Intelligent Drilling and Completion: A Review

Gensheng Li, Xianzhi Song*, Shouceng Tian, Zhaopeng Zhu

State Key Laboratory of Petroleum Resources and Prospecting, China University of Petroleum, Beijing 102249, China

Keywords:Intelligent drilling and completion Artificial intelligence Intelligent application scenarios Literature review Systematic discuss

A B S T R A C T The application of artificial intelligence (AI) has become inevitable in the petroleum industry. In drilling and completion engineering, AI is regarded as a transformative technology that can lower costs and significantly improve drilling efficiency (DE). In recent years, numerous studies have focused on intelligent algorithms and their application.Advanced technologies,such as digital twins and physics-guided neural networks, are expected to play roles in drilling and completion engineering. However, many challenges remain to be addressed, such as the automatic processing of multi-source and multi-scale data.Additionally, in intelligent drilling and completion, methods for the fusion of data-driven and physicsbased models, few-sample learning, uncertainty modeling, and the interpretability and transferability of intelligent algorithms are research frontiers.Based on intelligent application scenarios,this study comprehensively reviews the research status of intelligent drilling and completion and discusses key research areas in the future. This study aims to enhance the berthing of AI techniques in drilling and completion engineering.

1. Introduction

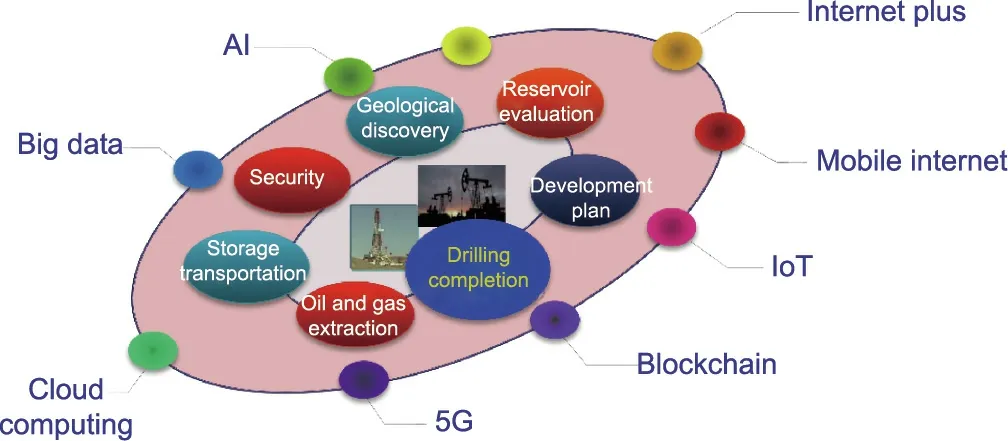

In recent years, the rapid development of artificial intelligence(AI)and big data technology has attracted extensive attention from various industries[1].Strategies for the development of AI,to seize the golden opportunity of the new technology, are being formulated by countries across the globe. In China, enhancing efforts on AI research and education has become a national strategy,and almost all industrial societies have formulated plans for intelligent transformation. As a capital- and technology-intensive industry, the oil and gas exploration and development industry has a greater demand for AI (Fig. 1), and this has attracted the attention of oil and gas companies worldwide[2].Through cooperation with digital companies,oil companies have accelerated their transformation to an intelligent and digital age [3].

Drilling and completion engineering,a critical part of the oil and gas exploration and development process, accounts for approximately 50% of the total cost. Drilling and completion engineering will be further increased in case of complex oil and gas resources,such as offshore and ultra-deep reservoirs[4].Drilling under these complex conditions has multiple challenges in terms of efficiency,risks, and costs, which requires technological innovation to improve efficiency and lower costs. Traditional empirical and physics-based approaches are limited and struggle to cope with increasingly complex drilling processes [5], such as the precise characterization of a complex reservoir and real-time optimization of the drilling process.AI and big data technologies have significant advantages in solving complex problems with strong nonlinear fitting and information-mining abilities. Therefore, intelligent drilling and completion technology is regarded as a transformative technology and has become a hot spot in the research and development of oil and gas industries.

