Towards Long Lifetime Battery: AI-Based Manufacturing and Management

Witold Pedrycz,,, Zhongbao Wei, Senior,, Chenghui Zhang, Senior,,Yunlong Shang,,, Remus Teodorescu,,, and Qing-Long Han,,

Abstract—Technologies that accelerate the delivery of reliable battery-based energy storage will not only contribute to decarbonization such as transportation electrification, smart grid,but also strengthen the battery supply chain. As battery inevitably ages with time, losing its capacity to store charge and deliver it efficiently. This directly affects battery safety and efficiency,making related health management necessary. Recent advancements in automation science and engineering raised interest in AI-based solutions to prolong battery lifetime from both manufacturing and management perspectives. This paper aims at presenting a critical review of the state-of-the-art AIbased manufacturing and management strategies towards long lifetime battery. First, AI-based battery manufacturing and smart battery to benefit battery health are showcased. Then the most adopted AI solutions for battery life diagnostic including state-ofhealth estimation and ageing prediction are reviewed with a discussion of their advantages and drawbacks. Efforts through designing suitable AI solutions to enhance battery longevity are also presented. Finally, the main challenges involved and potential strategies in this field are suggested. This work will inform insights into the feasible, advanced AI for the health-conscious manufacturing, control and optimization of battery on different technology readiness levels.

I. INTRODUCTION

TO achieve net-zero carbon emission targets around the world, numerous works regarding green energy have been explored, offering plenty of potential sustainable technologies in the field of transportation electrification and smart grid [1].Due to the superiority of high energy density and low selfdischarging rate, lithium-ion (Li-ion) battery has been widely utilized as an efficient energy storage technology in many applications from small electrical devices (i.e., mobile phone,laptop) to large ones (i.e., electrical vehicle (EV), electrical ship, electrical plane) [2], [3]. For example, the global Li-ion battery demand is expected to reach 1156 GWh by 2026,mainly caused by the huge demand of EVs (a market of 86 billion dollars). However, due to the frequently occurring electrochemical reactions, battery would inevitably age with time, losing the capacity to store charge and deliver it efficiently [4], [5]. This would also heavily affect battery performance and safety, making related health management solutions necessary.

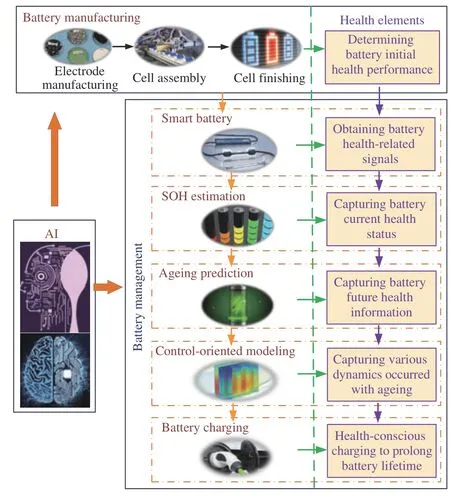

The lifetime of the battery is a consequence of multiple coupled ageing mechanisms affected by various elements,such as battery manufacturing, operations and environmental conditions. Fig. 1 illustrates several key aspects of artificial intelligence (AI)-based battery health improvement from the manufacturing and management perspective. On the one hand,as a highly complicated process involving several continuous or discontinuous stages, battery manufacturing significantly affects its intermediate product properties, further determining the final manufactured battery performance including not only its initial health (capacity, impedance, first cycle loss) but also energy and power density [6]. From the practical perspective,battery manufacturing generally consists of electrode manufacturing, cell assembly and cell finishing. The improved health performance of battery product heavily relies on the manufacturing management strategy development to increase the electrode volume ratio of active material and thickness.Furthermore, to meet the increasing requirement from consumers, battery manufacturing with high yield and low cost should be also considered [7]. To achieve these targets,battery manufacturing line as a whole needs to be fully explored and optimized [8]. Besides, as battery manufacturing parameters or variables have the order of tens or hundreds and are strong-coupled, all relevant process parameters, variables,product properties and interdependencies also need to be indepth analyzed.

On the other hand, battery operations play a more direct role in determining battery service life. After a battery is manufactured, it would work with different operating modes to supply or absorb electrical energy/power, where various management solutions are required. Specifically, reliable battery operation management first relies on the measurement of fundamental battery parameters, covering the routine measurements of current, voltage, temperature, and also new information like the battery stain and pressure, enabled by various emerging sensing techniques. Then to ensure reliable monitoring of battery health, battery current health information such as state-of-health (SOH) needs to be estimated in real-time, while battery future health status such as ageing trajectory requires to be predicted. According to the obtained battery health information, various strategies could be designed to prolong battery lifetime. Recalling the existing literature, a rather large number of researches have been done on AI-based battery health management. Among various researches, the following three aspects have been paid much attention for promoting effective health management of batteries as:

Smart battery with AI, which focuses on using advanced sensing techniques to provide multi-dimensional measurements for data acquisition of AI-based battery management.Apart from the current, voltage and temperature signals that have been frequently used in AI for battery life diagnostic and longevity enhancement, emerging advanced sensing techniques can give new data to reflect more inner multi-physical statuses of battery [9]. Existing works have evidenced the possibility to measure the strain, thermal response, optical characterization, and electrode potential [10], [11]. Hence, it is foreseeable that more valuable parameters can be input into AI techniques for battery health management. Besides, the emerging techniques of reconfigurable battery design further improve the upper limitation of the smart battery. This can be also enhanced by incorporating AI tools such as machine learning for smarter battery management [12].

Fig. 1. Several key aspects for AI-based battery health improvement from manufacturing and management (smart battery, life diagnostic, controloriented modeling, battery charging) perspective.

Battery life diagnostic with AI, which relates to the adoption of various AI tools to estimate battery SOH and predict battery ageing trajectory [13]. Here, SOH reflects how a battery is currently capable of storing and supplying energy or power relative to that at its starting life, which is usually calculated as the ratio of battery actual capacity or resistance and its initial value. Battery ageing trajectory represents the trend of battery future degradation under predefined operation cases. This is a key element to reflect how many cycles the battery would reach its failure threshold, further helping to reduce the users’ mileage anxiety on many battery applications such as electric vehicles (EVs). The existing research on SOH estimation and ageing trajectory prediction is quite extensive, although it mainly focuses on battery capacity, unless otherwise stated, this will also be our focus.

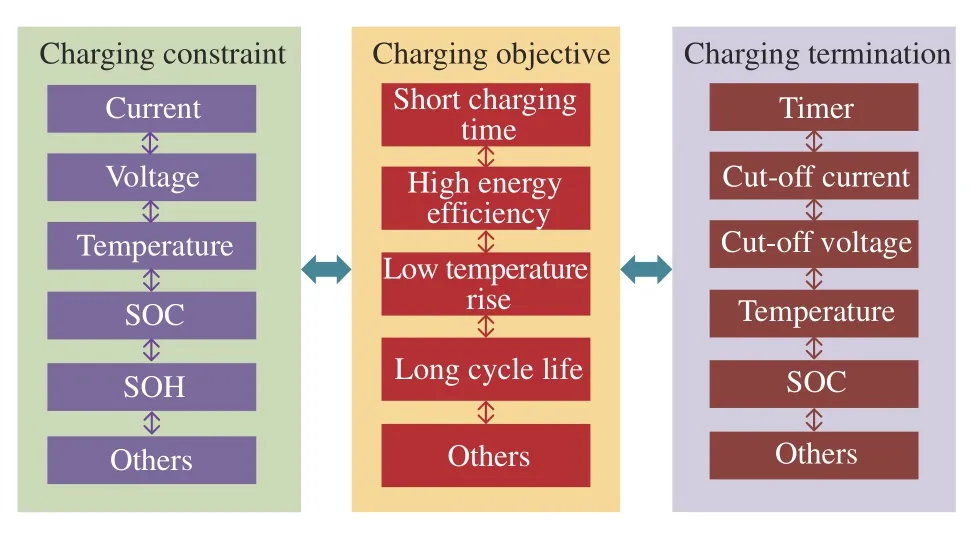

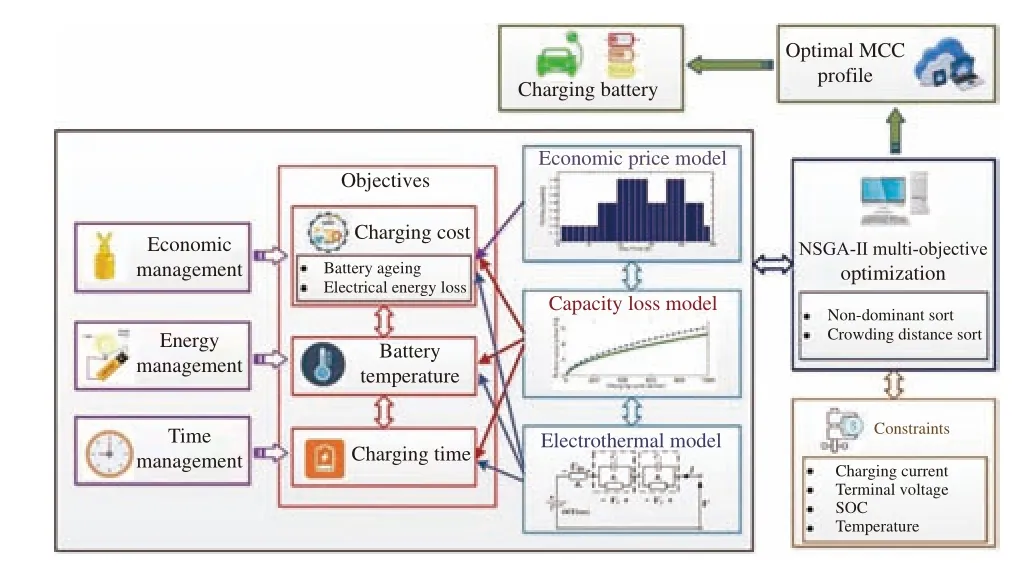

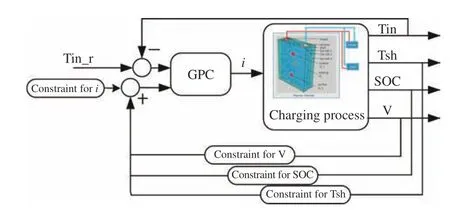

Battery longevity enhancement with AI, which mainly contains the elements of developing battery control-oriented model [2], and AI-based battery health-conscious charging[14] in this survey. As apart from ageing behavior, battery also presents complicated electrical and thermal coupling dynamics, which further requires various modeling techniques to capture these dynamics simultaneously. Furthermore, these models should have a compact structure with control-oriented nature to give timely and robust responses for real-time applications. Based upon these control-oriented models,objective functions or constraints related to battery health can be formulated. Then various AI-based solutions are designed to restrain battery degradation and enhance battery longevity in charging management: a key operation stage to determine battery operation safety and efficiency.

These three aforementioned aspects during battery operation management would also play a pivotal role in affecting battery health performance. In this regard, with the rapid development of automation science and engineering, a great number of related AI-based solutions have been reported in the literature.

