Effects of the electric field at the edge of a substrate to deposit a Ø100 mm uniform diamond film in a 2.45 GHz MPCVD system

Kang AN (安康), Shuai ZHANG (张帅), Siwu SHAO (邵思武),Jinlong LIU (刘金龙),2, Junjun WEI (魏俊俊),2, Liangxian CHEN (陈良贤),Yuting ZHENG (郑宇亭),2, Qing LIU (刘青) and Chengming LI (李成明),2,∗

1 Institute of Advanced Materials and Technology,University of Science and Technology Beijing,Beijing 100083, People’s Republic of China

2 Shunde Graduate School, University of Science and Technology Beijing, Foshan 528399, People’s Republic of China

3 State Key Laboratory of Advanced Metallurgy, University of Science and Technology Beijing, Beijing 100083, People’s Republic of China

Abstract In this study, uniform diamond films with a diameter of 100 mm were deposited in a 15 kW/2.45 GHz ellipsoidal microwave plasma chemical vapour deposition system.A phenomenological model previously developed by our group was used to simulate the distribution of the electric strength and electron density of plasma.Results indicate that the electric field in the cavity includes multiple modes,i.e.TM02 and TM03.When the gas pressure exceeds 10 kPa,the electron density of plasma increases and plasma volume decreases.A T-shaped substrate was developed to achieve uniform temperature,and the substrate was suspended in air from Ø70 to 100 mm,thus eliminating vertical heat dissipation.An edge electric field was added to the system after the introduction of the T-shaped substrate.Moreover,the plasma volume in this case was greater than that in the central electric field but smaller than that in the periphery electric field of the TM02 mode.This indicates that the electric field above and below the edge benefits the plasma volume rather than the periphery electric field of the TM02 mode.The quality,uniformity and surface morphology of the deposited diamond films were primarily investigated to maintain substrate temperature uniformity.When employing the improved substrate,the thickness unevenness of the Ø100 mm diamond film decreased from 22% to 7%.

Supplementary material for this article is available online

Keywords: MPCVD, 2.45 GHz, diamond film, plasma, simulation

1.Introduction

Recently, the demand for large diamond films has increased[1-3].Hot filament chemical vapour deposition (CVD)and DC arc plasma jet CVD are two frequently used CVD techniques already employed in industrial production [4-7].However, microwave plasma chemical vapour deposition(MPCVD)technique that can deposit high-quality diamond films is still under continuous development with respect to the preparation technology of large-sized diamond films.Currently, the 915 MHz MPCVD device is not extensively used in many countries; nevertheless, large-sized diamond films have been produced using 2.45 GHz microwave systems[8-11].Many studies have accomplished film diameters of the order of 3 in[12,13].Therefore,it is a promising attempt as 2.45 GHz MPCVD systems have been equipped in labs and factories globally.