Intelligent drilling and completion implies using big data, AI,information engineering,control theory,and other advanced transformative technologies in the drilling and completion process.It is expected to realize advanced detection,closed-loop control,precision steering, and intelligent decision-making through automated equipment to significantly improve drilling efficiency (DE) and reduce drilling costs. Intelligent drilling and completion technologies can be categorized into two branches: intelligent algorithms and intelligent equipment.Intelligent algorithms use AI algorithms to solve nonlinear and other complex problems and provide optimization and control schemes, providing necessary instructions and assistance for intelligent equipment. Intelligent equipment provides data sources and hardware support to establish and verify intelligent models.In this study,a comprehensive investigation and analysis of intelligent algorithms was conducted to determine the development status of,and trends in intelligent drilling and completion.

Fig. 1. Intelligent oil and gas engineering. The definitions of the abbreviations in this and subsequent figures can be found in the section ‘‘Abbreviations” at the end of the manuscript.

The application scenarios for AI in the intelligent drilling and completion process are first defined, and then scenario-specific algorithms and other research content, research gaps and future works,are reviewed. This study serves as a comprehensive review for researchers in intelligent drilling and completion, clarifies AI application scenarios, and provides an important reference for the development of intelligent drilling and completion.The definition of each abbreviation used in the manuscript can be found in the ‘‘Abbreviations” section at the end of manuscript.

