Frontiers of CO2 Capture and Utilization (CCU)towards Carbon Neutrality※

Lingyun ZHANG , Yanfang SONG , Jialin SHI , Qun SHEN , Deng HU , Qiang GAO , Wei CHEN,Kien-Woh KOW, Chengheng PANG, Nannan SUN*, and Wei WEI*,5

1CAS Key Laboratory of Low-Carbon Conversion Science & Engineering,Shanghai Advanced Research Institute,Chinese Academy of Sciences,Shanghai 201210,China

2Department of Chemical and Environmental Engineering,Faculty of Science and Engineering,University of Nottingham Ningbo China,Ningbo 315100,China

3Key Laboratory for Carbonaceous Wastes Processing and Process Intensification Research of Zhejiang Province,University of Nottingham Ningbo China,Ningbo 315100,China

4New Materials Institute,the University of Nottingham Ningbo China,Ningbo 315100,China

5School of Physical Science and Technology,ShanghaiTech University,Shanghai 201210,China

ABSTRACT CO2 capture, utilization, and storage (CCUS) technology is a rare option for the large-scale use of fossil fuels in a lowcarbon way, which will definitely play a part in the journey towards carbon neutrality. Within the CCUS nexus, CCU is especially interesting because these processes will establish a new “atmosphere-to-atmosphere” carbon cycle and thus indirectly offer huge potential in carbon reduction. This study focuses on the new positioning of CCUS in the carbon neutrality scenario and aims to identify potential cutting-edge/disruptive CCU technologies that may find important application opportunities during the decarbonization of the energy and industrial system. To this end, direct air capture(DAC), flexible metal-framework materials (MOFs) for CO2 capture, integrated CO2 capture and conversion (ICCC), and electrocatalytic CO2 reduction (ECR) were selected, and their general introduction, the importance to carbon neutrality, and most up-to-date research progress are summarized.

Key words: carbon neutrality,carbon reduction,decarbonization,CO2,CCU

1.Introduction

1.1.Carbon neutrality

The history of human civilization is accompanied by the exploration and utilization of fossil energies. Their extensive use has been an important supporting factor for the continuous progress of human society, but it also has resulted in a huge amount of CO2emissions, which has led to serious problems such as the greenhouse effect and climate change(IPCC, 2014). Mitigating climate change has become one of the most important themes in the world today, and CO2reduction is at the central part of this issue. In this context, many countries and regions have put forward “carbon neutrality”commitments, and carbon neutrality is becoming a new benchmark for evaluating countries’ ambitions and actions to reduce carbon emissions (Energy & Climate Intelligence Unit, 2021).

Carbon peaking and neutrality correspond to major changes in production and lifestyles, and revolutionary adjustments must be made to the existing energy structure and industrial system. In this process, a new energy system characterized by a high proportion of renewables will undoubtedly make decisive societal and economic contributions through decarbonization (IEA, 2020a). However, the reliability of renewables needs further verification due to their intermittency and high dependency on large-scale energy storage technology. Therefore, fossil energy will inevitably exist in the energy system in a certain proportion (5%-10%) for a long time (IEA, 2020a; Qu et al., 2020). On one hand, fossil energy can act as a “stabilizer” by balancing the volatility of renewable energy. At the same time, fossil energy is very important to ensure a continuous supply of high-quality energy. On the other hand, high-carbon industries such as steel, chemicals, and cement are important pillars of the modern economy, but the technological processes in these industrial sectors are relatively mature, with high technological inertia and high replacement costs. Low-carbon transformation and structural upgrading need to be carried out in an orderly manner, and the high-carbon characteristics of these industries will not change in the short term. Therefore, the use of a certain proportion of fossil energy and fossil resources will play an irreplaceable role in ensuring energy security and maintaining the integrity of the industrial chain.However, their use will inevitably lead to a certain amount of carbon emissions, which cannot be fully absorbed through the natural carbon sinks. As a result, artificial carbon sink technology, namely CO2capture, utilization, and storage(CCUS), will act as a safeguard towards carbon neutrality(IEA, 2020b).

1.2.CO2 capture,utilization,and storage (CCUS)

CCUS is a major technological option for the end treatment of CO2and includes three technical steps of CO2capture, CO2utilization, and CO2storage. CO2capture is mainly used to separate and enrich CO2from various emission sources and even the air, and it is the beginning of the entire CCUS chain. CO2utilization uses CO2as a raw material or working medium by chemical, biological, or geological methods, and completes carbon emission reduction at the same time. CO2storage injects CO2into a certain geological environment and isolates the CO2from the atmosphere for a very long period during which the CO2may be fixed by carbonation reaction with underground minerals.

CCUS is a recognized technology that can achieve large-scale emission reductions. The International Energy Agency (IEA) predicted that to achieve global carbon neutrality by 2070, CCUS technology will not only contribute 15%of emission reductions but also provide inevitable solutions to cement, steel, chemical, and long-distance transport industries (IEA, 2020b). The IPCC special report “Global warming of 1.5°C” pointed out that by 2030 and 2050, global CCUS capacity will reach 100-400 million tons yr-1and 3-6.8 billion tons yr-1, respectively (IPCC, 2018).

Under the new target of carbon neutrality, the positioning of CCUS has changed significantly. CCUS technology is the only option for the low carbon utilization of fossil energies on a large scale, which is of great significance to energy security. Meanwhile, CCUS technology is a necessary solution for the decarbonization of industries that have difficulty reducing their emissions, and it is the major option to solve the problem of unavoidable “process emissions” in industries such as steel, chemical, cement, and non-ferrous metals.CCUS technology is also the main source for the necessary carbon element under the carbon neutralization scenario,which avoids the massive exploitation and utilization of fossil resources. Last but not least, the negative emission effect achieved by the coupling of CCUS and renewables is a guarantee for achieving the carbon neutrality target; which is impossible to achieve by source reduction or energy-saving approaches alone.

CCUS can be further divided into CCS and CCU according to their different approaches of CO2abatement. In general, CCS can provide huge capacity for direct CO2reduction as suitable reservoir volumes for CO2storage are more than enough to accommodate all the potential emissions. The CCU pathway, on the other hand, is significantly less efficient for direct reduction. This is because for most CCU technologies, any consumed CO2by the process will be re-released at the end of the product life-cycle (Stevenson, 2019). In fact, the importance of CCU is its great potential for indirect reduction of CO2emissions by avoiding the use of fossil carbon. As such, a new “atmosphere-to-atmosphere” carbon cycle can be established, while the traditional “lithosphereto-atmosphere” mode can be largely replaced (Hepburn et al., 2019). As such, the overall CO2reduction capacity of CCU is high enough to apply considerable impact on carbon neutrality, and it is likely to create economic benefits as well.

Nevertheless, under the carbon-neutral scenario, routes for future CCU R&D may vary significantly, but one of the key features is that the necessity and application potential of some cutting-edge/disruptive CCUS technologies will greatly increase. In response to the above trends, this paper summarizes several cutting-edge/disruptive CCU technologies that are expected to play important roles in the carbon neutralization process from different dimensions. The latest progress and possible future trends are discussed to provide a reference for the research layout in the CCU field.

2.Direct air capture (DAC) and its indispensable carbon-negative feature for carbon neutrality

Direct air capture (DAC), as indicated by its name, is a process that captures CO2from the ambient air. This technology is appealing because, to some extent, it de-couples the emission source and carbon sink (i.e., the relative locations of the emission source and downstream CO2utilization/storage sites will not be a necessary concern). Therefore, infrastructure and expenditures for long-distance transportation of CO2can be avoided, resulting in the great potential to reduce the cost of CO2abatement. Additionally, DAC directly uses air as the upstream source, which is a preferred technology to address mobile emission sources (such as vehicles) and micro emission sources (such as buildings) (Sanz-Pérez et al., 2016).

