Tube-based Model Reference Adaptive Control for Vibration Suppression of Active Suspension Systems

Yashar Mousavi,, Alireza Alfi,, Ibrahim Beklan Kucukdemiral,, and Afef Fekih,

Dear editor,

With the developments of industrial automation in recent years,vehicle suspension systems have received a great deal of attention in industry and academia due to their critical role in the chassis performance of vehicles [1]. The suspension system is expected to guarantee the vehicle’s maneuverability and provide satisfactory ride comfort by absorbing the vibrations arising from the road surface excitations and ensuring road-holding capability and suspension safety. Motivated by the desirable performance of the model reference adaptive control (MRAC) approach, various literature studies have investigated its performance in diverse linear and nonlinear practical systems [2], [3] (for more background review, see Supplementary material-Appendix A). Aiming to improve the conventional MRAC in terms of closed-loop stability, asymptotical tracking, and robustness against uncertainties and external disturbances, authors in [4] developed the tube-based MRAC (TMRAC) approach. To simultaneously achieve the desired objectives,the developed scheme split the control signal into two main terms; an adaptive part and another part that corrects the control objective. In addition, an optimization problem is formulated to find the newly determined correction control component. However, although the method’s performance was verified using some simple single-input single-output unstable systems [5], more extensive investigations on complex practical systems are needed to validate its performance.The main contributions of this paper are to develop a novel tubebased MRAC approach for multi-input multi-output active suspension systems; a realistic design that guarantees ride comfort and suspension safety and achieves better control performance with reduced control effort in the presence of external disturbances compared to conventional methods. Moreover, to validate the method’s applicability in practical applications, three different road profiles are conducted to simulate distinct practical road situations, as the bump-dip road, random road, and sinusoidal profiles.Furthermore, the vibration suppression performance of the developed adaptive control scheme is investigated, and superior simultaneous ride comfort, road handling, and suspension safety are guaranteed compared to conventional MRAC [6] and SMC [7] approaches.