2. Intelligent application scenarios and research status

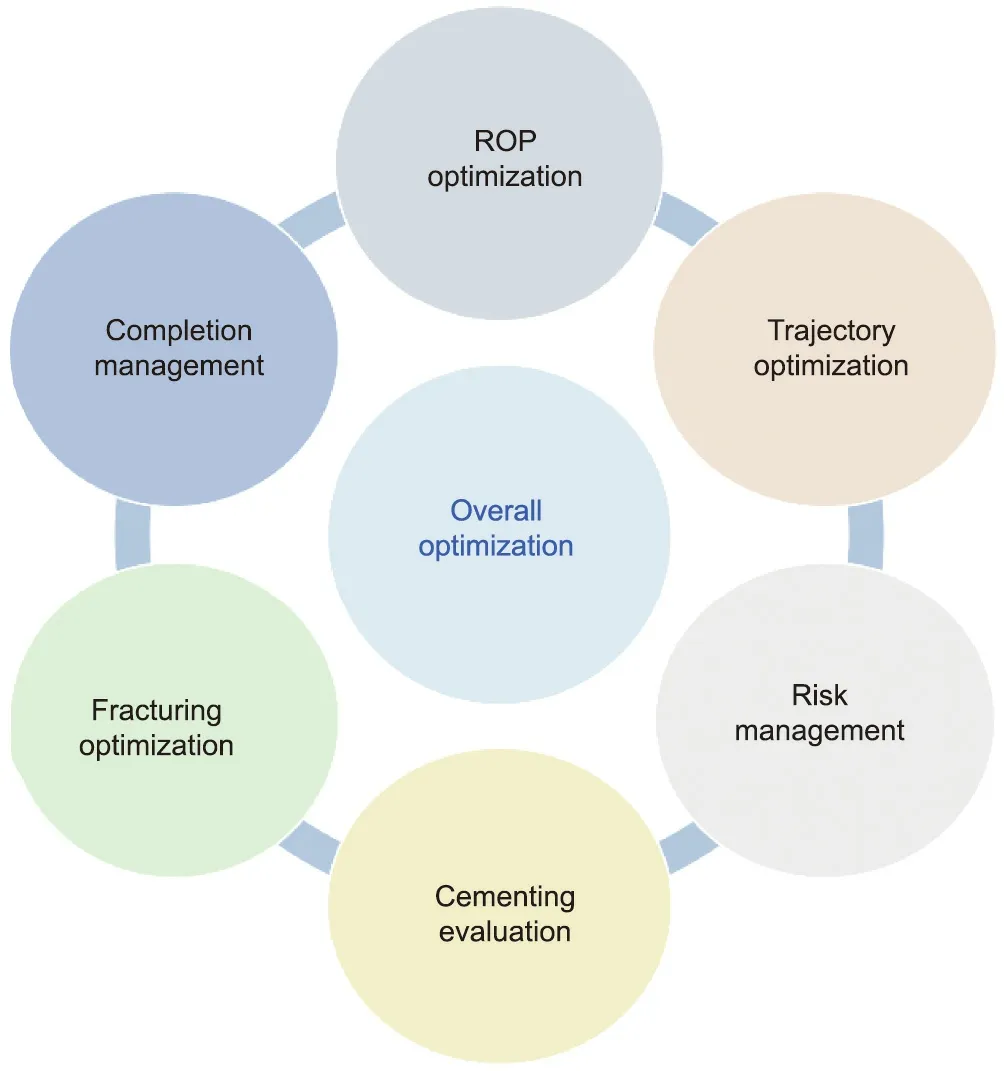

The application scenarios for AI in drilling and completion engineering refer to the use of AI technologies in certain engineering processes, including engineering conditions, data sources, and algorithms. This study divided intelligent drilling and completion into seven scenarios based on the engineering section and objectives, as shown in Fig. 2.

Fig. 2. Intelligent application scenarios in drilling and completion.

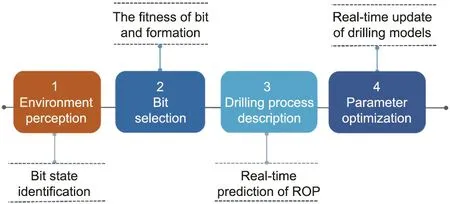

Fig. 3. Intelligent prediction and enhancement of ROP.

2.1. Intelligent prediction and enhancemental of drilling rate

An increasing number of wells have been drilled in deep, hard,and abrasive formations,generally resulting in severe bit wear and low drilling rates. It is also challenging to dynamically manipulate drilling parameters to ensure an ROP.The enhancement of the ROP requires intelligent algorithms to accurately characterize the drillability of the formations,select the best bit,and optimize the controllable parameters (Fig. 3).

2.1.1. Downhole environment perception

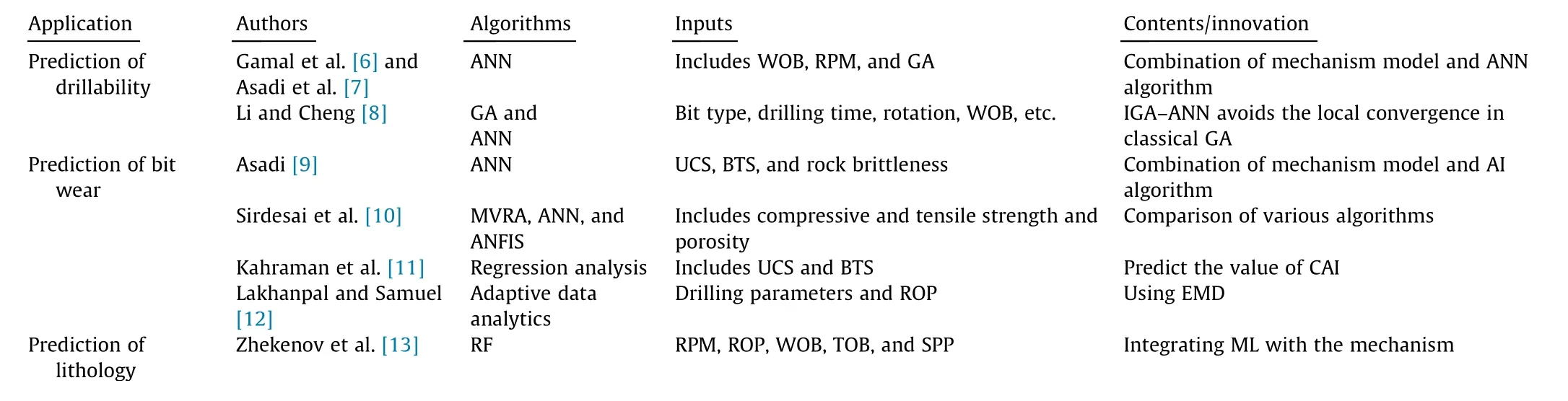

Environmental perception is the foundation of ROP enhancement.The formation lithology and bit wear can be accurately diagnosed using intelligent classification and regression algorithms.An accurate description of the bottom-hole environment, based on intelligent algorithms,is a reference for the optimization of drilling parameters and enhancement of the drilling rate. Conversely, it could also indicate identifying abnormal conditions and avoiding complex accidents. As shown in Table 1 [6-13], current studies on intelligent perception of the downhole environment mainly focus on the properties of the formation rock and bit wear.