DAC delivers its carbon reduction capacity by coupling with either CO2conversion or CO2storage. Firstly, CO2obtained from DAC can be used as a raw material to replace fossil resources to produce carbon-based chemicals. In this context, the resulting products will be carbon neutral throughout their life cycles. Practically, this reshapes the existing chemical industry, leading to a disruptive impact on the entire industry and supply chain. Secondly, coupling of DAC with CO2storage has a significant carbon-negative effect, and its capacity is huge if large-scale deployment and application can be carried out. This offers a solution to the historical emissions and meets the demand of “reducing atmospheric CO2concentration” in response to climate change.Furthermore, such a carbon-negative effect may also have beneficial impacts on the energy and industrial system, promoting DAC to become an important part in the new model of carbon-neutral social and economic infrastructure(Goglio et al., 2020).

Compared with industrial emission sources, the concentration of CO2in the air is extremely low, only slightly higher than 400 ppm. This means that the DAC process is very unfavourable in terms of thermodynamics. Therefore,it faces great technological challenges in aspects of absorbents/adsorbents, efficiency, and energy costs. These adverse factors often cause the consumption of a large amount of materials and energy, even achieving a level that may offset the CO2reduction capacity of the DAC process(Deutz and Bardow, 2021). Overall, the technological maturity of DAC is still low, and its application is still in early infancy. In recent years, related studies have mainly focused on high-performance absorbents/adsorbents, prototype demonstrations, and life cycle assessments.

2.1.Absorbents/adsorbents for DAC

Absorbents and adsorbents are the most important components of a DAC technology system, and their performance directly dictates the overall cost and efficiency of the process. At present, most DAC studies and demonstrations have focused on solid adsorbents, and only a few experiments have used liquid absorbents with alkali metal hydroxide solution as the main component. The reason is because those solid adsorbents possess obvious advantages in terms of kinetics, stability, and environmental footprints (Shi et al., 2020).

Physical adsorbents (such as activated carbons, molecular sieves, etc.) are rarely used for DAC, mainly due to their weak interaction with the CO2molecules, which leads to extremely low adsorption capacity and selectivity in low CO2concentration environments (i.e., air). For example,Kumar et al. compared the CO2adsorption performance of four physical adsorbents and an immobilized organic amine sample, which is a typical chemical adsorbent. They found that although the performances of these samples only showed slight differences in 15 vol.% CO2, the CO2adsorption capacities of physical adsorbents are more than one order of magnitude lower than those of chemical adsorbents in DAC conditions (Kumar et al., 2015).

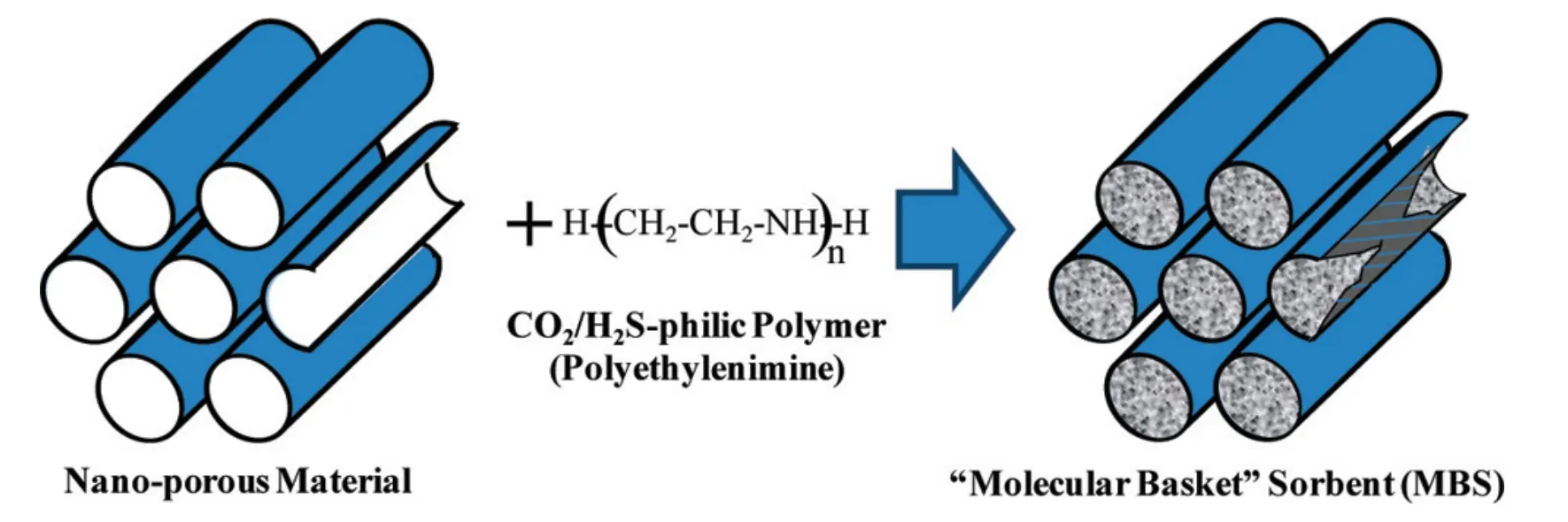

Compared with physical adsorbents, chemical adsorbents are more widely used for DAC. Among them, immobilized organic amines are a kind of important CO2chemical adsorbent. The earliest prototype of these adsorbents comes from the “molecular basket” material proposed by Song’s group (Fig. 1) (Xu et al., 2002; Ma et al., 2009). Then,Sayari’s group (Franchi et al., 2005; Sayari and Belmabkhout, 2010) and Jones’ group (Hicks et al., 2008;Didas et al., 2015) systematically developed the preparation method of immobilized organic amines, and in-depth studies on their adsorption behaviours and structure-performance relationship for CO2capture were performed. Due to the strong interaction between these adsorbents and the CO2molecules,their application in the DAC process has attracted extensive attention. For example, Goeppert et al. reported that fumed silica supported poly (ethyleneimine) (PEI) can effectively adsorb CO2from the air (Goeppert et al., 2011). In 2011,Choi et al. (2011) used 3-aminopropyl trimethoxysilane and tetraethylorthotitanate modified PEI as the adsorption components, which were loaded on porous SiO2, and they found that this type of material exhibited great DAC performance(adsorption capacity > 2 mmol g-1) and the use of modifiers can significantly improve the stability of PEI, rendering the material with excellent stability (Choi et al., 2011). Keller et al. used carbon nanotubes as a carrier for PEI to prepare a hollow fibre adsorbent. The adsorption capacity of CO2reached 1.07 mmol g-1under DAC conditions (Keller et al.,2018). In addition to the commonly used impregnation method, immobilization of amines can also be achieved by surface grafting. Although adsorbents prepared in this way have slightly lower CO2uptakes under DAC conditions,their overall stability can be significantly improved (Potter et al., 2017; Sabatino et al., 2021).

Fig. 1 “Molecular basket” sorbents [Reprinted from (Ma et al., 2009)].

Porous framework materials are a type of functional materials developed rapidly in recent years. The structure of these materials is highly ordered and can be finely characterized by various spectroscopic methods, thereby providing new dimensions for studying DAC mechanisms and performance tunning (Custelcean, 2021). For example, by the engineering of ligand for metal-organic frameworks (MOFs),Kumar et al. replaced the SiF62-pillar in SIFSIX-3-Ni material with TiF62-, which led to enhanced interaction between the framework and CO2, and thus the DAC performance of the material was effectively improved (Kumar et al., 2017).Bhatt et al. further explored possible strategies by adjusting the pore size, pore shape, and surface functional groups of MOFs, and a CO2adsorption capacity of 1.30 mmol g-1could be achieved at the condition of 400 ppm and 25°C,which is on a similar level to immobilized amine-based adsorbents (Bhatt et al., 2016). It should be noted that although the low-pressure CO2adsorption performance can be significantly improved through the optimization of MOFs structure, in general, its adsorption mechanism still relies on physical interactions, so it is easily affected by competitive adsorption of moisture. In fact, MOFs can also be used as carriers to prepare amine-based DAC adsorbents (Lu et al., 2013;Lee et al., 2014; Liao et al., 2016; Sen et al., 2019), and under the synergistic effect of multiple functional sites, the resulting materials may exhibit excellent DAC performance through several types of new adsorption mechanisms. For example, McDonald et al. used N, N’-dimethylethylenediamine (mmen) to functionalize Mg2(dobpdc) (dobpdc4-=4,4’-dioxidobiphenyl-3,3’-dicarboxylate). It was found that during the adsorption of CO2, there is a process of CO2insertion into the metal-amine bond, so the obtained CO2adsorption isotherm has step-shaped characteristics. This unique behaviour makes the material possess a higher working capacity than other chemical adsorbents (McDonald et al., 2015).Through the tunability of MOFs structure and the optimization of external amines, CO2adsorption capacity, kinetics,and regeneration performance under DAC, conditions can be further improved (Lee et al., 2014; Liao et al., 2016; Kim et al., 2020b; Martell et al., 2020).

