Micro powder injection molding of boron carbide components with SiC-Al2O3-Y2O3 sintering additives

Chngrui WANG, Zhiyou LI, Wei TIAN,*, Yuxin LI, Lin TANG,Qilong PANG, Minghe CHEN

a National Key Laboratory of Science and Technology on Helicopter Transmission, Nanjing University of Aeronautics and Astronautics, Nanjing 210016, China

b Ji’nan Technician College, Jinan 250000, China

c Shanghai Aerospace Equipments Manufacturer Co. Ltd., Shanghai 200245, China

d College of Mechanical and Electrical Engineering, Nanjing Forestry University, Nanjing 210037, China

KEYWORDS Composite materials;Fracture;Injection molding;Microstructure;Phase composition

Abstract Sintering additives and micro-powder injection molding offer an effective method to densify boron carbide(B4C)and make B4C components with complex shapes.By adjusting the proportion of three kinds of powders (SiC, Al2O3 and Y2O3), four kinds of sintering additives were prepared. The feedstock uniformity, debinding behavior, phase composition and microstructure of micro injection molded B4C components with different sintering additives were studied. The results showed that the defects such as lattice distortion and vacancy were introduced into ball milling, which increase the surface energy and benefit subsequent sintering densification. The feedstock had good uniformity and rheology that met the requirements of micro powder injection molding. After debinding, B4C components had enough strength and showed certain sintering characteristics.The addition of sintering additives was beneficial to densification and sintering temperature reduction. The addition of sintering additives formed a second phase in the B4C crystal and at the grain boundary of B4C crystal, which changed the fracture mode from transgranular fracture to mixed fracture mechanism with transgranular fracture.

1. Introduction

Due to its advantages such as low density, high modulus and excellent high temperature properties, BC component have good potential applications in wear, nuclear technology and microelectronics.BC ceramics had been used to manufacture control rod or radiation components, land armored vehicles, armed helicopters, and civil airliners.Besides it could be used as a gas distributing disk, focusing ring, microwave or infrared window, DC plug, thermocouple, diode, transistor and high temperature electronic equipment in the semiconductor industry.It also became an important nozzle material because of its ultra-high hardness and excellent wear resistance. Service life of a nozzle made by this material was much longer than that of an alumina nozzle, and many times longer than that of a WC and SiC nozzle.BC was also used as the first protective wall of a nuclear reactor and as the base material of neutron capture therapy for cancer treatment on account of its good thermal conductivity and thermal shock resistance.Although BC has high temperature strength,its application is still limited due to the difficulty in densification, low fracture toughness, and serious oxidation above 1000°C.

BC components had high melting point, low diffusion coefficient,high vapor pressure and covalent bond domination which is difficult to densify. Super high sintering temperature causes abnormal grain growth, and influences the mechanical properties of materials.It is an effective way to reduce the sintering temperature and restrain grain growth by adding sintering additives in the sintering process. At present, scholars at home and abroad had studied the effect of single sintering additives such as C, B, Fe, Ti, ZrB, Al, and AlOon BC.Li et al.pointed out that the density of BC composite increased with increasing the content of CrCand sintering temperature. Compared with the single sintering additive system,the multi sintering additive system has a better sintering additive effect.Xu et al.reported that adding multi sintering additives could promote the densification of the BC ceramics with microstructure refining.

At present, the commonly used forming methods of BC components are pressure sintering, hot pressing sintering, hot isostatic pressing, spark plasma sintering, etc.Although the above main forming processes of BC cloud obtain better density for BC components, there were still many limitations in the application, such as the limited shape of the components that cloud be produced, inability to form highly complex components,high production cost and low efficiency. Micro powder injection molding of BC is a good choice which cloud be used for the large-scale manufacturing of difficult to cut complex shaped ceramic components.A fully dense BC nozzle by injection molding with C as the sintering additive was first sintered at 2150-2175°C without pressure, and then was sintered at 2050°C and 200 MPa in an argon atmosphere by hot isostatic pressing.

In this experiment, the BC components were prepared by micro powder injection molding,and the influence of four different multi-element sintering additive systems on sintering characteristics, microstructure and mechanical properties of BC components was studied. The densification mechanism of BC components with sintering additives was discussed.

2. Experimental procedures

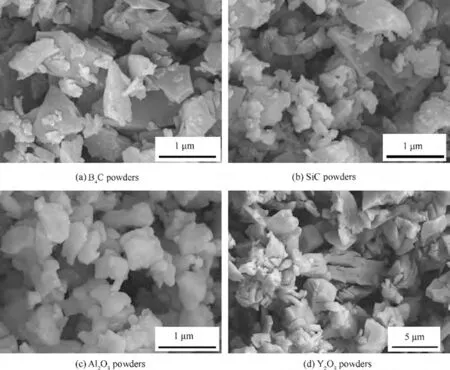

The particle size of BC powder produced by Mudanjiang Diamond Boron Carbide Co.,Ltd.,is 1.2 μ m,and its micro morphology and powder characteristics are shown in Fig. 1.Powder particles are irregularly shaped with sharp edges and corners, which can make the components have good shape retention when debinding. The particle size distribution of the powder is D3=5.11 μm, D50=1.17 μm, and D94=0.54 μm. The corresponding compositions of four different sintering additive systems are shown in Table 1. SiC powder particle size is 0.45 μm, provided by Ningbo seal factory Co.,Ltd.,AlOpowder particle size is 0.5 μm,purchased from Hebei Pengda New Material Technology Co.Ltd.,YOpowder particle size is 2.5 μm, purchased from Zibo Weijie Rare Earth Co. Ltd., and the corresponding powder micro morphology is shown in Fig. 1.