The definitions of the abbreviations in this and subsequent tables can be found in the section ‘‘Abbreviations” at the end of the manuscript.

2.1.2. Optimization and design of drilling bit

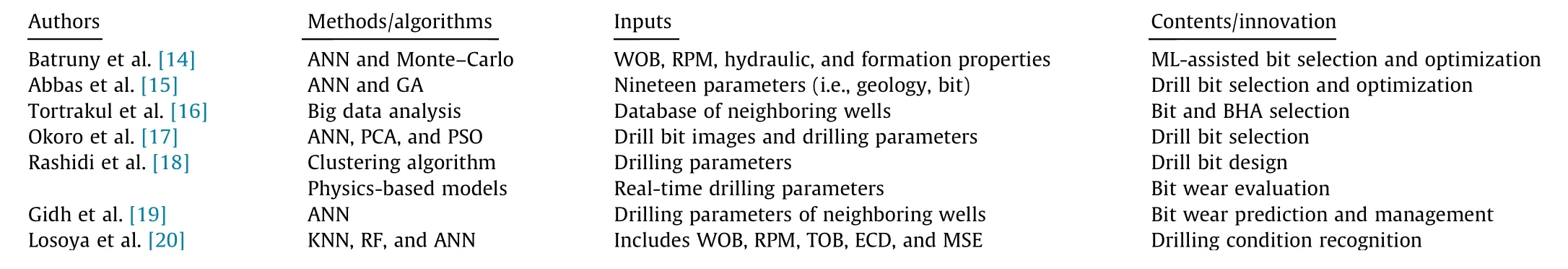

The drill bit and bottom-hole assembly are critical to the rockbreaking process. Bit selection and optimization not only select a suitable bit based on the lithology of formation, but also reveal the rock-breaking ability of different drilling tools, which guides the design of new high-performance bits. AI technology facilitates the selection of a suitable bit structure to ensure rock-breaking efficiency and bit stability.Numerous studies have been conducted on bit selection, bit optimization, and bit wear management, as presented in Table 2 [14-20].

2.1.3. Prediction and optimization of ROP

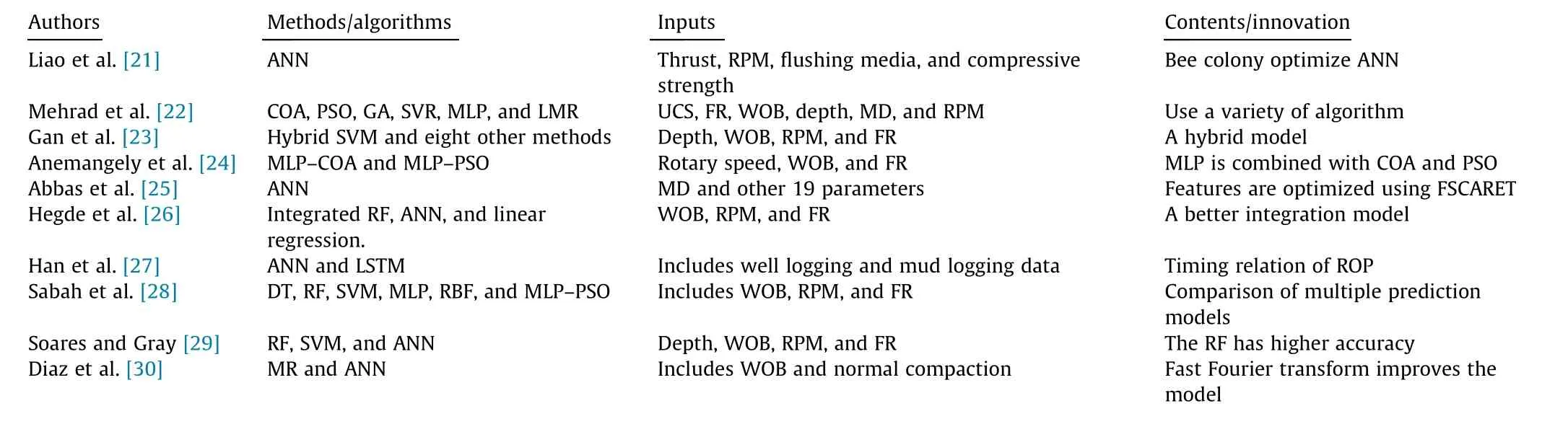

AI technology can discover the complex mapping relation between the ROP and impacting factors such as formation properties, bit characteristics, and drilling parameters, which is superior to the capability of physics-based models. It is not subject to the limitation of expert knowledge,and it can not only accurately predict the drilling rate of various conditions, but also provide optimized drilling parameters with real-time downhole conditions to obtain the optimum ROP and avoid downhole risks. Optimization algorithms and hybrid models are the main methods of improving the accuracy of the ROP prediction (as presented in Table 3 [21-30]).