In recent years, some new adsorption strategies have also been used for DAC processes. Based on the affinity difference between materials to CO2and water, researchers have proposed the concept of moisture-swing adsorption. In this process, the material captures CO2from air in a dry environment, while the competitive adsorption of moisture in a wet environment will liberate CO2molecules from the adsorbent surface (Shi et al., 2016; Yang et al., 2018). Inagaki et al. found that the aqueous solution of m-xylylene diamine(MXDA) can absorb CO2in the air and generate water-insoluble MXDA·CO2crystals. After simple filtration and separation, heating of MXDA·CO2can release CO2and complete the regeneration of MXDA. This process avoids the large amount of energy consumption required for the evaporation of solvent water in the traditional liquid absorption method(Inagaki et al., 2017). Based on a similar strategy, Brethomé et al. used a cheap and easily available amino acid aqueous solution to absorb CO2, and then the CO2loaded solution further reacted with guanidine compounds to form insoluble carbonates, which regenerated the amino acids simultaneously,and then the separated carbonate can be decomposed under relatively mild conditions to release CO2(Brethomé et al.,2018).

Table 1 summarizes recent research results on DAC adsorbents. Overall, the research and development of DAC absorbents/adsorbents still face great challenges. In this study, a model was designed to estimate the cost of DACadsorbents and the corresponding relationship between adsorbent performance and its highest allowable cost was studied(Fig. 2). Based on this model, it is found that if the service life of an adsorbent is 1000 cycles, its cost must be less than$1 kg-1. Currently, there are hardly any adsorbents so low in cost. Increasing adsorbent service life can reduce its highest allowable cost; with 100 000 cycles, the allowable cost of MOF (Diamine) materials is the highest, reaching $90 kg-1.However, the price of MOF material is generally higher than $10 000 kg-1, and its stability is far from the requirements(Shi et al., 2020). This work verifies the difficulty of developing DAC adsorbents from a cost perspective, but it should be mentioned that recently, several groups have reported several CO2adsorbents with excellent comprehensive performance, which provides new opportunities for reducing the cost of DAC technology (Nandi et al., 2015; Yue et al.,2017; Cavalcanti et al., 2018; Mukherjee et al., 2019; Lin et al., 2021).

Table 1. Summary of research results on DAC sorbents.

2.2.Prototype demonstrations of DAC

Devices and demonstrations are also major focuses in the DAC field. This is because the concentration of CO2in the air is low, so the gas processing capacity of the DAC process is huge, and there is little experience in an engineering perspective to date. Over the past decade, developed countries in Europe and America have attached great importance to the development and application of DAC, and several smallscale prototypes and demonstrations have been reported,which has laid an important foundation for the future development of DAC technology.

Climeworks, a company based in Switzerland, is the first company in the world that provides customers with CO2captured from the air. In 2017, the company built the world’s first commercial DAC device in Switzerland, which adopted modular design and used 18 adsorption units. An overall capture capacity of several hundred tons of CO2per year was achieved. In 2021, Climeworks built its latest Orca plant in Iceland. The Orca plant has a capture capacity of 4000 t yr-1(Fig. 3) and is the largest DAC demonstration in the world to date. The captured CO2is injected 700 m underground for mineralization and storage (Climeworks, 2021).

DAC technology from Global Thermostat uses temperature-swing adsorption and adopts immobilized organic amine adsorbents. Global Thermostat established the first pilot plant in 2010 and the first commercial DAC plant in Alabama in 2018. It is reported that the energy consumption can be reduced to less than 6 GJ (t CO2)-1, which is around the minimum for existing DAC demonstrations (Zhu et al.,2021).

Carbon Engineering established its first DAC pilot plant by using KOH and Ca(OH)2solutions as absorbents in 2015, and in 2017, the company succeeded in the conversion of air-captured CO2to liquid fuels. In 2019, the company began to design and build a million-ton DAC demonstration project. Its carbon capture cost is estimated to be $94-$232(t CO2)-1, with an energy consumption intensity of about 8.81 GJ (t CO2)-1(Keith et al., 2018; Engineering, 2021).

Fig. 2 Allowable price of DAC adsorbents [Reprinted from(Shi et al., 2020)].

Fig. 3 Orca plant from Climeworks [(©climeworks, 2022),used with permission].

2.3.Life-cycle assessment (LCA) of DAC

At present, there are still some controversies around the economic and environmental benefits of DAC. Therefore,its full life cycle assessment is also a research hotspot. By applying LCA to the actual operation data, Deutz et al.found that the DAC demonstration currently carried out by Climeworks has already achieved a carbon-negative effect.The carbon capture efficiencies of its two DAC plants reached 85.4% and 93.1%, respectively. However, the environmental benefits of the DAC process are closely related to energy sources. In an energy structure dominated by renewables, it is expected that the large-scale deployment of DAC technology (reaching 1% of global carbon emissions) will not be limited by materials and energy, and related environmental issues, if any, are relatively limited (Deutz and Bardow, 2021). According to calculations on carbon balance,Jonge et al. carried out LCA studies on a NaOH absorption DAC system, with a special focus on the life cycle carbon efficiency. Their results also showed that the energy source is very important to the emission reduction benefits of DAC.In general, the utilization of renewable energy is the simplest and most significant way to improve the carbon efficiency of DAC at this stage (de Jonge et al., 2019).

Terlouw and co-workers (2021b) proposed that it is necessary to incorporate CO2storage into the DAC’s LCA process in order to fully reflect the emission reduction benefits and other environmental impacts of DAC. Based on this idea, the authors compared and studied the environmental impact of direct air capture and storage (DACCS) under different power/heat sources and a variety of technology combinations. It was found that although a negative carbon effect can be achieved in several scenarios, it is necessary to select the best energy supply mode according to the energy infrastructure of different countries and regions. This is of pivotal importance to the emission reduction capability and the environmental impact of DAC (Terlouw et al., 2021a).

It should be mentioned that DAC technology is still very immature, so there are significant challenges in technology evaluation. Terlouw et al. (2021b) systematically summarized the current LCA works for carbon-negative technologies and pointed out that existing methods may induce confusion between avoided emission and negative emission, resulting in misleading conclusions. In order to better support the development of DAC technology in the future, it is necessary to strengthen the comprehensiveness of the evaluation and the transparency of the methods.