The addition of Ar to the feed gas is a technique used to deposit a large-scale diamond film in the 2.45 GHz MPCVD system.Zuo et al[14]deposited a Ø75 mm diamond film using Ar/CH4/H2with less than 5%uniformity.The other method is to use an MPCVD chamber with a multi-mode electric field,allowing the hybrid electric field to expand the plasma volume.The TM0mn-mode MPCVD chambers have mostly been reported in literature[15-17].Here,0 indicates that the electric field structure is axisymmetric, which yields circular plasma.The indices m and n indicate the number of electric field maxima (or lobes)in the radial and axial directions, respectively.Silva et al [15] designed a slender cylindrical substrate holder in the bottom part of the chamber, and the coaxial electric field mode TEM00ncould be introduced around the metallic substrate holder.Furthermore,an attached electric field was introduced under the outer edge of the substrate holder.The TM0-TEM00nhybrid mode was obtained in the cavity because of the additional field; in the 2.45 GHz MPCVD system, plasma can be maintained above the substrate with a diameter of up to 75 mm.The plasma distribution was affected by the attached electric field because it was closer to the central one electric field.Gu et al [18] adjusted the electric field distance between the TEM00nand TM0modes by varying the height of the substrate holder, achieving a more uniform plasma dispersion.A power density of up to 1000 W cm-3has been achieved for plasma above a Ø25 mm substrate.Weng et al [17] examined a multi-mode MPCVD chamber with the TM01and TM02modes.In this study, a large-volume plasma was used to deposit an Ø80 mm diamond film and then stimulated using a hybrid-mode electric field.Vikharev et al[12]tuned a large-volume plasma by decreasing the electric field gap between the TM01and TM02modes and weakening the electric field strength of the TM03mode.Because of the hybrid-mode electric field, Ø75 mm diamond films have been deposited with depositon rate of 2 μm h-1.For other MPCVD systems,the TM01mode electric field is the only one employed to excite plasma.An et al [8] used the central electric field above the substrate to achieve larger volume of plasma than the substrate size,and a Ø60 mm diamond film was deposited.Yu et al[10] used the MPCVD system in[8] to deposit Ø63 mm diamond films with high power density.They confirmed that as the power density increased, the deposition rate and diamond quality also increased.Recently, our group [11, 19-23] proposed seven types of MPCVD chambers; the diameter of the deposited films was mostly Ø50 mm because we only employed the electric field in the TM01mode.Several of these proposed chambers are multi-mode [19, 20, 24], which is essential for depositing large-sized diamond films.Depositing diamond films with a diameter of >100 mm using these MPCVD equipment is an attractive proposition.In the present study,the ellipsoid chamber previously proposed by our group[24] was employed to deposit Ø100 mm diamond films.

Temperature distribution is a crucial factor impacting the thickness uniformity of diamond films when using a 2.45 GHz MPCVD system to deposit large-sized diamond films.Plasma affects the temperature of the substrate, and the coverage area of the substrate by plasma has an essential impact on the temperature uniformity.When heated using plasma,the centre of the substrate has a higher temperature as the temperature of the plasma core is the highest.To obtain a uniform temperature, central heat transfer must be increased.Depositing diamond films >Ø80 mm is complex because of the low edge heating capacity in a 2.45 GHz system.Our previous work[25]revealed that an edge discharge surrounding the substrate can increase the edge plasma density, and therefore, increase the edge temperature and thickness.Consequently, the edge discharge can be introduced to raise the temperature surrounding the substrate edge.We propose a T-shaped substrate to introduce an electric field surrounding the substrate edge aimed to increase the edge thickness of Ø100 mm diamond films.