Table 1 Downhole environmental perception.

Table 2 Design and optimization of drilling bit.

Table 3 Intelligent prediction of ROP.

The prediction and optimization of the ROP are inseparable because the prediction results are an important reference for optimization. ROP optimization is an extension of ROP prediction,whereby optimal drilling parameters (e.g., WOB, rotational speed,and FR) are obtained in real time using optimization algorithms(Table 4 [31-40]).

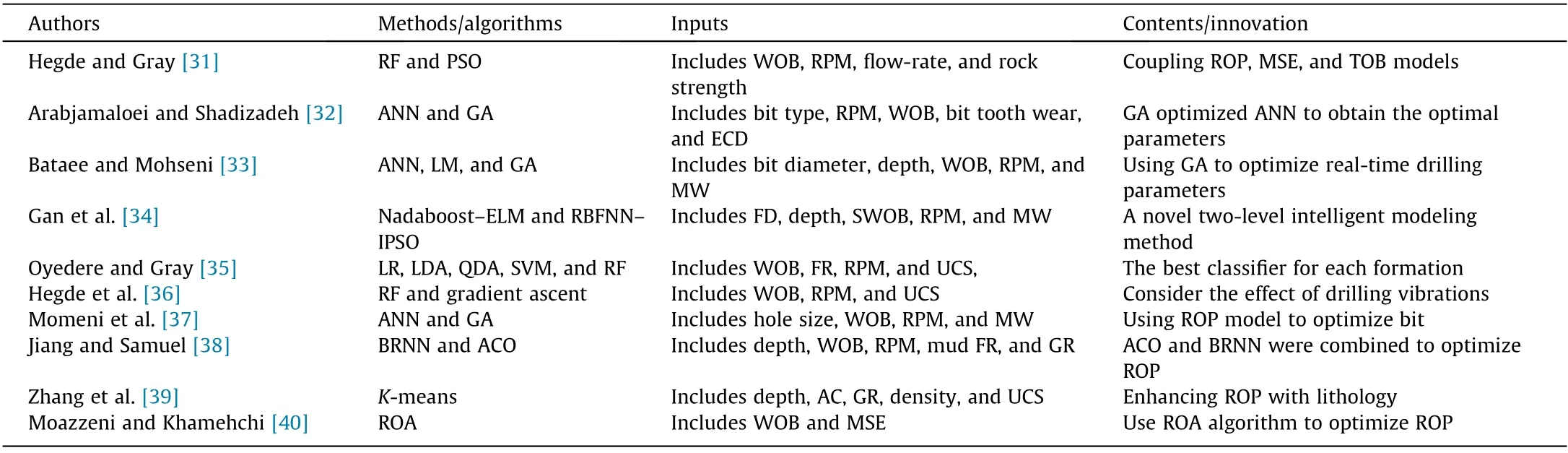

2.2. Intelligent prediction and optimization of a well trajectory

Deviated, horizontal, and extended-reach wells are commonly used for efficiently developing unconventional reservoirs.The drilling trajectories of these wells are prone to deviate from their design owing to the high abrasiveness,anisotropy,and heterogeneity of the formation rocks.Before drilling a well,the design process of the well trajectory can be optimized based on big data and AI technology. During the drilling process, the drilling trajectory can be calculated in real time, the degree of deviation evaluated, and steering controllable parameters optimized. Finally, the mapping relationship between the key controllable parameters and applied control instructions is established to form a closed-loop control framework.Intelligent design and real-time optimization of a borehole trajectory mainly includes intelligent prediction of the borehole trajectory, real-time evaluation, and optimization, and realtime control of the steering parameters (Fig. 4).