3.Flexible metal-organic frameworks (MOFs)and ultra-low cost CO2 capture technology

3.1.Flexible MOFs as CO2 adsorbents

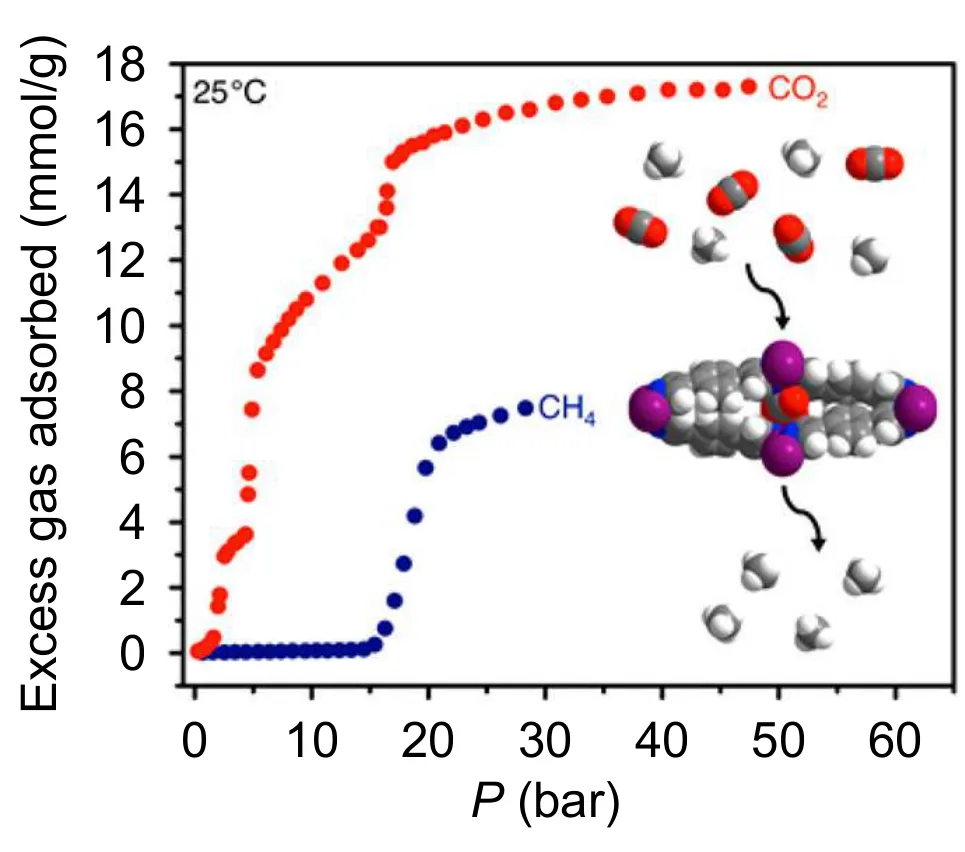

Metal-organic frameworks (MOFs) are one of the emerging and rapidly growing focuses in material science. These materials are constructed from complexation of metal ions or metal ion clusters with bridging organic linkers, which exhibit regular crystalline lattices with high surface area and well-defined pore structures (Furukawa et al., 2013; Yuan et al., 2018). In MOFs, both the metal nodes and the organic linkers can be readily adjusted. This offers an effective approach for the customization and delicate adjusting of the materials’ pore structure and functionalities. Therefore,MOFs can be widely applied in separation and catalysis science. In recent years, it was found that due to the dynamic properties of the framework component, MOFs that are responsive to external stimuli (pressure, temperature, ultraviolet light, etc.) can be synthesized (Matsuda, 2014). Based on this, construction of a reversible phase transformable CO2adsorption material can be realized to achieve an ultra-low cost CO2capture process (Schneemann et al., 2014)(Table 2). It should be noted that the energy consumption of the existing carbon capture process is relatively high, often accounting for 70% of the entire CCUS technology chain.

3.2.Light-responsive MOFs for CO2 adsorption

One of the general strategies to construct flexible MOFs is to use organic linkers with light-responsive function groups as subunits for the framework. Modrow et al. constructed the first porous MOF (CAU-5) with photo-switchable linker molecules (3-azo-phenyl-4,4’-bipyridine). Under the irradiation of UV light (365 nm), the azo-functionality switches from its thermodynamically stable trans-isomer to cis-isomer (Modrow et al., 2011). Similarly, CO2adsorption behavior can be reversibly altered upon photochemical or thermal treatment in an MOF (PCN-123) with an azobenzene functional group, which can switch its conformation (Park et al., 2012). Sensharma et al. reported the synthesis and characterization of a photoactive MOF (TCM-15), which revealed a dynamic response upon UV irradiation, leading to instant desorption of pre-adsorbed CO2. Based on FT-IR experiments and DFT calculations, the author verified that such release of CO2could be attributed to the structural flexibility of the materials (Sensharma et al., 2019). Lyndon et al.synthesized an MOF loaded with azo-type light-responsive groups. The material showed rapid response towards CO2adsorption during the light on-and-off switching cycles.This work directly verified the possibility of developing ultra-low energy consumption carbon capture technology based on flexible framework materials (Fig. 4) (Lyndon et al., 2013).

3.3.Guest-responsive MOFs for CO2 adsorption

Interaction between MOFs and guest molecules is an important way to stimulate flexibility. As early as 2003,Kitaura et al. introduced displacement freedom during the self-assembly process of rigid motifs, and they proved experimentally that the obtained material has a “gate-opening pressure” for different gases, which caused the MOF material to transition from a crystalline “closed” form into an “open”form. The authors suggest that the reason for this flexibility is the displacement of π-π stacked moieties in the material.At the same time, due to the different interactions between different gas molecules and materials, the gate-opening pressure also varied in different atmospheres. For CO2, the opening and closing pressure are only 0.4 and 0.2 bar, respectively(Kitaura et al., 2003). Stavitski et al. prepared amino-modified NH2-MIL-53(Al) and found that the modified material has excellent CO2adsorption properties compared with the unmodified counterpart. Very interestingly, it was found that instead of binding CO2chemically, the introduced amino groups actually played a role in adjusting the framework flexibility. In this way, the CO2adsorption capacity could be enhanced while the physical adsorption nature was not altered, and therefore, a significant increase in energy consumption for desorption was avoided (Stavitski et al., 2011).Using Cu as the metal center, 2,3-pyazinedicarboxylic acid(pzdc) as the ligand, and 4,4’-bipyridine (bpy) and 1,2-di-(4-pyridil)-ethylene (bpe) as the pillar, CPL-2 (Cu2(pzdc)2(bpy)) and CPL-5 (Cu2(pzdc)2(bpe)) were prepared, respectively. Both samples showed excellent CO2adsorption capacity and selectivity, and based on in situ synchrotron X-ray diffraction experiments, the authors showed that the chemical interaction between CO2and the materials triggered rotation of the pillar ligands. This distortion further introduced expansion of the framework lattice, which is the key factor for the high CO2adsorption performance (Marks et al., 2020).

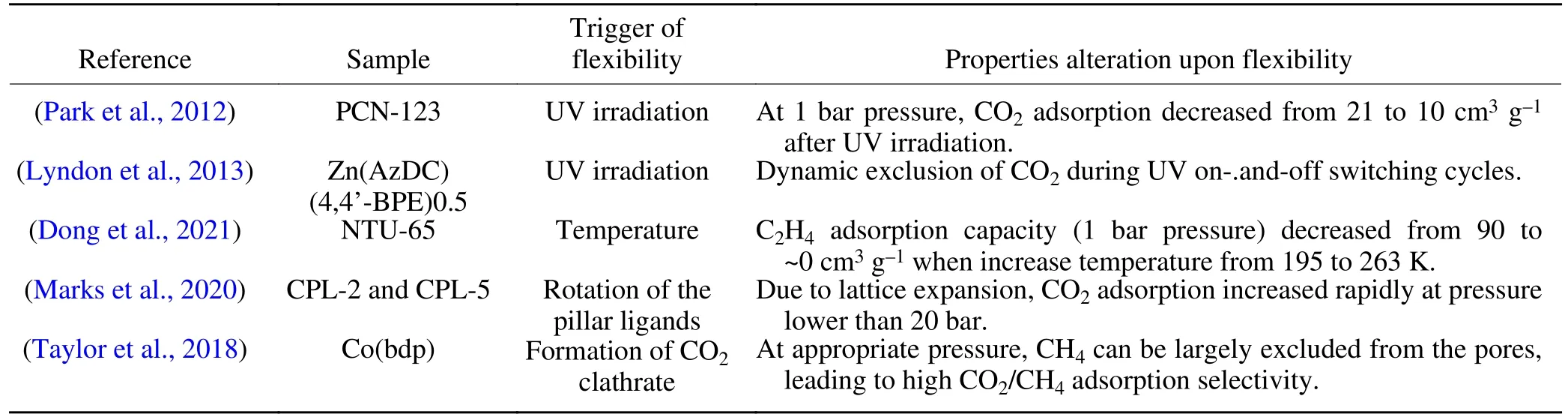

Table 2. Properties before and after breathing-MOF.

