Impact of Joule heating and multiple slips on a Maxwell nanofluid flow past a slendering surface

Shafiq Ahmad, Muhammad Naveed Khan, Sohail Nadeem,Aysha Rehman, Hijaz Ahmad and Rifaqat Ali

1 Department of Mathematics, Quaid-I-Azam University 45320, Islamabad 44000, Pakistan

2 Department of Mathematics, University of Gujrat, Gujrat, 50700 Pakistan

3 Section of Mathematics, International Telematic University Uninettuno, Corso Vittorio Emanuele II,39;00186 Roma, Italy

4 Department of Mathematics,College of Science and Arts,Muhayil,King Khalid University 9004,Abha,Saudi Arabia

Abstract This manuscript presents a study of three-dimensional magnetohydrodynamic Maxwell nanofluid flow across a slendering stretched surface with Joule heating.The impact of binary chemical reactions, heat generation, thermal radiation, and thermophoretic effect is also taken into consideration.The multiple slip boundary conditions are utilized at the boundary of the surface.The appropriate similarity variable is used to transfer the flow modeled equations into ODEs, which are numerically solved by the utilization of the MATLAB bvp4c algorithm.The involved parameter’s impact on the concentration, velocity, and temperature distribution are scrutinized with graphs.The transport rates (mass, heat) are also investigated using the same variables,with the results reported in tabulated form.It is seen that the fluid relaxation,magnetic,and wall thickness characteristics diminish the velocities of fluid.Further, the velocity,concentration, and temperature slip parameters reduce the velocities of fluid, temperature, and concentration distribution.The results are compared to existing studies and shown to be in dependable agreement.

Keywords: Maxwell nanofluid, slendering stretching surface, Joule heating, thermal radiation,thermophoretic effect

1.Introduction

The heat and flow transport scrutiny on stretchable surfaces has a remarkable engineering application such as improvement in the efficiency of paints and lubrication, manufacturing of glass fiber, paper production, glass blowing,aerodynamic extrusion of rubber sheets,and crystal growing,etc.Many researchers have discussed the flow over a stretchable/non-stretchable and linear/nonlinear surface.However, from the applicable point of view in real life, a stretching sheet of variable thickness can be more promising and effective in practical applications in plastic film, metal sparing, polymer extrusion, metallurgical process, etc.The flow over a variable thickness surface(slendering surface)has been given little attention.Although, some literature can be found related to the variable thickness surfaces.Nagendramma et al[1]discussed the 3D Casson nanofluid flow past a slendering surface in the presence of Cattaneo–Christov heat flux and slip effects.They found that velocity gradient is highly motivated due to increase in velocity slip parameter.Prakash and Devi [2] employed a hydromagnetic hybrid nanofluid flow to improve heat transfer rate across a slendering sheet at a prescribed surface temperature.It is also observed that hybrid nanofluid exceeds nanofluid in terms of efficiency.The magnetohydrodynamic (MHD) stagnation point flow of third grade fluid towards a slendering stretching surface in the involvement of variable thermal conductivity and double stratification effects is examined by Hayat et al[3].It is determined that increasing the magnetic parameter reduces the velocity field,whereas the wall thickness variable has the opposite effect.Reddy et al [4] characterized the nanofluid flow with MHD in the existence of slip effects through a slendering extending surface.Thermophoresis and Brownian parameters were shown to be capable of inflating the fluid temperature.Gayatri et al [5] demonstrated numerically the features of the nonlinear convective flow of Maxwell fluid along with the heat source/sink past a slendering stretching surface.They noticed that when a melting surface is present,the rate of heat transfer is much higher than when it is not.This result leads us to the conclusion that the melting surface is suitable for heating treatment.Reddy et al[6]emphasized the influence of activation energy and thermal nonlinear radiation on an MHD Eyring–Powell flow of nanofluid induced by slendering stretching surface.It is worth noting that larger values of radiative heat transport have a greater impact on temperature.In the presence of magnetohydrodynamic and thermal radiation, Mabood et al [7]investigate the boundary layer analysis of two-dimensional unsteady hybrid nanofluid flow across a flat/slendering stretched surface.The study’s main finding is that increasing the magnetic field and nanoparticle volume fraction parameters reduces skin friction while increasing the rate of heat transfer.Kumar et al[8]evaluated the flow and heat-transfer characteristics of hybrid ferrofluid caused by the stretching of an unsteady surface under the effect of an irregular heat source/sink.Simultaneous solutions for ferrofluids and hybrid ferrofluids are offered.Recently,Kumar et al[9]want to look at the flow and heat transfer characteristics of a timeindependent stagnation point flow of an electrically conducting magnetohydrodynamic micropolar fluid across a variable thickness surface.Some latest literature related to variable thickness sheets is presented in the [10, 11].

The quality of the product in the extrusion process mainly depends upon the mechanism of mass and heat transport.The transport of mass and heat has widespread applications in engineering and industrials processes.Some applications can be mentioned here, such as energy production, cooling reactor,power generation, and many more.The transport of mass and heat are used in controlling pollution and food industries.Mass diffusion by Fick’s law and thermal conduction by Fourier’s law can characterize the mechanism of mass and heat transport.Iqbal et al [12] examined the elements of thermal and solutal energy transfer in MHD Burger’s nanofluid dynamics.They used Fourier’s and Fick’s laws to investigate heat and mass transfer processes.Heat transfer analysis of Cu–Al2O3hybrid nanofluid with heat flow and viscous dissipation was performed by Ali et al[13].When heat and mass transport phenomena are combined with other important features such as internal heat generation and absorption, thermal diffusion effects, thermal radiations, nanofluidics, diffusion thermo effects, and variable transport properties, the analysis for three-dimensional flow past a stretching surface is more declines.In the presence of homogeneous-heterogeneous chemical reactions and entropy formation, Khan et al [14] studied the heat and mass transfer flow of a hybrid nanofluid including Hall and ion-slip effects.Sheikholeslami et al[15]use an experimental approach to show the results for nano-refrigerant boiling thermal transport within straighten channels.The findings show that raising the flattened fraction improves heat transfer.Furthermore, increasing the concentration of nanoparticles increases heat transfer within the ranges of the current experiment.Kumar [16] discussed the properties of heat transport and non-Newtonian nanofluid flow above an extending sheet with chemical reaction and factor of slip.The transport of heat and mass transfer of an unsteady 3D MHD flow of Maxwell nanofluid with temperature dependent transport properties, Joule heating, and chemical reaction is explored by Ahmad et al[17].They found that as the Deborah number increases,the velocity of the fluid decreases because it provides resistance to fluid motion.Kumar et al[18]introduced the heat transport and flow of non-Newtonian fluids numerically, by considering the Darcy–Forchheimer and convective boundary conditions.The factor of slip lowers the field of velocity, while the Biot number raises the distribution of heat.Malik et al[19]described the features of mass and heat transfer on Sisko fluid by the consequence of Cattaneo–Christov theory along with an extending cylinder.Heat transport exploration across a curved stretched surface in the presence of uniform magnetohydrodynamics is described numerically by Ahmad et al[20].Awais et al[21]observed the transportation of mass and heat transport on Casson MHD fluid flowing across a medium porous with the shrinking wall.Experimental investigation of thermal transport across oscillating flow inside a cylindrical tube is described by Bouvier et al [22].The observation of mass and heat transport on nanomaterial non-Newtonian liquid flow induced by chemical reaction and activation energy is deliberated by Punith Gowda et al [23].Considering different alternating magnetic fields, Zhang, and Zhang [24] investigated the heat transfer and pressure drop performance of magnetic nanofluids.The results demonstrated that alternating magnetic fields had a better effect on local heat transfer coefficients than unidirectional and non-magnetic fields in the same flow direction.Recently many latest studies related to heat, mass, and flow transfer are presented in the [25–28].