The matrix powder and sintering additives were made to mix evenly to eliminate agglomeration,avoid the uneven structure of components after sintering. The four different mixed powders weighed according to the proportion in Table 1 were ball milled on the self-made eight shaped ball mill. The ball milling tank was a polycarbonate tank, with anhydrous ethanol as the milling medium, and the ball was an AlOceramic ball with diameters of 10 mm and 5 mm (mass ratio: 1:1). In the experiment, anhydrous ethanol was selected as the ball milling medium to reduce the surface energy of the powder particles and the agglomeration of the powder. Moreover,anhydrous ethanol was easy to volatilize and would not increase the water content of the powder particles.

In addition, paraffin-based binder system was selected,mainly including PW, PP and stearic acid (SA). PW adopted high-efficiency paraffin was produced by Shanghai Hualing Recuperator Machinery Factory, with melting point of 58-60°C,SA was purchased from Tianjin Damao Chemical Rreagent Factory with a CH(HC)COOH content of not less than 99.0%,and a melting point of 67-70°C. PP was selected from polypropylene resin powder prepared by the intermittent method adopted by Harbin branch of CNPC, with a melting point of 160-175°C. And the binder ratio (mass ratio) of PW:PP:SA was 75:20:5.

The feedstock was mixed in the 2 L double planet mixer manufactured by Guangzhou Hongyun Machinery Factory,and was then extruded and granulated on the single screw extruder. The specific process is as follows: The weighed ceramic powder was added in the double planet mixer, the double planet mixer was heated to 175°C with a temperature holding time of 30 min. Then the double planet was start turning at a speed of 20r/min.And PP was gradually added into the barrel and mixed for 30 min. Afterwards, PW and SA were added and continuously mixed for 30 min. The last, cylindrical feedstock particles were produced by multiple extrusion on the extruder.

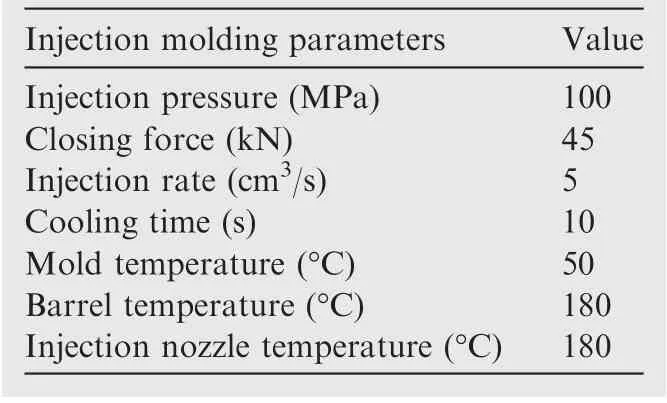

Babyplast 6/10 injection molding machine produced in Spain was used in the experiment. The optimized parameters of micro powder injection molding for the ceramic components in the experiment were decided after discussions on several experiments (Table 2).

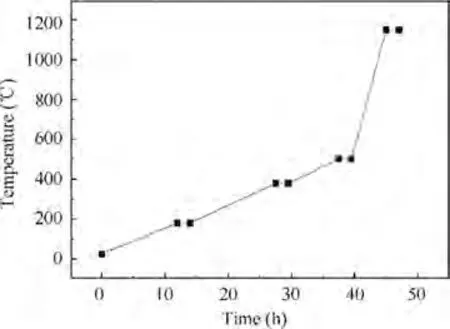

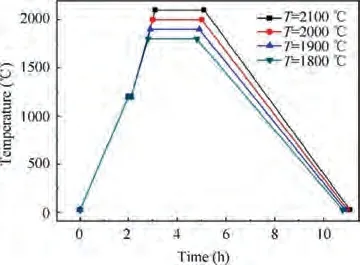

After micro powder injection molding, the components were adopted the technology of thermal debinding and pressureless sintering to obtain dense components.Combined with thermo dynamic analysis and DSC/TGA analysis of thermal debinding, the debinding processes of the injection molded BC components were determined, as shown in Fig. 2. Then,BC components were sintered by pressureless sintering in an argon atmosphere (Fig. 3).

Fig. 1 SEM micrographs of powders.

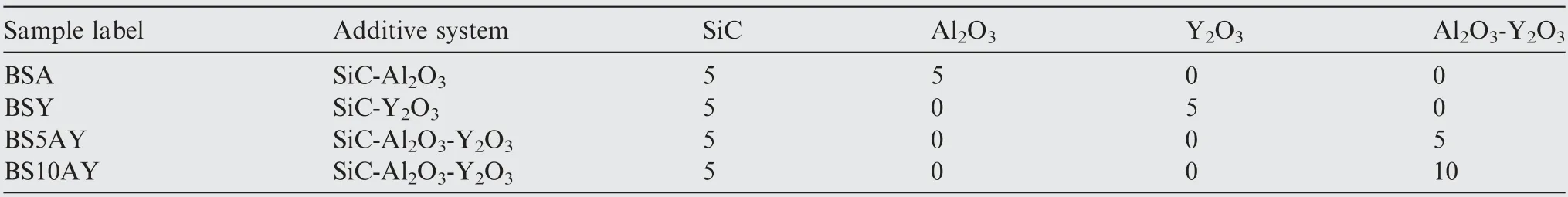

Table 1 Compositions of components with different additives (wt%).

