Quality property of beverage drink from Tiger nut milk,malted yellow maize blend

Akama Friday Ogori ,Amove Julius ,Owoicho Martins Eche

1Department of Home Science and Management,Faculty of Agriculture,Federal University,Gashua PMB1005,Yobe state,Nigeria.2Department of Food Science and Technology,Federal University of Agriculture,Makurdi PMB2373,Benue State,Nigeria.

Abstract Background:Beverage making is an effective method of product conversion of rhizomes and cereals particularly in the context of providing health/nutritional benefits.The Combination of Tiger nut and yellow maize to make a beverage drink would be promising.Therefore,Proximate,chemical,microbial and sensory qualities as influenced by blend variations was investigated.Methods:Tiger nut (Cyperus esculentus L.) and yellow maize(zea mays) were processed into fresh natural beverage drink.Tiger nut milk and malt extracted from malted yellow maize were blended at A (90% :10%),B (80% :20%),C(70% :30%),D (60% :40%) respectively and tiger nut milk (100%) was used as a control.Results:Proximate,chemical,microbial and sensory qualities revealed that protein,fiber,Titratable acidity ash and carbohydrate increased with increase in malt from yellow maize addition.Protein (2.20–6.34)%,Fibre (022–0.34)%,Ash (0.21–0.31)%,carbohydrate(2.21–13.58)%,Moisture (70.41–77.10)%,Fat (18.41–9.0)% values decreases with an increase in malted yellow maize addition.Result of the chemical analysis revealed that total solid (23.10–24.61),(2.81–5.91),Viscosity (68.01–92.01),pH (622–6.74) increased with increase in malted yellow maize addition while pH decrease with increase in malted yellow maize.Total viable count (8.0× 106±7.1–1.0 × 107±7.1) and total fungi count(3.15 × 106 ± 3.6–2 × 103 ± 1.4) increased among sample A (100%Tiger nut milk:0%malted yellow maize)and E(60%Tiger nut milk:40% malted yellow maize),except sample B(90%Tiger nut milk:10% malted yellow maize)C(80%Tiger nut milk:20%malted yellow maize)and D(70% Tiger nut milk:30% malted yellow maize).Significant differences existed in sensory scores for flavor/aroma (7–5),texture (5–7),taste (4–7) and general acceptability of the products (5–8).Conclusion:Beverage drinks prepared from tiger nut milk and malted yellow maize can be used as a beverage food for both young and older persons due to the products high nutrient density.

Keywords:tiger nut;yellow maize;malt;beverage;drink;sensorial;nutrients

Introduction

Beverage cereal food product made from individual maize (Zea mays)grains,sorghum (Sorghum bicolor) grains,millet (Pennisetum typhoideum) grains or rice (oryza sativa) are common and Africans’staple [1].These crops,particularly maize and sorghum are widely grown and produced in large quantity in African countries USAD,(2005)[2].

Tiger nut (Cyperus esculentusL.)is cultivated large in Nigeria.Tiger nuts are eaten raw and sometimes roasted and as hog feed or made into juice to make likely beverages.Tiger nut,an under-utilized crop had been reported by [3] to be high in fibre and for the management of nutritional diseases.Edible oil have been extracted from tiger nut with better physiochemical properties [4] High oxidative stability [5].Good cooking oil and resistance to chemical decomposition at high temperature [6].Similarly,tiger nut despite the name is a starchy tuber which has been widely used in the production of milk-like beverage.This beverage however,is deficient in glycemic index [7].Malting as a locally available processing technology has been widely accepted for its role in improving the nutrient content of cereals [1].Malting in the processing of cereals increases activity of endogenous phytase through novo synthesis,alpha-amylase activity and reduction in viscosity[5].Hence,this research aims at formulating and assessing the quality of a cheap and easily accessible beverage drink producible from tiger nut milk and malted yellow maize.This new beverage blend from indigenous food crops which are locally available and suitable for school age children may alleviate malnutrition.