To date, a few review papers on introducing battery manufacturing and management to benefit battery health performance were published, as summarized in Table I. On the one hand, it can be noted that in comparison with the battery operation management field where numerous solutions are available from various aspects, there are still limited explorations of deriving suitable AI strategies to benefit battery from the manufacturing perspective. On the other hand, for the battery operation management, these reviews mainly focus on one aspect such as the modeling [2], life diagnostic [13], [15], [16], and battery charging [14] alone,losing the opportunity to systematically explore all aspects towards long lifetime battery together. As the full lifespan of automotive batteries actually starts from manufacturing to operation management, these two stages are also significantly correlated to affect the battery service life. Furthermore, with the rapid advancements of cloud platforms and automation engineering, AI is becoming a promising tool in battery applications. In this context, a systematic review simultaneously covering both battery manufacturing and management especially from the AI perspective to improve battery health performance is urgently required.

In this article, an overview of various AI tools to benefit battery manufacturing and management towards long lifetime batteries are given and their related challenges are also discussed. The review is intended to inform AI tools selection and academic research agendas alike, thus boosting progress in AI-based battery manufacturing and management on different readiness levels. Specifically, the following topics are covered as:

1) For battery manufacturing, after introducing the fundamentals of producing battery, AI-based framework and most popular AI tools to achieve smart manufacturing and benefit battery initial health performance are discussed.

2) For smart battery, multi-dimensional sensing techniques feasible to battery data monitoring are reviewed. The integration of self-monitoring smart batteries into the future reconfigurable long-life battery system is further discussed.

3) For battery life diagnostic, classical AI-based solutions for both battery SOH estimation and ageing trajectory prediction are reviewed, and their merits and limitations are discussed.

4) For battery longevity enhancement, various controloriented battery models, health-conscious charging solutions are discussed with the survey of their related AI tools.

5) Current research gaps in the literature and suggest challenges for each aspect from the perspectives of bothbattery manufacturing and management are highlighted with some suggestions to boost future AI-based research in this area.

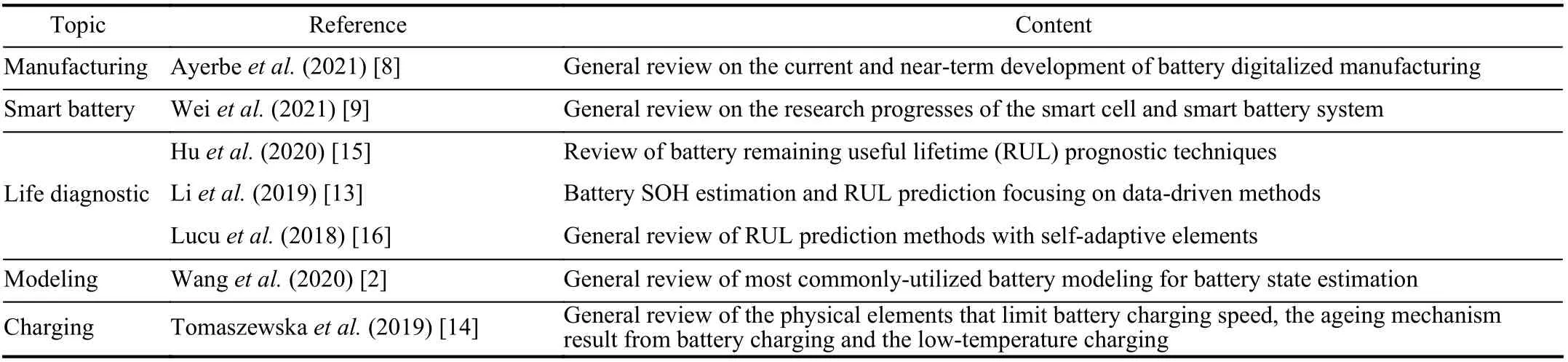

TABLE I AN OVERVIEW OF THE REVIEWS RELATED TO BATTERY MANUFACTURING AND MANAGEMENT TOWARDS LONG LIFETIME BATTERY

The remainder of this review is organized in the following manner: Section II discusses the battery manufacturing fundamentals, AI-based framework and various AI tools to benefit battery manufacturing. Section III focuses on the discussion of smart battery development to obtain data for AI development. Section IV presents battery life diagnostics with AI in terms of SOH estimation and ageing prediction. In Section V, AI-based solutions for enhancing battery longevity are surveyed and discussed. Section VI summarizes the main challenges and suggests the promising AI strategies for each aspect. Finally, the conclusion is given in Section VII.

II. BATTERY MANUFACTURING WITH AI

Manufacturing is the first stage of battery full-lifespan and would highly affect battery product performance, especially for its initial health. This section first introduces the fundamentals of battery manufacturing, followed by the discussions of various AI technologies in battery manufacturing in terms of their applications, merits and limitations.

A. Fundamentals of Battery Manufacturing

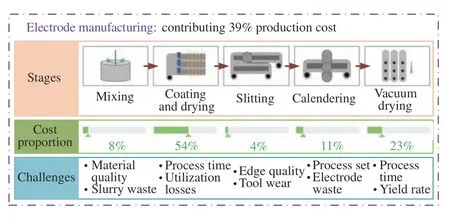

In general, battery manufacturing can be divided into two processes: electrode manufacturing and cell manufacturing[17]. For the former, it could contribute around 39% of battery manufacturing cost. As illustrated in Fig. 2, battery electrode manufacturing contains several individual stages: mixing,coating&drying, slitting, calendering, and vacuum drying,where these stages would contribute 8%, 54%, 4%, 11%, and 23% of the total electrode manufacturing cost, respectively.Specifically, after preparing materials such as active materials,conductive additives, solvent and binder, electrode manufacturing generally begins with a mixing stage to mix these materials within a tank (i.e., soft blender). Then the generated slurries would be coated onto the surface of metal foils(copper foil for anode while aluminum foil for cathode)through a coating stage. Afterwards, the coating products would be dried by a dryer with preset temperatures to remove solvent [18]. Then a slitting stage is conducted to cut the coated metal foil into strips, followed by a calendering stage to compress electrode foils. Finally, a vacuum drying stage will be also conducted to remove the leftover solvent in the electrode.

Fig. 2. Key stages of battery electrode manufacturing.

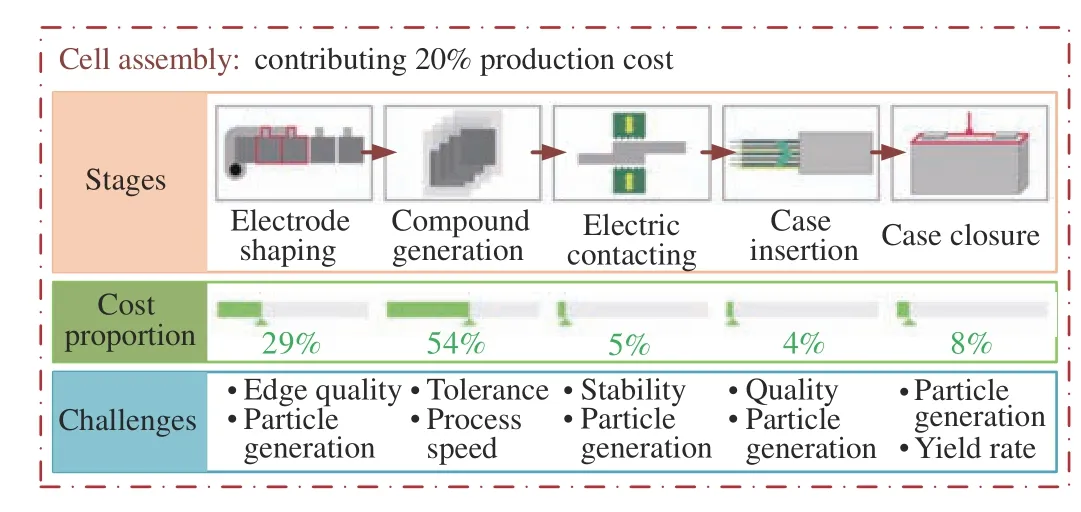

For cell manufacturing, it can be further divided into two processes including cell assembly and cell finishing, which contribute 20% and 41% of battery manufacturing costs [17],as illustrated in Figs. 3 and 4 , respectively. For the cell assembly, the manufactured electrode will be first cut out with suitable shapes in the electrode shaping stage. Then active material compounds will be generated during compound generation, followed by an electric contacting stage to create an electrically conductive joint and a case insertion stage to insert compound into cell housing. Afterwards, cell housing will be closed through laser welding to finish cell assembly.The stages of electrode shaping, compound generation,electric contacting, case insertion, and case closure would contribute 29%, 54%, 5%, 4%, and 8% of the total cell assembly cost, respectively.

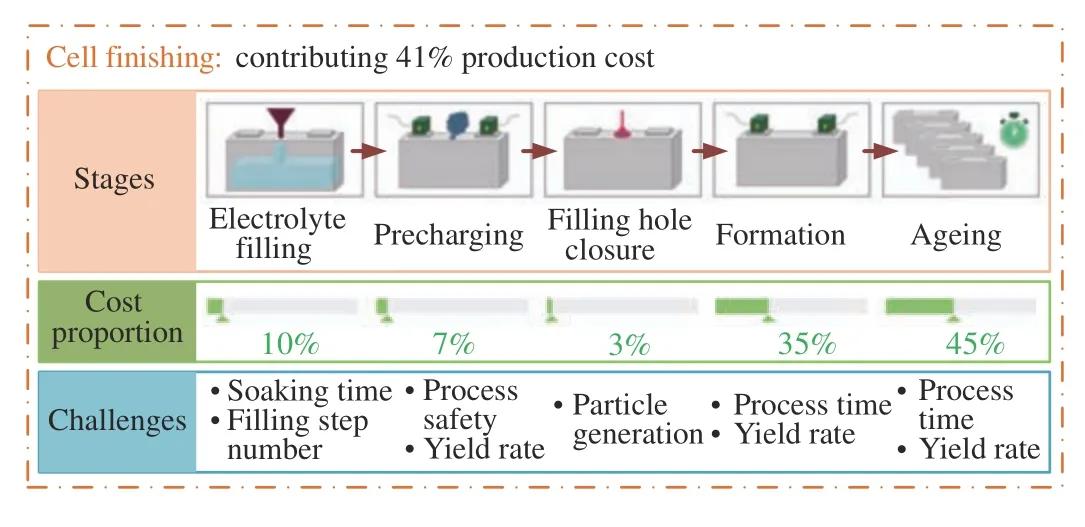

For cell finishing, the ion-conductive liquid will be first filled into the assembled cell in an electrolyte filling stage,followed by a pre-charging stage to pre-charge filled battery cell. Then the electrolyte filling hole will be closed in a stage of filling hole closure. After that, a formation and ageing stage will be carried out to initiate battery and identify micro short circuits within cells. Then the manufactured battery can be adopted for different applications. The stages of electrode filling, precharging, filling hole closure, formation, and ageing would contribute 10%, 7%, 3%, 35%, and 45% of the total cell finishing cost, respectively.

Fig. 3. Key stages of battery cell assembly.

Fig. 4. Key stages of battery cell finishing.

As the above-mentioned processes of battery manufacturing line contain many chemical, mechanical, electrical operations and often generates strongly-coupled variables in the order of tens or hundreds, the current mainstream solutions to analyze or evaluate its feature variables are still based on experiment experiences, expert advice, trial and error [6]. These approaches result in huge laborious and time costs, slow battery product development, and inaccurate quality control. In this context, reliable AI strategies have strong potential to accelerate and guide manufacturing optimization, as they could decouple correlations among various manufacturing parameters and further explore impact parameters towards resulting manufactured battery health performance.

