Analyzing the Supply Chain Resilience Strategy of the Biden Administration

Li Wei is Professor at the School of International Studies, Renmin University of China; Wang Li is a PhD candidate at the School of International Studies, Renmin University of China.The article was originally published inContemporary American Review, Issue 2, 2022.

Since taking office in 2021, US President Joe Biden has continued his predecessor’s strategic economic and technological competition policy with China.The administration adjusted the approach from an extensive“tariff war”to a more refined“industrial war”while maintaining high pressures in many key sectors.The“supply chain resilience”(SCR) strategy and the“tech war”cutting off supply chain ties with China in strategic industries are the two primary approaches in the US industrial competition with China.

In the supply chain crisis, the Biden administration justified its promotion of the supply chain resilience strategy to ensure economic security.On the one hand, it mobilized domestic and overseas resources to promote the supply chain resilience as a key way to economic development.And on the other hand, it is using supply chain resilience as an economic tool to win the strategic competition against China.The Biden Administration has used political power to reconstruct the global supply chain, and the supply chain resilience is regarded as the key approach to uniting its allies and partners.The supply chain resilience strategy is formulated with the US consideration of global economic competition with China in mind, intending to weaken or even replace China’s pivotal role in the global supply chain.

To better understand the Biden administration’s China economic strategy, one must study the supply chain resilience and its specific domestic and diplomatic implementing measures.In addition, when one realizes that industrial security is an essential component of a country’s economic security,the study is also important for China to correctly respond to external industrial threats and implement the“dual cycle”development strategy.

A Crisis-Driven Strategy

The supply chain resilience strategy is a product of supply chain threats.The supply chain is a business concept, and supply chain resilience is originally a business strategy at the enterprise level.Now it has increasingly become a concept of economic strategy at the national level.The development of the global supply chain is a result of economic globalization.With smooth globalization and rapid economic development, the supply chain network based on an extensive international division of labor evolved naturally.The profit-maximizing enterprises eagerly joined the global production network for maximum gains.However, the backlash against globalization caused by uneven benefit distribution threatens the social support of the globalized supply chain.The supply chain crisis might threaten a country’s economic security, pushing many countries to formulate relevant, appropriate policies and strategies.

Supply chain security: from an economic issue to a political issue

The Global Value Chain (GVC) Participation Rate measures the extent of an economy’s participation in the global supply chain.The rate fluctuations reflect the temporal and longitudinal changes in the global supply chain.Therefore, it is a proxy for the changes in the global supply chain and globalization.From 1995 to 2020, the global economies’GVC participation rate rose from 35.2 percent to 44.4 percent, reaching a peak of 49.3 percent in 2018.1Asian Development Bank et al.,“Global Value Chain Development Report 2021: Beyond Production,”November 2021, https://www.wto.org/english/res_e/booksp_e/00_gvc_dev_report_2021_e.pdf, p.4.There are two methods to measure the participation in global value chains, namely the trade-based method and the production-based method.The former is to calculate the share of indirect trading in gross exports.See Alessandro Borin and Michele Mancini,“Measuring What Matters in Global Value Chains and Value-Added Trade,”World Bank Policy Research Working Paper, No.8804, 2019.The latter is to calculate the share of unfulfilled domestic value-added export in gross domestic value-added.See Zhi Wang, et al.,“Measures of Participation in Global Value Chains and Global Business Cycles,”National Bureau of Economic Research, No.w23222, 2017.The change in GVC shows that increasing globalization at that time reflects the integration and complexity of the global supply chain significantly.However, two periods of decline deserve special attention, namely 2007-2008 and 2018-2020.The first decline was due to the international financial crisis, which changed the pattern of globalization from“Hyper-globalization”to“Slowbalization”with a shrinking global supply chain.2Zhong Feiteng,“Slowbalization, COVID-19 Pandemic and China’s External Economic Environment,”Teaching and Research, No.10, 2020, p.77.After the financial crisis, all parties began to realize the importance of supply chain resilience.In 2010, a think tank’s report pointed out that for safety considerations, companies should focus on the balance of efficiency and resilience rather than pure efficiency.3“Resilient Supply Chains in a Time of Uncertainty,”Economist Intelligence Unit, May 2010, http://graphics.eiu.com/upload/eb/Oracle_Supply_Chain_WEB.pdf.Moreover,the issue of supply chain resilience began to catch the attention of the governments.

Since the Obama administration, the US government has increasingly emphasized the supply chain issue.At first, supply chain security was taken as a collateral issue of cybersecurity and not treated as a standalone topic.The focus was on information security and leakage in the supply chain rather than the reliability of the physical supply chain.In 2010, the Obama administration announced the“Comprehensive National Cybersecurity Initiative,”which talks about establishing a comprehensive risk management mechanism for the global supply chain.4“The Comprehensive National Cybersecurity Initiative,”Obama White House Archives, March 2010,https://obamawhitehouse.archives.gov/issues/foreign-policy/cybersecurity/national-initiative.The Initiative showed that the Obama administration had begun recognizing the supply chain risks and the importance of supply chain security, though it still linked supply chain security to cybersecurity.

In 2012, the Obama administration released the“National Strategy for Global Supply Chain Security”policy paper.It is the first US official national strategy document elevating supply chain security as a distinct national security challenge.One of the stated goals in the policy paper is to foster a resilient supply chain, namely a global supply chain system that could withstand evolving threats and recover rapidly from disruptions.5“National Strategy for Global Supply Chain Security,”Obama White House Archives, January 23,2012, https://obamawhitehouse.archives.gov/sites/default/files/national_strategy_for_global_supply_chain_security.pdf.The paper aims to ensure the supply chain’s efficiency and resilience, with efficiency placed before resilience.The document indicated that the Obama administration still put economic prosperity before economic security.It also stated,“International trade has been and continues to be a powerful engine of the United States and global economic growth....The global supply chain system that supports this trade is essential to the United States economy and security and is a critical global asset.”6“Fact Sheet: National Strategy for Global Supply Chain Security,”Obama White House Archives,January 25, 2012, https://obamawhitehouse.archives.gov/the-press-office/2012/01/25/fact-sheet-nationalstrategy-global-supply-chain-security.Though the Obama administration made supply chain security a separate national agenda, it still emphasized it as an economic and commercial issue rather than a national security concern.7Executive Office of the President, US Department of Commerce,“Supply Chain Innovation:Strengthening America’s Small Manufacturers,”March 5, 2015, https://www.commerce.gov/sites/default/files/migrated/reports/supply_chain_innovation_report.pdf; National Economic Council, Office of Science and Technology Policy,“A Strategy for American Innovation,”October 21, 2015, https://obamawhitehouse.archives.gov/sites/default/files/strategy_for_american_innovation_october_2015.pdf.In 2009, the first version of“A Strategy for American Innovation”was released by the Obama administration without mentioning supply chains, while the updated versions of this document, released in 2011 and 2015,mentioned supply chains.

Following the global financial crisis, the status of supply chain security has gradually moved from a side issue into the center of the government’s main policy agenda.As a result, supply chain security slowly moved from purely commercial and economic discussion to becoming a major national and international issue.However, the Obama administration did not attempt to frame a supply chain strategy based on national security grounds.