The Archimedes drainage method was used to measure the density of the components.The phase composition of different components was analyzed by X-ray diffraction analysis(XRD). The X-ray diffractometer (D/MAX-RB, Rigaku,Japan)was irradiated with CuKα(λ=1.5418 A° )and recordedin the range of 2θ from 10° to 90°to analyze the structure of different components. The microstructure and fracture morphology of different components were observed by a scanning electron microscope (SEM, S-4700, Hitachi, Japan), equipped with a back scattered electron image. And a conventional transmission electron microscopy (TEM, CM12, Philips,Netherlands) observation was made on an operating at 120 kV.For the measurement of mechanical properties,a strip shape of 4 mm×4 mm×20 mm and a pellet sample of 25 mm in diameter and 20 mm in thickness were made; bending strength and fracture toughness tests were performed on an universal testing machine (Instron-1186, Cincinnati, USA).The hardness test was carried out using a micro-hardness tester(HVS-5,Huayin,China),measuring a load of 5 kg and holding the pressure for 10 s.

Table 2 Injection molding parameters of ceramic micro holes.

3. Results and discussion

3.1. Morphology change in mixed powders during ball milling

Fig. 2 Thermal debinding curves.

Fig. 3 Sintering curves.

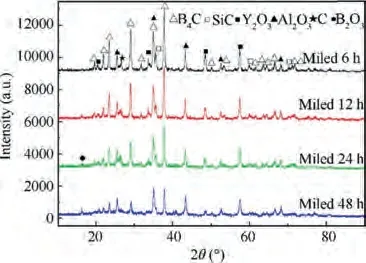

Taking BC samples with BS10AY sintering additive as an example, the changes in homogeneity and morphology of the powder under different milling times were studied, as shown in Fig. 4. It can be seen from Fig. 4 that after ball milling for 6 h,the sharp edges and corners of BC particles were passivated initially,but the overall morphology was similar to the original morphology of BC particles. After ball milling for 12 h, the powder particles were refined to a certain extent,and all kinds of powders were mixed evenly without obvious agglomeration.After ball milling for 24 h,the powder particles continued to be refined.After ball milling for 48 h,the average particle size was refined to 0.5 μm. XRD analysis was presented in Fig. 5. With the increase in milling time, the diffraction peak was widened to a certain extent,which illustrate that the grains were refined during the milling process. Since the main grinding mechanism of vibration milling was volume grinding, the large particles were divided into small particles through the impact and shear between the grinding ball and the particles, which also introduced lattice distortion and vacancy defects. The existence of these defects increased the surface energy, which was conducive to subsequent sintering densification. However, it cloud be seen in Fig. 5 that when the milling time was more than 24 h, a relatively obvious BOpeak appeared, indicating that with the increase in milling time, the BC powder began to oxidize. With the increase of ball milling time, the particle surface is constantly impacted by the steel ball,which makes its reactivity enhanced.With the refinement of BC powder, more surfaces of BC powder are contacted with oxygen in the ball mill which is conducive to the formation of BO.In addition,the initial oxidation temperature and peak exothermic temperature decrease with the increase of milling time.Due to a relatively low melting point and viscosity of BO, the glassy and fluid BOphase can heal the pores and pre-existing cracks.However,the BOproduced is covered on the surface of BC powder,which hinders subsequent sintering.For this reason,the ball milling technology of 12 h was used to pre-mix the powders Table 3.