B. AI-Based Framework for Battery Manufacturing Analysis

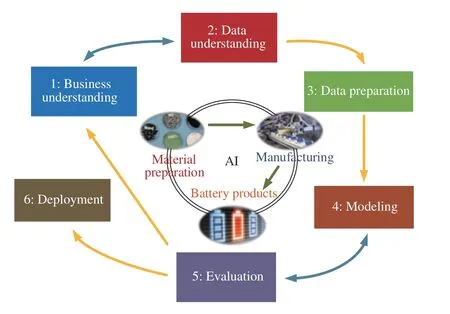

First, the framework is a key element to determine the performance of AI-based battery manufacturing analysis. To achieve efficient analyses of the whole battery manufacturing line, a classical AI-based framework called the cross-industrystandard-process (CRISP) [19] has been widely adopted, as illustrated in Fig. 5. This CRISP framework generally contains six steps including business understanding, data understanding, data preparation, modeling, evaluation, and deployment.Specifically, in the step of business understanding, target,requirement and restriction of AI-based activities would be the first set after exploring battery production line from a business perspective. Afterwards, several simple data analytic and visualization solutions (i.e., heat map, scatter plot) will be adopted to better understand data, while the obtained conclusions can be utilized to readjust the target of business understanding again. For the next data preparation, proper datasets from battery manufacturing need to be prepared for AI activity. This step is a heavily time-consuming but key process as the qualities of prepared data would highly affect model training. Therefore, suitable data preprocessing solutions (i.e., formatting, integration, standardization) need to be applied for generating high-quality manufacturing datasets.Then based upon these datasets, advanced regression or classification AI technologies will be utilized to derive AIbased models for meeting various analysis targets. In this process, AI-based model needs to be well trained considering both its structure and parameters. Next, for the evaluation step, AI-based results particularly in terms of the sensitivity analysis of battery manufacturing parameters and the predicted properties of battery products will be evaluated and explored. Here these results and conclusions could be visualized through the human interpretable graph, further helping battery manufacturers to obtain useful information and create new targets of battery manufacturing analysis.According to the obtained conclusions from AI technologies,the enhanced manufacturing solution or further evaluation can be proposed to boost battery manufacturing optimization and benefit the health performance of battery products.

Fig. 5. CRISP framework for battery manufacturing analysis with AI.

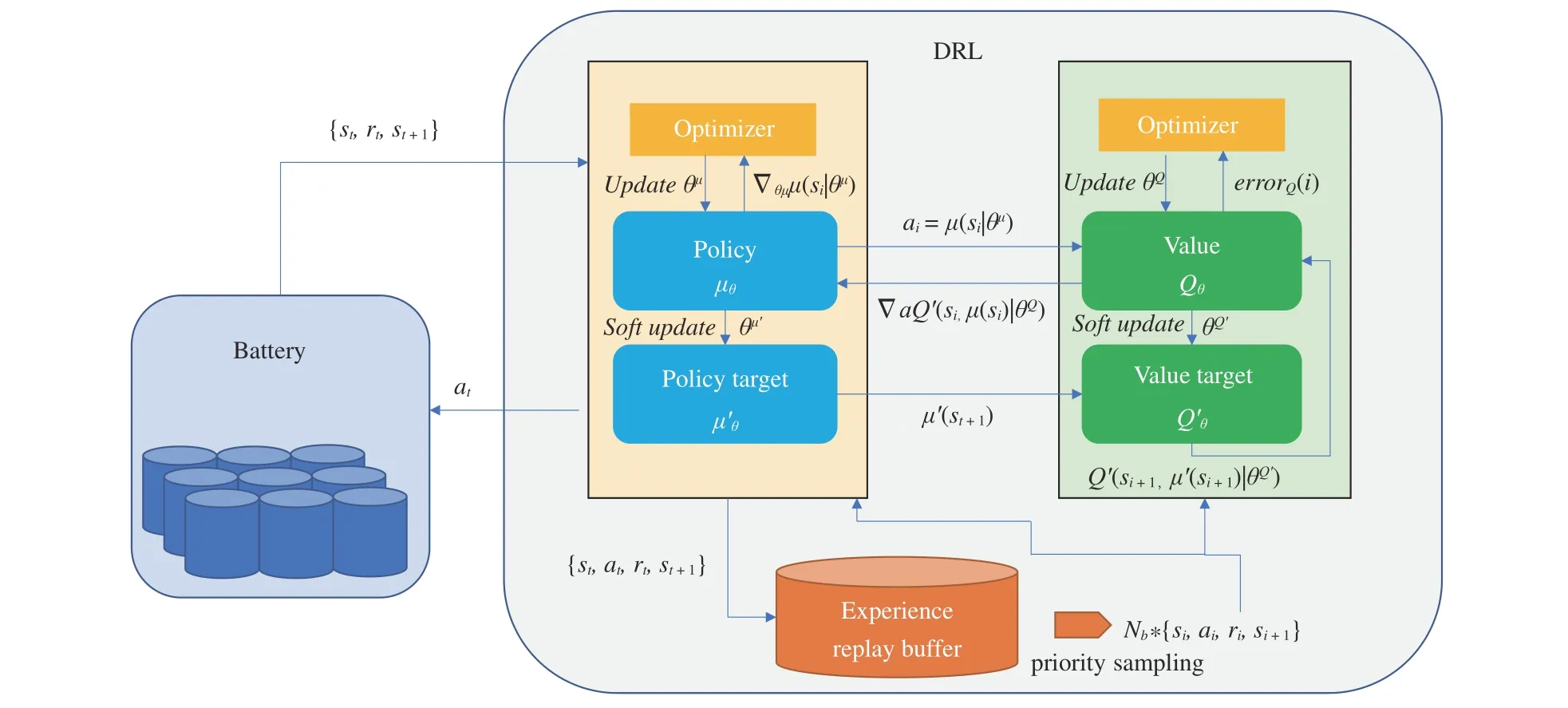

C. AI Tools for Battery Manufacturing

After designing a suitable AI-based framework, to perform efficient predictions and sensitivity analyses of battery manufacturing, AI tool especially machine learning (ML) is another crucial element. As there exist numerous AI tools, the key question here becomes how to select a suitable one to provide satisfactory prediction and sensitivity analysis results for different battery manufacturing requirements. Here the process parameters or variables of battery manufacturing are usually adopted as the inputs of ML to forecast properties of both intermediate and final battery products.

In this review, to well match the nature of battery manufacturing, AI tools are divided into non-interpretable and interpretable ones. Non-interpretable AI could just provide a prediction result without giving any sensitive information (i.e.,importance, interaction) of battery manufacturing parameters,while interpretable AI could provide this information. Yet, a key for battery manufacturing analysis is to not only predict manufactured battery properties but also present sensitivity analysis results of interested manufacturing parameters and variables. In this context, interpretable AI is gaining much more attention for the smart management of battery manufacturing.

1)Non-Interpretable AI

Support vector machine (SVM):Through using a kernel function to transform nonlinear cases into linear cases, SVM is a popular non-interpretable AI being competent to capture complex battery manufacturing processes when sufficient data are available [20]. For instance, based upon the classification output from SVM, Cunhaet al. [21] plotted a 2D graph to analyze the interdependency of three parameters (mass content of active materials, solid-to-liquid ratio and viscosity)in the mixing stage. In [22], after preprocessing battery manufacturing data by principal component analysis and Kmean, an SVM model was proposed to analyze the effects of three manufacturing parameters (solid-to-liquid ratio, polymer content and cosolvent ratio) on the solid-state electrolyte film.

For battery manufacturing, SVM is noticeable for handling quality classification issues as it could search the hyperplane separated classes with a maximal margin. In this case, a suitable kernel function needs to be carefully selected as it highly affects SVM performance. Besides, SVM prefers the battery manufacturing dataset with a small size as increasing training data size will lead to the increase of support vectors within an SVM, further causing a large computational burden.

Neural network (NN): For AI-based battery manufacturing applications, due to the advantages of providing competitive nonlinear predictions, another popular AI with none or weak interpretability is NN. For example, various NN models have been derived to forecast battery manufacturing’s intermediate product properties (electrode mass loading and porosity), cell quality (i.e., capacity) [21], [23] and also the potential CO2emission and cost-saving [24]. All these results indicate that NN-based models are capable of capturing battery manufacturing dynamics accurately if being well trained.

However, the performance of NN will be significantly affected by the adopted manufacturing data. In general, raw battery manufacturing data contains lots of outliers and missing values, which must be well preprocessed to ensure a high-quality dataset for NN training. In addition, the structure and corresponding parameters of NN are also other key elements to determining its performance. That is, without suitable structure and parameters optimization, NN is easy to cause overfitting or underfitting issues for different battery manufacturing analyses and prediction cases.

2)Interpretable AI

Linear model and quadratic model:Based upon a form ofy=k·in+sp, linear model belongs to the simple and compact AI tool for fitting a linear or hyperplane line to battery manufacturing data with strong interpretability. Hereinandyare inputs (manufacturing parameters of interest) and output(properties of intermediate or battery products), respectively.kis the weight vector to explain parameter importance, whilesprepresents a shifting parameter. For example, a generalized linear model was proposed in [23] for predicting formatted battery capacity/resistance, while electrode fabrication and electrolyte filling are identified as two crucial factors. Due to the compact structure, sensitive results of the linear model can be explained straightforwardly. However, as most battery manufacturing conditions have highly-nonlinear behaviors, a linear fitting is difficult to capture their relation. To further improve nonlinear fitting performance, linear model can be coupled with several higher-order terms to construct a quadratic model. For instance, in [25], the effects of formulation parameters on the manufactured battery electrode properties are quantified and explained by deriving different quadratic models. Due to a specific form with limited parameters, quadratic models also present low computational complexity and could be easily implemented. However, lows of battery manufacturing parameters are strongly-coupled with highly-nonlinear correlations, quadratic model is still difficult to handle such complex cases.

Tree-based AI models:As a decision-support AI through using flowchart-like logic, tree-based solution such as decision tree (DT), random forest (RF) and boosting-based tree presents strong interpretability to explain importance/correlations for battery manufacturing. For solo DT, through using a tree structure to divide complex prediction issues into numerous small ones, the importance of inputted manufacturing parameters can be easily explained by DT. For example, the AI models based on DT or its enhanced solutions were applied for property predictions of battery products via both regression and classification cases [21], [23], while the importance level of involved manufacturing parameters can be also quantified. However, DT’s structure is easy to be changed, making it unstable and inadequate for highly nonlinear battery manufacturing. To alleviate this limitation,numerous individual DTs can be combined by using various ensemble learning strategies. According to the bagging way,each DT within RF would be trained with the bootstrap subdataset, then the prediction performance of RF can be improved by combining all DTs’ outputs. For instance, in[19], an RF-based regression model was proposed to predict cell maximal capacity after the formation stage and quantify parameter importance from laser cutting, cell assembly and calendering. In [17], an RF-based AI model was designed to analyze the effects of manufacturing parameters on the energy efficiency of the manufactured battery. Based upon an RFbased classification framework, the importance and correlations of mixing and coating parameters on the quality classification of mass loading and porosity of electrode products were quantified in [26]. Besides, other ensemble solutions such as boosting are also used to combine DTs for analyzing battery manufacturing. For example, in [27], a RUBoost-based ensemble learning model was derived to handle the imbalanced issue for electrode quality classification, while the sensitivity analyses of various formulation parameters were also quantified.