Materials and methods

Materials

Sources of materialsFresh tiger nuts and yellow maize were obtained from North bank market,Makurdi Other ingredient include;sugar,sweetener and water which were also purchase from North bank market,Makurdi.

Preparation of Tiger nut milk from Tiger nutMilk from tiger nuts was prepared according to method of [8].Fresh tiger nut (1 kg) were cleaned,washed and rinsed with potable water after which they were blend several times and made into sludge with six liters (6 L) of water in a Q-link auto blender with serial no SB256.The sludge was strained using sieve cloth to extract milk.The mixture was pasteurized at 72°C for 15 minutes by autoclaving in Figure 1.Then we got tiger nut milk.

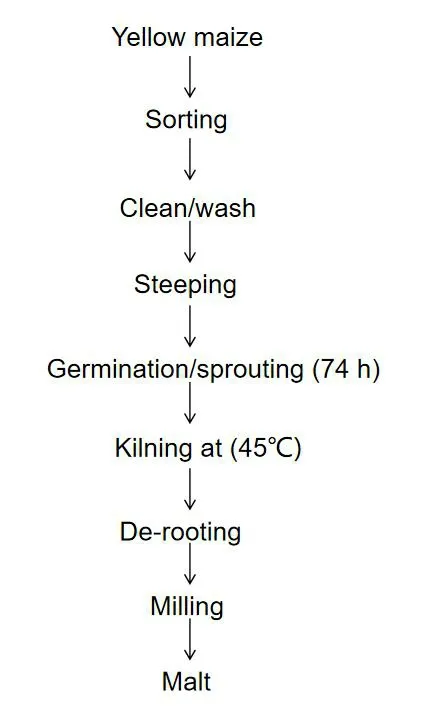

Preparation of malted yellow maizeYellow maize was malted according to the method of [9].The yellow maize was cleaned and washed in 5.0% sodium chloride (NaCl) solution to repress mold growths.The treated maize was steeped in water at room temperature The plastic water container was changed at 3 h intervals to stop fermentation for a total period of 9 h.The maize was drained and subjected to malting for a period of 72 h.After 72 h,the germination was arrested by kilning in the cabinet dryer at 45°C for 24 h and subsequently de-rooting prior to dry milling into flour to obtain maize malt flour.

Malt from the malted yellow maize was accomplished by the addition of 2.5 liters of clean water solution at 45°C to the malted while stirring for 15-20 minutes for malt produce.Figure 2 shows the flow chart for the production of malted yellow maize.