Taylor and co-workers prepared a Co (bdp) (bdp2-= 1,4 benzenedipyrazolate) MOF material with a flexible framework, which showed excellent adsorption selectivity for the separation of CO2and CH4. Based on in situ X-ray Powder Diffraction (XRD) measurements, the authors suggest that the high selectivity originates from a “reversible guest templating” effect. That is, in the adsorption process, the framework expanded to form CO2clathrates, and the expended framework collapsed back to the non-templated phase in the subsequent desorption process. Based on such a mechanism,CH4was completely removed during adsorption of a 1:1 CO2-CH4mixture (Fig. 5) (Taylor et al., 2018).

3.4.Regulating the flexibility of MOFs for CO2 adsorption

Although flexible MOFs have shown many advantages in CO2adsorption, how to regulate their flexibility to match practical conditions is still a challenging question.

Based on the excellent structural flexibility and mechanical resistance of MIL-53 series materials, Chanut et al.found that when an external force is applied to the materials,they gradually change from an open-pore form to a contracted form. More importantly, the pore size of the materials can be accurately controlled by the strength of the applied force.Based on this idea and considering specific separation objects, efficient separation of CO2/N2and CO2/CH4could be achieved under optimized external force conditions. At the same time, when the external force is unloaded, the material structure switched back to the open form, which led to gas desorption and material regeneration (Fig. 6). Clearly,such a strategy is superior to the conventional pressureswing or temperature-swing processes (Chanut et al., 2020).

Using NH2-MIL-53(Al) as a parent material, Bitzer et al. introduced Sc, V, Cr, and Fe as a second metal node to prepare NH2-MIL-53 (Al, M). Based on systematic characterizations, the authors found that the flexibility of the framework can be effectively adjusted by the presence of the second metal, which further altered the CO2capture performance of the resulting samples. In general, the construction of polymetallic MOFs can easily and effectively regulate the framework flexibility in a wide range, which has great potential in future applications (Bitzer et al., 2020).

Ghoufi’s calculation revealed that the flexibility of MIL-53 could be affected by the existence of an electric field in addition to the stimulation of the guest molecules, heat, and external forces, with a volume change of up to 40%. At the same time, varying the electric field strength led to the regulation of the unit cell volume. This provided a ready path for adjusting gas adsorption, which resulted in the efficient separation of CO2and CH4(Ghoufi et al., 2017).

Fig. 4 Light-responsive capture of CO2 [Reprinted from(Lyndon et al., 2013)].

Fig. 5 Separation of CO2 and CH4 by flexible framework material [Reprinted from (Taylor et al., 2018)].

Fig. 6 Flexibility regulation by external force [Reprinted from (Chanut et al., 2020)].

Dong et al. prepared a flexible MOF (NTU-65), and its flexibility is sensitive to temperature. Based on this characteristic, and together with the different gate-opening pressure of different gases, the authors successfully found a suitable operation window for the one-step separation of multi-component gases containing ethylene, ethane, and CO2. High purity ethylene of polymerization grade was obtained by this method, which may find important potential in the petrochemical industries (Dong et al., 2021).

4.Integration of CO2 capture and conversion(ICCC)

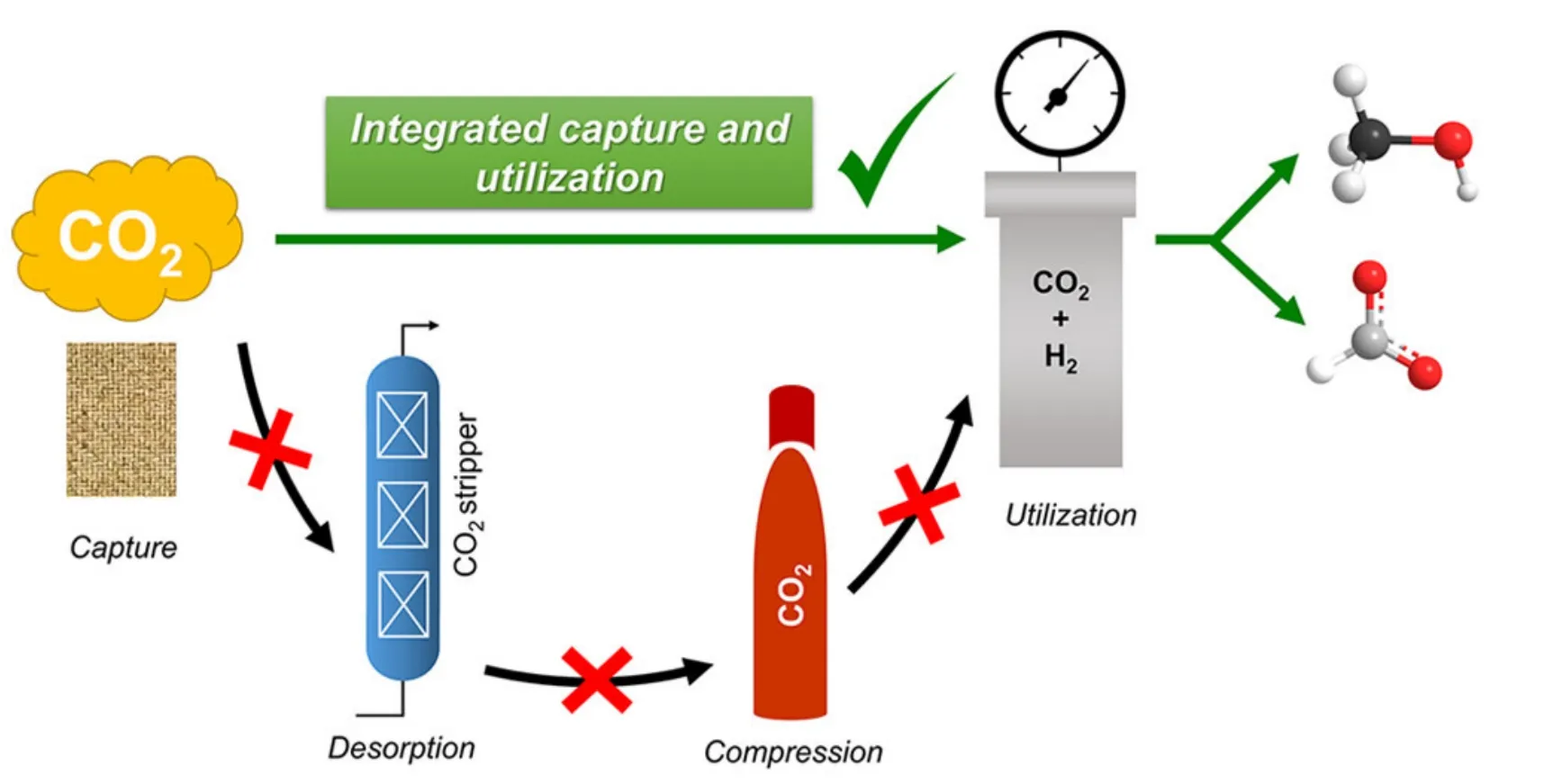

4.1.General basics of ICCC

Integration of CO2Capture and conversion (ICCC)refers to the connection of these two processes by their common microscopic steps, that is, the interaction between CO2and solid surface. During the new process, the captured CO2is directly converted to a value-added product without its desorption and enrichment (Fig. 7) (Zhou et al., 2020). Compared with the traditional CCUS chain, there are multiple advantages of ICCC. Firstly, it avoids the energy consumption of CO2desorption from absorbent/adsorbent in the traditional carbon capture process. Since this is one of the key factors causing the high cost of CCUS, it is thus expected that ICCC may significantly reduce the cost for CO2abatement.Besides, ICCC allows the disposal of CO2at close vicinity of its emission, which greatly reduces the demand for CO2transportation, and thus provides a solution to the sourcesink matching problem. It is also possible that the products from an ICCC process can be readily used in downstream chains or even by the original emitter, leading to decarbonization of the energy and industrial system. The above advantages dictate the significant application potential of ICCC in carbon neutralization scenarios. However, this technology is still in the stage of laboratory verification, and systematic investigations are needed to clarify more approaches that are suitable for the current emission sources.