3.2. Uniformity analysis of feedstock preparation

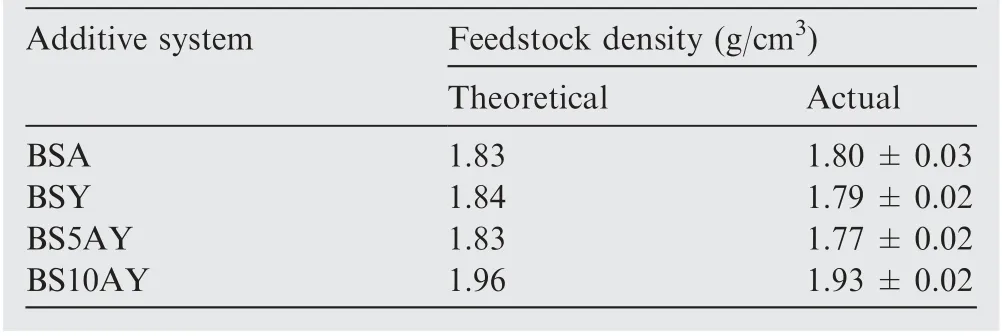

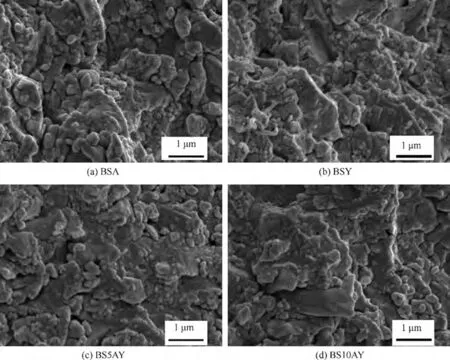

The uniformity of feedstock has a great influence on the quality of final components.The density gradient will appear after injection, and the void gradient will appear after debinding using nonuniform feedstock. Moreover, these effects are difficult to eliminate in subsequent work, and finally cause distortion of components after sintering. Therefore, SEM fracture analysis and Archimedes drainage method were used to measure the feedstock density and evaluate the feedstock uniformity. The fracture morphology of BC feedstock with different additives was analyzed (Fig. 6). Due to the irregular shape of BC particles, the stacking density of powder was lower than that of spherical particles. Therefore, even if the mixture was uniform, there would be some tiny holes in the feedstock during mixing.So that the actual density of the feedstock after mixing was lower than the theoretical mixing density.Density was measured by the drainage method, as shown in Table 2. It was found that the variation of density in each kind of feedstock was larger than that of ZrOfeedstock with spherical particles,which was mainly due to the uneven shape of BC particles used, resulting in the increase of space-time gap of mixture. The measured density of the feedstock was also lower than the theoretical density. The main reasons for this deviation are: first, the error in the process of proportioning and weighing; second, the loss of powder or binder in the process of mixing; and third, the error in the measurement of drainage method. The density of each feedstock change a little, and the subsequent impact can be ignored.With this process,four kinds of feedstock with different sintering additives are shown good uniformity, which can meet the requirements of subsequent injection molding.

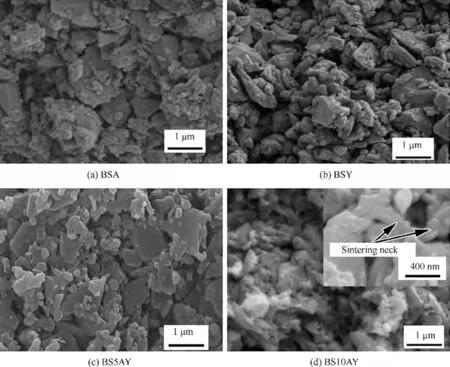

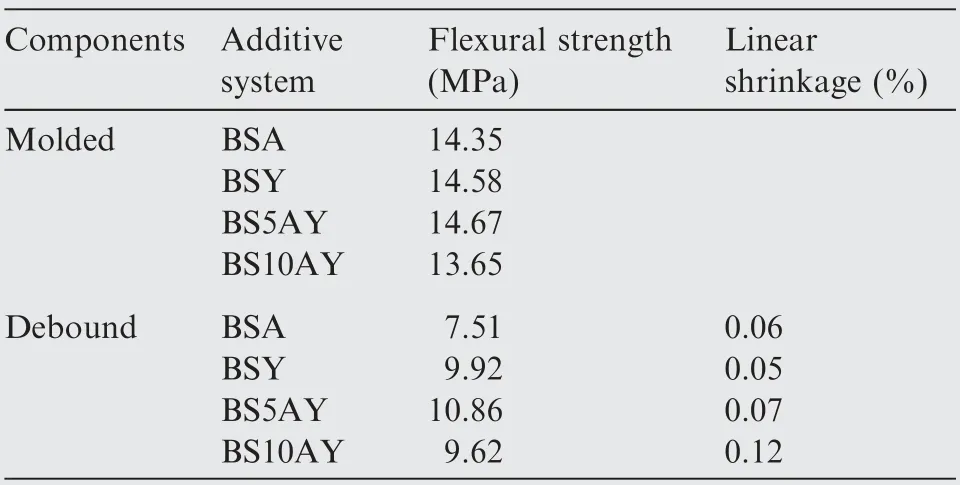

3.3. Analysis of microstructure, properties and strength after thermal debinding

The microstructure of BC components with different sintering additives after thermal debinding was observed, as shown in Fig. 7. It can be seen from the figure that the components of BSA, BSY and BS5AY are similar in micro morphology after debinding,showing weak sintering characteristics. Some small particles had begun to attach themselves to large particles and form small sintering necks.The components with BS10AY sintering additive showed better sintering characteristics. After debinding, the microstructure of BC components had little change, which also showed that higher sintering temperature was required to obtain dense BC ceramics. As shown in Table 4, the shrinkage of BC sample with BS10AY sintering additive showed better sintering characteristics was only 0.12%. However, due to the use of ultra-fine BC powder and sintering additive, the sample had better bending strength after debinding.During the thermal debinding of the sample,it was found that the debinding rate was too fast,the gasification rate of the binder was accelerated, and the generated gas exerted a certain pressure on the surrounding powder particles,causing cracks in the sample.Therefore,reducing the sintering temperature when debinding, especially below 500°C, can effectively avoid the generation of cracks. The experimental results show that the components with different sintering additives exhibit certain sintering characteristics after debinding,which is conducive to the strength after debinding. Therefore,weak sintering characteristics are shown in BSA, BSY and BS5AY samples after debinding, better mechanical properties and sintering characteristics is observed in BS10AY sample.

Fig. 4 SEM micrographs of B4C powders after ball milling for different times by using BS10AY additive.

Fig. 5 XRD patterns of B4C powders after ball milling for different times using BS10AY additive.

Table 3 Density values of the B4C feedstock with different additives.