Formation of the strategy: a product of great power competition and COVID-19 pandemic

The second decline in the GVC participation rate is from 2018 to 2020.The China-US trade war and the COVID-19 pandemic mainly cause this decline.Due to political and pandemic reasons, supply chain resilience has emerged as a major risk for the global economy again.8Supply chain management has four key dimensions, namely the“4R,”including“Responsiveness,”“Reliability,”“Resilience”and“Relationships.”Among them,“Reliability”refers to“the probability of the product to operate normally within a given period of time,”and“Resilience”refers to“the ability of the system to respond quickly to unexpected events when they occur.”See William Norris, et al.,“A Market-oriented Approach to Supply Chain Security,”Security Challenges, Vol.16, No.4, 2020, p.69;Martin Christopher,Logistics and Supply Chain Management(Upper Saddle River: FT Press,2016), pp.23-24; Chunghun Ha, et al.,“A Mathematical Definition and Basic Structures for Supply Chain Reliability: A Procurement Capability Perspective,”Computers and Industrial Engineering, Vol.120, 2018, pp.335; Martin Christopher and Helen Peck,“Building the Resilient Supply Chain,”International Journal of Logistics Management,Vol.15, No.2, 2004, p.4.The supply chain crisis has become a persistent major economic threat for the United States.9“The Coronavirus Effect on Global Economic Sentiment (December 2021),”McKinsey& Company,December 21, 2021, https://www.mckinsey.com/business-functions/strategy-and-corporate-finance/ourinsights/the-coronavirus-effect-on-global-economic-sentiment; International Monetary Fund,“World Economic Outlook: Recovery during a Pandemic,”December 2021, https://www.imf.org/zh/Publications/WEO/Issues/2021/10/12/world-economic-outlook-october-2021.Therefore, the supply chain security problem is increasingly being looked upon as a national security issue with political significance that cannot be ignored.

The Biden administration’s supply chain resilience strategy is promoted by political and economic means.The government is vigorously adjusting the country’s economic policies and supporting the changes with political and diplomatic initiatives to ensure that the supply chain can quickly respond to disruptions and return to normal.In other words, the Biden administration’s supply chain resilience strategy aims to protect the US supply chain’s security through new domestic and diplomatic measures.The short-term goal is to resolve the domestic supply chain crisis, while the long-term goal is to reduce dependence on unreliable foreign countries and companies.

The“pan-securitization”thoughts deeply influence the supply chain resilience strategy.The overarching reason for the Biden administration to formulate and implement the supply chain resilience strategy is the national security consideration, with the immediate reasons being the intensified strategic competition among major powers and the COVID-19 pandemic.

The intensifying major power competition was the immediate push to formulate the US’s supply chain resilience strategy.Since the Trump administration, the strategic thinking of the United States has become clear:to block China’s industrial development by restructuring global supply chains.The US believes that the intertwined supply chains with China threaten its national security as the competition intensifies.Therefore,it must start the“decoupling”process to reduce dependence on China’s supply chain.Therefore, the Trump administration imposes sanctions on China to eliminate the US trade deficit.By increasing tariffs on lowend industries, the administration hopes to drive up the manufacturing cost and price of Chinese products, thus reducing China’s attractiveness in the global industrial chain and guiding related industries to move out.10Christopher Balding,“A Roadmap for the Great US-China Divorce,”Bloomberg, September 17, 2018,https://www.bloomberg.com/opinion/articles/2018-09-16/trump-needs-allies-for-the-great-u-s-china-tradedivorce?srnd=opinion.However, judging from the results, the tariff war has failed.It has neither significantly reduced the volume of China-US bilateral trade nor the US trade deficit with China, much less hurting China’s industrial base.In 2018,when Trump launched the tariff war, China’s exports to the US increased.Though the bilateral trade volume declined in 2019, it rebounded again in 2020, almost returning to the level of 2018.In the meantime, China’s trade surplus with the US increased from 1.6 trillion yuan in 2015 to 2.2 trillion yuan in 2020.

The Biden administration followed the basic tenet of the Trump administration’s“strategic competition”with China but adjusted the primary approach to the supply chain resilience strategy.Its economic strategy is centered on the supply chain economic strategy, which the Trump administration did not focus on.Moreover, though the supply chain resilience strategy emphasizes“resilience”rather than“security,”its ultimate purpose is to improve US supply chain security.As pointed out in the capstone report released by the White House in February 2022, the US government must address the threats to economic resilience and national security before supply chains become more fragile.The earlier consensus that supply chain resilience is an issue for the private sector should change, and the US government must step in to address its increasing vulnerability.11The White House,“Executive Order on America’s Supply Chains: A Year of Action and Progress,”February 24, 2022, https://www.whitehouse.gov/wp-content/uploads/2022/02/Capstone-Report-Biden.pdf.

At the same time, the COVID-19 pandemic has prompted the US government to emphasize supply chain security at the national strategic level and use political intervention to secure supply stability.The COVID-19 pandemic has had a wide range of impacts for a prolonged time.The global supply chain has been significantly influenced due to global production and investment shrinkage and delivery delays.For most multinational companies, the reliability of their supply chains has declined.Many small and medium-sized suppliers cut production or bankrupt from supply chain disruptions.The global supply chain is mainly organized and controlled by multinational companies shaken by the pandemic.12“Global Value Chain Development Report 2021: Beyond Production.”This unexpected factor exacerbates the global supply chain crisis.The US, which has promoted offshoring before to maximize profit, had experienced significant industrial capacity loss or even“industrial hollowing,”suffers greatly from this crisis.The slowdown of the global flow of people and goods from the pandemic control measures provided a good rationale for the US to decouple from China forcibly.

In a nutshell, the shortcomings of the US supply chain have been fully exposed due to China-US“strategic competition”and the COVID-19 pandemic.The weaknesses forced the US government to formulate and implement the supply chain resilience strategy.The Biden administration has linked the supply chain with national security and shifted the emphasis from economic efficiency to security.

The Biden administration expects to achieve three major goals through the supply chain resilience strategy.First, strengthen the supply chain infrastructure and improve the transparency of the domestic supply chain,to alleviate the domestic supply chain crisis in the short term.Secondly,accelerating the process of manufacturing coming back or“reshoring,”a goal that previous administrations failed to achieve.The reshoring will help boost economic growth for the benefit of the middle class and alleviate domestic social and economic difficulties.Thirdly, encourage the outward migration of certain industries from China to other countries,thus changing China’s status as the“world’s factory”and reducing global dependence on China’s supply chains.These three goals reflect the strategic objectives of the Biden administration, both long-term and short-term, at home and abroad.They also determine the dual-track approach of the US when implementing the supply chain resilience strategy, moving together at home and abroad.

Domestic Moves

The Biden administration has been working on the supply chain strategy framework since the campaign period.In July 2020, Biden released a plan to“Rebuild US Supply Chains and Ensure the US Does Not Face Future Shortages of Critical Equipment”on his campaign website.13“The Biden Plan to Rebuild US Supply Chains and Ensure the US Does Not Face Future Shortages of Critical Equipment,”July 2020, https://joebiden.com/supplychains/.Upon his assumption of office, Biden put forward“six priorities”that did not include supply chain resilience.14The“Six Priorities”include controlling the COVID-19, tackling climate change, promoting racial equity and civil rights, providing economic relieves, reforming the immigration system, and repairing the international status of the United States.See The White House,“The Biden-Harris administration Immediate Priorities,”https://www.whitehouse.gov/priorities/.However,supply chain resilience quickly became the core of the administration’s economic strategy, as well as the pivotal focus of the government to integrate domestic and foreign resources for industrial revival at home and industrial competition with China abroad.Specifically, the Biden administration has taken the following domestic moves to promote the supply chain resilience strategy.

First, since the early days of his presidency, Biden has conducted systematic assessments of the supply chain risks faced by key US products and industries.In June 2021, the White House released the“100-Day Supply Chain Review Report,”which analyzed the supply chain vulnerabilities across four key products: semiconductor manufacturing and advanced packaging; large capacity batteries; critical minerals and materials;and advanced pharmaceutical ingredients.

Specific recommendations to promote the four products were provided, such as investment support and personnel training in the sector of semiconductor manufacturing and advanced packaging, partnership and energy security in the sector of large capacity batteries, labor standards and import reduction in the sector of critical minerals and materials, and transparency and partnership in the sector of advanced pharmaceutical ingredients.15The White House,“Building Resilient Supply Chains, Revitalizing American Manufacturing, and Fostering Broad-Based Growth,”June 2021, https://www.whitehouse.gov/wp-content/uploads/2021/06/100-day-supply-chain-review-report.pdf.