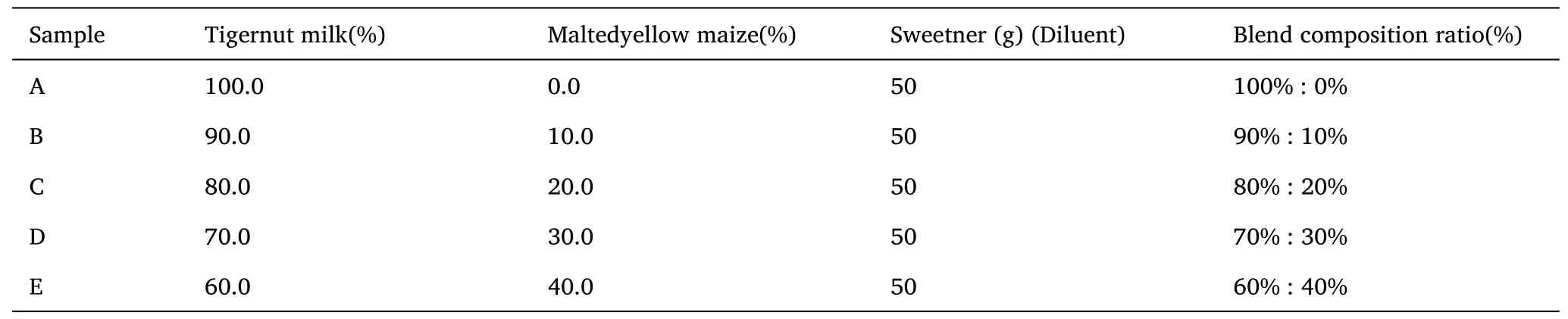

Formulation of BlendsMalted yellow maize flour (1 kg) was mixed with 2.5 liters of water vigorously after which it was sieved using fine sized sieve cloth to extract the malt.The malts were allowed to sediment after which the top layer was decanted.The malt was mixed vigorously with tiger nut milk after which sugar (50 g),sweetener was added.The product was then homogenized and pasteurized at 72°C for 15 minutes after which the product was hot filled in bottles and then cooled at 28°C.(Table 1).

Figure 1 The production of tiger nut milk[8]

Figure 2 Malted yellow maize production[9]

Table 1 Blends Formulation of Tiger nut milk and Malted Yellow Maize Beverage

Methodology

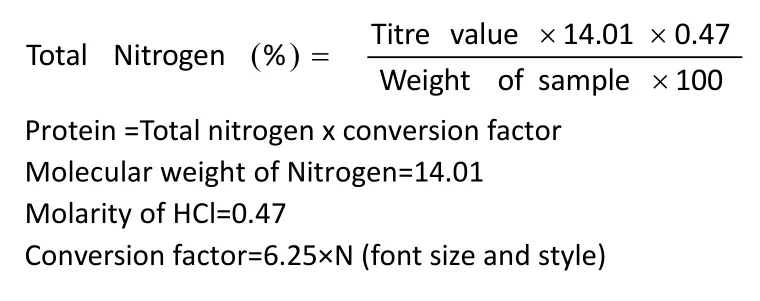

Protein determinationTwo grams of Malted yellow maize and tiger nuts milk were measured into kjedhal digestion tube and 15 mL of tetraoxosulphate (IV) acid (conc.H2SO4) added for quick dissolution.Kjedhal catalyst was added to speed up the process which later gave into clear solution.Distilled water (75 mL)was added to the tube after digestion the mixture was distilled upto 50 mL using 40% NaOH diluted solution,and then into 25 mL of 40 % boric acid.The mixture was titrated against 0.47 M HCl to first grey colour.Blank titre was.made titrated and value recorded AOAC (2012)[10]

Ash contentTwo grams (2 g) of beverage blend samples was measured into an empty porcelain ignitable crucible that was ignited,cooled and measured.The sample was ignited over a hot plate in a fume cupboard to char organic matter.The ignitable crucible was placed in the muffle furnace maintained at 600°C for 6 h.After ash,it was then cool in a desiccator and measured AOAC(2012)[10].

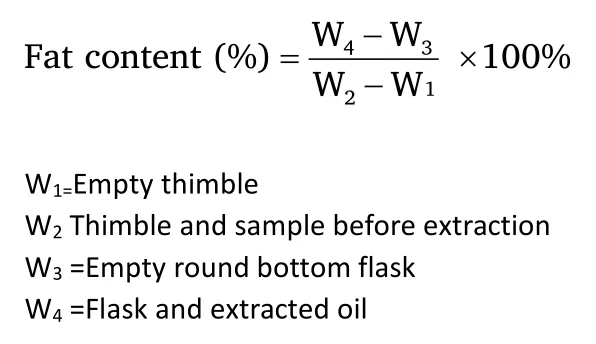

Crude fatMethod of AOAC (2012)[10] was used.Empty Soxhlet thimble was measured as W1.Five (5) grams of dried sample was then added and measured as (W2).The soxhlet bottom flask was cleaned and measured empty as (W3) and then filled up with petroleum ether up to three-quarter flask.Soxhlet extractor was fixed with a condenser to adjust the heat sources so that solvent boils gently.The thimble containing the sample solution was then put inside the Soxhlet apparatus and extraction was carried out for 6 h.At the end,flask containing the oil was dried in a hot-air oven for 1 h at 100°C to remove traces of water and solvent.Thereafter it was cooled and weighed as(W4).