2.2.1. Intelligent design of a well trajectory

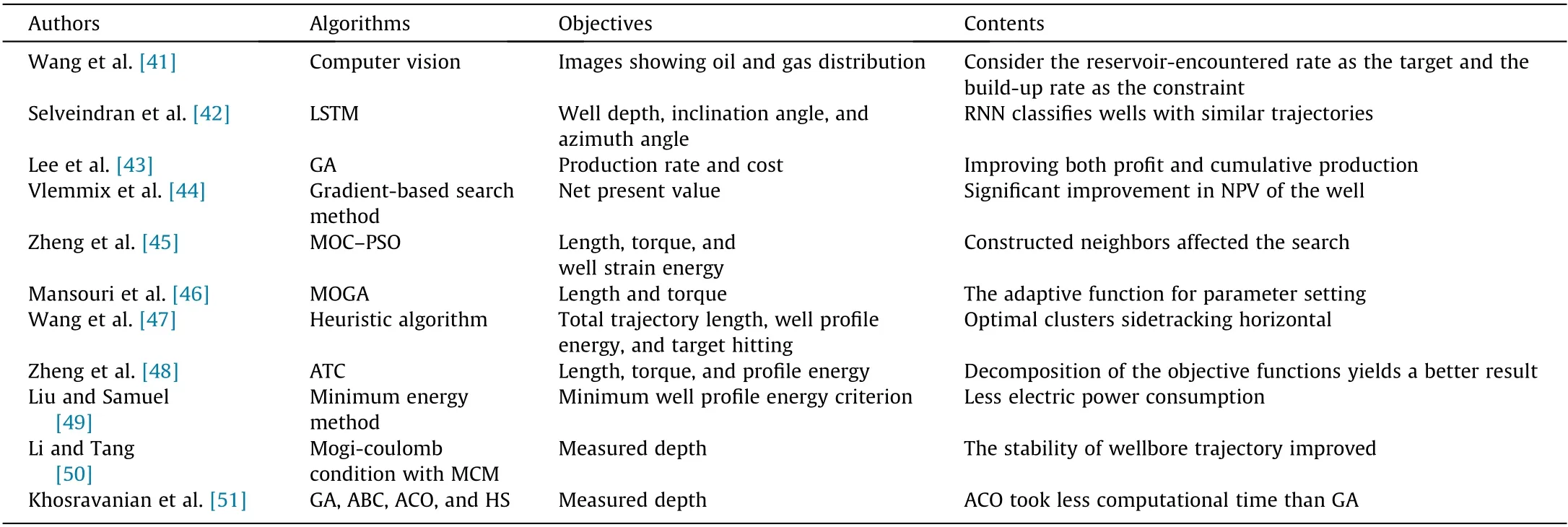

Based on the geological reservoir model,a well trajectory design process can be optimized and automated using intelligent technologies, such as computer vision algorithms. The intelligent design process aims to increase the contact area of the oil layer as much as possible while meeting the curvature requirements,considering torque and drag, total length, and other targets. This reduces the time costs compared to traditional design models. As shown in Table 5[41-51],the borehole trajectory design is an optimization problem of the parameter matrix, including deviation depth and deviation length, and the optimization objectives are usually borehole length, drill string torque, target hitting, and oil and gas production.

Table 4 Intelligent optimization of ROP.

Fig. 4. Intelligent prediction and optimization of a well trajectory.