2.Simulation and experiment

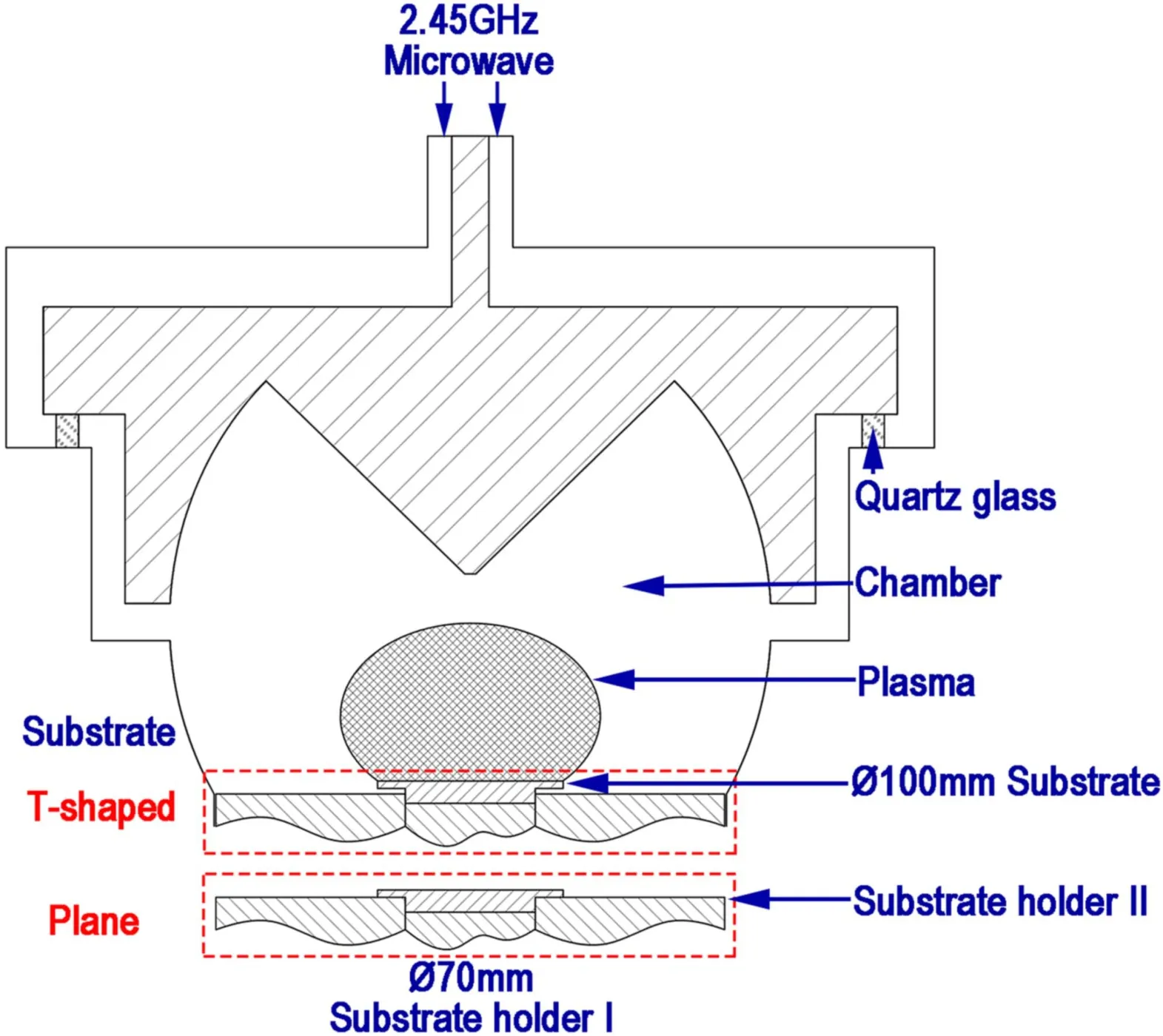

Figure 1 is a schematic of the circumferential antenna ellipsoidal resonant cavity-type MPCVD system previously developed by our research group.The chamber comprises a cone, an ellipsoid and a cylinder.The multi-geometric combination enables the resonant cavity to have multiple modes.The device is equipped with a 2.45 GHz/15 kW microwave source that can deposit uniform high-quality diamond films with high deposition rates at high powers [24].Microwaves with the frequency of 2.45 GHz enter the resonant chamber from the microwave inlet and couples the microwave into a strong electric field above the substrate, which is mounted at the bottom of the cavity.Under negative pressure circumstances, feed gas can be stimulated into plasma to deposit diamond.The core of this MPCVD system is to employ the bifocal features of the ellipsoid.When the only lower focal point is used, the strong coupling effect on microwaves is used to focus the electric field.The bottom of the end cavity is then designed with substrate holder I(Ø70 mm)and substrate holder II (Ø275 mm), which are separately movable and suitable for microwave tuning; moreover, they play an important role in adjusting the distribution of the electric field and plasma.

Figure 1.Schematic of the 2.45 GHz circumferential antenna ellipsoidal cavity-type MPCVD reactor to deposit 100 mm diameter diamond films.In the system, the substrate is placed upon the substrate holder I or II; the substrate’s upper and lower dimensions are Ø70 mm and Ø100 mm, respectively, forming the T-shaped and plane substrates.