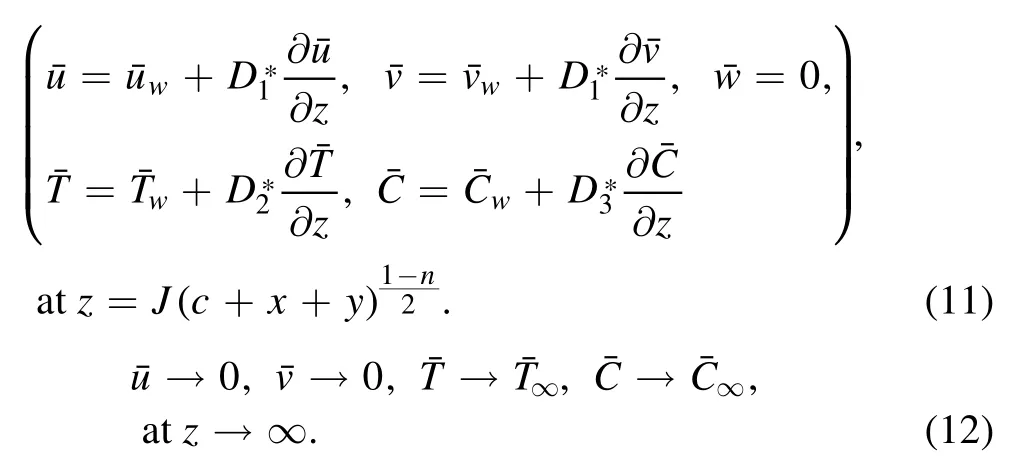

Slip conditions appear in the fluid where the viscous effects at the wall are negligible.Slip conditions are very necessary for many situations, like lubricated hydrophobic surfaces, porous and rough surfaces, coated surfaces, microvalve, micro nozzle,micro pumps, etc.On the other hand, nanoparticles and non-Newtonian fluids are not occupied the no-slip boundary conditions.Navier [29] first time developed the velocity slip boundary conditions followed by Maxwell[30].Andersson[31]evaluated the slip Newtonian liquid flow through an extending surface.Nawaz et al [32] investigated the effects of chemical reaction,partial slip,thermal temperature,and concentration slip on mass and heat transfer in a liquid with variable thermophysical parameters numerically.They determined that the diffusion of wall momentum in a fluid with constant viscosity is faster than the diffusion of wall momentum in a fluid with variable viscosity as temperature rises.In the influence of slip condition and thermophoretic mechanisms, Archana et al [33]examine the incompressible and squeezed Casson nanofluid flow between two parallel plates.The velocity component is found to be increased for the bigger squeezed parameter and slip parameter, although the temperature component follows the same pattern for Brownian motion and thermophoresis.Imran et al [34] anticipated the natural convection and radiative Maxwell liquid flow towards an exponentially extending surface along with slip conditions.The transfer of heat and flow investigation on MHD Maxwell nanofluid under the impact of variable thermal conductivity and slip conditions is carried out by Aziz and Shams[35].As a result of thermal radiation and the slip effect, Souayeh et al [36] study a mathematical model for heat transport and dusty hybrid flow of nanofluid on a stretched surface.They noticed that higher Pr values indicate a decline in heat transfer for both phases.Furthermore, when compared to ordinary nanofluid flow, hybrid nanomaterial flow performs a more effective function in the heat transportation process.The transport of heat and flow on a hybrid nanomaterial liquid with entropy generation and slip boundary conditions across an extending nonlinear surface was studied by Ahmad et al [37].Khan and Alzahrani [38] observed the Jeffrey nanofluid flow with combined features of Joule heating,slip effects,activation energy, magnetohydrodynamics (MHD), and thermophoresis diffusion.Above a nonlinear stretching sheet, Ahmad and Nadeem [39] numerically investigated the 3D radiative hybrid nanofluid flow in the presence of mixed convection, Darcy–Forchheimer, nonlinear source/sink, and activation energy.They showed that when the solid volume concentration of hybrid nanofluid is added,the heat transfer rate is high.Recently some researchers discuss the characteristics of mass and heat transport with slip effects and Joule heating (see [40–42]).

Furthermore,one of the most dominant variables in thermal transport processes is Joule heating.When a flow is transported via a magnetic field,the temperature of the fluid rises.This type of phenomenon arises when atomic molecules interact with moving molecules.Electric heaters, incandescent light bulbs,cartridge heaters, electric stoves, soldering irons, food processing, electric fuses, vegetable glycerine, electronic cigarettes,thermistor, and other industrial and technological applications employ joule heating.In light of certain implications,Swain et al[43] inspected the role of Joule heating and viscous dissipation on Williamson hydromagnetic liquid flow towards a nonlinear extending sheet embedded in a porous medium.With the influence of the magnetic field, Joule heating, and the Soret effect, Palaiah et al [44] evaluate the mass and heat transport features of Maxwell two-dimensional steady fluid flow via an extending surface.They determined that as the magnetic parameter was increased, the normal and axial velocity profiles decreased.The temperature and concentration profiles in the flow zone are reduced by increasing the Prandtl and Schmidt numbers, respectively.Ahmed et al [45] explore the solutal energy and thermal transport in the nano-Maxwell liquid flow across a porous medium with Joule heating, heat generation, and chemical reaction effects.Abdelhafez et al[10]describe an unsettled 2D influx of Maxwell nanofluid induced by an extending cylinder embedded in a porous medium with the impact of Joule heating and chemical reaction.They found that the Biot number and order of chemical reactions improves the rate of heat transfer.Islam et al[46]evaluate the thermal effects of a Maxwell mixed convection nanofluid flow spinning motion generated by a bidirectional and rotating stretching cylinder,taking into account the effects of an internal heat source/sink and Joule heating.

In the aforementioned literature, no study has been done yet to investigate the features of transfer of mass and heat on 3D Maxwell nanofluid flow across a slendering stretching sheet under the thermophoretic and radiation effects.Further,the multiple slip boundary conditions are implemented on the boundary of the surface.The obtained differential equations are turned into coupled ODEs by the utilization of relevant similarity variables.The solutions algorithm Bvp4c is used to manipulate the coupled ODEs.The outcomes are obtained and conferred by the assistance of graphs.The numerical values for mass and heat transport rate are presented in the table for different parameters.The following is the layout of this article: section one—introduction.The second section is dedicated to mathematical modeling, which includes all necessary equations as well as the application of boundary layer theory to partial differential equations.The results and discussion are covered in the third section.The paper comes to a close with some closing remarks and a summary.