4.2.ICCC for methanol production

Fig. 7 Integrated CO2 capture and conversion [Reprinted from(Zhou et al., 2020)].

Methanol is a very important platform chemical that is widely used as a fuel and a chemical raw material. Under the background of carbon neutrality, methanol is expected to become a renewable energy carrier that can replace fossil energy. The technology of CO2hydrogenation to methanol has attracted more and more attention in recent years,mainly because this process can greatly reduce the consumption of fossil resources for methanol synthesis, thereby bringing a significant effect of indirect reduction of carbon emission.

Reller et al. were among the earliest who investigated methanol producing ICCC process. In their work, N, NDiethylethanolamine (DEEA) and Cu/ZnO-Al2O3catalyst were mixed, and the system was in contact with high-pressure CO2(10-20 bar) and H2(50-70 bar) consecutively. As such, CO2was firstly absorbed by DEEA, and then CO2could be activated and converted to methanol by Cu/ZnOAl2O3. This experiment used high-pressure and pure CO2in the CO2capture stage, so it cannot be strictly classified as an ICCC process, but it clearly verifies the feasibility for the conversion of captured CO2to value-added products (Reller et al., 2014).

In 2016, Prakash’s group reported capturing CO2directly from the air and its conversion to methanol for the first time. They used pentaethylenehexamine as a CO2absorber and Ru-based Prince complex as a catalyst to convert the captured CO2to methanol under high-pressure H2. With the optimal conditions, the yield of methanol reached 95%and could be recovered by distillation (Kothandaraman et al., 2016). Based on this work, a series of follow-up studies on several principal technical difficulties were performed.Firstly, in order to improve the efficiency of amine absorbent, a two-phase system was developed to simplify the separation of catalyst and amine, and thus the cycling stability of amine could be enhanced (Kar et al., 2018). Additionally, the authors also reported that either immobilized amines or metal hydroxide solutions can also be used for CO2capture in the process, which might provide solutions to the instability issue of amine-based absorbents (Fig. 8)(Kar et al., 2019; Sen et al., 2020).

4.3.ICCC for CO/syngas production

CO is the main component of coke-oven gas and a common reducing gas in the metallurgical industry. In addition,syngas composed of CO and H2is a widely used synthetic building block, which can be converted to a range of chemicals. At present, the preparation of CO and syngas mainly takes coal as the raw material through coking and gasification, respectively. The energy consumption of these processes is high, and an additional water-gas shift is needed to fulfill the downstream requirements on H2/CO ratio for syngas,which further lowers the carbon efficiency by converting some CO to unusable CO2. Therefore, carbon emission from CO/syngas production is huge, and relevant industries are facing severe pressures under the scenario of carbon neutrality. In recent years, some researchers have also studied the feasibility of preparing CO/syngas through the ICCC strategy by combining CO2capture with either its direct hydrogenation or reforming with alkanes.

Fig. 8 Integrated CO2 capture and conversion to methanol [Reprinted from (Kar et al., 2019)].

Ni/CaO-Al2O3mixed oxide was prepared by Li et al.by using CaO for high-temperature adsorption of CO2and Ni as the catalyst for CO2-CH4reforming. This system can efficiently convert adsorbed CO2into syngas, but due to the sintering of CaO, the materials are gradually deactivated in prolonged cycles (Li et al., 2009). In Qiao’s work, γ-Al2O3was successively impregnated with K-Ca double salts and Ni species, acting as the CO2adsorption and catalytic component, respectively. CO2adsorption and subsequent reforming with ethane to prepare syngas were then performed successfully (Qiao et al., 2017).

Bobadilla et al. prepared FeCrCu/K/MgO-Al2O3bi-functional materials, and an ICCC process was carried out based on reverse water gas shift to produce syngas. The process can be operated stably under simulated flue gas conditions containing oxygen and steam (Bobadilla et al., 2016). Ce doped Ni-Ca composite oxides were prepared by Sun et al.,in which the oxygen vacancy on CeO2can significantly enhance the activation of CO2, and thus its ICCC stability could be improved. When the Ca/Ni/Ce ratio is 1:01:0.033,the material can achieve 100% CO selectivity and 51.8%CO2conversion at the optimum temperature (650°C); no deactivation was observed in 20 capture-conversion cycles(Sun et al., 2019). Fe-Co-Mg-Ca multicomponent composites were prepared by Shao and co-workers. It was found that the existence of MgO can effectively lower the sintering of CaO, and the synergistic effect between MgO and CaO benefited CO2adsorption, whereas Fe and Co species can provide additional oxygen vacancies for CO2activation. Therefore,the material shows excellent ICCC performance with 90%CO2conversion and nearly 100% CO selectivity. The authors also proposed a heterojunction redox mechanism. It was considered that the newly formed Fermi level in Fe5Co5Mg10CaO significantly lowered the Fe3+/Fe2+redox potential. Therefore, electron transfer became easier, which is responsible for the enhanced activity of CO2conversion in reverse water-gas shift (RWGS) reaction (Fig. 9) (Shao et al., 2021).

4.4.ICCC for CH4 production

CH4has a high hydrogen content, so the carbon emission during the CH4consumption process is relatively low.Through hydrogenation reaction, CO2can be directly converted to methane under atmospheric pressure, and its reaction temperature is significantly lower than that of reforming and reverse water gas. Therefore, it can be better coupled with existing industrial emission sources to realize the ICCC process. This is also the most studied direction in the ICCC field.

In the process of ICCC for CH4production, the adsorption step and conversion step can be coupled in several ways. For example, Veselovskaya et al. used tandem reactors, where K2CO3/Al2O3adsorbent was loaded in a first reactor for CO2capture, and 4% Ru/Al2O3catalyst was used in a second reactor for CO2conversion after it was purged out from the first reactor via H2(Veselovskaya et al., 2018).Alternatively, potassium-containing hydrotalcite and nickelbased catalyst were loaded in a single bed via a layer-bylayer way, and CO2adsorption and subsequent conversion to CH4were then achieved at 300°C -350°C, with a yield of 2.36 mol CH4kg-1cat h-1(Miguel et al., 2017). In Sun’s work, MgO and Ru/CeO2were employed as adsorbent and catalyst, respectively, and their physical mixture was used for the ICCC to CH4process, however, the conversion rate of CO2in such a combination is relatively low (Sun et al.,2020).

In contrast to the above strategies, a combination of adsorption and catalysis sites in a single material is the most straightforward way. Farrauto’s group reported on a range of experiments based on this idea. The performances using Na, K, Mg, and Ca oxides as adsorption sites and Rh, Ru,Ni, Pt, and Co as the catalytic sites were thoroughly investigated. Meanwhile, the influences of reaction conditions and related mechanisms were also clarified (Duyar et al., 2015,2016; Zheng et al., 2016; Arellano-Treviño et al., 2019a, b;Proaño et al., 2019).

The process of continuous abatement of CO2in simulated flue gas by ICCC was reported by Zhou et al. In their work,Ni-MgO-Al2O3two-dimensional nanosheets were used as a bi-functional material. Through the optimization of reaction temperature, capture, and conversion time interval, the authors realized nearly 100% CO2capture and conversion under isothermal conditions (Fig. 10). The overall efficiency of the process has been greatly improved compared to the traditional temperature-swing and pressure-swing adsorption(Zhou et al., 2020).

5.Electro-catalytic CO2 reduction (ECR)

5.1.General basics of ECR

Electro-catalytic CO2reduction (ECR) represents the processes that convert CO2via an electro-chemical way. In sharp contrast to the conventional thermal-catalytic process where high temperature and pressure are normally needed for CO2activation and conversion, ECR processes can be readily carried out in much milder conditions (atmospheric pressure and room temperature). Meanwhile, as the required energy can be largely provided in the form of electrons, the ECR processes can be directly integrated with low-grade renewables, and H2O, rather than other energized molecules,can be used as a hydrogen source. As such, ECR enables the transformation of renewable energies to chemical energies in form of fuels and/or chemicals including CO, hydrocarbons(methane, ethylene), hydrocarbon oxygenates (formic acid,methanol, ethanol, etc.), or a mixture of them, and after their consumption, the released CO2can be recycled to close the carbon loop (Yang et al., 2016). All these merits give ECR great promise for the realization of carbon neutrality. In Table 3, we summarized several representative results from recent publications on ECR.