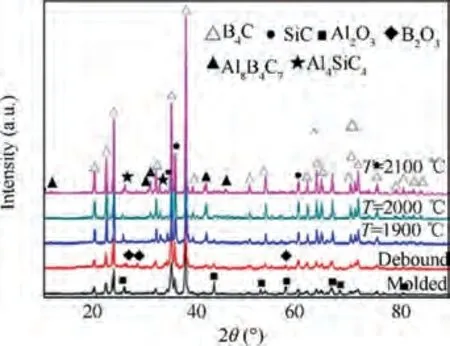

3.4. XRD analysis of sintered components with different additives

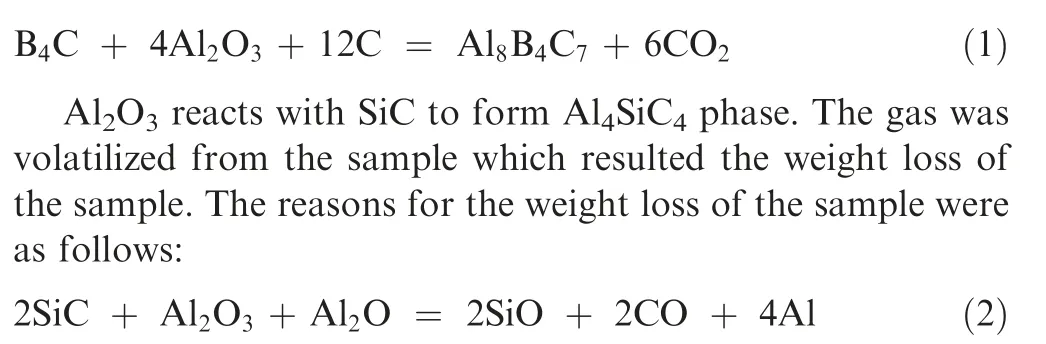

The XRD results of BC components sintered with BSA sintering additive system were further analyzed (Fig. 8). After ball milling, the mixed powder was mainly composed of BC, SiC and AlOphases.The debound sample was carried out under an argon atmosphere, and the presence of a small amount of Oin the argon, slightly oxidizes BC to produce BO. With the increase in sintering temperature, the intensity of AlOpeak was weakened, and two new peaks were appeared. It was found that two new peaks were AlBCand AlSiCphases, respectively, mainly because of the reaction among AlO, BC and SiC during sintering.Since the original BC powder used in the experiment contained a small amount of C, the reaction during sintering was as follows:

With the increase in sintering temperature, the above reactions were continued,which was made the weight decreasing of the components. There were still AlOphases in the components after sintering at 2100°C, and the phase composition in the components was mainly BC, SiC, AlBC, AlSiCand AlO.

Fig. 6 SEM micrographs of B4C feedstock with different additives.

Fig. 7 SEM micrographs of debound B4C components using different additives.

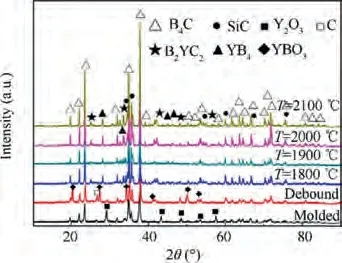

The XRD results of BC components sintered with BSY sintering additive system were shown in Fig. 9. After ball milling, the mixed powder mainly consisted of BC, SiC and YOphases, and a small amount of C. After debinding, the diffraction peak of YOdisappeared. And a new peak(YBO) appeared which was caused by the reaction of BOproduced by oxidation of BC and YO. The reaction was as follows.

Table 4 Flexural strength and linear shrinkage of different components after molding and debinding.

This reaction generally took place between 700°C and 1150°C, and the new phase covered the surface of YOparticles, which made the YOdiffraction peak basically disappearing. The YBOdiffraction peak then appeared. In the sintering process, the whole diffraction peak went through little change. After sintering, the reaction between YOand YBOphases produced BYCand YBphases, resulting in the disappearance of YOand YBOphases. The reaction process was accompanied by gas phase emission, resulting in weight loss of the sample after sintering. XRD results showed that the reaction had been completed at a lower temperature.After sintering, the components mainly contained BC, SiC,BYCand YBphases, and no reaction was found between SiC and YO.

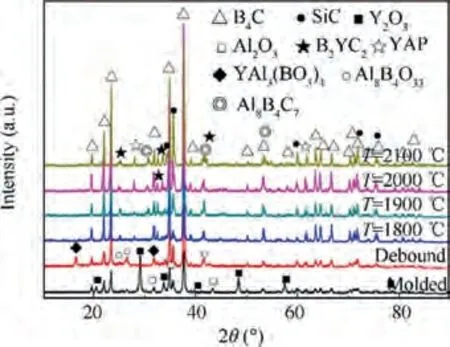

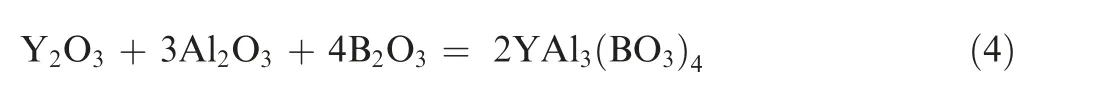

The XRD results of BC components sintered with the BS5AY sintering additive system were presented in Fig. 10.After ball milling, the mixed powder was mainly composed of BC, SiC, AlOand YOphases. After debinding, the diffraction peaks of AlOand YOphases became very weak. This was because BOproduced by BC oxidation reacted with AlOand YOto form a new phase (YAl(-BO)) covering the surface of AlOand YOparticles during debinding. The reaction was as follows.