2.Mathematical modeling

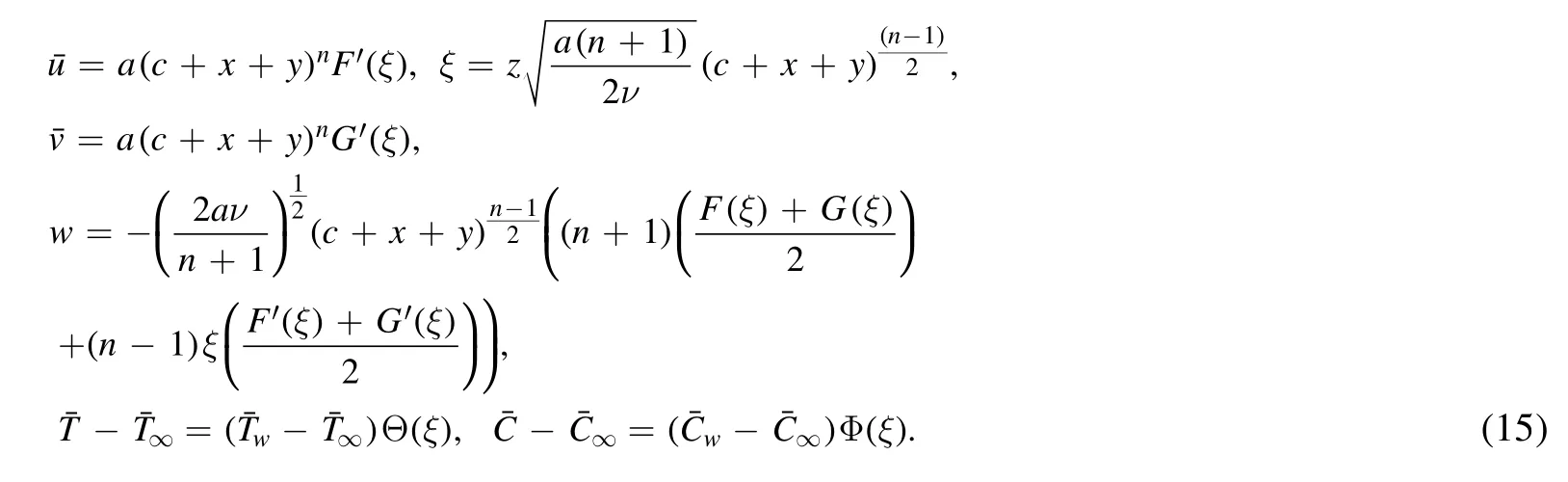

Consider,3D,incompressible,laminar,electrically conducting Maxwell flow of nanofluid across a stretching surface of variable thickness with bearing slip effects.Effects of magneto hydrodynamics (MHD), viscous dissipation, heat generation,Joule heating, binary chemical reaction, and thermophoretic effect are also considered.Thecan be considered as the variable thickness of the sheet.To make the sheet sufficiently thin, we chooseJsmall, we also assumed that the stretching velocities in x- and y-directions arerespectively.Herenis the power-law index and it considern≠ 0,because forn= 1 results to a flat surface,also forn< 1 andn> 1 are the surface shapes yields to inner convex and outer convex by the reduction and augmentation of wall thickness respectively.The flow region isz≥ 0, in which z-axis is normal to xyplane.Figure 1 shows a representation of the physical model.In the direction normal to the sheet, a non-uniform magnetic fieldB(x,y) is applied.The concentration and temperature at the boundary of the surface are represented byandrespectively,and away from the surface,it signifies byandrespectively.

Figure 1.Flow configuration of the problem.

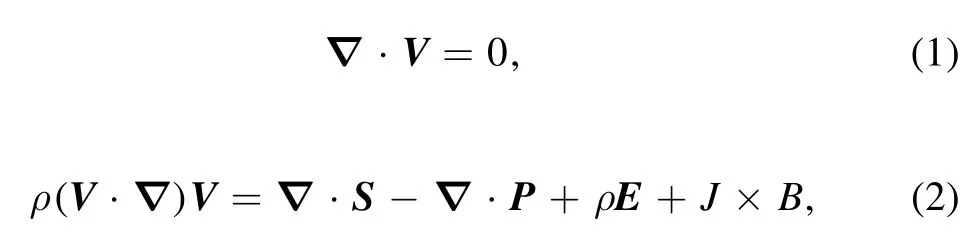

By the utilization of the above supposition, the developed equations are in the form,

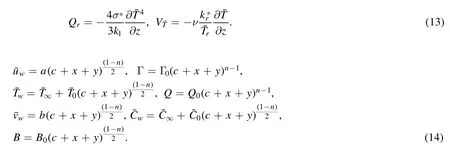

Hereρis the density of the fluid,DBis the mass diffusivity,αis the thermal diffusivity,ρE+J×Bis the body forces,Qris the radiative heat flux,Q0is the heat generation/absorption,τis the ratio of capacities (molecular to heat),VT¯ is the thermophoretic velocity effect,cpis specific heat.The extra stress tensor for Maxwell fluid is S, which is defined as,

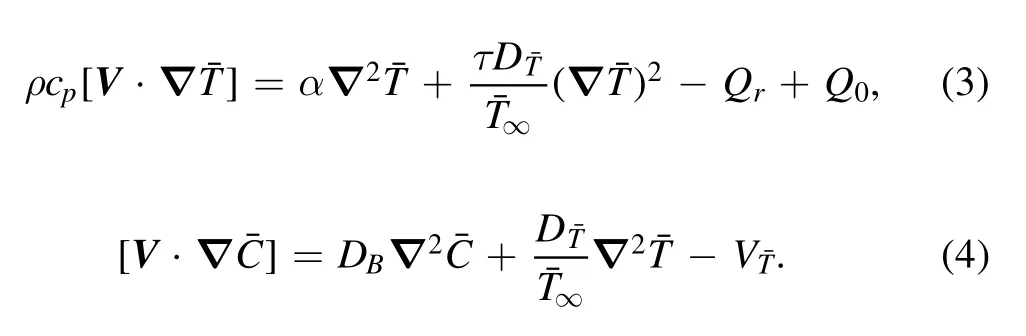

whereA1is the Rivlin–Ericksen tensor (A1= (∇V)t+ ∇V),λ0is the relaxation time,μis the viscosity, andis the material derivative.Invoking the boundary layer approximation, the above equations become [40, 42],