Figure 2.Three-dimensional image of a resonant pattern of microwaves in the ellipsoidal MPCVD cavity:(a)front view and(b)bottom view.

In this study, a T-shaped substrate wafer was placed on the substrate holder I.The substrate’s upper and lower dimensions are Ø100 mm and Ø70 mm, respectively.The substrate can be lowered such that the outer part between Ø70 and Ø100 mm can be close to the substrate holder II.In this scenario, the substrate is referred to as a plane substrate.When the substrate was raised, the outer part between Ø70 and Ø100 mm hung in the air, and consequently, formed a suspension.The substrate can be described as a T-shaped substrate in this situation.The diameter of the substrate holder II is larger than 2λ (here, λ is 122.4 mm for 2.45 GHz microwaves).Consequently, the distance between the cavity wall and plasma is larger than (6/7)λ, thereby allowing for accommodating a higher power.The large-size cavity is the base of the multi-mode electric field and plasma.

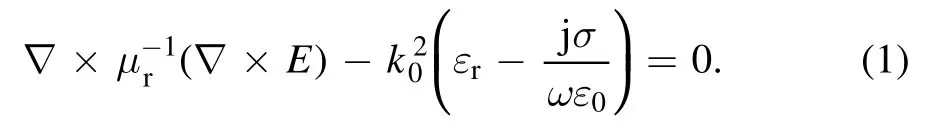

A phenomenological model was used as the simulation method developed by our group [9, 11, 20, 22].Three interconnected moduli (i.e.microwave electric field, plasma and gas temperature)are simulated in the simulation model.The core equations are shown as follows:

The microwave electric field in the MPCVD reactor can be modelled by solving the following Maxwell’s equation:

Electron density can be simulated using the conservation equation.This equation was developed from the equation reported in [26]:

Energy conservation equation:

In equations (1)-(3), E denotes the microwave electric field;ω and k0denote the angular frequency and wave number of the microwave, respectively; ε0denotes the electric permittivity of vacuum; μr, εrand σ denote the relative permeability, relative permittivity and conductivity of the microwave media, respectively; Dedenotes the diffusion coefficient; Rvrdenotes the coefficient of electron recombination;Radenotes the rate coefficient of electron loss through attachment to neutral particles; Rcdenotes the rate coefficient for electron production; Qhdenotes the absorbed power density of plasma;k denotes the thermal conductivity;and Tgdenotes the gas temperature.

In this simulation model, the characteristics of plasma are assumed to be independent of time.The production rate of electrons is assumed to be proportional to the absorbed power density.Gas convection is ignored,and the energy conservation equation is used to describe gas energy conservation.

Based on the simulation results, deposition experiments were conducted; the parameters are listed in table 1.Here,sample I deposition uses a plane substrate,whereas sample II deposition uses a T-shaped substrate.

Table 1.Deposition conditions for Ø100 mm diamond films.

3.Results and discussions

3.1.Resonant pattern of microwave in the ellipsoidal MPCVD cavity

Figure 2 shows a 3D resonance mode diagram in the MPCVD cavity.Figures 2(a)and (b)show the front- and bottom-view images, i.e.the yz and xy planes, respectively.This indicates that the resonant cavity had a multi-mode electric field type with a strong electric field at the centre of the bottom of the resonant cavity, and the electric field strength in other areas was weak.Owing to the large volume of the chamber, the modes TM02nand TM03n(here, n > 1)[15] overlap around the substrate and generate a large-volume plasma ball due to the interaction of multiple parts.The TM02nand TM03nmodes were close to the substrate holder II.As per Weng et al[17], this multi-mode electric field is required to create a large-size electric field and is the foundation for depositing large-scale diamond films for the 2.45 GHz MPCVD system.Several modes of an electric field in this ellipsoidal resonance chamber exhibited the capacity to form large-volume plasma;however,the diameter of the electric field of the TM02nmode was greater than Ø120 mm.