Following these recommendations, the White House quickly established the Supply Chain Trade Strike Force and the Supply Chain Disruptions Task Force.The US Trade Representative led the first task force and was asked to propose unilateral and multilateral enforcement actions against unfair foreign trade practices that have eroded critical supply chains.The second task force is composed of the Secretaries of Commerce,Transportation, and Agriculture and intended to bring the full capacity of the federal government and society to address supply chain disruptions and supply/demand mismatches.16The White House,“Fact Sheet: Biden-Harris administration Announces Supply Chain Disruptions Task Force to Address Short-Term Supply Chain Discontinuities,”June 8, 2021, https://www.whitehouse.gov/briefing-room/statements-releases/2021/06/08/fact-sheet-biden-harris-administration-announces-supplychain-disruptions-task-force-to-address-short-term-supply-chain-discontinuities/.In February 2021, Biden signed the Executive Order on America’s Supply Chains, requesting review of the progress and effectiveness of implementing supply chain policies in six key industries, namely defense, public health, information and communications technology, agriculture and food products, energy, and transportation.In February 2022, the White House also released a supply chain assessment report for six key industries, calling for continued attention to supply chain security.17“Executive Order on America’s Supply Chains: A Year of Action and Progress.”

Second, facing the supply chain crisis, Biden has“prescribed the right medicine”to mitigate the supply chain vulnerabilities.The administration focuses on solving the transportation problems that affect the supply chain system.In 2021, US port congestion worsened significantly.From April to November, the proportion of imported goods that stayed in West Coast ports for more than five days increased sharply from 13.1 percent to 50 percent, while the average wait time for containers at the port rose from four to eight days.18Pacific Merchant Shipping Association,“West Coast Trade Reports,”https://www.pmsaship.com/trade-reports/.The situation was even worse in the Ports of Los Angeles and Long Beach, the biggest ports in the United States that process nearly40per cent of all containerized imports of the country.In November and December of 2021, the containers were left waiting at the two ports for more than four days, sometimes even eight days, far exceeding the wait time of Savannah port, another major US port on the East Coast, and Shanghai Port, the largest port in China.19The White House,“Remarks by President Biden on the Nation’s Supply Chains,”December 1, 2021,https://www.whitehouse.gov/briefing-room/statements-releases/2021/12/01/remarks-by-president-bidenon-the-nations-supply-chains/.

The Biden administration has adopted a multi-pronged approach to mitigating port congestion.On the one hand, short-term measures such as personnel adjustment and port operation coordination have been taken.The White House appointed a Port Envoy in the Supply Chain Disruptions Task Force to coordinate with the Secretary of Transportation on the port congestion issue.After Vice President Kamala Harris’s discussion with the heads of the ports, the Ports of Los Angeles and Long Beach agreed to extend operating hours and reduce related fees.20The White House,“Readout of Virtual Roundtable on Collective Efforts to Address Global Supply Chain Bottlenecks,”October 13, 2021, https://www.whitehouse.gov/briefing-room/statementsreleases/2021/10/13/readout-of-virtual-roundtable-on-collective-efforts-to-address-global-supply-chainbottlenecks/; Federal Maritime Commission,“Temporary Revision to PierPass to Take Effect,”November 29, 2021, https://www.fmc.gov/temporary-revision-to-pierpass-to-take-effect/Long-term measures have also been taken, such as constructing supply chain infrastructures.Port infrastructure is a crucial part of Biden’s infrastructure plan.In November 2021, the Biden administration pushed Congress to pass the“Infrastructure Investment and Jobs Act,”of which a total of $17 billion would be used for port construction and water transport.21“H.R.3684-Infrastructure Investment and Jobs Act,”117th Congress (2021-2022), November, 2021,https://www.congress.gov/bill/117th-congress/house-bill/3684/actions?q=%7B%22search%22%3A%5B%22infrastructure%22%2C%22infrastructure%22%5D%7D&r=1&s=3.In the same month, the Biden administration also launched the“Port Infrastructure Development Grant Program,”the only federal grant program fully dedicated to port infrastructure investment.22The White House,“Fact Sheet: The Biden-Harris Action Plan for America’s Ports and Waterways,”November 9, 2021, https://www.whitehouse.gov/briefing-room/statements-releases/2021/11/09/fact-sheetthe-biden-harris-action-plan-for-americas-ports-and-waterways/.