Crude fiber determinationThe crude fiber content was analyzed using AOAC(2012)[10] method.Two (2) grams of beverage sample was measured and put in a 250 mL beaker.Mixture was boiled for 30 minutes with 100 millitres of 0.12 molar concentration of H2SO4and then filtered.The filtrate was washed using boiled water until no acidic trace detected.This procedure was done twice and filtered with hot water and methylated spirit thrice.The residue was transferred into ignitable crucible and dried in the oven at 103°C for 1h.The crucible with its content was cooled in a desiccator and then weighed as(W1).The residue was then taken into a furnace for ash at 600°C for 1 h.The ashed sample was removed from the furnace and put in a desiccator to cool and measured as(W2).

Where:

W1=crucible and residue,W2=final ashed sample

Carbohydrate content determinationCarbohydrate content was determine by difference as described by [11].

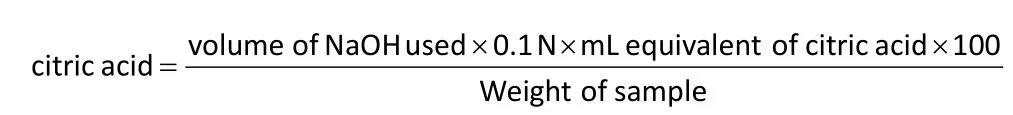

Determination of total titratable acidityThe AOAC (2012)[10]method was used.10 g of sample was dissolved in 100 mL of distilled water.A 10 mL aliquot of supernatant was titrated with 0.1N NaOH using phenolphthalein as indicator.

Determination of total soluble solidsTSS was determined using AOAC (2012)[10].Dry empty dishes were weighed and 5 g of the samples were added.These were placed on a boiling water bath and left to stand until the water was evaporated from the samples.The samples were placed in an oven at 102°C for 2.5 h.They were allowed to cool and records taken.

Viscosity determinationThe juice samples viscosity was determined using a Brookfield viscometer (model Lv-3) with spindle number at 60 rpm AOAC (2012)[10].

Microbiological analyses of the BlendsMicrobiological analysis of the juice was done as described by [12] for determining the total bacteria count and yeast and mold count.The drink was serially diluted and introduced into sterile petri dishes after which molten agar was poured mixed and allowed to set.The different agar plates were incubated under appropriate conditions.Nutrient Agar (NA) was used for the enumeration of total bacteria count at 37°C for 24-48 h and Sabourd Dextrose Agar (SDA) was for the enumeration of moulds and yeasts in the samples at(28 ± 2°C)for 3-5 days.

Agar well technique as described by [13] was used to determine the antibacterial activity of the beverage extracts.The test organism(Salmonella typhii) was diluted with Muller Hinton broth to 0.5%McFarland equivalent standard [13].A 25 mL of Mueller Hinton Agar(HiMedia) plates were checked for sterility and carpet streaked with an overnight broth cultured of bacterial isolate,using sterile cotton buds.A sterile cover cock borer of 6 mm diameter was used to make uniform wells on the surface of the streaked agar media.With the aid of a micropipette the wells were filled up with 200 µL each of the undiluted juice extract (A-E).The plates were stand for 1 h in the refrigerator to allow proper diffusion of the extract.Plates were incubated at 37°C for 24 h after which the diameters of zones of inhibition were measured and recorded in millimeter.A solution of 25 mg/mL amoxyllin was prepared and 5 mg (200 µL) was used as control.

Determination of pHThe pH was determined using an electronic digital pH meter,following the method outlined in AOAC(2012)[10]The pH was standardized and the electrode was rinsed with distilled water,the electrode was dipped into 5 g of sample which was mixed in 50 mL of water.