Fig. 9 Heterojunction redox mechanism for CO2 capture and conversion to syngas [Reprinted from (Shao et al., 2021)].

5.2.ECR to CO

Fig. 10 Continuous capture and conversion of CO2 to CH4[Reprinted from (Zhou et al., 2020)].

Selective ECR to CO is a promising route toward industrial implementation because the produced CO can be used as a chemical feedstock to produce numerous higher-value chemicals or fuels, such as liquid fuel, low carbon olefin,and low carbon alcohol. However, direct reduction of CO2to *COO-involves a one-electron transfer process with a very negative redox potential (-1.9 V versus reversible hydrogen electrode (RHE)), which significantly inhibits the activation of CO2(Hunt et al., 2003). Therefore, suitable electrocatalysts should be developed to stabilize the *COO-intermediate, thereby reducing the activation overpotential.

Metal catalysts including Au, Ag, Zn, and Cd with both weak hydrogen and oxygen adsorption (Uesaka et al., 2018)have been widely investigated for ECR to CO. Among them,Ag exhibits extraordinary ECR to CO performance. For example, Yang’s group reported that when an Ag nanoparticle/ordered-ligand interlayer catalyst is applied in a gas-diffusion environment, a high FE of 92.6% for CO formation at a high current density of 400 mA cm-2could be achieved. It was verified that the interlayer structure facilitated the synergistic effect between multiple components and is responsible for such excellent performance (Kim et al., 2020a). Singleatom catalysts (SACs) with individual metal atoms dispersed on solid substrates can maximize atom utilization efficiency and thereby enhance catalytic performance. In comparison with bulk Ni metal that catalyses hydrogen evolution exclusively under ECR conditions, the Ni single-atom counterpart can selectively electrochemically reduce CO2to CO. Zhang et al. designed a methoxy group of functionalized nickel phthalocyanine (NiPc-OMe) molecules supported on carbon nanotubes, which catalyses the ECR to CO process with>99.5% selectivity. The electron-donating OMe groups could enhance the Ni-N bond strength in the Ni-N4sites and accelerate CO desorption, thereby improving the catalyst stability (Zhang et al., 2020).

Metal-free carbon-based materials were also found to be effective for ECR to CO. However, the pristine, defectfree carbon materials are less effective, and incorporating heteroatoms such as nitrogen into the carbon matrix is necessary to improve activity. Su’s group reported an N-doped CNT synthesized through the pyrolysis of mixtures of poly (diallyl dimethylammonium chloride) and oxidized CNTs. By adjusting types and contents of the used nitrogen dopants, a maxi-mum FE of 90% for CO formation and stable operation over 60 h with total current density and FE of 5.8 mA cm-2and 85% can be achieved, respectively. During the reaction,the N-containing functionalities played an important role in stabilizing the*COO-intermediate, and this is the key for the sample to possess high performance (Xu et al., 2016).

Table 3. Summary of research results on ECR catalysts.

5.3.ECR to hydrocarbons

With the combination of hydrogen from water, CO2can be electrocatalytically converted to hydrocarbons, mainly containing methane (CH4) and ethylene (C2H4), via eight electron-proton and twelve electron-proton reaction processes,respectively. Cu-based nanoparticles can produce hydrocarbons at moderate overpotentials. This is attributed to the appropriate strength of CO chemisorption on Cu, and protonation or dimerization of CO is considered to be a key step towards the formation of single- (CH4) or multi-carbon(C2H4) hydrocarbons (Peterson et al., 2010) (Kortlever et al.,2015). During the above mechanism, the *CO coverage on the catalysts can significantly influence the ECR activity and selectivity. A high *CO coverage can readily trigger C-C coupling that enhances C2H4formation, while less*CO on the catalyst surface might not be competitive enough over hydrogen evolution reaction (Huang et al.,2017).

In the past several years, significant progress has been made in ECR to C2H4conversion, including catalysts, electrolytes, and electrodes. A typical example was reported by Sargent’s group where a Cu electrocatalyst at an abrupt reaction interface in an alkaline electrolyte (7 M KOH) reduces CO2to C2H4with 70% FE at a potential of -0.55 V vs.RHE. The remarkable performance is correlated to hydroxide ions on or near the Cu surface, which lowered the activation energy barriers of ECR and C-C coupling (Dinh et al.,2018). A graphite/carbon NPs/Cu/PTFE electrode was further constructed to prevent flooding problems and stabilize the Cu catalyst surface, thereby resulting in enhanced stability over the prolonged operation for 150 h. Afterwards, they developed a Cu-Al alloy electrocatalyst to further improve the FE of C2H4to 80% at a current density of 400 mA cm-2in 1 M KOH electrolyte. They suggested that the Cu-Al alloys provide multiple sites and surface orientations with near-optimal CO binding for both efficient and selective ECR (Zhong et al., 2020).

The progress on ECR to CH4, which has the highest heating value of 55.5 MJ kg-1among all the ECR products, is far behind that of C2H4. There is still a lack of applicable catalysts with satisfactory CH4selectivity. Only very recently,Xiong et al. fabricated an Ag@Cu2O core-shell structure.By fixing the Ag core and adjusting the Cu2O envelope size,the *CO coverage and *H adsorption at the Cu surface can be modulated to steer the ECR pathway towards CH4. The optimal catalyst delivered a high CH4FE of 74% ± 2% and a partial current density of 178 ± 5 mA cm-2at -1.2 V vs.RHE (Xiong et al., 2021). Yadav and co-workers reported an amine functionalized N-doped GQDs for efficient ECR to CH4. It revealed that the CH4yield (partial current density) increased linearly with amino group (NH2) content. Consequently, a maximum CH4FE of 63% could be obtained over the catalyst with the maximum NH2content of 9.07 atomic concentration (at. %) (Yadav et al., 2022).

5.4.ECR to oxygenates

Investigations on ECR to oxygenates mainly focus on formic acid (or formate) and ethanol via two electron-proton and twelve electron-proton reaction processes, respectively.Formic acid is an important product from ECR that has been widely explored as a hydrogen carrier. The common strategy for industrial production of formic acid is carbonylation of methanol, which, however, requires intensive energy input. It is thus highly desired to directly convert CO2to formic acid via the ECR process, which was predicted to have a production potential of 475 kt yr-1by 2030 globally.(Contentful, 2021).

Several metals, including Sn, In, and Bi, have been investigated as electro-catalysts for selective ECR to formic acid or formate. Among these metals, Sn commands the most attention for its low toxicity and cost. Bai and some of the coauthors of this paper developed a Pd-Sn alloy electrocatalyst for exclusive formic acid formation (FE>99%) in a 0.5 M KHCO3solution. The presence of Pd modified the electronic configuration and oxygen affinity of Sn, which stabilized the HCOO* intermediate and the subsequent formic acid formation (Bai et al., 2017). Recently, Zheng’s group developed a surface-Li-doped Sn (s-SnLi) catalyst, which exhibited a high FE of 92% and a partial current density of 1.0 A cm-2for producing formate. The introduction of Li dopants into the Sn lattice enabled the localization of negative charges and lattice strains to their neighbouring Sn atoms; thereby,both activity and selectivity of ECR to formate were enhanced (Fig. 11) (Yan et al., 2021).

Ethanol, a kind of clean and renewable liquid fuel with a heating value of -1366.8 kJ mol-1, is a preferred product from ECR. Owing to the higher energy density and ease of storage and transportation compared to gas products,ethanol has also been considered as one of the optimal candidate fuels that substitute or supplement fossils in many applications (Shih et al., 2018). Moreover, ethanol is also an important and widely used common chemical feedstock for organic chemicals and medical disinfectants. Based on the considerable market demand, direct conversion of CO2to ethanol using only water and driven by renewable energy is highly desired.