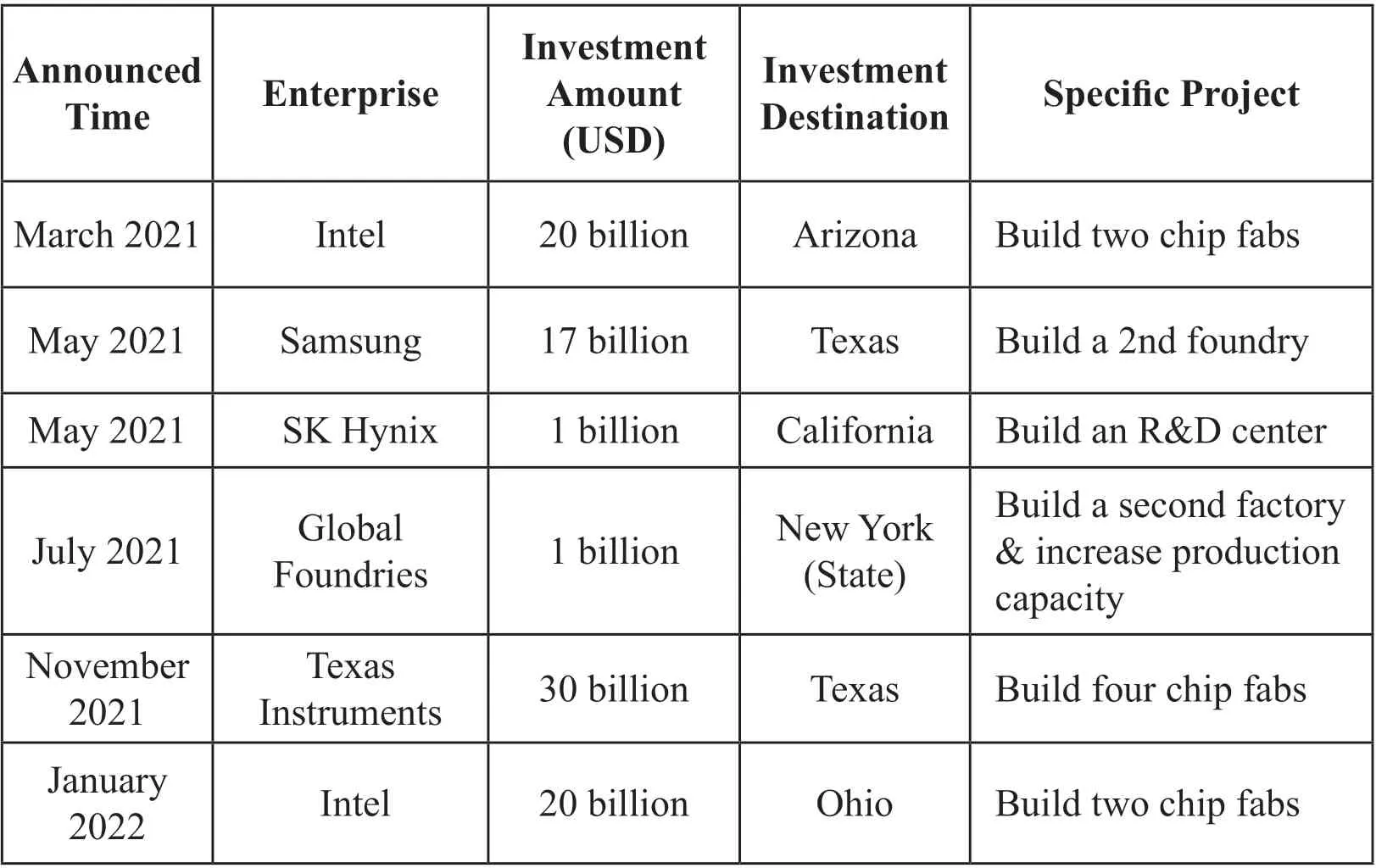

Third, the Biden administration has picked the semiconductor industry as the administration’s supply chain reconfiguration starting point.On the one hand, the Biden administration attempts to improve the transparency of the semiconductor industry to solve the current chip shortage,23The White House,“Remarks by President Biden at a Virtual CEO Summit on Semiconductor and Supply Chain Resilience,”April 12, 2021, https://www.whitehouse.gov/briefing-room/speechesremarks/2021/04/12/remarks-by-president-biden-at-a-virtual-ceo-summit-on-semiconductor-and-supplychain-resilience/.with the perception that the low transparency of the industry causes fluctuations in the semiconductor supply chain.In September 2021, Secretary of Commerce Gina Raimondo and National Economic Council Director Brian Deese convened a semiconductor supply chain meetingto implement transparency improvement measures.To get complete information about the supplies and demands of the chips and coordinate the supply chain, the US launched a request for information asking all parties in the supply chain—producers, consumers, and intermediaries—to voluntarily share information about inventories, demand, and delivery dynamics.24The White House,“Readout of Biden administration Convening to Discuss and Address Semiconductor Supply Chain,”September 23, 2021, https://www.whitehouse.gov/briefing-room/statements-releases/2021/09/23/readout-of-biden-administration-convening-to-discuss-and-address-semiconductor-supplychain/.On the other hand, the Biden administration has tried to attract semiconductor companies to come back to the United States, aiming to consolidate the Enticed by Biden’s strong policy support, many semiconductor companies have announced new investments in the United States.For example, at a business meeting between the United States and the Republic of Korea(ROK) in May 2021, Samsung and S.K.Hynix announced new investment plans in the United States.25Among them, Samsung announced that it would invest $17 billion to build a second foundry in Texas, and SK Hynix announced an investment of US$ 1 billion to set up a R&D center in Silicon Valley.See Myeong-seok Chae,“Korean Companies Including Samsung, LG, and SK to Expand Investment in US,”Global Economic News, February 2, 2022, https://en.g-enews.com/view.php?ud=202202221033579381c4c1a19e2e_9.American companies have also joined in (see Table 1 for details).26“Intel Announces Major Expansion in Arizona,”Intel, March 23, 2021, https://www.intc.com/newsevents/press-releases/detail/1452/intel-announces-major-expansion-in-arizona;“Intel Announces Next US Site with Landmark Investment in Ohio,”Intel, January 21, 2022, https://www.intel.com/content/www/us/en/newsroom/news/intel-announces-next-us-site-landmark-investment-ohio.html.Since Biden’s inauguration, the semiconductor companies have announced a total of more than $80 billion in long-term new investment in the United States, focusing on manufacturing rather than R&D.This will undoubtedly enhance the US’s capacity to control the market and technology of the semiconductor industry and helps maintain its nearly monopolistic hold of the industry.

Table 1 Semiconductor Companies’Investment Plans to the US since 2021

In addition, bills related to technology competition proposed in the US Congress reflected the United States’effort to keep its dominant leadership position in the semiconductor supply chain.The“US Innovation and Competition Act of 2021”and the“America COMPETES Act of 2022”passed by the Senate and the House, respectively, proposed to allocate more than $50 billion to encourage manufacturing and investment in key industries like semiconductors.27“S.1260 - United States Innovation and Competition Act of 2021,”117th Congress (2021-2022), June 8, 2021, https://www.congress.gov/bill/117th-congress/senate-bill/1260/all-actions?q=%7B%22search%22%3A%5B%22innovation+and+competition%22%2C%22innovation%22%2C%22and%22%2C%22compe tition%22%5D%7D&s=3&r=1&overview=closed#tabs.Although the two parties still have differences in the details of the bills, they have reached a consensus on increasing support for semiconductor R&D and manufacturing.Compared with the White House’s plans, the Congress bills reveal a strong sense of“strategic competition”and enhance local semiconductors’local manufacturing capacity.The congressional moves showed that the US semiconductor competition strategy had exceeded the administrative scope.

Fourth, as a supporting measure of the supply chain resilience strategy, Biden has promoted the“Buy American”agenda by signing executive orders and issuing initiatives.For example, in 2021, Biden signed an executive order requiring the federal government to prioritize purchasing products made in the United States.It also suggested raising the threshold for domestic goodsin federal procurement, increasing the proportion limit of domestic goods, and requiring the suppliers to provide specific data on the percentages of“Made in America”products.Although the executive orders only regulate federal procurement, they would also affect or interfere with the procurement direction of the suppliers, indicating that the Biden administration has been working to increase self-sufficiency and reduce dependence on other countries, especially China.

Generally, the domestic measures of the Biden administration’s supply chain resilience strategy have three characteristics.First,government-business cooperation.Compared to the Trump tariff war that affects goods, the Biden administration’s supply chain strategy skips the merchandise.Instead, it directly affects the businesses, which are important nodes of the supply chain network.The businesses are the key implementing party in the supply chain resilience strategy.In his speech, Biden quoted John Furner, CEO of Walmart US, saying that“the combination of private enterprise and government working together has been successful...there’s been a lot of innovation.”28“Remarks by President Biden on the Nation’s Supply Chains.”Second,different policies for different industries.As pointed out by the“100-day Supply Chain Review Report,”building resilient supply chains requires a sector-by-sector approach because different products or industries have different characteristics, and not all recommendations apply to all industries.29“Building Resilient Supply Chains, Revitalizing American Manufacturing, and Fostering Broad-Based Growth,”p.8.The supply chain network involves many parts and industries,requiring multiple departments to jointly assess the business and product environment to formulate a successful strategy.That means the successful implementation of the supply chain resilience strategy requires a“whole of government”approach with cross-agency collaboration.Third,supply chain resilience is a combination of crisis response and routine management.The Biden administration has been promoting the supply chain resilience strategy as an emergency measure to deal with the supply chain crisis and as a regular job.For example, on port congestion, besides immediate measures to mitigate short-term congestion problems blocking domestic supplies of goods,30The White House,“Recent Progress at Our Ports: Robust Inventories and New Moves Toward Greater Velocity,”November 29, 2021, https://www.whitehouse.gov/nec/briefing-room/2021/11/29/recent-progressat-our-ports-robust-inventories-and-new-moves-toward-greater-velocity/.Ocean carriers will be charged$100 per container per day if the container sits at the terminal for too long, compounding in $100 increments per container each day.the Biden administration has also carried out port modernization and digitization measures to improve the ports’operating efficiency and information transmission efficiency from a longterm perspective.

Diplomatic Moves

The US’s supply chain resilience strategy would be impossible to implement without the cooperation of its allies and partners.Therefore,in addition to domestic measures, the Biden administration intends to build a new economic coalition to improve supply chain resilience, which targets China.Vigorous“supply chain diplomacy”has been carried out globally.The formation of the“Supply Chain Alliance”and“Coalition of Democracies”are complementary setups to each other.31Shi Yinhong,“The Biden administration’s Posture toward China: Behaviors beyond Strategic Military Front,”Journal of International Security Studies, No.6, 2021, p.8; Zhang Qian,“Comments on the Issue of Values Alliance of the Biden administration,”China Security Studies, No.10, 2021, p.4.The former is to secure US leadership in the global economy under the guise of“supply chain security”amid the COVID-19 pandemic.The latter is to defend US hegemony in soft power with democratic values as the core.The Biden administration has actively promoted“supply chain diplomacy”at global,regional and bilateral levels, striving to build a comprehensive supply chain network.