In summary, tree-based AI models have shown obvious merits for battery manufacturing applications in terms of accuracy, robustness and interpretability. However, many potentials of tree-based AI still need to be explored. On the one hand, as many parameter pairs in battery manufacturing chain present strong-correlated, it becomes significantly meaningful to derive suitable AI solutions based on tree model to quantify manufacturing correlations. On the other hand, it is also promising to improve the interpretability of the tree model by coupling different interpretable solutions such as accumulated local effect and H-statistic [28]. In this case,more information such as dynamic effects and interactions of battery manufacturing parameters of interest can be quantified.

Others:Apart from the aforementioned ones, some other interpretable AIs are also notable. For example, through deriving a multivariate KPI-based AI model, effects of battery manufacturing towards properties of battery product (i.e.,capacity, resistance) were quantified and analyzed in [29].Based upon a least absolute shrinkage/selection operator model with least angle regression, effects of manufacturing parameters on the qualities of battery products (capacity and formation loss) were analyzed [30]. Through deriving Gaussian process regression-based model with automatic relevance determination kernel, effects of mixing parameters(active material mass content, solid-to-liquid ratio, viscosity)and coating comma gap on manufactured electrode mass loading were analyzed in [31]. Through building a sureindependent-screening and sparsifying-operator model, effects of pressure during calendaring on the macroscale or mesoscale properties of electrode products were analyzed in [32].

Although satisfactory prediction or analysis performance could be obtained in these researches, the transferability and generalization from these AI-based methods are still unknown for other battery production analysis applications. In light of this, more experiments need to be given to further explore their data analysis performance in the battery production domain.

III. SMART BATTERY WITH AI

After manufacturing, battery needs to equip advanced sensing technology to obtain valuable data signals for the AIbased battery management for improving its safety, efficiency and health. This section reviews the state-of-the-art sensing techniques applicable for both regular and embedded measurement. The concept of the smart battery and the associated reconfiguration-enabled smart battery system are discussed.

A. External and Embedded Sensing

Smart battery refers to the battery system equipped with advanced sensors. The embedded sensors applied to smart batteries can be divided into external and internal embedded sensors. These sensors can monitor the data of the circuit current, voltage, temperature, electrochemical reaction,component parameters, and battery volume, respectively.According to the mathematical model and algorithm of battery management, the battery parameters obtained through sensors can comprehensively identify and master the performance and health of the battery to realize intelligent management.

1)Current Measurement

The current measurement is indispensable for the smart battery, as it plays a pivotal role in intelligent-oriented battery safety, state estimation, fault tolerance, and so on. The mainstream technologies of current sensing in traditional batteries are divided into two categories: the hall-effect sensor and the shunt resistor, which are also applicable to smart batteries.

The principle of the hall-effect sensor is detecting the current-propositional voltage by the electro-magnetic induction at the sensor terminals [33]. Although it has remarkable advantages such as electrical isolation and insensitivity to temperature changes, the hall-effect sensor also possesses unignored disadvantages such as low accuracy in small-current monitoring, susceptibility to electromagnetic interference,large volume and high cost. As a consequence, the hall-effect sensor theoretically exhibits most of its applications on the module or pack current measurement of the smart battery.

On the other hand, the shunt resistor straightforwardly relies on Ohm’s Law to identify the current by the voltage drop in a high-precision, low-value resistor, which is serially connected to the measured circuit. Attributed to its simple structure and low resistance, the shunt resistor promises a high current measurement accuracy of up to 0.1% [33] and a negligible influence on the volume occupation and temperature rise of the battery pack. However, the requirement of extra isolation circuitry and sensitivity to the surrounding temperature of the shunt resistor also needs to be considered in practical application. In summary, the shunt resistor is more suitable for cell-level current sensing of the smart battery.

2)Voltage Measurement

Accurate voltage information is of great significance for fault-tolerant control, determination of charge/discharge termination, and parameter/state calculation of the smart battery. The most widely-used method for voltage measurement is the integrated circuit sampling, where the battery is connected to an analogue-to-digital converter for collecting battery voltage information. At present, the battery voltage sampling has realized the chip industrialization, which can be potentially extended for the use of smart batteries, such as the intelligent battery monitoring chip MM9Z1_638 launched by NXP [9]. Moreover, the embedded voltage sensor also exhibits its potential for the application of in-situ voltage measurement of smart batteries [28].

3)Temperature Sensor

It is well-recognized that the temperature is not uniformly distributed between the battery’s inside and surface, especially during high-rate operation. It has been reported that the temperature rise could reach five times higher in the internal than the battery surface [34]. The excessive temperature buildup can significantly affect the physical and electrochemical process in the cell and potentially lead to irreversible damage of battery health performance or even hazardous thermal runaway. This truth confirms the necessity for equipping the Li-ion battery with internal embedded temperature sensors.

The resistance temperature detector (RTD) has been widely employed for battery internal temperature measurement.Illustratively, a commercial RTD was embedded into a coin cell with two isolation diaphragms between cathode and anode[35]. Compared to the commercial RTD, the thin-film RTD is more promising since it can minimize the impact of sensor embedment on the performance of battery. A thin-film multipoint RTD sensor (50 μm in thickness) was implanted into the Li-ion battery cell for internal distributed temperature measurement [36]. The embedded RTD sensor was also used in specially-designed Li-ion batteries like the all-climate battery [37]. Within this structure, the resistance of heating foil presents high linearity with the surrounding temperature,which motivates the direct use of heating foil for battery internal temperature sensing.

Thermocouples have been inserted into the Li-ion battery to measure the single-point/distributed internal temperature.Illustratively, T-thermocouples were inserted in pouch or cylinder cells [38] for internal temperature monitoring. The Ktype thermocouple was embedded in the middle of the jelly roll forin-operandointernal temperature measurements [39],and a significant radial temperature gradient of 3.5 ±0.2°C/mm was observed. Unlike the aforementioned wirebased methods, a copper foil thin-film thermocouple was embedded into a pouch cell forin-situand internal temperature measurement [40]. The acquisition of real-time internal and spatially-distributed temperature provides valuable information for future smart management with more detailed self-diagnosis data.

4)Expansion and Pressure Measurement

Li-ion batteries undergo reversible stress/strain changes which cause the cell-level volume changes during operation.Moreover, the long-term degradation and excessive utilization further cause irreversible volume changes. For example, the electrolyte of the Li-ion battery decomposes and generates a large amount of gas when excessively used [41]. This can further trigger the serious thermal runaway event. Therefore, it is of great value to measure the battery volume for enhanced battery monitoring and safety management.

The external pressure sensors have been frequently used for Li-ion battery monitoring. For example, the pressure sensor used by General Electric Company works by inducing electromagnetic eddy currents in the surface material of the Li-ion battery. The change in the battery volume can be directly mapped from the change of eddy current. In particular, the greater the distance between cells, the weaker the eddy current. Another external embedded sensor is a carbon nanotube coated sensor. This sensor is fabricated by spraying a carbon nanotube layer on the sensor with better deformability [42].

Despite the effective measurement of expansion and pressure at the battery surface, the internal strain is much more complicated and more linked to the inner physical processes of the Li-ion battery. Errors from external pressure sensors are complicated by strains in the battery casing that are not caused by internal expansion, such as strains caused by constraints between cells. When the airstrike between cells is taken up by battery swelling, the swelling inside the battery is not observable by the strain of the battery case. From this viewpoint, the embedded sensing of expansion and strain is more meaningful to reflect the real status of battery.

5)Fiber Bragg Grating Sensing

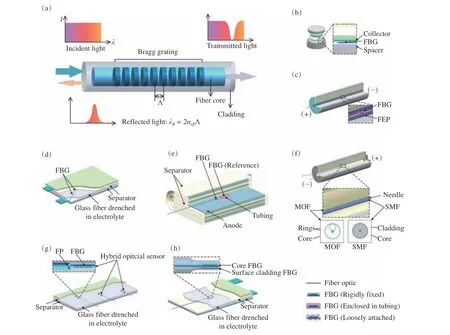

The optical fiber bragg grating (FBG) sensors are an emerging type of sensor that is generally capable of sensing changes in strain and temperature. Due to its small formfactor, chemically inert, and immunity to electromagnetic interference, the FBGs have been used to measure battery cells in recent years. Early explorations applied the FBGs to measure cell surface signals. In the in-depth exploration, the FBGs have been embedded inside the battery. It will be described in detail below.

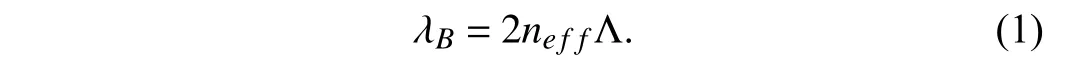

The optical FBG sensors are formed by etching periodic grating planes in the core of an optical fiber, as shown in Fig. 6(a). The spacing between the gratings is defined as Λ,and the other characteristic parameter,ne f f, is called the effective refraction index. A detailed discussion has been presented in our previous work [9]. According to the Bragg conditions, the Bragg wavelength λBis described as

Therefore, since bothnef fand Λ are affected by mechanical stress and thermal environment, the optical FBG sensors can be used to measure strain and temperature.

Extensive efforts have been made to embed the FBGs inside different types of batteries for internal measurement, like the cylindrical cell [43], coin cell [44] as shown in Fig. 6(b),cylindrical cells [45] illustrated in Fig. 6(c), and a customized pouch cell in [46], as shown in Fig. 6(d). One important merit of FBG sensor is the simultaneous measurement of multiple parameters like temperature and strain. It can be seen from (1)that λBis affected by bothnef fand Λ. Therefore, the decoupling of the cross-sensitivity between temperature and strain can potentially promise the co-measurement of them. In recent studies, a variety of decoupling methods are proposed,such as two FBGs in series [47] as shown in Fig. 6(e), a specially designed micro-structured FBG [10] as shown in Fig. 6(f), tilted fiber Bragg grating (TFBG) [48], and the FBG combined with FP (optical Fabry-Perot sensor) [9] as shown in Fig. 6 (g). The dual FBG fiber optic sensors are also designed to observe the strain and temperature of the battery during thermal runaway [49], as shown in Fig. 6(h).

Besides, other types of fiber optic sensors have also been used in batteries. For instance, the fiber optic evanescent wave sensor [50] was used to directly sense the changes in optical properties of electrode materials. Rayleigh scattering sensor[51] was used to achieve distributed measurement of battery internal temperature.

In summary, the optical FBG sensors show promising application due to their small size, fast thermal response,simultaneous measurement of temperature and strain changes,multiplexing and distributed measurements, etc. Combining the FBGs with AI algorithms, smart batteries can achieve advantageous properties. In further work, the following issues should be carefully considered and properly resolved: the tolerance to the internal cell environment, decoupling temperature and strain signals, and the miniaturized and economical interrogator.