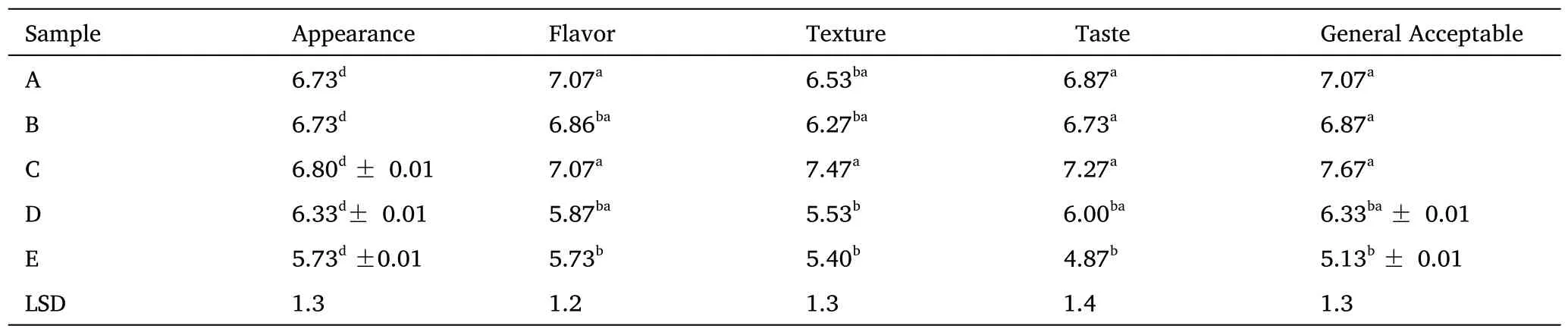

Sensory EvaluationSensory evaluations were carried out to assess consumers’ preference using point hedonic scale [14].Ten panelists were used to evaluate the following attributes;appearance or colour,smell,taste and general acceptability of the jam.The panelists were selected from students of the college of Food Science and Human Ecology,Federal University of Agriculture,Makurdi.For each sample,10 g of beverage was served in white disposable plates with some water to rinse after each sample.The plates were coded with three digit random numbers and randomized between panelists.After each sample by panelist,panelist rinsed their mouth with clean provided water before proceeding to the next sample.The evaluation took place at 10am in the sensory evaluation laboratory.

Statistical AnalysisResults were expressed as a mean value and standard deviation of two determinations.Datas were analyzed using one-way analyses of variance (ANOVA) using Statistical Package for Social Science (SPSS) version 20.0 software 2011 to test the level of significance at 5% probability(P<0.05).