Fig.8 XRD patterns of B4C components at different stages with BSA additive.

Fig.9 XRD patterns of B4C components at different stages with BSY additive.

Fig. 10 XRD patterns of B4C components at different stages with BS5AY additive.

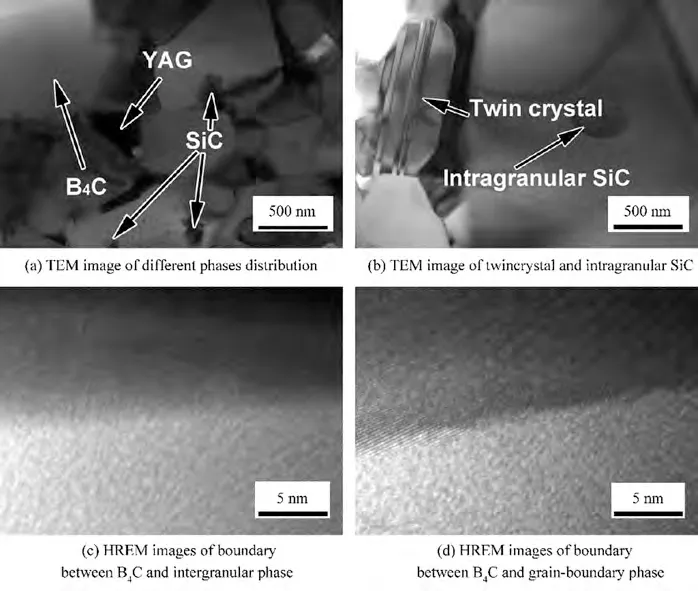

This reaction usually took place between 800°C and 1150°C, and the product was YAl(BO). In the process of debinding, the formed YAl(BO)would decompose itself to form AlBO,with the precipitation of BO.The decomposition would continue during sintering. The produced BOvolatilized which resulted in weight loss of sample.In addition,the reaction among BC, SiC, AlO, and YOcontinued to form AlBCand BYCphases during sintering.The formation of gas phase led to further development of weight loss.For added AlOand YO, liquid phase formed, sintering temperature was reduced and sintering density was increased.As a result of reaction, AlOwas consumed, and the molar ratio of AlOand YOchanged. XRD results showed that the liquid phase formed during sintering was YAP(YAlO),and the reaction was as follows:

The phase change of BC components sintered with BS5AY was similar to that of BC components sintered with BS10AY.With the increase in sintering temperature, the sintering activity of BC and SiC particles increased,and AlOreacted with YOon the interface of some BC and SiC particles to form liquid phase(reaction(6)).Under the action of capillary force,the rearrangement of solid particles was realized, and the densification rate of parts was accelerated. The components mainly included BC, SiC, YAG (YAlO) and BYCphases. Since the content of other impurity phase was very small, the BC components sintered with BS5AY obtained excellent sintering density at low temperature.

Fig. 11 Relative density and weight loss of B4C components sintered in different temperatures with different sintering additives.

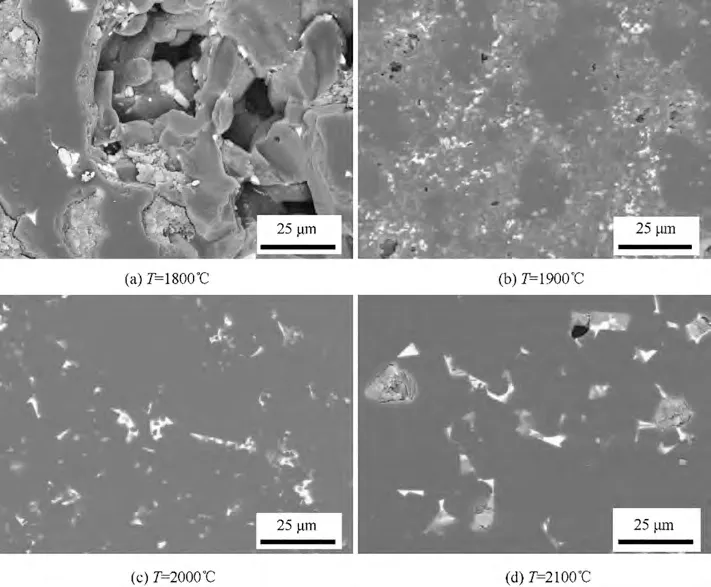

Fig. 12 BSE micrographs of B4C components with BS10AY additive sintered at different temperatures.

Through XRD analysis of sintered BC components with different additives, it was found that the new phases are produced for each additive during sintering. The phase composition affects the microstructure and mechanical properties of the sintered samples.Compared with the other three additives,the phase composition of the samples with BS10AY additive is relatively simple which is beneficial for density and performance improvement. Therefore, BS10AY additive is an ideal choice as the sintering aids.