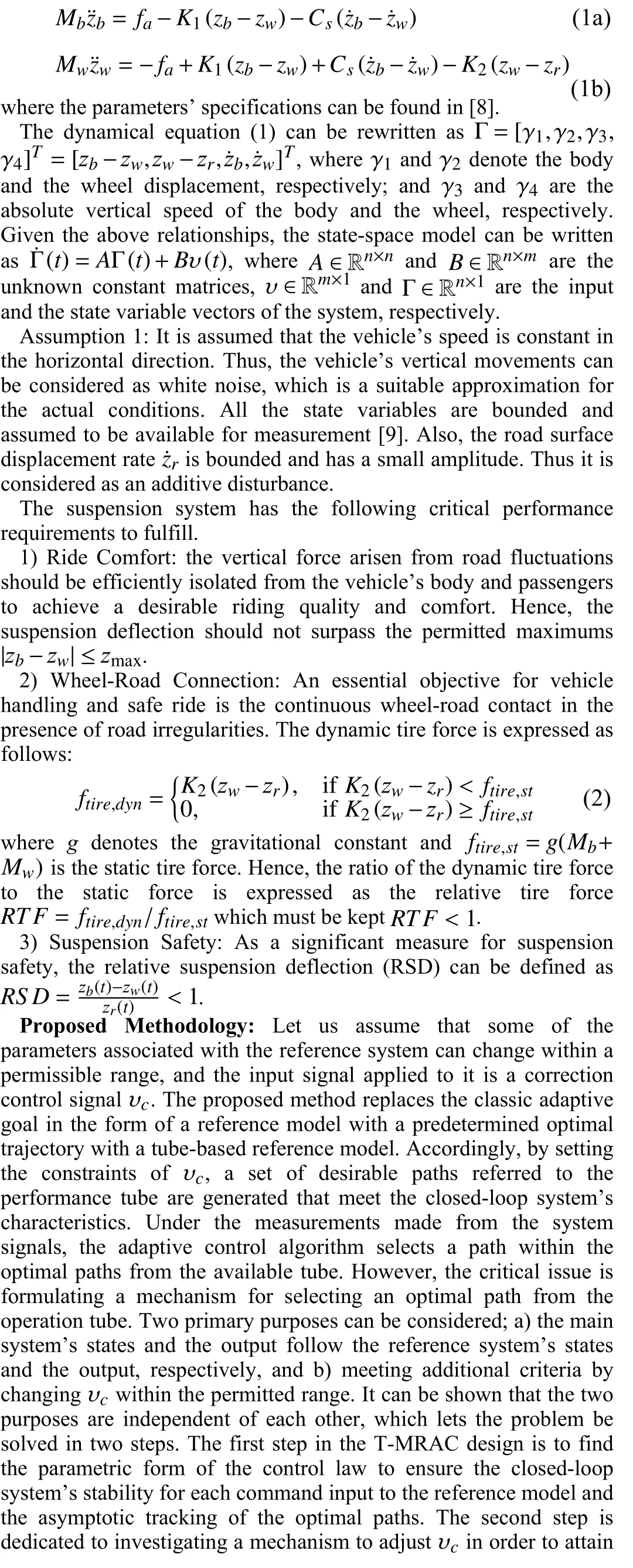

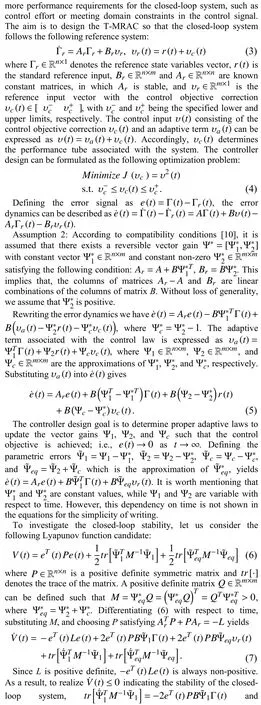

Problem Statement: The quarter-car active suspension system can be expressed as follows [8]:

Simulation Results and Discussions: The efficiency of the proposed control scheme in terms of ride comfort, wheel-road connection, and suspension safety will be investigated in detail through simulations, and its performance is evaluated with respect to MRAC [6] and SMC [7] methods. The considered parameters for the quarter-car suspension system under study are adopted from [8].Three different road profiles are considered to simulate different practical road situations, namely the bump-dip road [1], a class C random road profile as per the international organization for standardization (ISO) 8608 [11], and sinusoidal profiles (for more details on road profiles, see Supplementary material-Appendix D).