B. Reconfigurable Battery System and Control

The smartness of the smart battery not only exists in the advanced sensing but also reflects in the implementation level.In addition to the implementation of battery balancing which is commonly adopted in traditional battery, the reconfigurable battery topology, an innovation on the unchangeable static connection of intra-pack cells, are emerging in recent years as a special form of future smart batteries [9].

Fig. 6. Working principle of the optical FBG sensor and the integration methods of the optical FBG sensors embedded into battery cells [9]: (a) principle of FBG measurement; (b) embedded into coin cell; (c) embedded into the cylindrical cell; (d) embedded into pouch cell; (e) decoupling of temperature and strain;(f) micro-structured FBG sensor embedded in a cylindrical battery for temperature and pressure measurement; (g) tilted FBG sensor for temperature and refractive index co-measurement; (h) FBG-FP dual sensor for decoupled measurement of temperature and strain.

The most prominent feature of the reconfigurable battery is to adaptively change the connection modes between cells or modules through the switches deployed at cell surroundings.The above change of the connection mode contains two aspects: the transformation between the series and parallel connection, or the adjustment of cell access status. By freely changing the series-parallel form among cells, the mutual back-up of the parallel connection and the voltage superposition of the series connection can be both obtained, in addition to the cell-current redistribution during the configuration changing process. With the purposeful access or exit of cells, the time-domain intermittent on/off of the cells or modules is possible, promising the all-cell independence and further the potential for various forms of performance optimization of the battery pack.

1)Reconfigurable Topologies

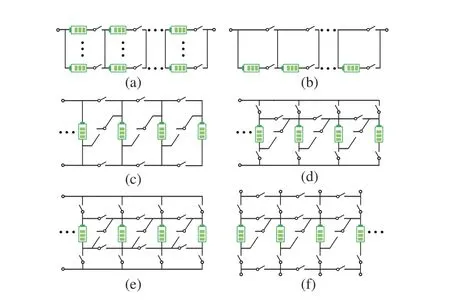

The number of switches allocated to each cell is directly related to the overall reconfigurability of the pack. Diverse reconfigurable topologies with 1~6 switches per cell have been reported in the existing literature [52].

1~2-switch topologies:Duo to the small number of switches around each cell, the reconfigurability of topologies with 1~2 switches is quite limited. For instance, the 1-switch topology shown in Fig. 7(a) only supports the access and exit of the cell. When the number of switches increases to 2, the reconfigurable topology in Fig. 7(b) allows the bypass of cells in addition to the access-exit at the cell-level. Although the reconfigurability is relatively weak, the assembly difficulty and manufacturing cost of 1~2-switch topologies are lower than that of complex topologies.

Fig. 7. Reconfigurable topologies with different number of switches.

3~4-switch topologies:The typical 3~4-switch topologies are depicted in Figs. 7(c) and 7(d) respectively. Other reconfigurable topologies with 3~4 switches can be obtained by changing the position and connection form of switches.The characteristics of this kind of reconfigurable topology with a medium number of switches are the arbitrary change of cell connection. For example, the 3-switch topology shown in Fig. 7(c) supports the all-cell configuration changing between the series, parallel and parallel-series connection, and the 4-switch topology in Fig. 7(d) additionally supports the seriesparallel configuration. As the least-number-of-switch topology allows the configuration changing, the 3~4-switch topology reaches a relatively ideal compromise between complexity and flexibility.

5~6-switch topologies:Adding additional switches to the configuration-changeable 3~4-switch topologies brings 5~6-switch topologies with more functional expansion. In specific,the 5-switch topology depicted in Fig. 7(e) is able to cope with any cell fault under any cell connection. By adding another switch, the 6-switch topology in Fig. 7 (f) possesses extra charging/discharging ports at every individual cell, and thus multiple loads with different voltage requirements can be simultaneously satisfied by a pack made up of reconfigurable cells. Although the cell flexibility and fault-tolerance of the 5~6-switch topologies both have been enhanced, numerous switches inevitably weaken the reliability and increase the assembly difficulty of the pack.

It can be seen from the comparison of different topologies that the reconfigurability of battery is proportional to the number of switches set at each cell. Although the increase in the number of switches can significantly improve the performance of battery in various aspects, it also brings disadvantages of complex configuration and difficult assembly. In real applications, appropriate reconfigurable topology should be selected based on the specific requirements of different scenarios to achieve the balance of complexity and flexibility.

2)Reconfiguration for Long-Life Battery

With the ability of configuration adaptive switching, the reconfigurable battery promises multiple merits, such as efficient equalization, charging efficiency improvement,thermal balancing. Focusing on the long-life battery discussed in this paper, the reconfigurable topology can prolong the lifetime of the battery pack through three ways: faulty cell isolation, efficient equalization and SOH-oriented regulation.

Faulty cell isolation:Because of the permanently fixed connection between battery cells, the countermeasures that a traditional battery pack can take in the face of cell failures are quite limited. Once any single cell exceeds its safe operating range, including current, temperature, etc., the entire battery pack will be cut off immediately before the single-cell fault propagates and causes more serious consequences. This simple fault handling method is inefficient, as one cell failure in the pack causes the failure of the whole battery pack.

Attributed to the all-cell independence of the reconfigurable topology, the faulty cell can be isolated without affecting the operation of the entire pack when any cell fault is detected.For parallel cell faults, the cell isolation is relatively simple.When a parallel cell fails, the switch connected to it is directly disconnected, and the flux originally shunted to the fault cell is undertaken by other parallel cells. As for the series cell faults, the reconfigurable topology is required to be functioned with cell bypass to ensure the continuous conduction of the series circuit when the isolation performs. Moreover, redundant cells are usually needed to compensate for the voltage drop caused by the isolation of series-faulted cells [53].

Efficient equalization:Due to the manufacturing tolerance,environmental difference and temperature gradient, cells within the pack are prone to capacity inconsistency.Traditional battery management strategies terminate the discharge of the whole battery pack when the weakest intrapack cell reaches the discharge cut-off, regardless of the considerable capacity in other cells that is unutilized. In this way, the weak cells always bear the heaviest depth of discharge, which inevitably leads to its accelerated ageing and the premature retirement of the whole battery pack.

Facing the above situation, a series of reconfiguration-based efficient equalization strategies are proposed for the long-life battery, which falls into two categories, i.e., rule-based and optimization-based. The rule-based strategies are characterized by the timely bypassing of the weakest cell within the pack. For example, the last cell in the descending voltage or state-of-charge (SOC) sequence was alternately isolated in[54], [55] respectively. By comparison, the optimizationbased strategies have the merit of guaranteed optimality in equalization. Targeted for different purposes, the optimization algorithms like dynamic programming (DP) was used to explore the optimal cell combination with maximum pack capacity, for searching the optimal reconfiguration-based operation policy of cell balancing, or to optimize the configuration combination for the minimum SOC consumption [56].The above methods all contribute to the realization of efficient equalization and further the long-life battery.

SOH-oriented regulation:The above reconfigurationbased faulty cell isolation and efficient equalization extend the lifetime of the battery pack from indirect angles. In fact, the reconfigurable smart battery also provides a straightforward way for the pack life extension by SOH-oriented optimization.

The essence of reconfiguration-based battery life extension is assigning the smallest load current to lower-SOH cells. This is possible because any two cells and any cells to load in the reconfigurable topology are decoupled. In this way, cells with different initial SOH gradually converge along with chargedischarge cycles, and together reach the pack-retired SOH value eventually. Within this context, an intelligent battery system where the cells can freely choose its belonging module through a reconfigurable switch array in [57]. With the exploitation charge recovery effect and cell scheduling scheme, the lifetime of the battery is extended by 22%.Another attempt is coordinating the charging time and individual cell lifetime for the maximum lifetime of the pack through the model predictive control (MPC) [58]. Although the research object in [58] is supercapacitors, the reconfigurable property of the employing algorithm makes it suitable for the SOH optimization of battery pack. Authors in [59]examined the life extension effect of a DP-based management strategy of the reconfigurable battery, where the cells with more energy are activated more often than worse performing cells. Results show a lifetime enhancement of more than 16%is achieved by the reconfigurable topology compared with the conventional battery system. All these clues confirm the feasibility of SOH-oriented regulation for a long life battery on the basis of reconfiguration technology.

IV. BATTERY LIFE DIAGNOSTIC WITH AI

During battery operation, effective life diagnostic is fundamental for providing information of battery health. This section focuses on the discussion of two key elements of battery life diagnostic: battery SOH estimation and ageing trajectory prediction. The SOH represents the battery current health status [55], while the ageing trajectory stands for battery future health status such as the length of time from present point to the end of total service life [56]. In real battery life diagnostic, battery SOH estimator usually adopts AI to capture the underlying mapping among various health features and battery current capacity status, while battery ageing predictor generally uses the historical and current health information as the inputs into AI to predict battery future ageing information such as future ageing trajectory and battery remaining useful life (RUL).

A. Battery SOH Estimation

State-of-health (SOH) estimation is crucial to provide battery current health status information [60]. AI-based solutions such as the model-based [61] and data-based approaches [62] have been widely studied in the literature for the high-fidelity SOH estimation of battery. In general, AIbased battery SOH estimation consists of offline training and online estimation. During the training process, the informative health indicators should be extracted based on the ageing data and the AI-based model learns and updates the weights and biases to fit the training data. The well-trained model is then applied on battery operation management system to estimate real SOH based on the raw data. In this section, the AI-based methods are grouped into statistical data-driven AI and neural network-based AI.

1)Statistical Data-Driven AI

For the statistical data-driven AI, they are generally based on the combination of statistical theory and other mathematical principles.

Support vector machine (SVM):SVM has been viewed as an effective statistical data-driven AI technique for battery SOH estimation. It belongs to one type of kernel functionbased solutions to transform the nonlinear issue with lowdimensional space into the linear issue with higherdimensional space. SVM could make battery life diagnostic with the following equation as:wherehandhirepresent battery health features,K(·) stands for kernel function,Wiare weights to connect feature space and output,εis a term to reflect independent noise. Current estimators mainly adopt SVM as a regression tool for continuous battery ageing value prediction. For example,based upon the constant charging process, some effective features were extracted from incremental capacity and differential voltage curves to estimate battery SOH through using SVM [63]. Differential temperature [64] and the time interval of an equal voltage difference [65] have been also adopted as the input features for the SVM model to estimate battery SOH. Similarly, the nonlinear relationship between entropy features from charging data and battery SOH was established by SVM [66], where the elevated efficient features could improve the efficiency of the SVM-based SOH estimator.

It should be known that by involving different kernel functions, the performance of the SVM-based battery SOH estimator can be improved. For example, the radial basis function was employed as the SVM’s kernel function, leveraging an exhaustive searching algorithm to search the optimized parameters for SOH estimation. The kernel parameters can be also flexible according to different training samples,making the SVM estimator become more robust to practical scenarios. To achieve accurate estimation results regardless of the working conditions for batteries, a least square SVM that fully uses the support vectors to fuse the features of different training sets was designed in [67], making the estimator becomes robust to temperature, discharge rate and depth of discharge. Besides, SVM could also serve to update the parameters of model-based SOH estimation method. The offline established SVM can update the current SOH/capacity value as the model’s parameters. The battery degradation model can be established by using SVM to formulate a statespace function covering battery capacity [68].