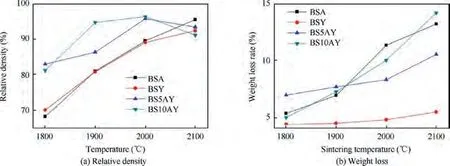

3.5. Sintering characteristics

The density and weight loss rate of components with different sintering additives at different sintering temperatures were shown in Fig.11.The density of the components sintered with BSA and BSY additives increased with increasing sintering temperature, and the best sintering effect was obtained after sintering at 2100°C. The densities were 95.53% and 92.41%for BSA and BSY,respectively.BC components with BS5AY and BS10AY sintering additives (as shown in Fig. 11(a)) had similar changes in trend.With the increase in sintering temperature,the density first increased and then decreased,the sintering activity of BC and SiC particles increased. AlOreacted with YOon the interface of some BC and SiC particles to form a liquid phase. Under the action of capillary force, the solid phase rearrangement was realized, and the densification rate of components was accelerated. When the temperature continued to rise, a large amount of liquid phase volatilized,resulting in an increase in the loss of BC components quality,a decrease in the effect of combustion additives and the density of components. With BS5AY and BS10AY as sintering additives, the optimal preparation temperature of BC samples was the best at 2000°C.

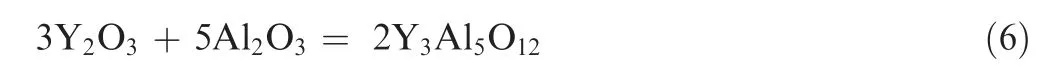

Fig. 13 BSE micrographs of B4C components sintered at different temperatures with different sintering additives.

For the BC components added with sintering additives,weight loss occured during sintering, as shown in Fig. 11(b).The weight loss in the sample with BSY additive was relatively stable, and it did not change much with the sintering temperature. For other liquid phase sintering additives, the sample increased with the increase in sintering temperature.The specific reasons were detailed in the previous section (Section 3.4).There are two main reasons, one is that the reaction between BC and the sintering additive produces gas discharge; the other is the volatilization of the liquid phase with the increase in sintering temperature. Through the study on the sintering mechanism of BC samples with different sintering additives,it is found that compared with solid-phase sintering, liquidphase sintering is more conducive to the densification of BC samples. After sintering at 2100 ℃, 2000 ℃and 2000 ℃, the density of BSA, BS5AY and BS10AY reached the maximum value, which is 95.53%, 96.31% and 97.56%, respectively.

3.6. Microstructure evaluation

The microstructure changed in BC components with BS10AY sintering additive at different sintering temperatures were shown in Fig. 12. Since the formation temperature of AlOand YOliquid phase was higher than 1800°C, there were more voids in the sample after sintering at this temperature,but the density was still much higher than that of BSZ and BSY combustion additives (as shown in Fig. 11(a)), and the sintering additives were still in the original state of dispersion.The emergence of YAG liquid phase rapidly increased the densification rate when the sintering temperature rose to 1900°C(Fig. 12(b)). And the number of voids decreased. There were also two kinds of substrate phases,gray phase and bright white phase. It cloud be inferred with XRD analysis that the matrix phase was mainly BC phase, gray phase was mainly SiC phase, and bright white phase was mainly BYCand YAG phase. The components were nearly completely dense and the voids of BC components basically disappeared when the sintering temperature increased to 2000°C (Fig. 12(c)). The shapes of bright white phase and gray phase were irregular as multi-angular shapes.Due to the irregular shape of the original BC powder,the contact surface between the BC powder and the sintering additive powder was irregular, which was caused by the reaction at different interfaces during sintering.The interface between phases was clear. The sintering temperature continued to increase (Fig. 12(d)), so that the sintering temperature was too high, and the liquid phase production rate and liquid phase evaporation rate were accelerated at the same time. A typical grain growth of liquid phase filmed propulsion way under the chemical driving force generated by the difference in component concentration would occur,which made the grain growth deviate from principle growth,and developed abnormal growth.

The microstructure of BC components sintered at different temperatures with different sintering additives was shown in Fig. 13. Fig. 13(a) showed the microstructure of BC components with BSY sintering additive sintered at 2100°C. The gray phase was SiC, and the bright white phase was BYCand YB.The microstructure of BC components sintered with BSA and BS5AY was similar to that of BC components sintered with BS10AY. The microstructure of BC components sintered with BSA and BS5AY at 2100°C and 2000°C were shown in Fig. 13(a) and (b), respectively. The microstructure of the components after liquid phase sintering was better than that of solid phase sintering.

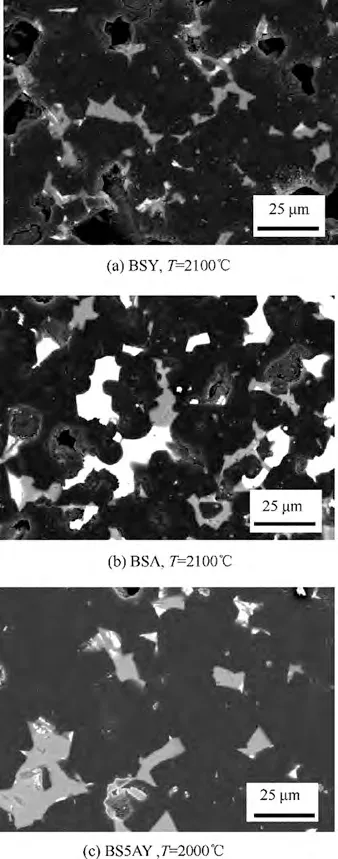

Fig. 14 TEM images and HREM images of B4C components with BS10AY additive.

Fig. 15 SEM micrographs of fracture surfaces for sintered B4C components using different sintering additives at 2100°C.