The suitable boundary conditions are defined as [40],

Where,

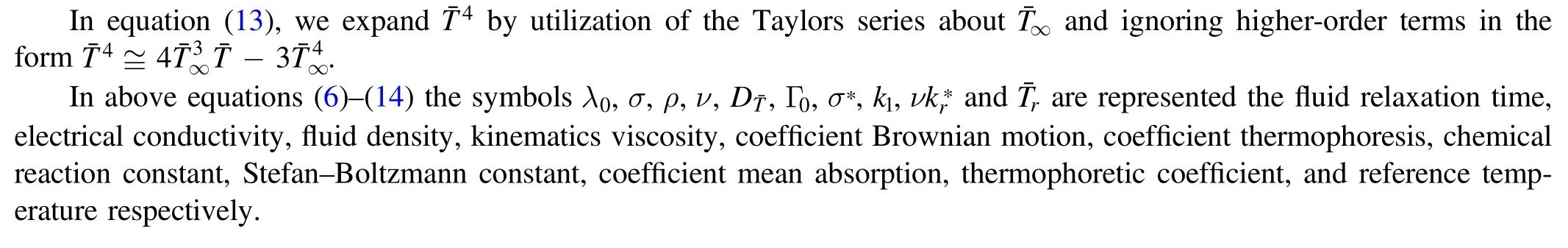

2.1.Similarity transformation

The relevant similarity variables are characterized as [6, 40],

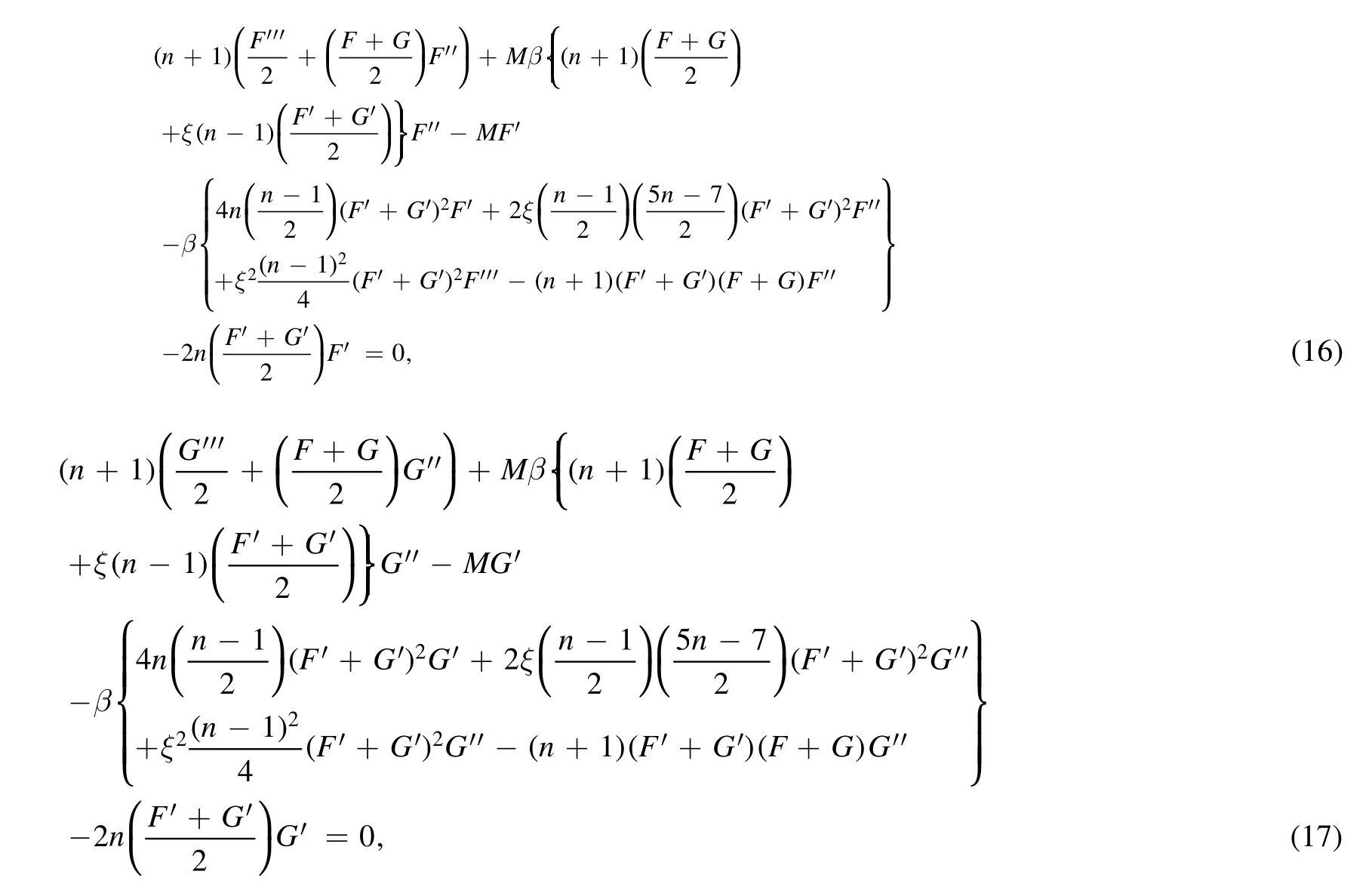

Using equation (15) the dimensionless form of equations (6)–(12) is,

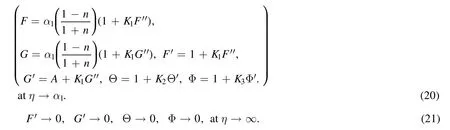

The convenient boundaries take the following form,

To make computations easier, the interval[α1,∞)should be transformed[0 ,∞) ,we introduce the following functions,