3.2.Effect of the substrate holder on the electric field and plasma characteristics

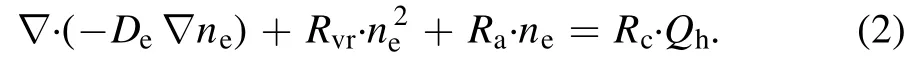

Figure 3 shows the electric field stimulated by the resonant cavity with a power of 10 kW when plasma load is not considered.The electric field distribution is displayed in figures 3(a)and (b)with or without a Ø100 mm deposited substrate.It indicates that regardless of an existing substrate,the electric field is approximately 80 mm in diameter, which is comparable to the size of the large-size diamond film deposited by the current 2.45 GHz microwave system[12, 17].Figure 3(b)demonstrates that the Ø100 mm substrate does not affect the size of the electric field; however, a comparison of the electric field above the substrate indicated that introducing the substrate reduced the intensity of the electric field.For a substrate diameter of 60 mm, the plasma zone excited by an electric field in this size can effortlessly cover the surface and a uniform diamond film can be easily deposited.

Furthermore, under these conditions, the chamber pressure may increase, enhancing the deposition rate of the diamond film.After the addition of the substrate,an electric field forms at the edge of the substrate,as illustrated by the red box in figure 3(b).The electric field varies from the intrinsic modes exsiting in the chamber.The additional electric field is superimposed from the right-angle edge of the substrate.As per our previous studies [24, 25], the plasma excited by the edge electric field considerably influences the diamond deposition rate,wherein the addition of the substrate increases the plasma volume.