First, at the global level, the Biden administration has sought to rally international support by launching the global supply chain summit.During the G20 summit in Rome in 2021, President Biden organized the first Summit on Global Supply Chain Resilience, which was attended by eleven G20 members and four non-G20 members.32The White House,“Fact Sheet: Summit on Global Supply Chain Resilience to Address Near-term Bottlenecks and Tackle Long-term Challenges,”October 31, 2021, https://www.whitehouse.gov/briefingroom/statements-releases/2021/10/31/fact-sheet-summit-on-global-supply-chain-resilience-to-address-nearterm-bottlenecks-and-tackle-long-term-challenges/.

The participating countries are all key players for the US in building the supply chain alliance, and they can be divided into three categories.First are the developed countries that are US traditional allies and partners,such as the United Kingdom, Germany, Canada, Australia, Japan, the ROK, Singapore, etc.These are the core countries of the US supply chain alliance.Second, certain emerging economies like India, Indonesia and Mexico, which the US regarded as the main alternative manufacturing base to China.Third, countries with monopoly power on certain resources,like the Democratic Republic of the Congo and the Netherlands.Congo supplies nearly seventy per cent of the world’s cobalt, one of the key raw materials for high-energy batteries.The Netherlands is home to ASML,the only company in the world producing the EUV lithography machine indispensable in making advanced chips.

The Summit on Global Supply Chain Resilience is the US’s initial attempt to build the supply chain alliance, which reflects the US’s ambition to coordinate the global supply chain network.China,the“world’s factory,”was not invited to the meeting.This summit is the largest multilateral supply chain meeting convened by the Biden administration.It shows that the US is accelerating the process of establishing the supply chain alliance with supply chain resilience as the core, though no joint statement has been issued after the meeting.The convening of this summit is the starting point, not the end.The participating countries have reached a consensus at the summit, agreeing to promote the diversification of the supply chain ecosystem, improve transparency, strengthen information sharing and work for future cooperation.33Ibid.On this basis, the US Secretary of State and Secretary of Commerce would convene a multi-stakeholder summit in 2022 to promote follow-up cooperation related to the supply chain alliance and build a larger supply chain network.

Second, at the regional level, the Biden administration has consolidated the economic pillar of the“Indo-Pacific Strategy”by vigorously promoting supply chain resilience diplomacy under the“Indo-Pacific”framework.The Biden administration has adopted and enriched the“Indo-Pacific Strategy”of the Trump administration.In 2021,the United States, Japan, India and Australia held“Quadruple Security Dialogue”(QUAD) summits online and offline, and supply chain cooperation was a key topic under QUAD.34The White House,“Fact Sheet: Quad Summit,”March 12, 2021, https://www.whitehouse.gov/briefingroom/statements-releases/2021/03/12/fact-sheet-quad-summit/; The White House,“Quad Principles on Technology Design, Development, Governance, and Use,”September 24, 2021, https://www.whitehouse.gov/briefing-room/statements-releases/2021/09/24/quad-principles-on-technology-design-developmentgovernance-and-use/.The“Critical and Emerging Technology Working Group”was launched after the online summit, and the“Technical Standards Contact Group”was established after the offline summit, as well as the“Semiconductor Supply Chain Initiative.”The US is trying to start coordinating efforts in the technical standard setting of new promising technologies among the four“Indo-Pacific”countries on a pivot scale and then expand the effort to cover a broader area in the future.The supply chain alliance can be gradually expanded within the framework of the“Indo-Pacific.”

The United States has continuously expanded its supply chain alliance based on QUAD.When attending the 16th East Asia Summit, Biden proposed jointly promoting the“Indo-Pacific Economic Framework”(IPEF) with its partners.In addition to the digital economy, clean energy,infrastructure, labor standards, and supply chain resilience are key parts of the framework.35The White House,“Readout of President Biden’s Participation in the East Asia Summit,”October 27,2021, https://www.whitehouse.gov/briefing-room/statements-releases/2021/10/27/readout-of-presidentbidens-participation-in-the-east-asia-summit/.US Secretary of Commerce Raimondo said that instead of rejoining the Comprehensive and Progressive Trans-Pacific Partnership,the United States would establish a new economic cooperation mechanism under the“Indo-Pacific”framework.36“US Commerce Chief Sees Indo-Pacific Economic Framework Early Next Year,”Reuters, November 17, 2021, https://www.reuters.com/world/asia-pacific/us-commerce-chief-sees-indo-pacific-economicframework-early-next-year-2021-11-17/; Yoichi Takita,“US Won’t Join CPTPP but Will Seek New Framework: Raimondo,”Nikkei Asia, November 16, 2021, https://asia.nikkei.com/Economy/Trade/USwon-t-join-CPTPP-but-will-seek-new-framework-Raimondo.The Biden administration has been vigorously advancing its economic diplomacy around this framework,including Raimondo and US Trade Representative Katherine Chi Tai’s visits to Asia in 2021 and Secretary of State Antony Blinken’s visits to Southeast Asia.37Hiroyuki Nishimura,“US Counters China with New Indo-Pacific Framework,”Nikkei Asia, December 19, 2021, https://asia.nikkei.com/Politics/International-relations/Indo-Pacific/US-counters-China-with-new-Indo-Pacific-framework.The IPEF might be a springboard for the US to build the global supply chain alliance, as it provides a platform for the US to cooperate with key countries.

Third, at the bilateral level, Japan, the ROK, India, Vietnam and Malaysia are the pivotal countries for the Biden administration to build the supply chain alliance.Japan and the ROK are major manufacturing countries and China’s strong competitors in high-end manufacturing industries.They enjoy first-mover advantages in key industries such as semiconductors, new energy vehicles, and batteries.Therefore, the US has tried making Japan and the ROK trustworthy anchors in its semiconductor supply chain.Former Japanese Prime Minister Yoshihide Suga was the first foreign leader to visit the United States during Biden’s presidency.During the visit, the two leaders issued a joint statement to establish a“Competitiveness and Resilience Partnership”(CoRe), with supply chain cooperation being an important part of it.38The White House,“US- Japan Joint Leaders’Statement:‘US – Japan Global Partnership for a New Era’,”April 16, 2021, https://www.whitehouse.gov/briefing-room/statements-releases/2021/04/16/u-sjapan-joint-leaders-statement-u-s-japan-global-partnership-for-a-new-era/.Raimondo chose Japan for her first visittoAsia and successfully promoted the establishment of the“Japan-US Commercial and Industrial Partnership”(JUCIP), which aimed to strengthen supply chain resilience cooperation in semiconductors and other industries.39US Department of Commerce,“Joint Statement between Department of Commerce Secretary Gina Raimondo and Ministry of Economy, Trade, and Industry Minister Hagiuda Koichi,”November 15, 2021,https://www.commerce.gov/news/press-releases/2021/11/joint-statement-between-department-commercesecretary-gina-raimondo-and.In May 2021, during a visit to the United States, then-ROK President Moon Jae-in discussed the semiconductor supply chain and other related topics with Biden, laying the foundation for US-ROK supply chain cooperation.The agreement led to the announcement of more than $30 billion in new investment from Korean companies to the US in the semiconductor and electric vehicle industries.40The White House,“Statement by NEC Director Brian Deese and National Security Advisor Jake Sullivan on Samsung Announcement of New Semiconductor Facility in Texas,”November 23, 2021, https://www.whitehouse.gov/briefing-room/statements-releases/2021/11/23/statement-by-nec-director-briandeese-and-national-security-advisor-jake-sullivan-on-samsung-announcement-of-new-semiconductorfacility-in-texas/.To strengthen cooperation on the semiconductor supply chain, the US and the ROK established a new mechanism of“Semiconductor Partnership Dialogue”under Raimondo’s promotion.They held the first meeting on December 8, 2021, discussing technical cooperation, personnel exchanges and industrial investment.41US Department of Commerce,“Readout of Secretary Gina M.Raimondo’s Call with Minister of Trade, Industry, and Energy of the Republic of Korea Moon Sung Wook,”December 21, 2021, https://www.commerce.gov/news/press-releases/2021/12/readout-secretary-gina-m-raimondos-call-minister-tradeindustry-and.With these moves, the US has gradually developed supply chain cooperation with Japan and the ROK centered on semiconductors.