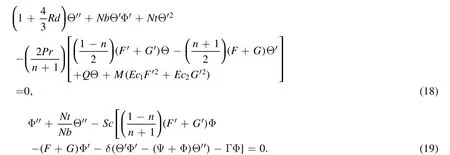

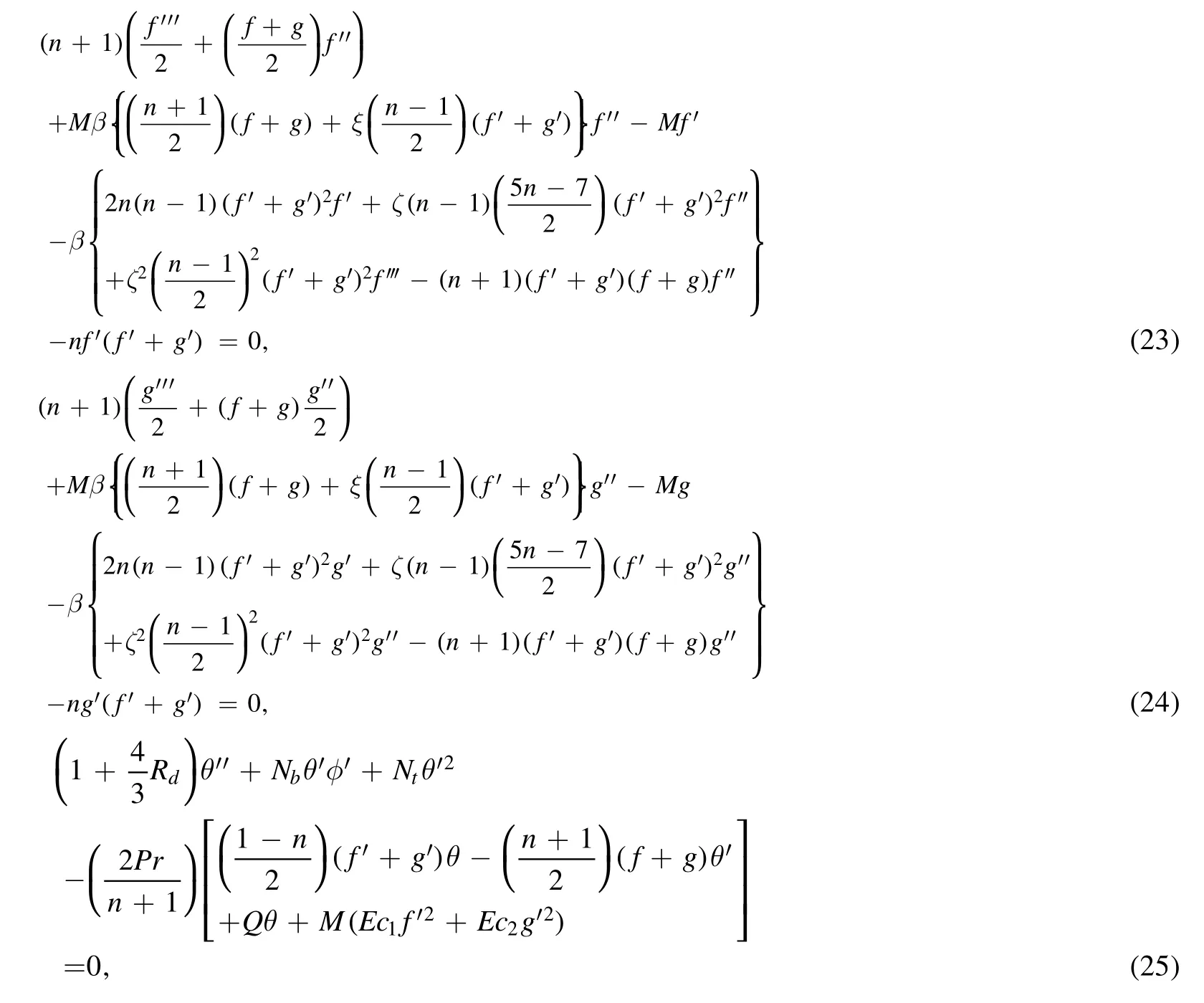

Using equation (22), the equations (16)–(21) takes the following forms,

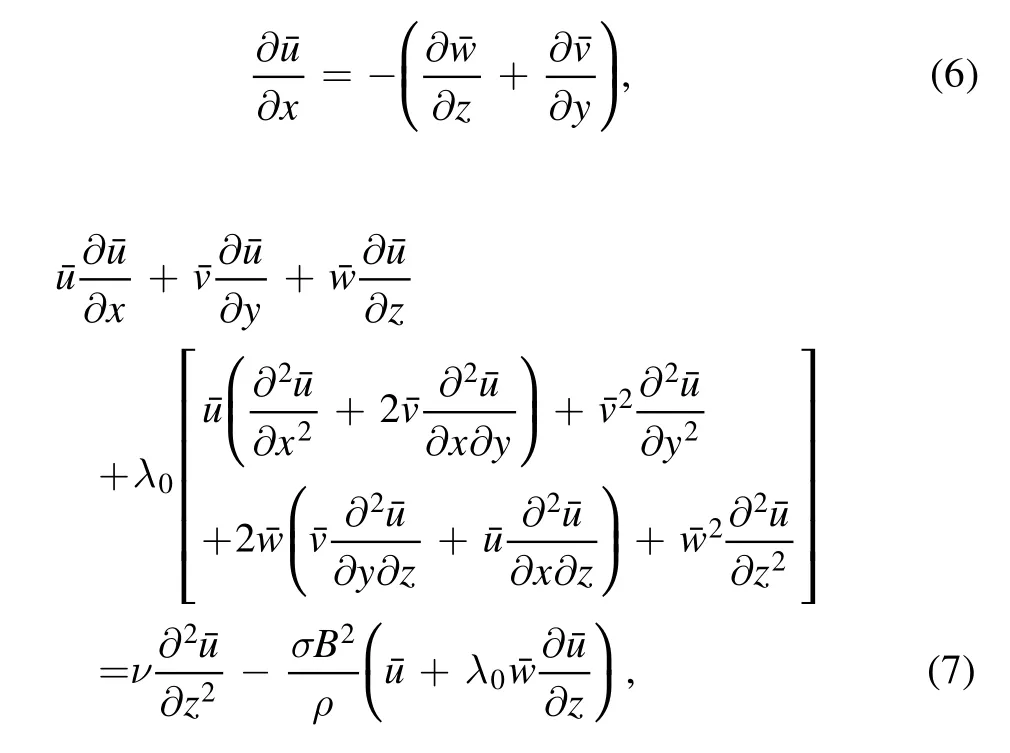

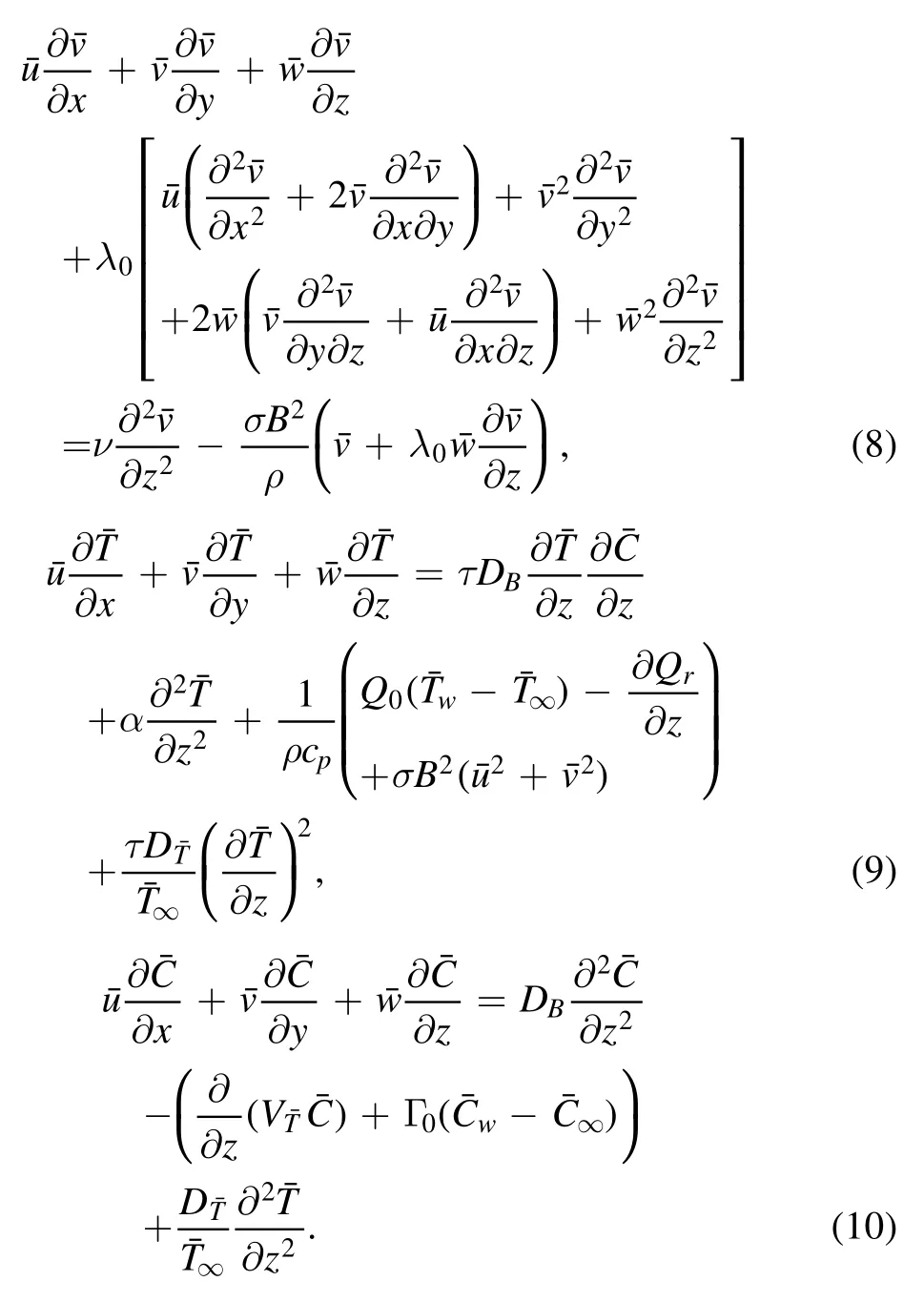

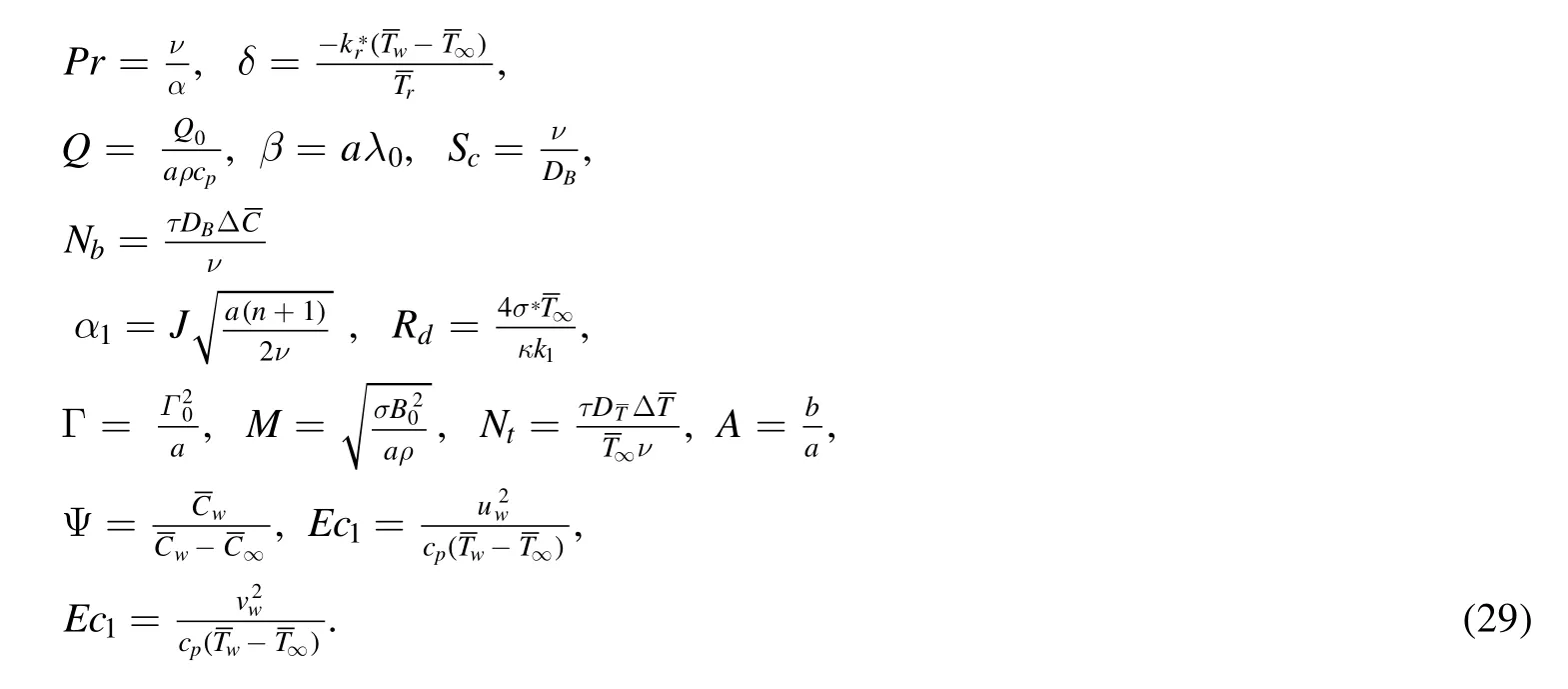

The evolving characteristics are fluid relaxation parameter, Eckert number in x-direction, magnetic parameter, radiation parameter,Eckert number y-direction,Brownian motion parameter,heat absorption/generation parameter,Prandtl number,concentration difference parameter, Schmidt number, thermophoresis parameter, temperature ratio parameter, stretching ratio parameter, and variable thickness parameter are symbolized byβ,M,Ec1,R d,Ec2,Nb,Q, ψ,Sc,Nt,δ,Pr,A,andα1respectively.Further,K1,K2,andK3are the velocity slip,thermal jump,and concentration jump parameters,respectively.Mathematically these parameters are specified as,