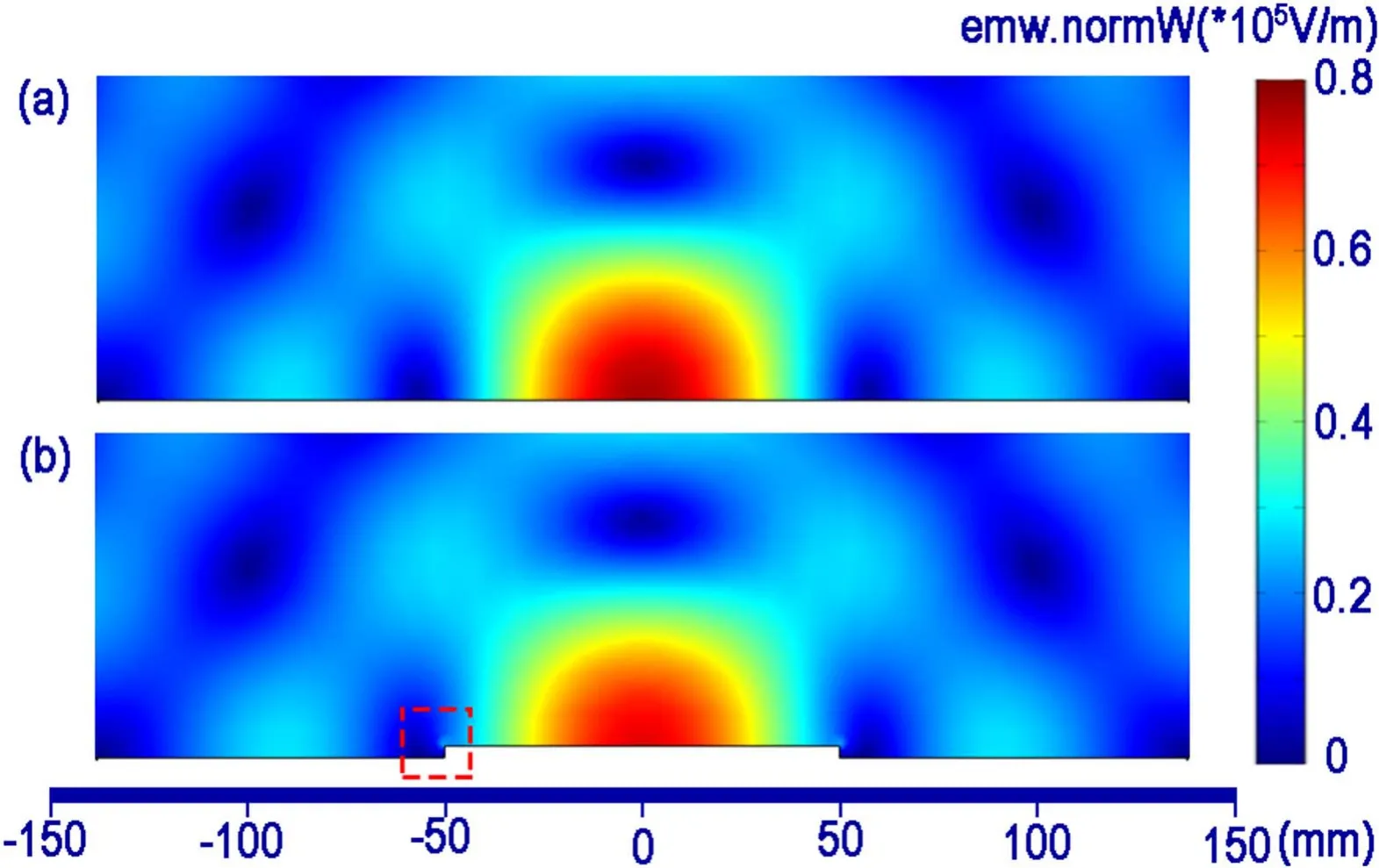

Figure 4(a)shows the the electron density distribution when a plane substrate with a thickness of 3 mm is placed in the resonant cavity using the phenomenological method.Figure 4(c)shows the corresponding electric field distribution.Thus, we can observe that the electric field in the MPCVD system weakens considerably after the introduction of the plasma load.The distribution and volume of the TM02electric field do not change extensively after plasma is generated.The plasma distribution is larger than the central electric field size but smaller than the whole TM02mode electric field size.Consequently, plasma is primarily excited by the central electric field, with the fringe electric field playing an important role in plasma expansion.Thus, the electric field has a certain influence on plasma, but it cannot entirely constrain the plasma shape and distribution.To examine this aspect, the electric field measuring instrument employed in [26] may be an answer to this question.

Figure 3.Distribution of electric strength without plasma in the microwave system for the input power of 10 kW: (a)no substrate and (b)Ø100 mm substrate with 3 mm thickness.

Figure 4.Electron density distributions inside the circumferential antenna ellipsoidal-type MPCVD chamber simulated using a phenomenological model for the input power of 10 kW and hydrogen gas pressure of 8 kPa with (a)plane substrate and (b)improved substrate; electric field distribution with (c)plane substrate and (d)improved substrate after introducing plasma.

Figure 5.Electron density distributions inside the MPCVD chamber with the hydrogen gas pressures of (a)10, (b)15, (c)20 and (d)8-20 kPa at the edge of the substrate (the vertical distance within 70 mm from the substrate surface).

Because of the low edge heating effect of plasma,increasing the substrate’s temperature is challenging, which results in a low edge temperature;this in turn is not conducive to temperature uniformity.One of the most important criteria for growing the diamond film is a constant temperature.Consequently, increasing the edge temperature is important for the 2.45 GHz MPCVD growth of 100 mm diamond films.By comparing figures 4(a)with (b), it is difficult to obtain variations in plasma volume and electron density when the substrate changes to a T-shaped one (b).As shown in figure S1 (available online at stacks.iop.org/PST/24/045502/mmedia)(in supplementary materials), the electron density increases with the T-shaped substrate, demonstrating that the plasma volume grows to a certain degree.It has a positive effect on the heat up at the substrate’s edge.The electric field after introducing plasma is then studied to determine the cause,as illustrated in figures 4(c)and(d).Comparing the red boxes one and two in figures 4(c)and (d), respectively, after switching to a T-shaped substrate, there were electric fields above and below the edge, with the intensity of the below electric field being high.The reduced electric field may have a similar impact to the electric field in the additional TM mode.This electric field influences the plasma morphology; however,the greater effect of this substrate is reflected in the heat dissipation.The T-shaped substrate is suspended between Ø70 and 100 mm.This design reduces the vertical heat dissipation in the substrate’s edge region and improves the substrate temperature’s uniformity.