In summary, SVM presents good performance to cope with small-sample problems, nonlinear characteristics, and highdimensional issues. Therefore, it is an effective choice for estimating battery SOH.

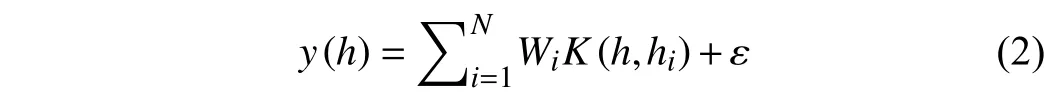

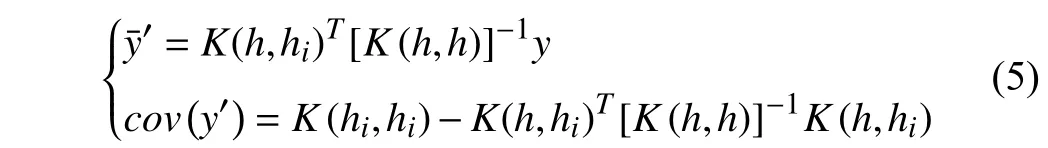

Gaussian process regression (GPR):GPR is another type of kernel function-based statistical AI tool through coupling Bayesian framework. By defining a mean function and a kernel function asM(·) andK(·), the probability distribution of GPR can be described as

Supposing there exist the same Gaussian distribution betweenbatteryhealthfeatureshandhi,thecorresponding outputy′can bepredictedbyaconditional distributionas

with

wherey′,, andcov(y′) represent the GPR posterior prediction, its mean and covariance values, respectively.N(·)stands for a normal distribution.yis the output vector related toh. In this way, GPR has the ability to provide probability distributions by deriving covariance vectors around the mean prediction values. Due to this uncertainty quantification nature, GPR has been widely adopted in the applications of battery SOH estimation. For example, Sonet al. [69] utilized GPR to fuse multi-physics features such as the loss of active material (LAM) and the loss of lithium-ion inventory (LLI)for estimating battery SOH. GPR model can also be promoted based on modifying the kernel function. In [70], GPR is compared with linear regression, SVM and relevance vector machine under different operating conditions for the three types of batteries and has the best performance with its rootmean-square error lower than 1.3%.

Bayesian network (BN):Bayesian network is a directed acyclic graph, which is suitable for illustrating uncertain and probabilistic events. Each node in the Bayesian network contains practical meaning and needs to be designed artificially. Therefore, the BN framework is capable of incorporating uncertainty and causality.

In [71], an online battery SOH estimation with the dynamic Bayesian network model that uses the charging voltage profile as input was proposed to provide the probability of the battery being in different capacity classes. According to this previous model, current and temperature profiles were also added as the hierarchical Bayesian model inputs to estimate battery capacity [72]. BN model was further validated on real-world operational EV data incorporating the vehicle’s physical properties and environment-related parameters [73]. Results show that the model can capture the increasing SOH dispersion trend during battery ageing. The estimated SOH range can fully cover the calibrated SOH at different ageing stages.

2)Neural Network-Based AI

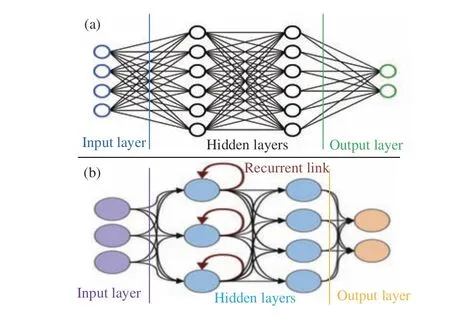

The neural network (NN) was designed to mathematically mimic the genetic activity of the human brain. It usually consists of one input layer, several hidden layers and one output layer. For the SOH estimation, the NN-based method typically trains the nonlinear mapping between measurable features and battery capacity through its structures, and the trained model is further used for real-time SOH estimation.

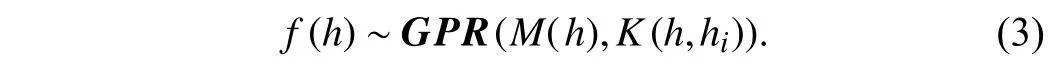

Feedforward neural network (FNN):FNN is the primitive neural network with forward propagating output, as illustrated in Fig. 8 (a). Back propagation NN (BPNN), radial basis function (RBF) NN and extreme learning machine (ELM) are commonly used structures belonging to this type.

Fig. 8. NN structure: (a) FNN; (b) RNN.

BPNN is coupled with forward propagating output and back propagating errors. It fine-tunes the weights and thus, after several iterations, the model becomes more reliable and is adopted in SOH estimations. For example, a three-layer BPNN was proposed to estimate battery SOH, whose inputs are the parameters of the first-order equivalent circuit model(ECM) and output is the current value of SOH [74]. Despite high accuracy, the model is not feasible under various working conditions. To this end, the resistance in the ECM was combined with stress factors like temperatures, charge rate and depth of discharge to train the SOH estimator based on BPNN [75]. Furthermore, a sparse auto encoder (SAE)-based BPNN structure was designed to estimate battery SOH based on voltage data at a later constant-current charging stage which is robust to the uncertain initial charging state[76]. SAE was adopted to extract the hidden feature related to battery ageing state out of the battery voltage data in its later charging stage, and then this ageing feature was used to estimate battery SOH through a BPNN.

RBF NN is widely adopted due to its strong fitting abilities.The RBF training process can be online, which means that it is convenient to adjust the weight of the NN online and obtain good estimation performance. Despite the simple structure,the RBF network has also been validated under several kinds of discharging conditions. Maoet al. [77] also utilized RBF NN to integrate original feature data due to its simple structure and dynamically updated parameters.

ELM is a random vector functional link NN estimating only the output weights after the input weights and the hidden layer biases are chosen randomly. Therefore, ELM has much less amount of computation and is much faster than other learning methods. Gouet al. [78] validated that ELM training time is much lower than conventional algorithm based on Matlab.However, the whole life cycles are tested to evaluate the estimation accuracy and the relatively low accuracy and poor stability are still problems for ELM. To achieve high accuracy and good generalization performance, a bagging-based ELM was proposed to estimate battery SOH [79]. Bagging was used to reconstruct the dataset so that multiple base-level ELMs can be trained. However, the randomness in ELM could generate unstable outputs in its implementation stage which leads to the fact that ELM is commonly coupled with other algorithms.

Recurrent neural network (RNN):RNN couples the hidden layer with a loop that updates the weights and biases in the hidden layer with sequence data as inputs, as illustrated in Fig. 8(b). It is a promising method to capture the long-term correlations suitable for SOH estimation. It has been proved that RNN is a suitable candidate for handling sequential data for estimations but has a demerit of short-term memory [80].To mitigate this disadvantage, long short-term memory(LSTM) and gated recurrent unit (GRU) are designed with the capability of controlling the information flow in a series of sequences.

In LSTM, the gated recurrent unit is used to control gradients information propagation. Based on the analyzed features, a standard LSTM model was employed to achieve SOH estimation in different types of batteries [81]. However,unwanted error information remains in the memory after several cycles. To this end, a constant error carousel was added to the output gate in LSTM to improve SOH estimation based on the NASA dataset [82]. Also, a deep LSTM was proposed and the parameters of the model can be properly adjusted in real-time by using the historical data [83].Furthermore, the proposed method allows variable input dimensions, which provides a better understanding of the historical data and ensures good generalization ability.

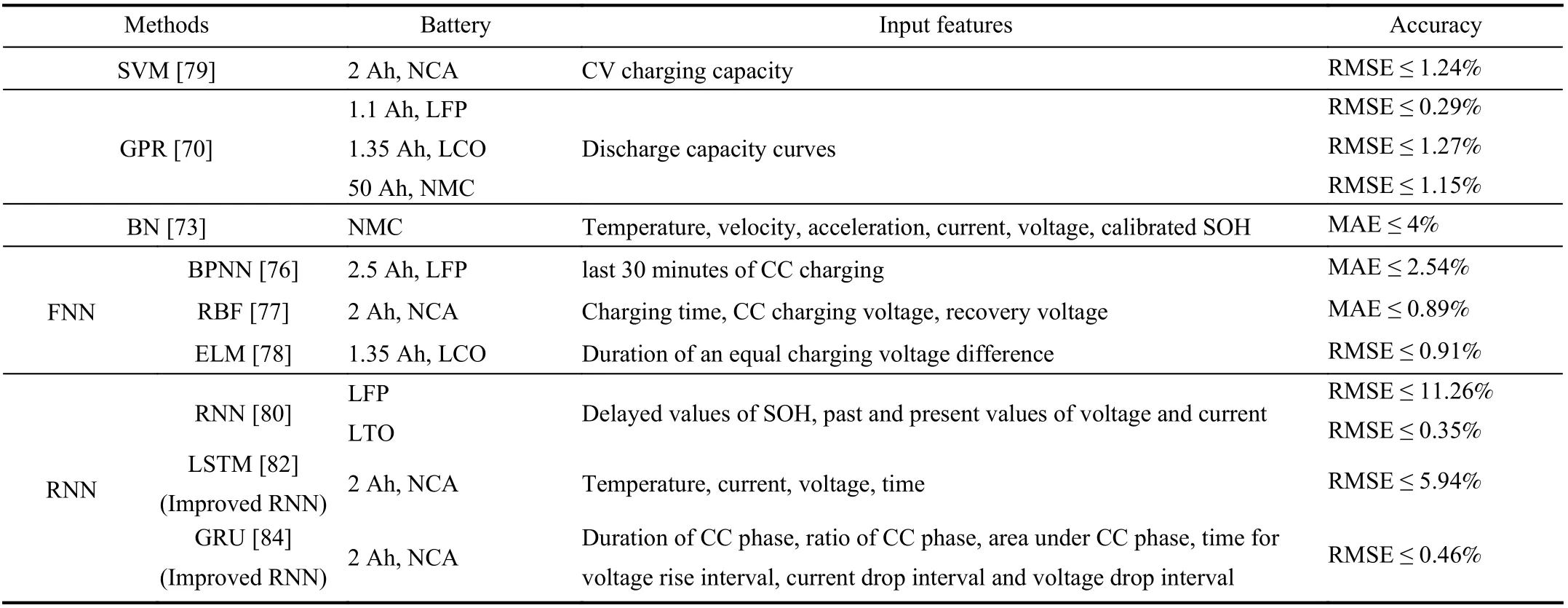

TABLE II COMPARISON OF VARIOUS AI METHODS FOR SOH ESTIMATION

GRU NN addresses the problem of vanishing gradients like LSTM with fewer parameters. It uses the update gate and rest gate to control the amount of past information that should be taken into consideration and which will be left behind. The proposed GRU-based method has been implemented and tested on battery data gathered at various temperature values giving similar estimation errors with LSTM with fewer parameters. Although this model alleviates long-term dependency, it cannot effectively select the relevant input feature when dealing with multivariate time series prediction.To address this problem, a dynamic spatial and temporal attention-based GRU model for SOH estimation was proposed[84]. 1D convolutional layer as the information embedding takes into account spatial correlations of the inputs while GRU captures dependencies for time steps.