2.2.Physical quantities

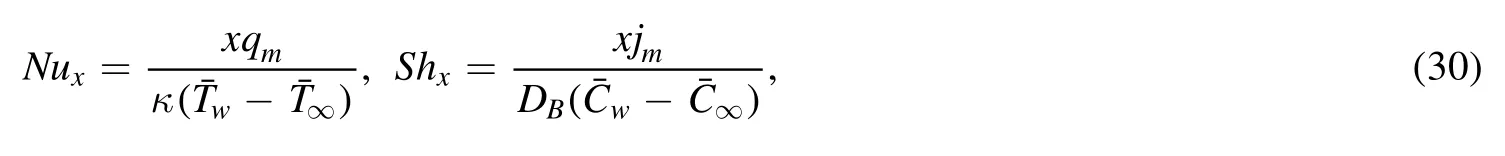

The quantities concern to the physical point of view of the problem like Nusselt number and Sherwood are defined mathematically as,

In equation (17)qmis heat flux andjmis mass flux, which is stated as,

The dimensionless form Nusselt and Sherwood number are defined as,

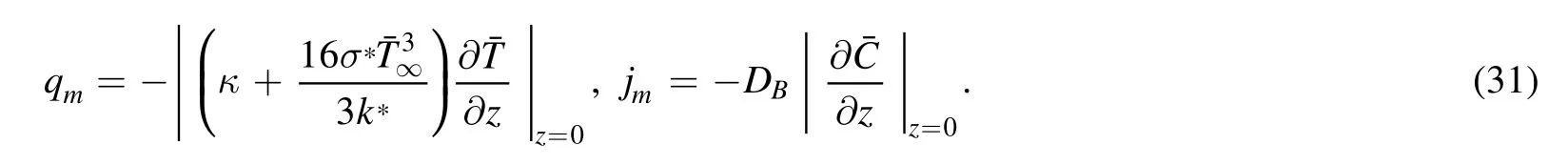

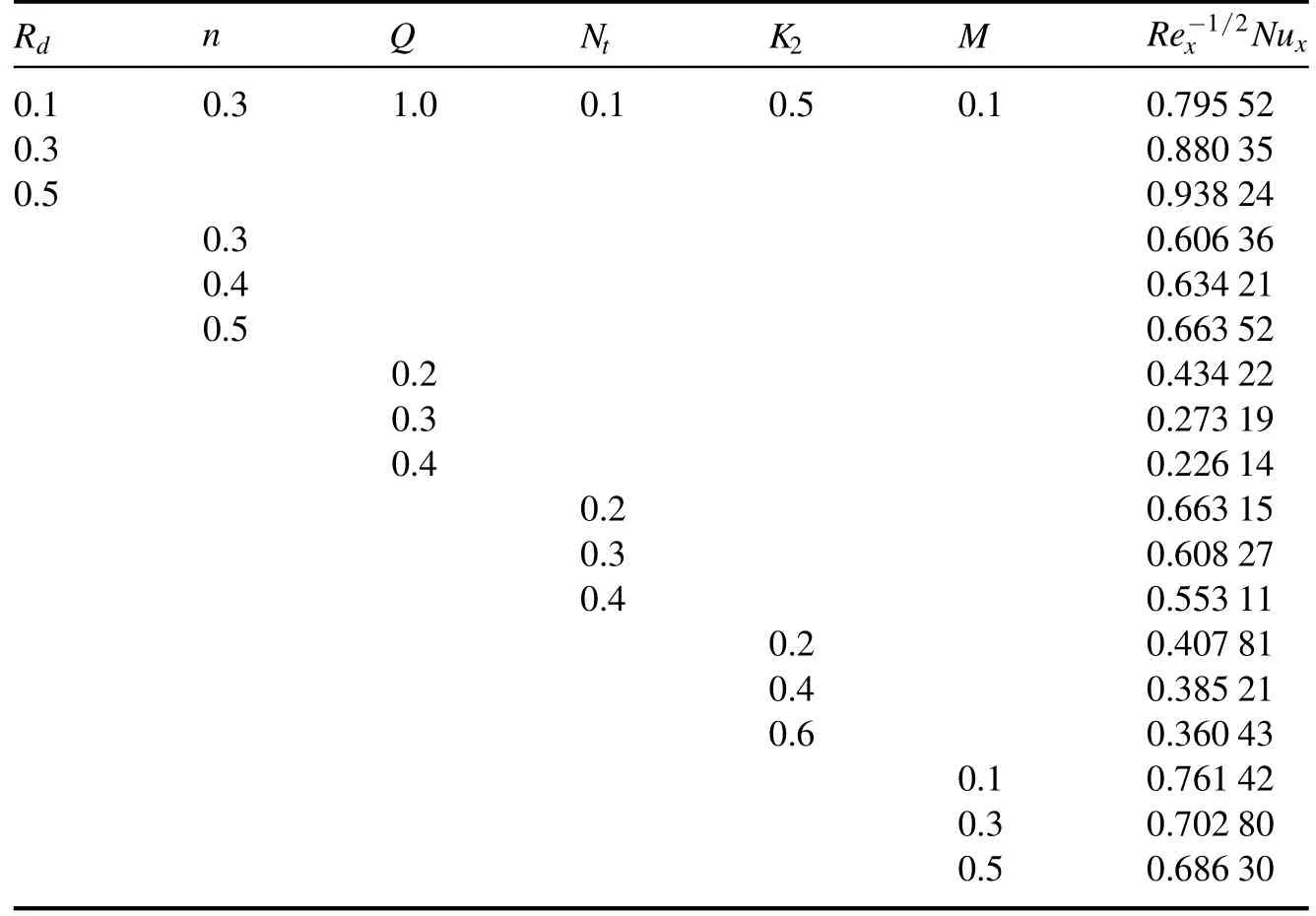

Table 1.Estimation of f ′′(0) and g ′′(0) with previous data, when M =α1= 0= K1 =K2.

Table 2.Numerical values of Nux for several parameters.

Table 2.Numerical values of Nux for several parameters.

?

Table 3.Numerical values of for several parameters.

Table 3.Numerical values of for several parameters.

?