Furthermore, after inserting methane into the chamber during diamond deposition,the temperature uniformity under the substrate would be improved.Moreover,a pure hydrogen atmosphere is employed in the heat-up process in the real deposition process, and there is no plasma light in the gap.However, an interesting phenomenon is that there will be plasma in this gap after methane is added.Our simulation adopted the phenomenological model, and the parameters were derived from a hydrogen atmosphere; therefore, the green plasma in the gap cannot be calculated through simulation.However, its existence makes a considerable contribution toward heating the edge region and ensuring the temperature of the substrate edge, which can attain uniform deposition better.

3.3.Electron density distributions in the MPCVD cavity with the improved T-shaped substrate

Figure 5 demonstrates the simulation results of the plasma distribution under diverse cavity pressures utilising the T-shaped substrate.Figures 5(a)-(c)are the simulation results at the pressures of 10, 15 and 20 kPa,respectively.As shown in figure 5, the plasma electron density increases and plasma volume decreases considerably with the increase in the cavity pressure.Figure 5 shows that the electron density at 20 kPa is greater than that at 10 kPa, which is almost twice the relationship.At a cavity pressure of 10 kPa,the plasma can cover the surface of the substrate.When the pressure reaches 15 kPa,the plasma volume is only close to the substrate’s size.In this situation, covering the substrate is difficult for plasma.The challenge is that plasma heats the edge of the substrate,and it is difficult to maintain consistent temperature distribution.Figure 5(d)shows a graph of the electron density distribution at the vertical distance from the edge of the substrate at 8-20 kPa.Moreover, the figure shows that after the cavity pressure becomes >10 kPa, the edge plasma electron density slowly reduces.The result indicates that when the cavity pressure increases, the plasma volume decreases, which is consistent with many prior studies in the field of MPCVD research.However, for 8 kPa, the highest electron density value at the edge is less than that at 10 kPa.As the distance from the substrate surface continues to increase, the electron density becomes higher than that at 10 kPa.The radial dimension of the plasma reduces,and the axial size rises at 8 kPa,compared with that at 10 kPa.This is attributed to a decrease in the ionization energy of radial gas when plasma is excited by the axial electric field at 8 kPa, thus consuming energy owing to the electric field’s action.Consequently, the deposition conditions in the diamond film deposition are as follows: chamber pressure of 10 kPa and power of 10 kW.

Figure 6.(a)A uniform Ø100 mm diamond film deposited using the 2.45 GHz MPCVD system, (b)Raman spectra and (c)surface morphology of areas one, two and three of the film.

3.4.Validating the simulation with experiments

Based on the simulation results, the diamond film was deposited using the configurable parameters presented in table 1, where samples I and II employed the plane and T-shaped substrates, respectively.Figure S2 (in supplementary materials)and figure 6 are the morphology and Raman results of the diverse regions of samples I and II,respectively.In figure S2, sample I has the biggest grain size in area one,whereas area three has the smallest.Furthermore, the Raman intensity of area three is lower than that of the other two areas,revealing that the uneven temperature leads to variations in the morphology and size of crystal grains.However, the morphology and size of different regions of sample II are similar, and the Raman results revealed no major difference.