Table II illustrates the detailed performance comparison among various AI algorithms for battery SOH estimation.According to the above comparison and analysis from the perspective of theory and application, it can be concluded that AI-based technologies are able to possess immense potentialities in battery SOH estimation. The opportunities of using the great advantages of AI in future battery SOH estimation research are worthy of being explored considering the advancement of the algorithms and engineering applications.

B. Battery Ageing Prediction

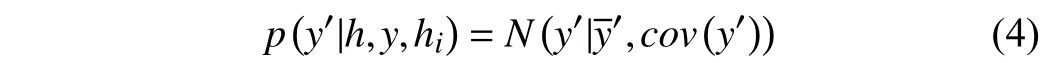

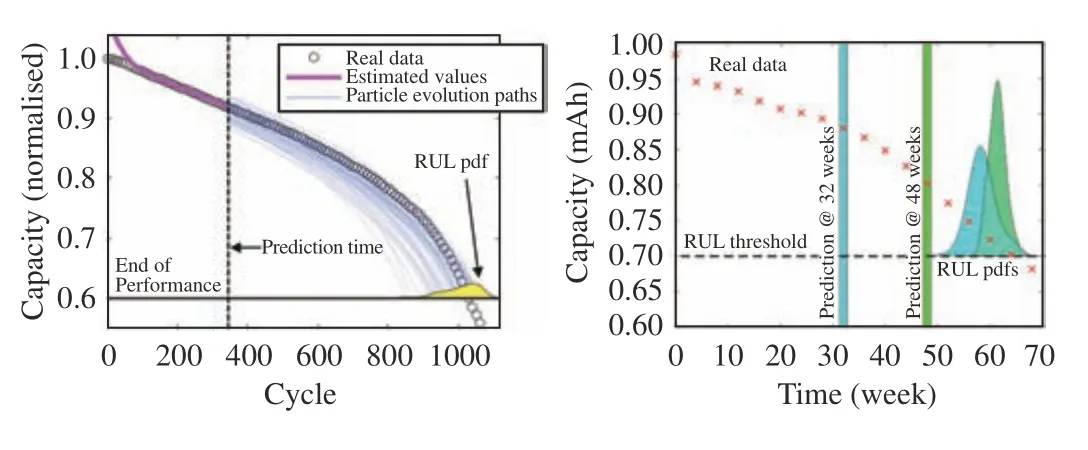

Battery ageing prediction is another key part of battery life prognostic to provide future health information of battery. The existing research on battery ageing prediction includes the battery future capacity and RUL prognostics [16], as illustrated in Fig. 9. Future capacity prognostics refers to the prediction of battery future capacity trajectory based on its usage history [85]. RUL prognostics refers to capturing how many cycles a battery would reach its failure threshold.

Fig. 9. Battery ageing prediction: (a) Future capacity prognostics; (b) RUL prognostics [16].

Numerous AI-based solutions have been designed to achieve reasonable battery ageing prediction, which can be divided into non-probabilistic one and probabilistic one. In the former, the output of the AI model is just a single point without any information to reflect its probability distribution,while both mean value and probability distribution will be output from probabilistic AI. For real applications, a key aspect of battery ageing prediction is not only providing point prediction value but also the uncertainty level of such prediction. In this context, probabilistic AI gains more attention for the uncertainty management of battery ageing prediction.

1)Non-Probabilistic AI

Neural network (NN):Through mimicking human brain activities, NN is a powerful AI in the field of future ageing prediction. Both FNN and RNN have been also successfully adopted to achieve single point prediction of future capacities and RUL. For FNN, input data would just go in one direction to predict battery future ageing. For example, after analysing voltage information from the charging curve, an FNN was designed in [86] to predict battery RUL. Through involving the migration concept, a migrated FNN was proposed in [87]to predict battery ageing trajectory, while the corresponding experiment time to obtain training data can be saved. For RNN, one obvious difference between FNN is that a recurrent link is existed to provide a feedback connection. Due to this recurrent link, the previously inputted information could be kept for a period of time, making RNN become efficient for capturing correlations of battery ageing. Battery ageing usually contains hundreds of cycles and the capacity information within these cycles is highly correlated. In this context, RNN is promising to capture the long-term correlations of battery degradation, making it becomes popular in future ageing prognostics. For example, an RNNbased framework was derived in [88] to capture the long-term tendency of Li-ion battery degradation. In [89], through combining the benefits of both RNN and GPR, a hybrid AI model was designed to predict battery future ageing and achieve uncertainty management for battery cycling mode.

One obvious benefit of NN is its strong ability to capture highly-nonlinear relations of battery ageing. However, a large amount of input data are generally needed for NN training and validation. Besides, for large-scale battery ageing prognostics,the computational complexity of NN is still a bottleneck. As NN structure is crucial for battery ageing prediction performance and its optimization belongs to the open technique issues. Instead of traditional trial and error with high time consumption, automatic AI solutions such as fast recursive algorithm [90] are worthy of combining with NN solutions.

Support vector machine (SVM): Based upon various kernel functions, current battery ageing prediction solutions mainly adopt SVM in the regression way to predict continuous ageing point, known as support vector regression (SVR).SVR here is realized through searching the minimum margin fit. For example, through using particle swarm optimization to tune kernel parameters, an SVR-based model was designed in[91] to predict battery RUL with improved accuracy. Through first using a feature vector selection approach to decrease data size from two battery health indicators, an SVR-based model was designed in [61] to capture underlying mapping between health indicators and future capacities, leading to an improved RUL prediction.

For battery ageing prediction, SVM is competent for training datasets with small sizes. However, the amount of support vectors would increase when the training data size becomes larger. To further enhance the performance of SVR in large-scale training cases, decremental solution and incremental solution [92] could be adopted in SVR training.

2)Probabilistic AI

In comparison with non-probabilistic AI, prognostic one could handle uncertainty from the measurement, operation condition and model itself. In real applications, probability theory will be adopted by probabilistic AI to quantify uncertainties, where the probability distributions of battery ageing prediction could be utilized for related uncertainty management.

Gaussian process regression (GPR):Deriving from the Bayesian theory, GPR presents superiority in battery ageing prognostics in terms of being flexible, non-parametric and probabilistic [93]. Through using different covariance (kernel)functions, GPR could realize mean prognostics of battery future ageing and present variance around this mean prediction for quantifying associated uncertainties [15]. For example, according to a parametric model for describing prior information of battery ageing, a GPR-based model with multiple outputs was proposed in [94] for battery RUL prediction. Based upon the combination of electrochemical impedance spectroscopy (EIS) and GPR, both battery SOH and RUL were predicted in [95]. A GPR model with an effective automatic relevance determination (ARD) structure was proposed in [96] to predict battery calendar ageing, while the underlying mapping among future capacity, storage temperature, and SOC can be captured. In their later work[97], a modified GPR model considering the battery degradation mechanism and knowledge was designed to predict battery future capacities under various cyclic conditions. To reduce ageing experiment and consider the effects of knee point, a migrated GPR was proposed in [98] to predict battery future two-stage ageing trajectory, which could significantly benefit battery second-life applications.

The performance of GPR would be heavily affected by its mean and covariance functions, which must be well designed.As battery ageing is complex and would be affected by various factors, just using a single covariance function is easy to cause unreliable prognostics especially for capturing highly nonlinear mapping with multi-dimensional inputs. In this context, the isotropic kernel with improved structures such as ARD is preferable. To avoid overfitting caused by the improper hyperparameters, the solution of minimizing GPR’s negative log marginal likelihood [99] is suggested.

Relevance vector machine (RVM): RVM is similar to SVM but coupled with a probabilistic method. Through using a Bayesian framework with high sparsity to describe weights,probabilistic battery ageing predictions can be offered. For example, through using relevance vector to represent battery capacity degradation, an RVM-based model was proposed in[100] for future capacity ageing prognostics with uncertainty quantification. To further enhance the long-term ageing prediction performance of RVM, an incremental learning solution was designed in [101], while the corresponding RUL prediction performance was also improved.

In summary, RVM is capable of providing an easy training stage and satisfactory predictions with the probability distributions. It also presents an obvious limitation as lots of training data are needed, further causing high memory requirements particular for many ageing input cases.

V. ENHANCED BATTERY LONGEVITY WITH AI

Battery life diagnostic mentioned in the above section could help users to obtain both battery current and future health states. Afterwards, suitable AI-based solutions need to be developed to enhance battery longevity. This section first introduces several widely-adopted control-oriented models with the specific forms to capture various battery dynamics that occurred with ageing, followed by the discussions of various AI technologies in achieving battery health-conscious charging.

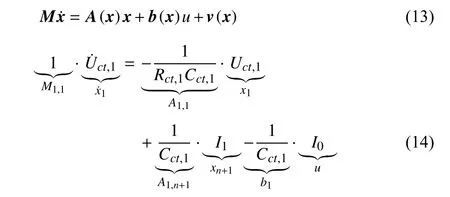

A. Battery Control-Oriented Modeling

Recent trends in model-based control strategy for long life battery have cumulated a proliferation of studies about battery control-oriented modeling. There are three factors that greatly influence the applications of control-oriented battery models.Firstly, model equations are supposed to be as easy as possible for solving to promote the efficiency of control algorithms in battery management systems (BMSs). Secondly, a large number of model parameters barrier the model identification process due to the high computing complexity and over-fitting issue. Hence, the control-oriented battery models should avoid large amounts of model parameters. Thirdly, the physicsbased model should be able to explain the dynamics of more battery internal states and parameters, which facilitates promoting the diversity of control objects and constraints. For this concern, it is important for the control-oriented model to take physics property into account. In this sub-section, stateof-the-art battery control-oriented modeling solutions are discussed. Particularly, the pros and cons of popular battery control-oriented models are compared in Table III.