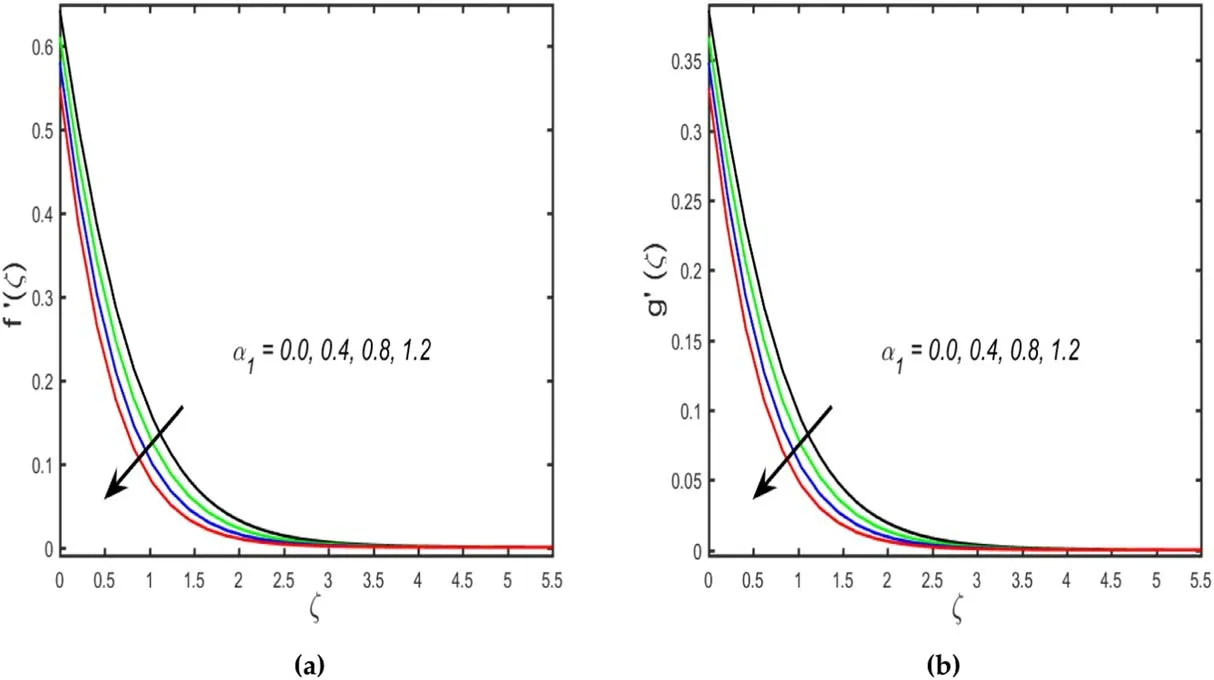

Figure 2.(a), (b): Variation in α1 alongf ′(ζ) and g′(ζ) sketch.

Rexis the Reynolds number.

3.Results and discussion

The three-dimensional Maxwell nanofluid flow by the impact of Joule heating, thermal radiation, multiple slips, and chemical reaction through a slendering stretching surface is observed in this study.In this section, we examine the physical configuration of various characteristics through the graph.The MATLAB bvp4c algorithm is utilized to solve the ordinary differential equation.Table 1 assesses the current problem classification to Nandi et al [40] available related results.This paper is in excellent alignment with a previously published study.Tables 2 and 3 described the numerical observation of Nusselt number and Sherwood number for several parameters.It is noted from the table 2, that the stronger values ofnandRdimprove the heat transfer rate,while opposite trend is obtained for the growing values ofQ,Nt,K2,andMdeclines the heat transfer rate.Further,table 3 observed that larger estimation ofNb,n,Sc,δ, andKrboosts the mass transfer rate, whereas opposite trend is observed for the greater values ofK3.

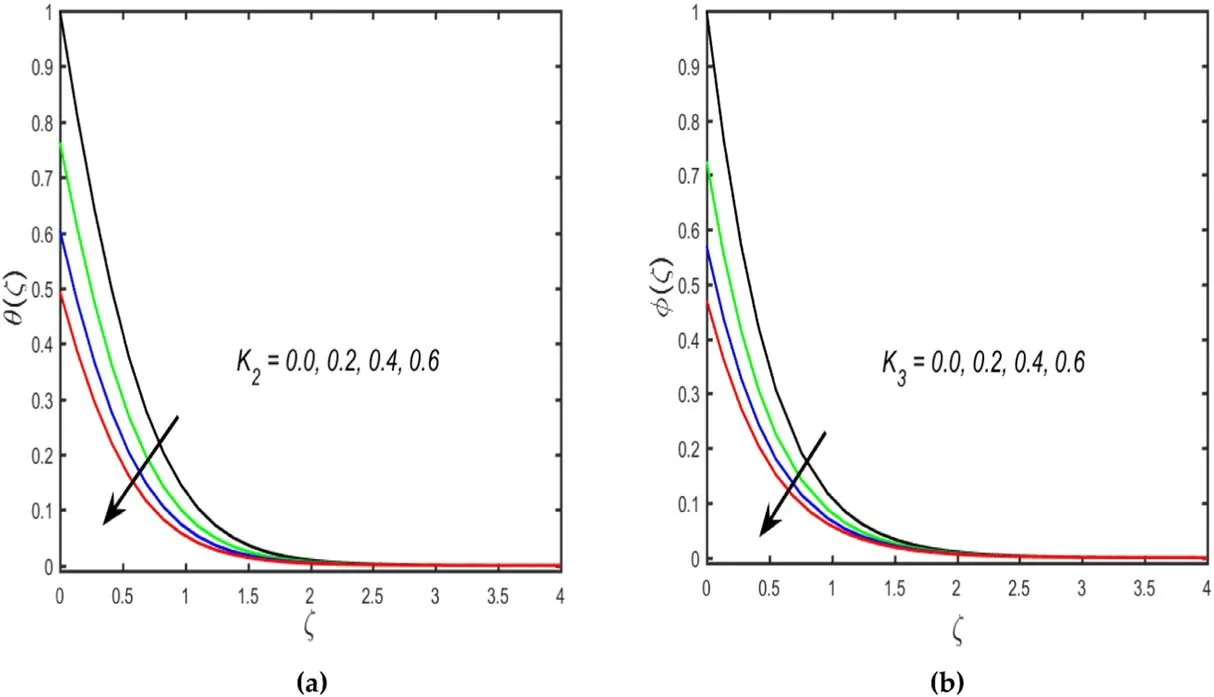

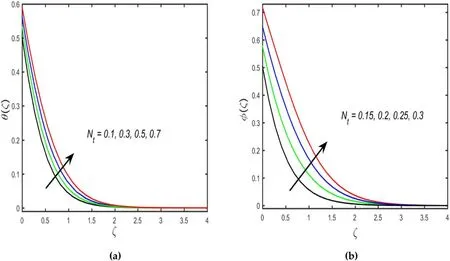

Figures 2(a) and (b) illustrates the consequences ofα1(wall thickness characteristics) on the fluid velocities in the direction x- and y-axis.It is depicted from the figures that in both directions the velocity shows decreasing behavior by the larger estimation of wall thickness parameter.Physically, by increasing theα1retarding factor occurs which slowing down the velocity of fluid, as a result the momentum boundary layer thickness decreases.The influence of theβ(fluid relaxation parameter)on the velocity field along the y-and xaxis direction is demonstrated in figures 3(a) and (b).The velocity sketch and thickness of the boundary layer are designated to reduce asβincreases.Physically,βis the relationship between observation and relaxation time; as relaxation time increases, resistance to liquid movement increases, resulting in reduction in the velocityf′(ζ) andg′(ζ).Moreover,due to increment of theβfluid behave like a solid and the fluidity of the fluid reduces, therefore fluid velocity declines consequently.The characteristic ofQ(heat generation)on thermal distribution is observed in figure 4(a).The sketch clarify that the thermal sketch enlarges with the stronger estimation ofQ.Physically, more heat is produced and the density of fluid reduces by the enlargement ofQ,therefore the temperature and related boundary layer thickness boosts.The radiation parameter impact on the temperature sketch is scrutinized in figure 4(b).The thermal layer increases with larger estimation ofRd.Thermal radiation generates the extra heat energy in the fluid flow as this is the external source of energy which applied on surface of the geometry thus,the temperature distribution of flow increases.Figures 5(a)–(c) demonstrates the consequences ofM(magnetic parameter) on fluid velocity and temperature field.The fluid velocities in x-and y-directions reduces by the increment ofM.This is specified in figures 5(a) and (b).Further,fluid temperature increases due to lager estimation ofM(see in figure 5(c)).The physics behind this is that the Lorentz force occurs with higher the magnetic parameter which produces resistance in the flow field, yields the fluid velocity contracts, and temperature enhances.The significance of velocity slip factor on the velocity distribution along x- and y-axis is demonstrated in figures 6(a) and (b).The figures show thatg′(ζ)andf′(ζ)diminishes close to the boundary,although the opposite trend is shown afar from the solid boundary wall with the elevation ofK.1This demonstrates that near the boundary wall, velocity slip tends to diminish velocities in both directions,however far away from the boundary wall, they show reverse trend.The variation of temperature field against temperature slip parameterK2is demonstrated in figure 7(a).The temperature distribution show decreasing behavior with higherK.2The thermal accommodation coefficient is enhanced on a physical level for larger amount ofK2,as a result,there is less heat diffusion in the flow direction.As a result,θ(ζ) decreases.Figure 7(b)exemplify the influence of concentration jump parameter(K3)on nanoparticle concentrationφ(ζ).Theφ(ζ) show opposite behavior with the growth ofK.3The variation ofNt(thermophoresis characteristics)on concentration and temperature distribution is examined in figures 8(a) and (b).The temperature and nanoparticle concentration distribution enhance withNt.From the physical point of view, it is seen that thermophoretic force warm molecules travel from the hottest fluid area to the coldest fluid region in this type of flow,causing fluid particles to improve temperature and concentration distribution.Further,their corresponding thickness of thermal and concentration boundary layer enhances withNt.