India and Vietnam are emerging manufacturing countries and important destinations for global industrial relocation, with rising positions in global industrial chains.They have been gradually eating into China’s manufacturing share.The United States is trying to accelerate this process by reconstructing the global supply chain, making India and Vietnam the low-end manufacturing bases that might replace“Made in China”in global supply chains.India is a core country in the US’s Indo-Pacific Strategy and an important bilateral partner for supply chain cooperation.In July 2021, Blinken visited India for the first time as Secretary of State, during which he met with the Indian Foreign Minister and emphasized supply chain cooperation.42US Department of State,“Secretary Blinken’s Travel to India and Kuwait,”July 23, 2021, https://www.state.gov/secretary-blinkens-travel-to-india-and-kuwait/.Supply chain and investment cooperation were also important when Indian Prime Minister Modi visited the United States and met with Biden and Harris in September 2021.43The White House,“US-India Joint Leaders’Statement: A Partnership for Global Good,”September 24,2021,“https://www.whitehouse.gov/briefing-room/statements-releases/2021/09/24/u-s-india-joint-leadersstatement-a-partnership-for-global-good/.Two months later, the US International Development Finance Corporation (DFC) announced that it had approved up to five hundred million US dollars in debt financing to First Solar, the largest US solar energy manufacturing company, to support its construction of solar panel manufacturing plants in Tamil Nadu, India.The acting CEO of DFC called it a key investment in strengthening USIndia supply chain cooperation and a milestone of the US’s supply chain diversification effort.44The United States International Development Finance Corporation,“DFC Announces Approval to Provide up to $500 Million of Debt Financing for First Solar’s Vertically-Integrated Thin Film Solar Manufacturing Facility in India,”December 7, 2021, https://www.dfc.gov/media/press-releases/dfcannounces-approval-provide-500-million-debt-financing-first-solars.

Vietnam is also an important partner of the United States for supply chain cooperation.In August 2021, Harris visited two countries in Southeast Asia, one was Singapore, the richest country in the region, and the other was Vietnam.Harris also became the first US vice president to visit Vietnam since the end of the Vietnam War.When meeting with Vietnamese leaders, Harris didn’t directly mention supply chain resilience but emphasized supply chain-related issues such as bilateral investment and market access.45The White House,“Remarks by Vice President Harris in Press Conference in Hanoi, Vietnam,”August 26, 2021, https://www.whitehouse.gov/briefing-room/speeches-remarks/2021/08/26/remarks-by-vice-presidentharris-in-press-conference-in-hanoi-vietnam/.In the following month, Raimondo discussed supply chain resilience more directly with Vietnam’s Minister of Industry and Trade during a phone meeting, hoping to maintain the stability of the supply chain through US-Vietnam cooperation.46US Department of Commerce,“Readout of Secretary Gina M.Raimondo’s Call with Vietnamese Minister of Industry and Trade Nguyen Hong Dien,”September 1, 2021, https://www.commerce.gov/news/press-releases/2021/09/readout-secretary-gina-m-raimondos-call-vietnamese-minister-industry.Vietnam poses a notable threat to China’s manufacturing industries, as statistics show that Vietnam has already replaced China as the main producer of many famous brands.Replacing China in the popular brand manufacturing chain is an important reason behind the US’s attempts to absorb Vietnam into its supply chain system.47Taking Adidas and Nike, the famous consumer brands, as examples.In 2020, 42 percent and 15 percent of Adidas footwear products were produced in Vietnam and China, respectively, while the figures were 35% and 31% in 2013.In 2010, Vietnam surpassed China to become the largest producer of Nike footwear products.In 2021, Vietnam accounted for 51 percent of Nike footwear production, and China’s share was 21 percent.See Hugo Guerreiro,“Where Is Nike Made? Is It in China or Vietnam?”The Men Hero,March 1, 2022, https://themenhero.com/where-is-nike-made/; Sophie Chapman,“Vietnam Becomes Main Manufacturer for Adidas and Nike Footwear,”Manufacturing, May 17, 2020, https://manufacturingdigital.com/procurement-and-supply-chain/vietnam-becomes-main-manufacturer-adidas-and-nike-footwear.

Malaysia is another country worthy of attention, which the Biden administration adsorbs into the IPEF for supply chain cooperation.The last stop of Raimondo’s first visittoAsia was Malaysia.During her visit there, Raimondo held a round-table meeting with business leaders from the semiconductor industry of the two countries and visited ON Semiconductor’s manufacturing plant.After the round-table meeting,the two sides announced that they would strengthen cooperation on the semiconductor supply chain’s transparency, security and resilience.48US Department of Commerce,“Readout of Secretary Gina M.Raimondo’s Official Visit to Malaysia,”November 18, 2021, https://www.commerce.gov/news/press-releases/2021/11/readout-secretary-gina-mraimondos-official-visit-malaysia.The two countries also issued a joint statement, confirming Malaysia’s key role in the semiconductor supply chain and negotiation plans on relevant cooperation, intending to sign a formal agreement in early 2022.49US Department of Commerce,“Joint Statement by US Secretary of Commerce Gina Raimondo and Malaysian Senior Minister of International Trade and Industry Mohamed Azmin Ali,”November 18, 2021,https://www.commerce.gov/news/press-releases/2021/11/joint-statement-us-secretary-commerce-ginaraimondo-and-malaysian.When Blinken visited Malaysia, he also expressed the same willingness, that is, to work with the Malaysian government and enterprises to strengthen cooperation in the semiconductor supply chain.50Antony Blinken,“Secretary Antony J.Blinken and Malaysian Foreign Minister Saifuddin Abdullah at a Joint Press Availability,”US Department of State, December 15, 2021, https://www.state.gov/secretaryantony-j-blinken-and-malaysian-foreign-minister-saifuddin-abdullah-at-a-joint-press-availability/.

In short, the Biden administration has been vigorously promoting supply chain resilience at global, regional and bilateral levels, aiming to rebuild an America-centered global supply chain network and weaken China’s role.Due to the poor manufacturing state in many industries and sluggish technical innovations, the US cannot maintain the leading role in the global supply chain by itself and has to turn to its allies and partners.The real goal of its“supply chain diplomacy”is to mobilize the resources of all countries to solve the current supply chain crisis in the United States and maintain its privileged position in the global supply chain.The domestic moves are for the absolute security of the US supply chain, while the diplomatic moves are for the relative security and the rebuilding of a UScentric global supply chain system.51Zhao Kejin and Lang Kun,“On the Supply Chain Security under China-US Competition,”Northeast Asia Forum, No.2, 2022, p.26.

Its Impacts on China and Limitations

The supply chain resilience challenge has become a key issue in the global strategy of the United States and an important part of the“great power competition”strategy.52Guan Chuanjing,“Safe Operation and Strategic Adjustment of US Global Supply Chain Policy,”International Security Studies,No.1, 2022, p.76; Li Shujun and Wang Xiaoming,“The National Security Logic and Realization Path of Global Supply Chain Adjustment in the United States,”International Security Studies,No.1, 2022, p.122.The United States hopes to achieve dual goals through the“supply chain resilience”strategy.On the one hand, it supports enterprises to shorten the supply chain and promote onshore and nearshore production, to revive domestic industry in the United States.On the other hand, some industries are encouraged to accelerate their transfer from China and reduce their dependence on China by cultivating substitutes.The shortened supply chain or transferring back to the United States harms China in more than one way.China’s industrial security will be threatened,industrial upgrading will be hindered, and China’s dependence on foreign industries will intensify.