Result and discussion

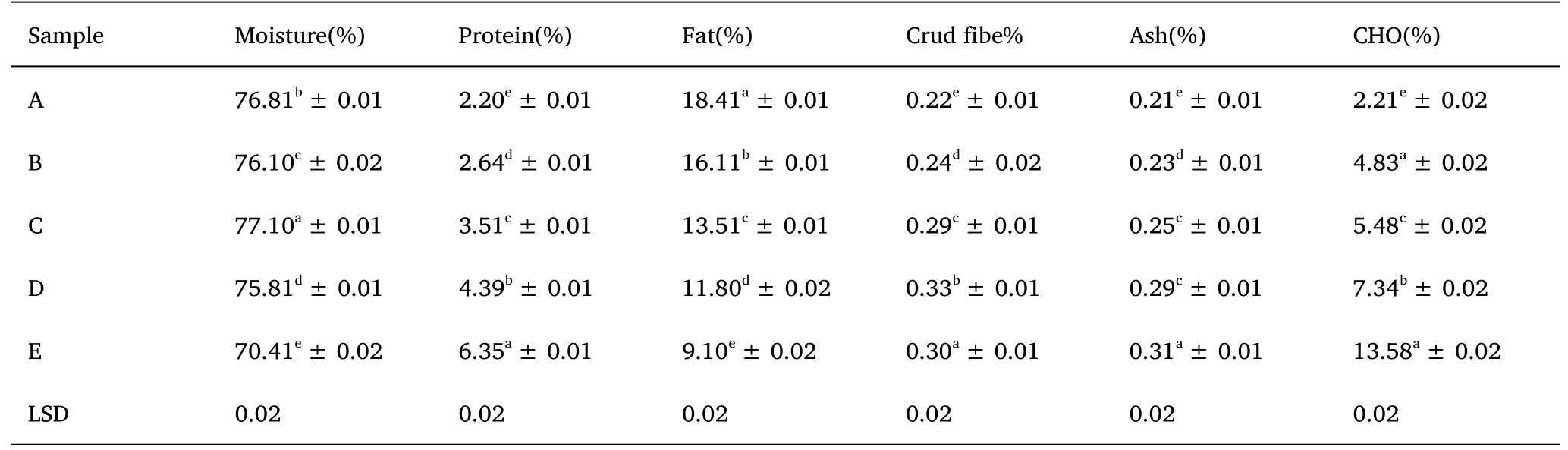

The proximate composition of blend of tiger nut milk and malted yellow maize is presented in Table 2.Moisture content ranged from 70.41% -77.10%,sample A,the control has the highest moisture content but there was gradual decrease in moisture content among the samples,this is as result of the fact that as the ratio blend increases with malted yellow maize the moisture content decreases,this might be due to continuous malting of the mixed blend beverage drink.There was significance differences at probabilityP<0.05 in moisture content among the samples(ABCDE) with LSD 0.02.Protein content of the blend ranged from 2.20%–6.35%,with significance differences at probabilityP<0.05 in protein content in all the samples with LSD 0.02.Sample A has the lowest values of protein content while sample E has the highest amount of protein content as the ratio blend increases with malted yellow maize,the protein content increases.This value slightly agreed with (2%-4%) [13],on tiger nut proximate values.The slight reduction might be due to processing approach into milk and infinite dilutions from malted yellow maize,chelating bio-nutrients and use up of nutrients by malt enzymes.Fat content ranged from 18.41% to 9.10% with significance difference at probabilityP<0.05 in all the samples with LSD 0.02.Fat content was found to be high in sample A,but decreases among the rest samples with increase in the ratio blend.This implies that as the ratio blend increases with malted yellow maize the fat content decreases accordingly.Fiber content ranged from 0.33% to 0.34% with significance difference at probabilityP<0.05 in all the samples with LSD 0.02.Sample A has the lowest amount of fiber while sample E has the highest amount of fiber,the fiber content increases with increase in the ratio blend.This may be due to malting process.Ash content ranged from 0.23% to 0.31% with significant differences at probabilityP<0.05 in all the samples with LSD 0.02.Sample A has the lowest amount of fiber content and sample E has the highest amount of fiber content.There was a gradual increase in the samples as the ratio blend with malted yellow maize increase.Carbohydrate ranged from 2.21% to 13.58% with significant differences at probabilityP<0.05 in carbohydrate content in all the samples with LSD 0.02.Sample A has the lowest carbohydrate content and sample E had the highest,as the ratio blend increased with malted yellow maize.There was an increase in the carbohydrate content accordingly.

Table 2 Proximate Values of Beverage Drink From Tiger nut milk and malted yellow maize