Figure 3.(a), (b): Variation in β alongf ′(ζ) and g′(ζ) sketch.

Figure 4.(a), (b): Plots ofQ and Rd alongθ (ζ).

Figure 5.(a)–(c): Plots of M along f′ (ζ) ,g′(ζ) andθ (ζ).

Figure 6.(a), (b): Plot of K1 alongf ′(ζ) and g′(ζ).

Figure 7.(a), (b): Plots of K2 and K3 alongθ (ζ) andφ (ζ).

Figure 8.(a), (b): Plot of Nt alongθ (ζ) andφ (ζ).

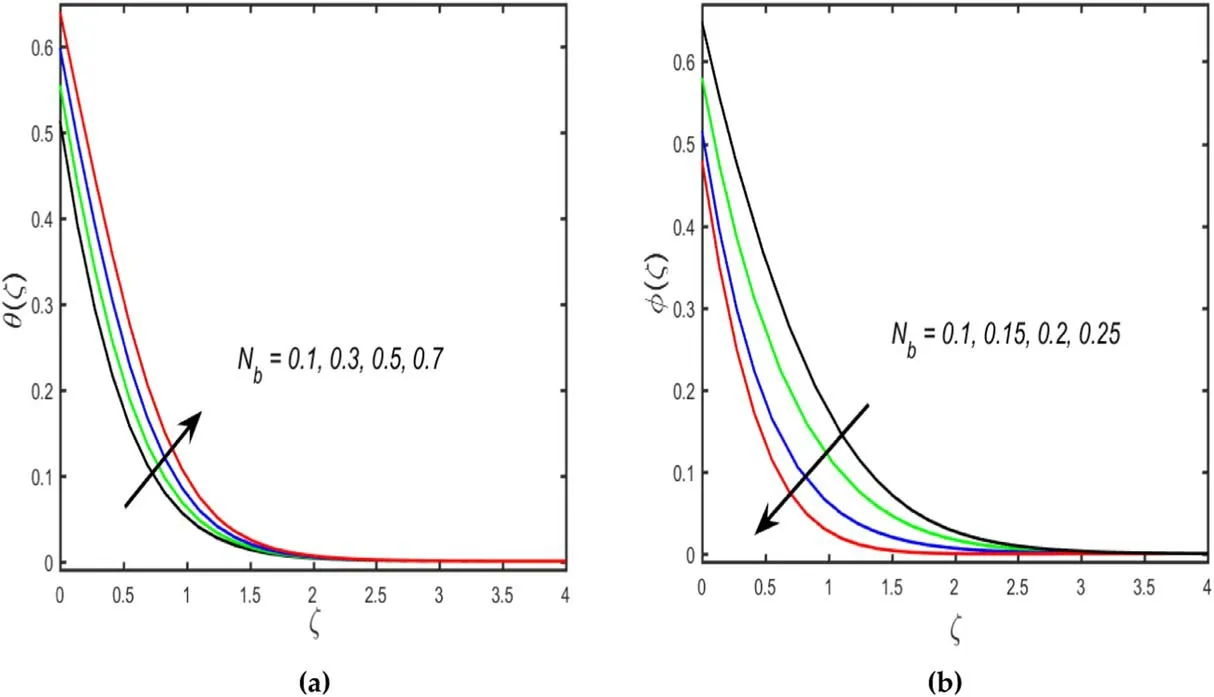

Figure 9.(a), (b): Plot of Nb alongθ (ζ) andφ (ζ) .

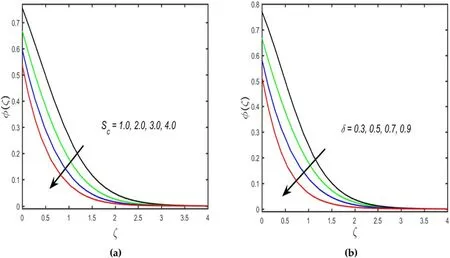

The effect of theNb(Brownian motion parameter)on theθ(ζ)andφ(ζ)plots is seen in figures 9(a)and(b).It is found that by the escalationNbthe temperature field raises, and concentration become lowering.Physically, the collisions between the fluid particles grow as the value ofNbrises.As a result,extra heat is produced,causing the fluid temperature to rise and the fluid concentration to fall.Figure 10(a)shows the influence ofScon the nanoparticle concentration.It is deliberated that the concentration sketch reduces by the improvement ofS.cPhysically,Scis a mathematical representation of the relationship between momentum and mass diffusivity.The mass diffusivity is devalued by the increment of the Schmidt number, thereby the mass concentration of decreases.In figure 10(b), the efficiency of temperature ratio characteristics (δ) is observed.It is noticed that mass concentration decaying function for largerδ.

Figure 10.(a), (b): Plots ofSc andδ alongφ (ζ).

4.Conclusions

The flow model of Maxwell nanomaterial liquid with Joule heating,multiple slips and thermal radiation,is addressed utilizing MATLAB algorithm bvp4c non-Newtonian fluid flow across a stretch sheet affects a wide range of industries and applications of engineering.The petroleum industry, polymeric fluids, solar plants, air conditioning, heat exchangers, refrigeration, food processing,cooling towers,transpiration,plastic and rubber sheet manufacture, crop damage due to freezing, and chemical engineering are all covered by this fluids model.

The key points of the paper are arranged as follows:

• The thickness of the momentum layer is reduced by the wall thickness parameter,Deborah number,and magnetic parameter.Such that, the fluid velocities are reduced.

• The thermal thickness layer boosts with heat generation,radiation, and magnetic parameters, while it reduces for larger amount of thermophoresis, temperature jump and Brownian motion parameter.

• The concentration function is lessened when the Schmidt number, concentration difference parameter, concentration jump parameter, and Brownian motion parameter improve, however it is enhanced as the thermophoresis parameter increases.

• The velocity gradientf′′ (0) andg′′ (0) rises by boosting the value of the wall thickness characteristic and powerlaw index characteristic.

• Characteristic of radiation and power-law index parameter enhance the heat transfer rate, while the heat generation, magnetic characteristic, and temperature jump characteristic reduced the heat transfer rate.

• Schmidt number and Binary chemical reaction characteristics increase the mass transport rate, while theconcentration jump parameter decreases the mass transfer rate.

Acknowledgments

The authors extend their appreciation the deanship of Scientific research at King Khalid University for funding through research group program under grant number R.G.P 1/135/42.

Communications in Theoretical Physics2022年1期

Communications in Theoretical Physics2022年1期

- Communications in Theoretical Physics的其它文章

- Thermally stratified flow of hybrid nanofluids with radiative heat transport and slip mechanism: multiple solutions

- General interaction quenches in a Luttinger liquid

- A gauge theory for two-band model of Chern insulators and induced topological defects

- Local stability analysis of a low-dissipation cyclic refrigerator*

- Theoretical analysis of RNA polymerase fidelity: a steady-state copolymerization approach

- Alkali-metal(Li,Na,and K)-adsorbed MoSi2N4 monolayer: an investigation of its outstanding electronic, optical, and photocatalytic properties