First, the“supply chain resilience”strategy may stimulate some enterprises, especially the mid and low-end manufacturing industries,to move out of China, undermining China’s industrial security.Industrial transfer manifests the dynamic process of global supply chain adjustment.Gradual industrial transfer conforms to economic law and is a normal global supply chain adjustment phenomenon.As some Southeast Asian countries are showing more comparative advantages in labor and production costs,there have been signs of labor-intensive industries transferring from China to Southeast Asian countries.53Yue Shengsong,“China and Southeast Asia in the Fifth International Industrial Transfer: Comparative Advantages and Policy Options,”Southeast Asian Studies,No.4, 2021, p.134; Dong Xiaojun,“Reducing Excess Capacity through International Transfer: Five Global Waves, Two Models and China’s Exploration,”Economic Research Reference,No.55, 2014, p.8.The low-end industries of the industrial chain,such as the labor-intensive ones, could have been naturally“metabolized”through China’s industrial upgrading or market mechanism, which would have gradually promoted the transfer of some industries within China to other parts of the world.However, the“supply chain resilience”strategy formulated and implemented by the United States has interfered with the market through government forces.The acceleration of the process of low-end industries moving out of China, and being forced to have large-scale industry transfer before the completion of industrialization, may damage the foundation of the Chinese economy and delay China’s industrialization and modernization.

In addition, rapid industrial emigration will directly reduce China’s tax revenue.China’s tax revenue mainly comes from businesses, and the reduction of corporate tax will lead to the contraction of both fiscal revenue and fiscal expenditure, thus affecting the country’s macroeconomic control ability.Moreover, the“supply chain resilience”strategy by the United States pushes industries to move out of China faster than they would otherwise,which may lead to instability in China’s labor market.

The biggest impact of industrial transfer, especially the transfer of manufacturing, is on the job market.The United States is creating“substitutes”for China in the manufacturing sector, accelerating the transfer of manufacturing from China to Southeast Asia and other regions.For the overall economy, China’s industrial structure and supporting measures may not be able to adapt to such upheaval in the short term.For regional economies, in the case of irregular single-point outbreaks of COVID-19, personnel flow is still limited, and it is difficult for local job markets to coordinate and fill gaps.For regions that rely heavily on the manufacturing industry, the relocation of the manufacturing industry may cause short-term employment pressure that they cannot adjust easily.More seriously, the strategy may initiate a chain reaction of industrial relocation.Some industries have formed a complete ecological system in China’s industrialization.If one or some leading enterprises withdraw, the production and sales of the upstream and downstream enterprises will all be affected.Related enterprises of the industrial chain may follow the exodus, starting a chain reaction from a single enterprise’s migration to an industrial cluster’s migration.As a result, both China’s industrial ecology and economic security will be jeopardized.

Second, the US strategy of“supply chain resilience”may discourage multinational enterprises, especially high-tech enterprises,from investing in China and inhibit China’s industrial upgrading.The US shortens the supply chain of high-tech industries, encourages American businesses to withdraw their high-tech industries back to the US, and reduces purchases from China.The moves are not conducive to China’s fostering of an industrial environment in the high-tech sector and threaten its industrial transformation and upgrading.In the past, China’s industrial upgrading was mostly achieved by integrating into the global industrial chain and supply chain, in which multinational companies in China, especially American companies, played a key role.For example,Apple’s production and accessory procurement in China directly drove the rise of China’s smartphone industry chain, while Tesla’s production in China activated China’s electric vehicle market.54Lingling Wei, et al.,“Elon Musk Needs China.China Needs Him.The Relationship Is Complicated,”The Wall Street Journal, December 4, 2021, https://www.wsj.com/articles/elon-musk-needs-china-chinaneeds-him-the-relationship-is-complicated-11638594026.Moreover, the United States encourages, induces or coerces industrial backflow in the high-tech sector will hurt the channels for China to learn advanced technologies from high-tech enterprises and bring them into China, which prevents China from enjoying the spillover benefits of investment made by high-tech enterprises.As a result, China’s industrial upgrading process is being hindered, as well as its independent technology research and development.

At the same time, the US strategy of“supply chain resilience”weakens the impetus for China’s industrial upgrading and further increases the risk that China will fall into a version of the middle-income trap on industrial transformation; that is, the middle-end and low-end industries have moved out, while the high-end domestic industries are not yet mature.55Rui Mingjie,“Strategic Thinking, Goal and Path of Constructing Modern Industrial System,”China Industrial Economics,No.9, 2018, p.26; Xu Nan and Li Jianjun,“International Financial Crisis and the Transformation and Upgrading of China’s Processing Trade—Based on the Perspective of Global Production Network,”Finance and Trade Economics, No.4, 2010, p.103.Industrial upgrading and technological progress could have mitigated the economic threat of industrial transfer.Unfortunately, this strategy of the United States has made it more difficult for China to hedge the risk of industrial transfer through industrial upgrading.56Luo Yifu,“East Asia’s Industrial chain Changes and Overcoming the‘Middle Income Trap’: A Case Study of Thailand’s Economic Development,”Southeast Asian Studies,No.1, 2021, p.60.The strategy was designed to reduce the vulnerability of and promote diversification of the supply chain in the US In fact; it hindered China’s industrial upgrading,thus fundamentally weakening the material basis of the Chinese economic model.

Third, the US strategy of“supply chain resilience”will damage the ecosystem of China’s self-contained industrial chain and increase China’s industrial dependence on the outside world.China could have developed a relatively independent and complete industrial supporting system if economic laws had taken their natural course, but this trend is being blocked or even reversed by the“supply chain resilience”strategy.Currently, China faces two categories of industries relocated in two directions simultaneously.

The two categories of industries include low-end and high-end industries; the two directions are the outward migration of Chinese industries to Southeast Asian countries and the reshoring back to European and American countries.These two new trends are the major difference between China’s industrial transfer and the earlier four waves of global industrial transfer.It is also the manifestation that the“supply chain resilience”strategy of the United States is taking effect.As a result,China’s industrial system will be squeezed in both the upstream and downstream of the supply chain.It is sandwiched between the technology and innovation pressure from developed countries in the high-value end and the low-end manufacturing competition from downstream countries regarding factor costs, particularly over wages.China needs to deal with both suppression and chasing economic environments at the same time.57Yong Wang and Shang-Jin Wei,“The Sandwich Effect: Challenges for Middle-Income Countries,”National Bureau of Economic Research, June 7, 2019, https://www.nber.org/conferences/east-asian-seminareconomics-2019; Wang Yong,“New Opportunities and Challenges for China’s Industrial Upgrading in the Period of the 14th Five-Year Plan: From the Perspective of New Structural Economics,”International Economic Review, No.1, 2021, p.63.China’s full industrial chain will be seriously jeopardized if this trend continues.It will be difficult or impossible for China to form a closed loop in its industrial chain.China’s industrial chain will increasingly depend on the external world, with the low-end chain relying on Southeast Asia and other newly emerging manufacturing centers and the high-end chain relying on Europe, the United States, etc.The development will exacerbate the sensitivity and vulnerability of China’s industrial chain to external shocks.

More importantly, the“sandwich effect,”compounded by geopolitical factors, will put more pressure on the Chinese economy.The United States is working with major countries upstream and downstream of the supply chain through economic and diplomatic means to bring the two pressures squeezing the Chinese in the middle in sync.For the countries that take an industrial transfer from China, the Biden administration’s“supply chain resilience”strategy will help them attract foreign investment, expand export trade and increase employment, and force them to improve infrastructure,thus achieving a virtuous cycle of industrial growth.However, to undertake industrial transfer and seize the opportunity for faster development of the manufacturing industry, some countries have begun to adjust and optimize their industrial policies and increase subsidies to foreign-funded businesses.58Yu Nakamura,“Foxconn Set to Make iPhone 12 in India, Shifting from China.”Suppose this trend continues for a long period; the trend will change the development pattern of the global manufacturing industry and fundamentally threaten China’s key position as the“factory of the world”in the global industry chain.