Table 3 Chemical composition of blends of tiger nut and malted yellow maize

The chemical composition of blend of tiger nut and malted yellow maize is presented in Table 3.Total solid ranged from 23.10% to 24.61% with significance difference atP<0.05 in total solid of samples with LSD 0.02.Sample C has the lowest amount of total solid while sample E has the highest.There was an increase in total solid of the samples accordingly as the ratio blend with malted yellow maize increases.This observation is due to nutrient density as a result of solid malted yellow maize addition and malting process [14,16,17].TTA content ranged from 2.81% to 5.91% with significance differences at probabilityP<0.05 TTA content of all the samples with LSD 0.02.Sample A has the lowest TTA content while sample E has the highest,this implies that tiger nut is low in TTA than malted yellow maize reason being malting converts and utilizes radical and nutrients during synthesis [17,18].Viscosity ranged from 68.01%–92.01% with significance differences at probabilityP<0.05 in all the samples with LSD 0.02.Sample A has the lowest viscosity,followed by sample B,C,E and sample D which has the highest viscosity.The viscosity increases as the ratio blends increases with malted yellow maize.This agreed with [15],that increased concentration as a result of malt addition increases viscosity68%-87% and pH with ranged from 6.22% to 6.74% with significant differences at probabilityP<0.05 among sample A,B,and C with LSD 0.02,but there was no significant differences among sample D and E.The pH decreases with an increase in the ratio blends.Beverage drink sample A had the highest pH level but beverage drink sample E had the lowest pH level.

The microbial composition is presented in Table 4.Total viable count ranged from 8.0×106±7.1 to 1.0×107± 0 with significance differences at probabilityP<0.05 among sample A and sample E,but there was no significance differences among sample B,C and D.Total fungi counts ranged from 3.15×106± 3.6 to 1.2×103±1.4 there was no significance differences among all the samples.The decrease in microbial load is safe for human consumption [1].The acid condition of the sample may be due to acidic nature of the beverage with increase in malting addition.

The sensory attribute of blend of tiger nut and malted yellow maize is presented in Table 5.Appearance of the blend ranged from 6.80 to 5.73 with LSD of 1.3,there was no significant differences in all the samples.Sample C had the highest scores and sample E has the lowest scores.Flavor/aroma of the blend ranged from 7.07 to 5.73 with LSD 1.2.There was not significance differences among sample A,B,C and D,but there was significance differences at probabilityP<0.05 in sample E.Sample A and C has the high scores of 7.07 and sample E has the lowest scores of 5.73 intense of flavor/aroma.Texture of the blend ranged from 5.40 to 7.47 with LSD 1.3.Sample A and B are the same with sample D and E,but there was significance differences atP<0.05 in sample C.Sample C has the highest scores of 7.47 and sample E has the lowest scores of 5.40 for of texture.Taste of the blend ranged from 4.87 to 7.27 with LSD 1.4.There was not significance differences among sample A,B,C and D,but there was significance differences at probabilityP<0.05 in sample E.Sample C has the highest scores of 7.27 and sample E has the lowest scores of 4.87 in taste.General acceptability ranged from 5.13 to 7.67 with LSD 1.3.Sample A,B and C are the same that is,there was no significant difference among them,but there was a significance difference among sample D and E.The ratio blend of 80% tiger nut milk and 20%malted yellow maize has the highest scores of 7.67 and the ratio of 60%tiger nut milk and 40% malted yellow has the lowest scores of 5.13 for general acceptability.

Table 4 Microbial Composition of blend of Tiger nut and malted yellow maize

Table 5 Sensory Attribute of Blend of Tiger nut and malted yellow maize

Conclusion

The result revealed that milk prepared from Tiger nut and Malted Yellow maize is a potential beverage drink for both young and old persons due to the beverage high nutrient density.Based on the sensory evaluation,the Tiger nut Malted yellow maize blend and tiger nut milk were also acceptable beverage drink.It is therefore recommended that beverages from tiger nut milk and malted yellow maize in the ratio 80%:20% could possibly alleviate protein-energy malnutrition in adult and school age children.

- Food and Health的其它文章

- Potential clinical relevance of L-Carnitine supplementation in oncology

- Double Ribbons campaign:How to reduce the incidence of breast cancerand cervical cancer in Chinese women

- Influence of storage life and variety on the micro-nutrient compositions of stored cocoyam-based products

- Vitamin A supplement:a key strategy to prevent vitamin A deficiency among young children in Afghanistan

- Phytochemical,anti nutrient,invitro-protein digestibility and functional properties of(Balanites aegyptiaca(L.)Delile)Aduwa protein meals,Protein Concentrate and Isolate