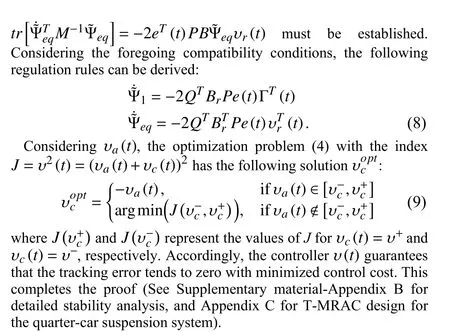

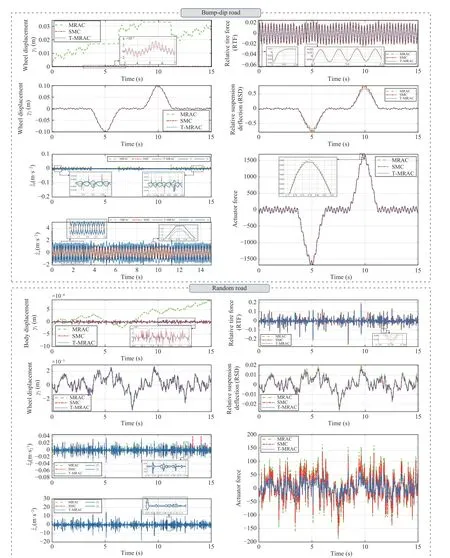

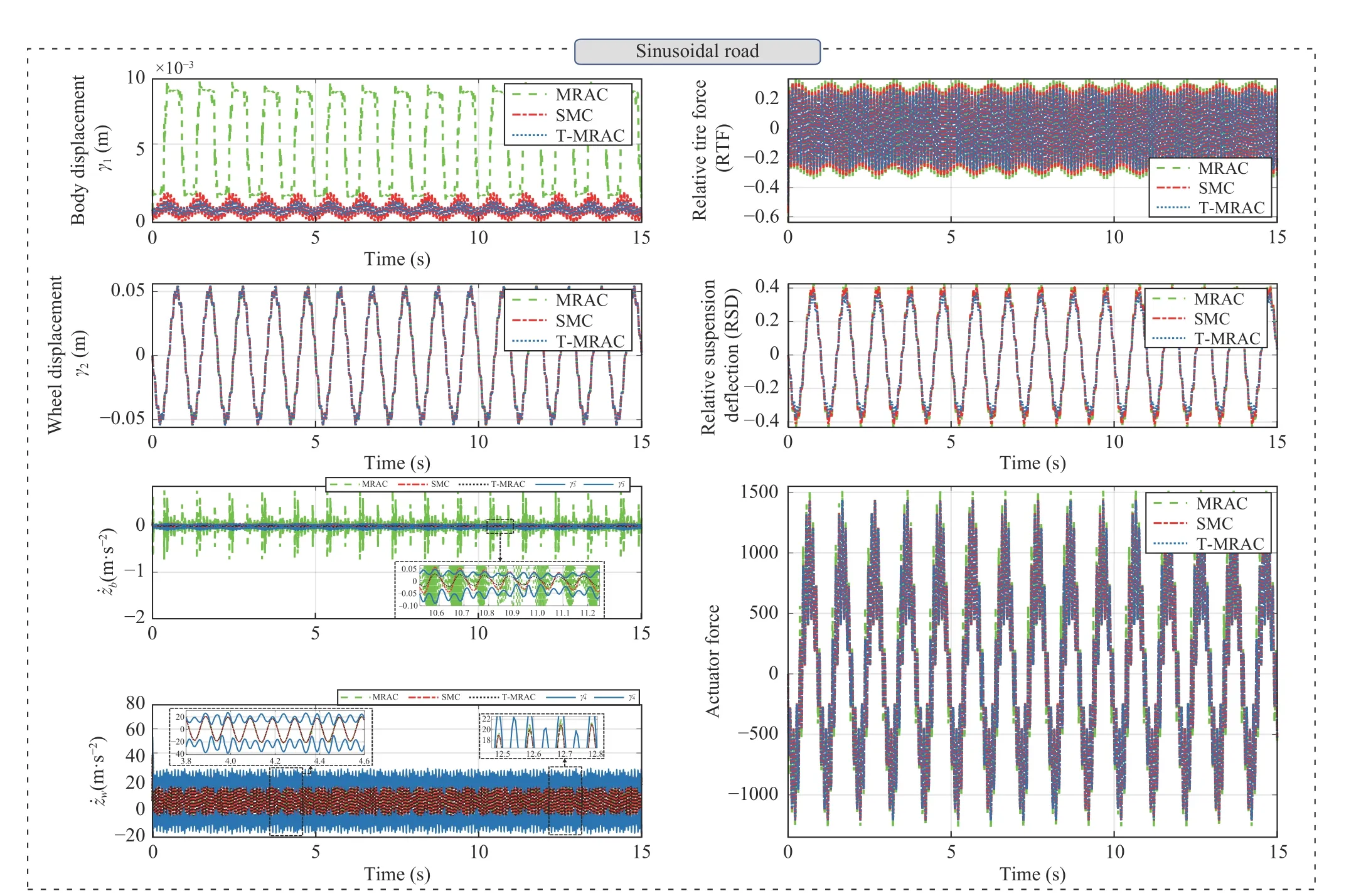

The vertical displacement of the vehicle’s body and the wheel is directly related to the suspension performance, while their vertical speeds are affiliated with the ride comfort. Fig. 1 demonstrates the closed-loop responses of the sprung vertical displacement and speed,RTF and RSD, and the actuator force for all the three profiles. From the bump-dip section, it can observe that although all the three control approaches provide a similar wheel displacement performance, the MRAC method fails to provide a suitable suspension performance in terms of vehicle’s suspension deflection,and the SMC approach demonstrates an acceptable yet inferior performance as compared with the proposed T-MRAC. Also, the TMRAC outperforms the MRAC and SMC approaches by providing more ride comfort and effectively suppressing the vibrations arising from the bump-dip road situation. Similar to the bump-dip road, the three control approaches demonstrate an analogous wheel displacement performance in the random road section. However, the T-MRAC outperforms the MRAC and SMC methods by delivering a more attenuated body displacement performance. Also, more ride comfort is achieved by T-MRAC, and the vibrations arising from the class C random road profile are efficaciously suppressed. Thus, the proposed T-MRAC has a similar isolation performance with that of the bump-dip road, which confirms the efficiency of T-MRAC by providing more ride comfort. It is evident from the sinusoidal section that, compared to T-MRAC and SMC methods, the MRAC approach fails to provide a smooth body displacement performance and attain less ride comfort. However, although similar to the previous two cases, SMC demonstrates a sort of acceptable performance yet has some performance degradations with respect to the proposed TMRAC, which further validates the vibration suppressing performance of the T-MRAC method. Also, from the comparative illustration of RTF and RSD in all road situations, one can observe that the limitations are well-respected and the physical constraints are guaranteed within their ranges. Furthermore, considering the obtained actuator forces in all three road situations, the T-MRAC provides better suspension performance with less effort. For more performance analysis, see Supplementary material-Appendix E.