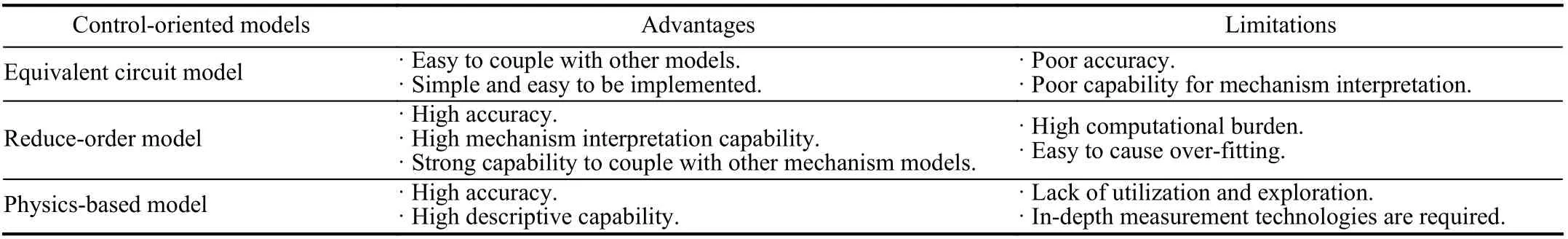

TABLE III COMPARISONS OF POPULAR BATTERY CONTROL-ORIENTED MODELS

1)Equivalent Circuit Modeling

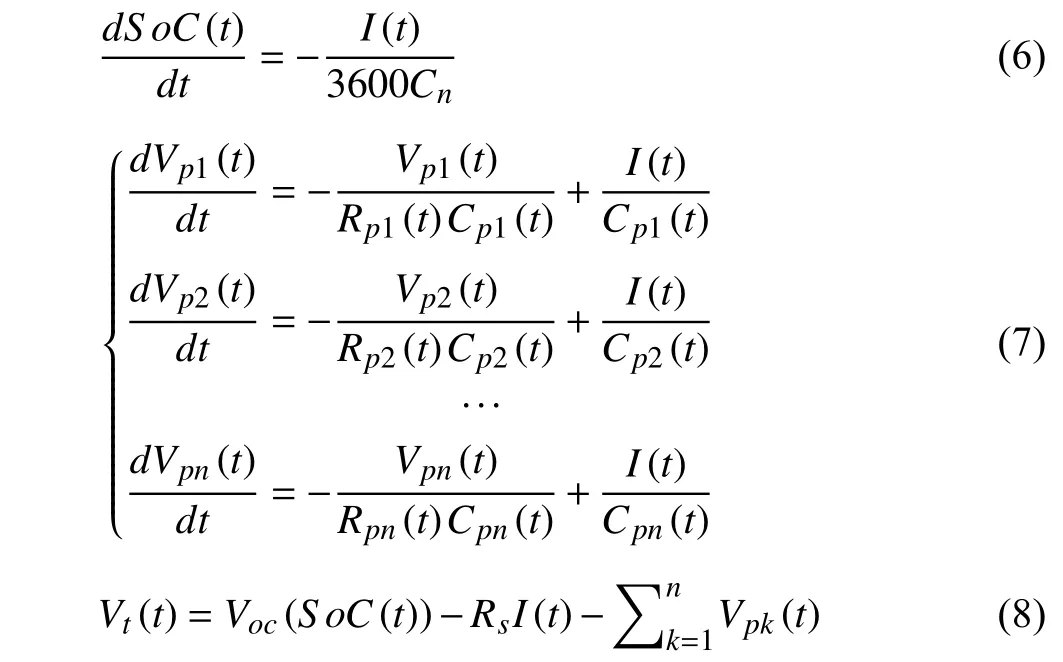

Equivalent circuit model (ECM) has been widely used for battery management like state estimation, peak power prediction, and fault diagnostic, benefited from its low computation complexity and reasonable accuracy. Many ECMs have been reported with comparable accuracy in most battery operating conditions. A typicaln-order resistorcapacitor (RC) model is shown in Fig. 10(a). Generally, the construction of ECM follows Kirchhoff’s laws as shown in the following equations:

where currentIis defined to be positive for discharging, andCnis the nominal capacity.Vpkdenotes the voltage of resistorcapacitor pair,Vocis the open circuit voltage (OCV), andVtis the terminal voltage. The resistances,RpkandRs, and the capacitanceCpk, are associated with SOC.

Fig. 10. Popular battery control-oriented models: (a) equivalent circuit model; (b) reduced-order model; and (c) physics-based model.

In [102], based upon the constant-voltage charging reconstruction, a battery SOH estimation algorithm was proposed. The reconstruction process here uses the ECM to describe the current and capacity evolvement during the constant-voltage phase. The main drawback of ECMs is the lack of abilities for the mechanism interpretation. As a result,for most application situations, ECMs are coupled with other models to acquire a comprehensive description of Li-ion battery. For example, a two-state thermal model was coupled with a second-order ECM to realize electrothermal dynamicsconscious fast charging [103]. Based upon this electrothermal model, the ageing model was further incorporated in [104] to establish a similar electro-thermal-ageing coupled model for battery health-conscious charging applications.

In summary, with the development of estimation and control requirements, simple ECMs can hardly satisfy the requirement of multi-physical constraints and safety or degradationconscious battery applications. Instead, the coupled ECMs incorporating multiple simple sub-models become more suitable.

2)Reduce-Order Modeling

The Pseudo two-dimensional (P2D) electrochemical model proposed by Doyle et al. has a higher descriptive capability of internal electrochemical states than ECMs [105]. However,the computational complexity of P2D models is much higher than that of ECMs due to the requirement of solving partial differential equations (PDEs) [106]. To overcome this issue,the control-oriented reduced-order electrochemical model has been studied extensively.

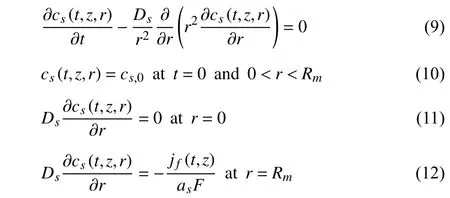

Among the existing reduced-order models, the single particle model (SPM) shown in Fig. 10 (b) is the most representative one viewing most utilizations. As the entire SPM is too large to be displayed properly, we exemplarily show the solid-phase diffusion equations and its initial and boundary conditions as follows:

wherecsis the Li-ions concentration inside spherical solid particles,Dsis the solid phase diffusion coefficient of Li-ions inside the solid particles,Rmis the radius of the particle,jfis the local volumetric transfer current density,asis the specific interfacial surface area, andFis the Faraday’s constant.

It is recognized that solving the solid-phase diffusion equations in SPM occupies the majority of computing resources. Therefore, extensive endeavors have been devoted to simplify the solid-phase diffusion process. For instance,based on the analytical solution of solid-phase diffusion equations, the concentration distribution was approximately described by the particle surface concentration and average concentration using several first-order inertia links [107].Based on this, the second-order PDEs were reduced to firstorder ordinary-differential equations, which greatly reduces the computational complexity. Moreover, polynomial solutions are widely used for solid-phase diffusion simplification under the galvanostatic conditions. For example, a polynomial approximate solution for solid-phased diffusion was developed in [108], which reduces the complicated PDEs to a few simpler differential algebraic equations. Similarly, by ignoring the specific concentration distribution, the particle surface concentration can be calculated using the parabolic profile method [109].

Although the reduce-order models can significantly reduce computation complexity, the number of model parameters is quite large compared with that in ECMs. Generally, reducedorder models have around twenty parameters to be determined, which complicates the parameter identification and aggravates the memory requirement of BMSs. To remedy this deficiency, lumped-parameter model has been used for parameter reduction to eliminate the redundant/unobservable model parameters, which can also increase the efficiency and confidence of model identification. As a result, combining the lumped-parameter model and reduced-order model can greatly promote the feasibility of control-oriented electrochemical models [110].

As a physics-based model, the electrochemical models can observe and control the battery internal state in more depth. In terms of application, the electrochemical models can be coupled with other mechanism models like the lithium plating model and particle-level mechanical model to achieve a refined description of Li-ion battery’s inner dynamics. As the electrochemical model can describe each voltage component of anode and cathode, the anode potential is proposed as an indicator for charging control. A reduce-order model was used to estimate and control the solid-phase concentration and side reaction potential in [111]. With the help of a three-electrode battery, the reduce-order model was calibrated in [112] to observe and control the anode potential for achieving platingfree fast charging. Coupled with a particle-level mechanical model, a reduced-order model was established to suppress the mechanical stress overflow during the fast charging process of the battery [113].

In conclusion, to appropriately utilize the advantage of the high descriptive capability of electrochemical model, the reduced-order models are usually coupled with various mechanism models. To date, there have been extensive works on the reduced-order model in an effort to reduce the computing complexity and to eliminate the redundant model parameters. Nevertheless, the efficiency and reliability are still expected to be improved for real-world applications.

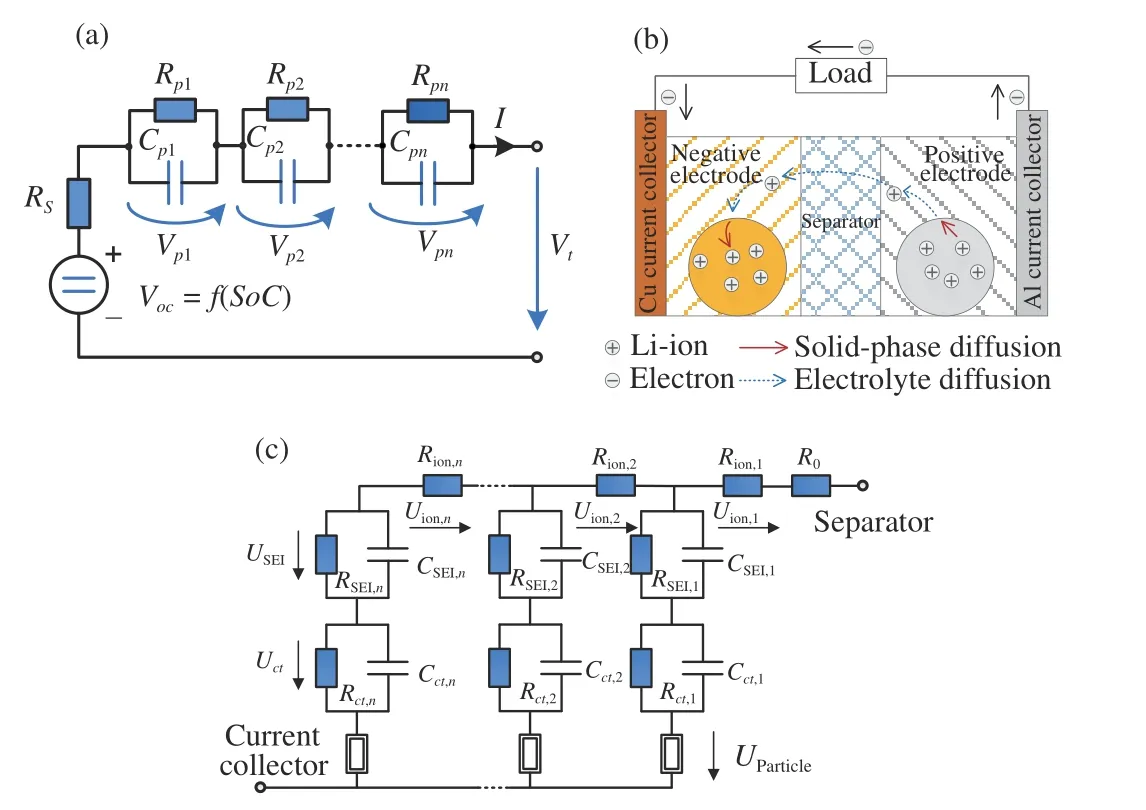

3)Physics-Based Modeling

As mentioned above, although numerous ECMs can fit the experiment results accurately, the lack of mechanism explanations can also lead to a wrong interpretation of parameters and internal states. This aspect is the main drawback of ECMs for state-accounted control, compared with a physics-based model like the P2D electrochemical model. Improved by ECMs, physics-based model can be established with rich recognition of internal behaviors deriving from more in-depth measurement technologies.Different from the traditional parameter identification of ECMs or electrochemical models, physics-based models not only fit the terminal voltage from the data point of view but also utilize the information of reference electrode or electrochemical impedance spectroscopy (EIS) to calibrate critical internal parameters. With the help of the reference electrode, the potential from the anode and cathode can be additionally obtained. As a result, physics-based models derived from the three-electrode battery can simulate the battery internal potential behaviors more accurately. For instance, a novel decomposed electrode model was proposed in [114] for real-time anode potential observation and fast charging control in BMSs. Two ECMs based on the decoupling of anode and cathode potentials by reference electrode were designed in [115]. Results showed high accuracy for both the anode potential and the terminal voltage under various working conditions.