Figure 7 illustrates the radial thickness distribution of the diamond film prepared on the T-shaped substrate.The figure shows that the thickness unevenness is <7%.The T-shaped substrate’s thickness is more uniform than the uneven thickness of the plane substrate,i.e.>22%,indicating that the temperature is more uniform [27-29].Furthermore, the edge thickness has a specific increase compared to the position close to the edge,which indicates that edge discharge plasma promotes the increase in the film thickness.The overall thickness of the T-shaped substrate is moderately uniform,demonstrating that the introduction of gaps at the edge of the substrate plays a vital role in temperature uniformity.The plane substrate used for the deposition of sample I has a low temperature because of the large heat dissipation area.Furthermore,the edge temperature is moderately reduced,and the deposition thickness of the diamond film is small.

Figure 7.Thickness distribution of the diamond film deposited using the T-shape and plane substrates.

However,an obvious step of thickness difference could be observed in the annular region with a diameter of ~80 mm.It is simple to maintain a consistent temperature in an area with a diameter of 80 mm,which is the size used in the current study.The uniform diamond film deposited using the 2.45 GHz microwave system exhibits a similar size.Increasing the edge temperature of the Ø80 mm substrate is important for maintaining the uniformity of the substrate temperature.In case of sample II,a gap is created beneath the substrate and an electric field is introduced below it.This gap inhibits the heat dissipation at the edge of the substrate.Moreover, because of the effect of the additional electric field surrounding the substrate, plasma appears in the gap,which plays an essential role in maintaining the edge temperature.All these effects benefit the thickness uniformity.For obtaining the temperature distribution of the diamond film deposition procedure,temperature measurement is required;however,the size of the temperature measurement hole of the equipment is small,and the substrate surface temperature cannot be completely measured.During the deposition procedure,sample I exhibits a relevant temperature variation between the inside and outside of the Ø80 mm ring.As per our knowledge, the temperature variation exceeds 40 °C.After using the T-shaped substrate, the temperature becomes uniform and the naked eye cannot identify the temperature difference.

4.Conclusions

In this work, ellipsoidal MPCVD simulation and experimental verification demonstrate that a Ø100 mm diamond film can be deposited using the central electric field of the TM02mode and additional edge electric field.The substrate is placed on the base by designing a T-shaped substrate;subsequently,a gap between Ø70 and Ø100 mm is introduced at the edge.Consequently, a strong additional electric field is introduced into the gap to generate the compound mode electric field’s impact.The edge electric field can affect the edge of plasma, increase the temperature in the edge area and achieve uniform temperature.The enhanced T-shaped substrate’s diamond film deposition exhibits high quality, with comparable morphology and grain size in different locations.Furthermore,the simulation results show that the size of the periphery electric field in the TM02nmode remains unaffected when plasma is added,indicating that plasma is influenced by the electric field but not completely confined.

Acknowledgments

This work was sponsored by National Key Research and Development Program of China (No.2019YFE03100200),National Natural Science Foundation of China (No.5210020483), Postdoc Research Foundation of Shunde Graduate School of University of Science and Technology Beijing (No.2020BH015)and Fundamental Research Funds for the Central Universities(No.FRF-MP-20-48).The authors are very grateful for their financial support.

Plasma Science and Technology2022年4期

Plasma Science and Technology2022年4期

- Plasma Science and Technology的其它文章

- Quantitative analysis and time-resolved characterization of simulated tokamak exhaust gas by laser-induced breakdown spectroscopy

- Influence of plasma-induced reflected wave variations on microwave transmission characterization of supersonic plasma excited in shock tube

- Quality enhancement and microbial reduction of mung bean (Vigna radiata)sprouts by non-thermal plasma pretreatment of seeds

- In situ quantification of NO synthesis in a warm air glow discharge by WMS-based Mid-IR QCL absorption spectroscopy

- Realizing high efficiency and large-area sterilization by a rotating plasma jet device

- Study of post-arc residual plasma dissipation process of vacuum circuit breakers based on a 2D particle-in-cell model