magnetization (M–H) curves for S15 measured around reverse MT. BelowTt, the quasi-linear increased magnetization under a magnetic field up to 50 kOe indicates the weak-magnetic behavior. The magnetic hysteresis is low due to the absence of change of magnetization induced by variation between austenite and martensite.AboveTt,characteristic FM behaviors with low saturation-field of austenite can be observed,showing that the samples are easy to be magnetized and saturated with increasing magnetic field. In the vicinity ofTt, obviously magnetic-field-induced reverse MT,with critical field(Hcr)of 42 kOe,can be seen,the feature of metamagnetic transformation with obvious magnetic hysteresis appears.

Table 2. The values of ∆Sm and RC under the field change of 50 kOe for Ni35Co15Mn33Fe2Ti15 and reported magnetocaloric materials,respectively.

Fig.3. (a)Isothermal magnetization(M–H)curves for Ni35Co15Mn33Fe2Ti15 with wheel speed of 15 m/s. (b)–(d)Magnetic entropy changes(∆Sm)in magnetic field change of 50 kOe for Ni35Co15Mn33Fe2Ti15 with wheel speed of 15 m/s,30 m/s,and 45 m/s,respectively.

Fig.4. Magnetic field dependence of(a)∆Sm and(b)RC curves in the field change up to 50 kOe for Ni35Co15Mn33Fe2Ti15 with wheel speed of 15 m/s,30 m/s,and 45 m/s,respectively.

In Fig. 4(b), the RC curves also increase quasilinearly with increasing wheel speed. The RC values reach 76.5(191.9)J/kg and 85.5(212.7)J/kg with ∆H=(20)50 kOe for S15 and S45, respectively. TheRCvalues decline to 36.8 (92.1) J/kg, nearly half of the maximum values of S15,for S30 owing to a smaller FWHM and comparative ∆Smvalue calculated by two formulas above. Thus, the optimal values appear in S45 (listed in Table 2) and are comparable with and even larger than that of reported magnetocaloric materials, such as 91.5 J/kg for Ni50Mn32.7Cu1.3In16with ∆H=20 kOe[56]and 206.8 J/kg for Ni35Co11Fe4Mn35Ti15,[31]197 J/kg for Ni36.0Co14.0Mn35.7Ti14.3,[42]121 J/kg for Mn50Ni32Co8Ti10,[57]239.7 J/kg for Ni36.5Co13.5Mn35Ti15[58]with ∆H= 50 kOe. The increase of wheel speed not only tailors MT but also enhances magnetocaloric performances(large ∆SmandRC),which makes the all-d-metal ribbon more probable for magnetic refrigeration application.

4. Conclusion

In summary,we investigated the crystal structure,martensitic transformation, and magnetocaloric effect of all-d-metal Ni35Co15Mn33Fe2Ti15alloy ribbons with different wheel speeds (15 m/s, 30 m/s, and 45 m/s). The results indicate that three ribbons crystalize ordered B2-type cubic structure at room temperature, and crystal constant is 5.893(2) ˚A,5.898(4) ˚A, and 5.898(6) ˚A, respectively. With the increase of wheel speed, theTtdeclines andTACslightly increases due to the decrease of grain size. More importantly, the enhanced magnetocaloric effect is also been gained. The maximum value (S45) of magnetic entropy change (∆Sm)and refrigeration capacity (RC) are 15.6 (39.7) J/kg·K and 85.5 (212.7) J/kg in the fields of 20 (50) kOe, respectively.Therefore,Ni35Co15Mn33Fe2Ti15alloys are considerable candidate for magnetic refrigeration.

Acknowledgments

Project supported by the National Natural Science Foundation of China(Grant Nos.52001102 and 51771003).

- Chinese Physics B的其它文章

- Magnetic properties of oxides and silicon single crystals

- Non-universal Fermi polaron in quasi two-dimensional quantum gases

- Purification in entanglement distribution with deep quantum neural network

- New insight into the mechanism of DNA polymerase I revealed by single-molecule FRET studies of Klenow fragment

- A 4×4 metal-semiconductor-metal rectangular deep-ultraviolet detector array of Ga2O3 photoconductor with high photo response

- Wake-up effect in Hf0.4Zr0.6O2 ferroelectric thin-film capacitors under a cycling electric field