Cu is the only reported metal so far that can electrochemically catalyse ECR to ethanol. However, the selectivity is extremely low due to its moderate binding energy with most reaction intermediates. To promote the selectivity towards ethanol, manipulation of the binding strength of reaction intermediates on Cu is a commonly used strategy. Xu et al.reported a carbon-supported Cu catalyst via an amalgamated Cu-Li method, by which most Cu is atomically dispersed on the carbon surface. The high initial dispersion of single Cu atoms favors the selective ECR to ethanol with FE reaching ~91% at -0.7 V vs. RHE and outstanding durability of 16 h. However, the current density (around 1.8 mA cm-2) is still below the industrial level (Xu et al., 2020). Based on recent investigations, the improvement of current density is at the expense of ethanol FE. For instance, Sargent’s group coated a nitrogen-doped carbon (N-C) layer on a Cu surface to build a confined reaction volume, which promoted C-C coupling and suppressed the breaking of the C-O bond in HOCCH*, thereby promoting ethanol selectivity in ECR.Under a current density of 300 mA cm-2, an ethanol FE of(52 ± 1) % is achieved on 34% N-C/Cu (Wang et al., 2020).Metal-free nitrogen-doped carbon materials have also been recently reported to be capable of ethanol production from ECR, which delivered comparable catalytic activities to Cubased catalysts and even better durability. Song and co-workers developed a metal-free cylindrical mesoporous nitrogendoped carbon as a robust catalyst for selective ECR to ethanol. The synergy of nitrogen heteroatoms and highly uniform cylindrical channel structures dramatically boosted C-C bond formation in ECR. Therefore, the catalyst enabled efficient production of ethanol with a high FE of 77%at -0.56 V vs. RHE in 0.1 M KHCO3(Song et al., 2017).Inspired by the potential of adjusting the nanostructure of the catalyst to acquire multi-carbon compounds, the group further developed a hierarchical porous N-doped carbon with micropores embedded in the channel walls of N-doped ordered mesoporous carbon. By controlling the micropore content, the ethanol formation rate is improved by one order of magnitude compared to that of the counterpart without medium micropores. These reports have provided new insights for designing highly efficient electrocatalysts for ECR to ethanol in the future (Song et al., 2020).

Fig. 11 Scheme illustrations of (a) electrochemical lithiation preparation of the s-SnLi catalyst, and (b) its function mechanism for ECR to formate [Reprinted from (Yan et al., 2021)].

Fig. 12 The demonstration system of CO2 electrolysis for syngas production [Reprinted from (Carbon Energy Technology Co. LTD, 2020)].

6.Summary

Clearly, CCUS will play an important role in reaching the carbon neutrality target, not just at its current stage, but more so after future development. In particular, deep decarbonization requires a considerable revolution of the current energy and industrial infrastructure. Therefore, cutting-edge/disruptive CCUS technologies are becoming increasingly important and influential.

In this paper, we reviewed four technologies that are regarded as frontiers of CCUS. In Table 4, their relevance to carbon neutrality over other low-carbon technologies,advantages over regular CCUS technologies, and difficulties for future development are summarized.

DAC is one of the rare technologies that is able to offer negative emission, and very uniquely, DAC also provides a solution to historical emissions. Both characteristics are necessary to suppress climate change. When comparing with other CCUS technologies, localization of DAC is highly flexible. Therefore, the necessity for CO2transportation can be minimized by deployment of DAC in close vicinity of CO2emitters and/or downstream utilization/storage sites. Based on such a feature, DAC is an ideal approach for distributed,mobile, and small-scale emitters. Currently, DAC is an immature technology, and the process cost is relatively high. Efficient absorbents/adsorbents, coupling with renewable energies, process engineering, and scaling-up are among the most urgent issues to be solved.

Flexible MOFs are a type of smart materials that can potentially alter the landscape of many applications. When they are used as CO2adsorbents, their reversible breathing behavior toward external stimuli may change the fundamental thermodynamic driving force for adsorbent regeneration and thus enable less energy-intensive strategies over traditional temperature-swing and pressure-swing processes. Lowering the cost of CO2capture by flexible MOFs is of particular importance to facilitate the large-scale application of CCUS,which in turn guarantees carbon neutrality to be achieved.However, the performance of the reported flexible MOFs cannot meet the requirement of practical application. Further research, including design of a suitable process, is needed.

ICCC technology represents a new way of carbon recycling, which may promote the formation of low-carbon models and processes of the industrial system. This is of promise as decarbonization of industrial departments is considerably difficult. Compared with existing CCUS technologies, ICCC has obvious advantages in terms of cost reduction, source-sink matching, and so forth. Nevertheless,ICCC is still in the laboratory verification stage. How CO2capture and its conversion can be efficiently combined, how value-added products can be obtained, and how the process can be adjusted to match practical application scenarios are still questionable at this stage.

Recently, ECR has been one of the most eye-catching areas in catalysis. Due to its natural connection with renewable electricity, the process manages to close the carbon loop of fuels and chemicals by storing the low-grade renewable energy. Therefore, large-scale deployment of ECR can effectively avoid consumption of fossil fuels and thus contribute carbon reduction in an indirect way. Compared with other CO2conversion technologies, the ECR process can be carried out under very mild conditions. Additionally, ECR can be readily modularized, which greatly facilitates its scaling up. The primary technical difficulties of ECR include the design and preparation of the catalyst with high activity and selectivity and engineering challenges related to couplingwith low-grade renewable energy.

Table 4. Summary of selected CCUS technologies.

7.Outlook

CCUS technology is the only approach that can achieve large-scale and low-carbon utilization of fossil energy and resources, which will surely play an important role in coping with climate change. However, under the new goal of carbon neutrality, the positioning of CCUS technology has changed significantly, and the application scenarios of some cuttingedge/disruptive CCUS technologies have been greatly expanded, which is expected to constitute inevitable carbon reduction solutions for the energy and industrial system.

The CCUS technologies reviewed in this paper have attracted widespread attention from both the academia and industrial sectors, and their feasibility has been well verified,with some technologies having been demonstrated on a certain scale. In the future, it will be necessary to further strengthen related investigations on materials, mechanisms,processes, and engineering. These will lead to the lowering of process costs and clarification of application scenarios,eventually promoting the practical application of the technologies. It should be noted that in recent years, research on CCUS and related fields has progressed very rapidly, and this paper is not comprehensive as it only lists a limited number of examples. Facing the future, cutting-edge/disruptive CCUS technologies will continue to emerge and develop,and we anticipate they will offer important contributions to carbon neutrality.

Acknowledgements.This work was supported by Shanghai Science and Technology Committee (Grant Nos. 21692112200 and 20DZ1207500) and Inner Mongolia Science and Technology Department (Grant No. 2021ZD0020).

Open AccessThis article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing,adaptation, distribution and reproduction in any medium or format,as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material.If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence,visit http://creativecommons.org/licenses/by/4.0/.

Advances in Atmospheric Sciences2022年8期

Advances in Atmospheric Sciences2022年8期

- Advances in Atmospheric Sciences的其它文章

- Preface to the Special Issue on Carbon Neutrality: Important Roles ofRenewable Energies, Carbon Sinks, NETs, and non-CO2 GHGs※

- Electronic Supplementary Material to:The Chinese Carbon-Neutral goal:Challenges and Prospects*

- Electronic Supplementary Material to:The Variability of Air-sea O2 Flux in CMIP6:Implications for Estimating Terrestrial and Oceanic Carbon Sinks*

- Electronic Supplementary Material to:The Synergism between Methanogens and Methanotrophs and the Nature of their Contributions to the Seasonal Variation of Methane Fluxes in a Wetland:The Case of Dajiuhu Subalpine Peatland*

- Electronic Supplementary Material to:Ocean-atmosphere Teleconnections Play a Key Role in the Interannual Variability of Seasonal Gross Primary Production in China*

- Electronic Supplementary Material to:Changes in Global Vegetation Distribution and Carbon Fluxes in Response to Global Warming:Simulated Results from IAP-DGVM in CAS-ESM2*