But the Biden administration’s“supply chain resilience”strategy does not necessarily turn out to inflict incalculable damage on China.The advantages of China’s manufacturing industry in terms of infrastructure, market size, talent pool and industrial clusters will not disappear in the short term.These advantages will hedge against the“supply chain resilience”strategy of the Biden administration.Since the reform and opening up, China has maintained a high speed and largescale infrastructure construction; it also improved systems of various infrastructures that have met economic growth needs.59Liu Zhi and Xiuying Liu,“Is China’s Infrastructure Development Experience Unique?”Journal of Chinese Economic and Business Studies,2022, pp.1-18.The“new infrastructure”driven by technological innovation, which can also meet the needs of high-quality development, is driving the digitalization of Chinese manufacturing.60Liu Tengfei et al.,“Boosting the Digital Transformation and Upgrading of China’s Manufacturing Industry with‘New Infrastructure’,”Times Economy and Trade,No.2, 2022, p.117.The strong growth prospects of the Chinese market, which outperforms other emerging markets, are attracting many multinational companies, including those from the United States, to continue to increase their investment in China.61US-China Business Council,“Member Survey,”August 6, 2021, https://www.uschina.org/sites/default/files/uscbc_member_survey_2021_-_en_0.pdf; Liu Lifeng,“Countermeasures for the Transfer of International Manufacturing Industry Chain,”China Economic and Trade Guide, No.10, 2020, p.60.In addition, the quantity and quality of China’s talent pool are internationally competitive.China’s total scientific and technological human resources exceed 100 million,ranking first in the world.

Moreover, the quality of science and technology talent is steadily improving.China is producing almost twice as many science and engineering PhDs as in the US, and the quality of China’s overall education is improving very fast.62Remco Zwetsloot, et al.,“China Is Fast Outpacing US STEM PhD Growth,”Center for Security and Emerging Technology, 2021August, https://cset.georgetown.edu/publication/china-is-fast-outpacing-u-sstem-phd-growth/.Moreover, manufacturing industry clusters have been formed,especially in the eastern region of China, which reduces the production and transaction costs of related manufacturing industries.The ecosystem formed also makes China more internationally competitive and attractive to the outside world.63Xu Kangning,“Industrial Clusters and Competitiveness in Open Economy,”China Industrial Economics,No.11, 2001, p.26; Gao Bai and Zhu Lan,“From‘World Factory’to Industrial Internet Power:Creating Competitive Advantage in the Era of Intelligent Manufacturing,”Reform, No.6, 2020, p.33.Therefore, it will not be easy for the Biden administration to realize its goal to drive a large-scale shift of industrial supply chains away from China.

In addition, the United States faces multiple challenges in implementing its“supply chain resilience”strategy.First, the United States,its allies, and its partners are not necessarily on the same page regarding supply chains.The United States is trying to build a supply chain alliance based on safeguarding its own interests, which not all countries fully acknowledge.A“smaller group”has emerged even from the four“Indo-Pacific”countries.In September 2020, Australia, India and Japan were willing to strengthen supply chain cooperation.In April 2021, the three countries issued a joint statement on the Supply Chain Resilience Initiative(SCRI) to build a“mini-cycle”of supply chains.64Department of Foreign Affairs and Trade,“Joint Statement on the Supply Chain Resilience Initiative by Australian, Indian and Japanese Trade Ministers,”April 27, 2021, https://www.dfat.gov.au/news/mediarelease/joint-statement-supply-chain-resilience-initiative-australian-indian-and-japanese-trade-ministers.The Initiative, which includes the three countries of the Quadrilateral Security Dialogue in the Indo-Pacific region, does not include the US, partly because it cannot agree with Australia, India and Japan on important issues.It is not in other countries interests for the US to take aggressive measures against reliance on China for some key products.

Second, companies’instinctive pursuit of profit makes them less willing to comply with the coercive strategy of the Biden administration.A good supply chain strategy should reflect the coexistence of efficiency and security.Still, after securitizing the“supply chain resilience”strategy and putting excessive emphasis on security, the strategy sacrifices economic efficiency.When it is difficult to balance economic efficiency with industrial security, the choice of investment or withdrawal under political pressure will greatly increase businesses’operating costs.65Liu Lifeng,“Countermeasures for the Transfer of International Manufacturing Industry Chain.”Taiwan Semiconductor Manufacturing Co.(TSMC), for example, has said that building a factory in the US was based on a“political drive”rather than purely technical or commercial reasons and that the cost was much

higher than expected.66Charlie Campbell,“Inside the Taiwan Firm That Makes the World’s Tech Run,”Time, October 1, 2021,https://time.com/6102879/semiconductor-chip-shortage-tsmc/.Although this cost will eventually be distributed to consumers through increasing product prices, businesses will face the risk of losing part of the market in the process, and their enthusiasm to cooperate with this strategy will inevitably be affected.Tesla, the largest electric car maker in the United States, appears to have chosen not to cooperate, as it continues to increase its investment in China and may open a second electric car manufacturing plant in the country despite the strong calls from the Biden administration for investment repatriation.67Steven Loveday,“Is Tesla Planning China Factory 2? Denies Location but Not Plans,”Inside EVs,November 4, 2021, https://insideevs.com/news/545586/tesla-planning-another-china-factory/.It can be seen that policy coercion cannot completely control investment behavior,and enterprises driven by interests will still fight against the strategic demands of the US government.

Conclusion

Supply chain resilience has economic and national security implications and has become an issue discussed at the national strategic level.68Guan Chuanjing,“Safe Operation and Strategic Adjustment of US Global Supply Chain Policy.”The Biden administration used the supply chain crisis as a tool to mobilize political resources, took accompanying measures to improve the competitiveness of US industries, and used government power to include private enterprises in a“supply chain resilience”strategy.This strategy seems to be in the domain of the US domestic economy, but constructing a supply chain alliance has revealed the nature of its economic competition with China.After returning to multilateralism, the Biden administration has been active in building alliances, the most important of which are values and supply chain alliances.The value alliance built based on ideology often cannot overcome the contradiction between idealism and realism.Still, the supply chain alliance can serve as the bridge between idealism and realistic interests.69Xing Ruili,“An Analysis of the Biden Administration’s Conception of the League of Democracies,”Contemporary American Review,No.3, 2021, p.55.

Once the process of supply chain reconstruction starts, it will be irreversible.However, reshaping the global supply chain structure is a longterm process.In the short term, China can maintain its advantages and attraction in industrial development.At the same time, the US government has to deal with conflicting interests with its Allies and businesses at home when implementing the“supply chain resilience”strategy.Therefore, China’s position in the global supply chain will not change materially in the short term.

However, China needs to be proactive by focusing on the new challenges posed by the Biden administration’s“supply chain resilience”strategy and working to offset these negative effects through appropriate policy tools.First, China should fully use its existing advantages over infrastructure, talent, market size and industrial clusters and constantly improve its investment environment.Thus, attraction to multinational enterprises in China will be further increased, hopefully resulting in a delay in the pace of the transfer of its industrial chain and supply chain and extending the time frame for China’s industrial upgrading.China must take advantage of the available window time to guide the gradual transfer of industries.Secondly, increasing investment in scientific research should be encouraged to promote industrial upgrading through technological progress.Third, China needs to improve its domestic industrial ecosystem and strive to build the complete industrial value chain to prevent key technologies and key products from being“choked.”Fourth, China’s supply chain could be developed horizontally and vertically, promoting the diversification of supply links horizontally and the vertical extension of the industry up and down.Finally, with strengthened industrial cooperation with Southeast Asian countries, China will be able to deepen its complementary advantages with these countries, to create a virtuous circle within the region.Another necessity would be winning the countries in the“grey zone”to prevent the US from building a global supply chain alliance that excludes China.