Conclusions: Using the on-line goal adaptation concept, a tubebased MRAC scheme was developed in this paper to improve the vertical dynamic performance of active suspension systems in the presence of parameter uncertainties and road disturbances. Three road profiles were considered to assess the performance of the developed adaptive control paradigm in terms of ride comfort, road handling, and suspension safety, compared to conventional MRAC and SMC approaches. The results regarding the developed T-MRAC demonstrated a superior vibration suppression performance with less control effort, validating the effectiveness of the theoretical design results. In addition, it was found that the relative suspension deflection and relative tire force constraints were well-respected within their permissible ranges and successfully fulfilled the vehicle handling and suspension safety objectives. Furthermore, the obtained comparative RMS results of the suspension system dynamic output under different road profiles revealed the superior performance of TMRAC in terms of ride comfort quality improvement and road disturbance mitigation.

Fig. 1. Performance investigation for the three road profiles; a comparison between MRAC, SMC, and T-MRAC (within the permissible rangeγ−3 ≤γ3 ≤γ+3 and γ−4 ≤γ4 ≤γ+4). The insets show the details of the regions highlighted by dashed black lines.

IEEE/CAA Journal of Automatica Sinica2022年4期

IEEE/CAA Journal of Automatica Sinica2022年4期

- IEEE/CAA Journal of Automatica Sinica的其它文章

- Energy Theft Detection in Smart Grids: Taxonomy,Comparative Analysis, Challenges, and Future Research Directions

- On the System Performance of Mobile Edge Computing in an Uplink NOMA WSN With a Multiantenna Access Point Over Nakagami-m Fading

- Continuous-Time Prediction of Industrial Paste Thickener System With Differential ODE-Net

- Unmanned Aerial Vehicles: Control Methods and Future Challenges

- A Braille Reading System Based on Electrotactile Display With Flexible Electrode Array

- A Short-Term Precipitation Prediction Model Based on Spatiotemporal Convolution Network and Ensemble Empirical Mode Decomposition