The TEM morphology of BC sample sintered with BS10AY sintering additive was shown in Fig.14.The particles were relatively small and most of them were nearly spherical(Fig. 14(a)). The TEM image was analyzed by the scribe method. After sintering, the ceramic grain size was 3 μm,which showed that the use of ultrafine powder was conducive to obtaining the microstructure with a smaller grain size. The addition of SiC, formed YAG and BYCwas conducive to refining the grains and inhibiting the abnormal growth of the grains.The grains of YAG and BYCwere mainly distributed at the boundaries of BC grains,while some of SiC grains were distributed over the boundaries,and the other SiC grains were distributed inside the BC grains, forming the intragranular SiC. Due to the addition of liquid phase, some abnormally grown grains were also found, as shown in Fig. 14(b). The number of abnormally grown grains was relatively small,and the size of crystalline SiC formed inside these grains was large.During the sintering process,due to the influence of sintering temperature and liquid phase formation, the atomic movement at the BC grain boundary was intensified in some components, and the grain boundary grow rapidly. Some pores and additive phases were wrapped in it.As the grain continues to grow, the additive phase wrapped in it forms the intragranular structure. It was found that the BC twins were easy to appear at the grain boundaries of some abnormally growing grains. Fig. 14(c) and d showed the high- magnification image of the grain boundary between the BC grain and its inner crystal SiC, and between the BC grain and other grain boundary phases. The grain boundary was relatively clean,and no interaction between the phases was found.Other grain boundary phases also played a good role in strengthening the BC matrix.

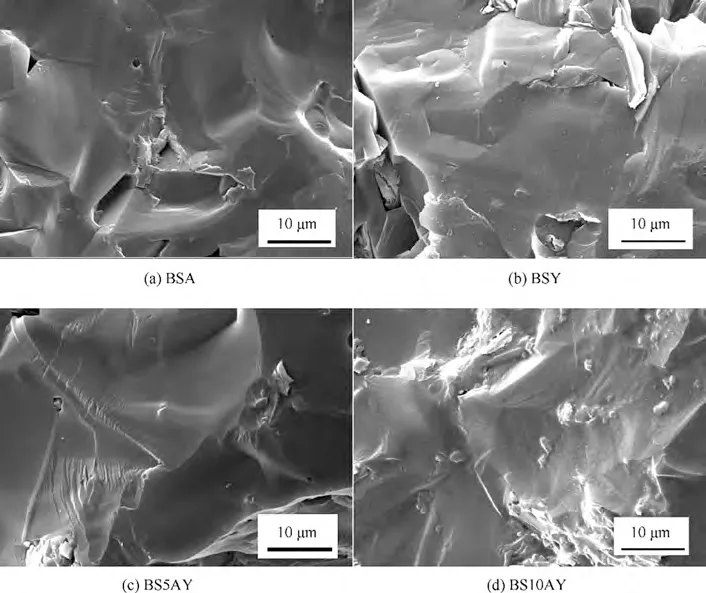

The fracture morphology of BC sample after sintering with different additives was presented in Fig. 15. After sintering with four different sintering additives,the fracture modes were similar,mainly transgranular fracture,with a small amount of intergranular fracture at the grain boundary of BC and other phases.In the BC grain without other phases,the fracture was relatively flat, and the crack was relatively flat. The remaining pores after sintering accelerated the fracture. As shown in Fig. 15(a), when the crack passed through the pores directly,the fracture in the relevant area was flatter, without crack bifurcation, deflection and torsion. However, there were a few generated cleavage steps and fluvial fractures where the second phase(including intragranular phase and grain boundary phase) existed. The cracks were bifurcated, deflected, and twisted when passing through the second phase and making the crack growth path become circuitous. The addition of stress field near the tip of the phase disturbing crack hindered the growth of the macro-crack and enabled the crack to expand too much. Deflection and distortion occurred in the process which improved the fracture toughness of the material.Moreover, the distribution of the added phase was not uniform, which caused some influence on fracture toughness and required further study.

4. Conclusions

The micro powder injection molding process of BC sample was studied by adding four kinds of sintering additives. The effects of sintering additives on feedstock preparation,debinding,densification and microstructure of BC sample were analyzed. The main conclusions are as follows:

(1) The prepared feedstock density is lower than the theoretical density,and the feedstock has good pseudoplastic rheological properties and good uniformity, which is conducive to subsequent process and performance realization.

(2) After debinding,BC components show certain sintering characteristics, and a certain number of sintering necks appear. The components have enough strength to avoid being damaged during subsequent sintering and handling.

(3) XRD analysis shows that the main phase groups after sintering with BSA are BC, SiC, AlBC, AlSiCand AlO. The main phase groups after sintering with BSA are BC, SiC, BYCand YB. The main phase groups after sintering with BS5AY are BC,SiC,AlB-C,BYCand Yap.In addition,the main phase groups after sintering with BS10AY are BC, SiC, YAG and BYC.

(4) Sintering with SiC-AlO-YOsintering additives is an effective way of the densification of BC ceramics. With the increase in sintering temperature, the porosity of BC components decreases, and the addition phase changes from the equiaxed initially to long strip.

(5) The addition of sintering additives changes the fracture mechanism of BC components from the transgranular fracture of pure BC to the interaction mechanism of intergranular fracture and transgranular fracture, so as to improve the mechanical properties of BC components.

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

This work was supported by the National Natural Science Foundation of China (Grant No. 52075250), the China Postdoctoral Science Foundation (No.2020M683376) and the National Key Laboratory of Science and Technology on Helicopter Transmission (No. HTL-O-19G09).