2.2.2. Real-time evaluation and optimization of a wellbore trajectory

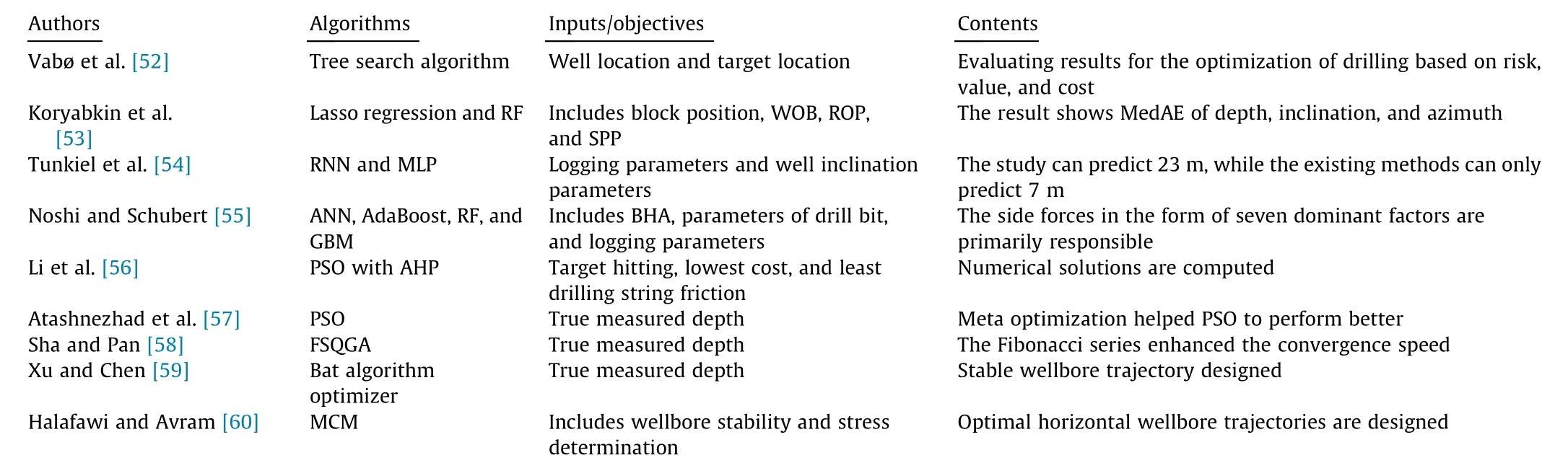

The difference between a drilling trajectory and the designed trajectory can be evaluated using intelligent algorithms, and it can be subsequently reduced by optimizing controllable parameters such as the drilling angle.The optimization of a drilling trajectory is a multi-objective process, where parameters such as the smallest deviation, well length, and friction are objectives, and others such as the deflecting capacity of the BHA are constraints.In contrast to a well trajectory design, a wellbore trajectory optimization requires real-time calculation of the optimization results,which requires higher computational efficiency. The trajectory evaluation not only involves the fitness between the actual and real trajectories, but also considers the cost, risk, and drilling stability of the wellbore (Table 6 [52-60]).

2.2.3.Intelligent decision-making and closed-loop control of a wellbore trajectory

A control model must be established to construct an optimized well trajectory. The model discovers the mapping relationship between the key controllable parameters (i.e., the applied control instructions)and the holding,building,and dropping of the angles.Subsequently,closed-loop control can be realized using highly efficient downhole data transmission technology and intelligent tools(e.g., BHA and bit).

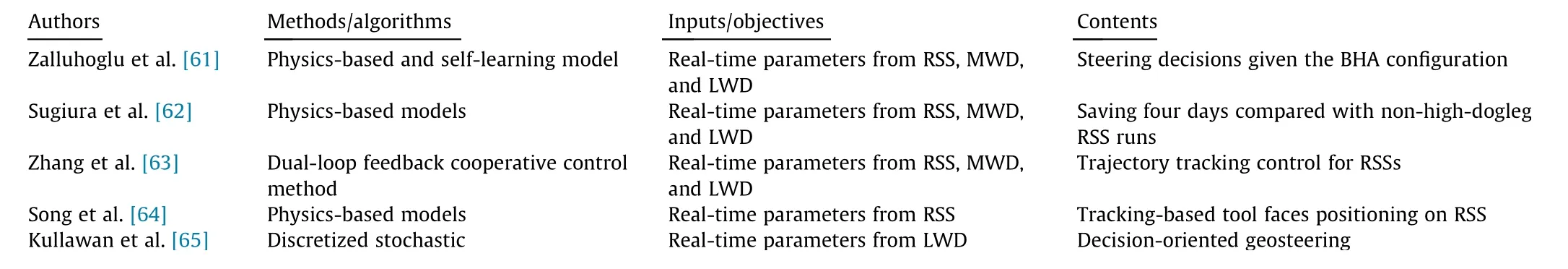

Trajectory control is a combination of the control strategy and tool (Table 7 [61-65]), and it requires specific control methods to be designed according to the BHA or steering tool. Furthermore,information on real-time logging and LWD is required for trajectory control.

2.3. Intelligent warning and control of drilling risks

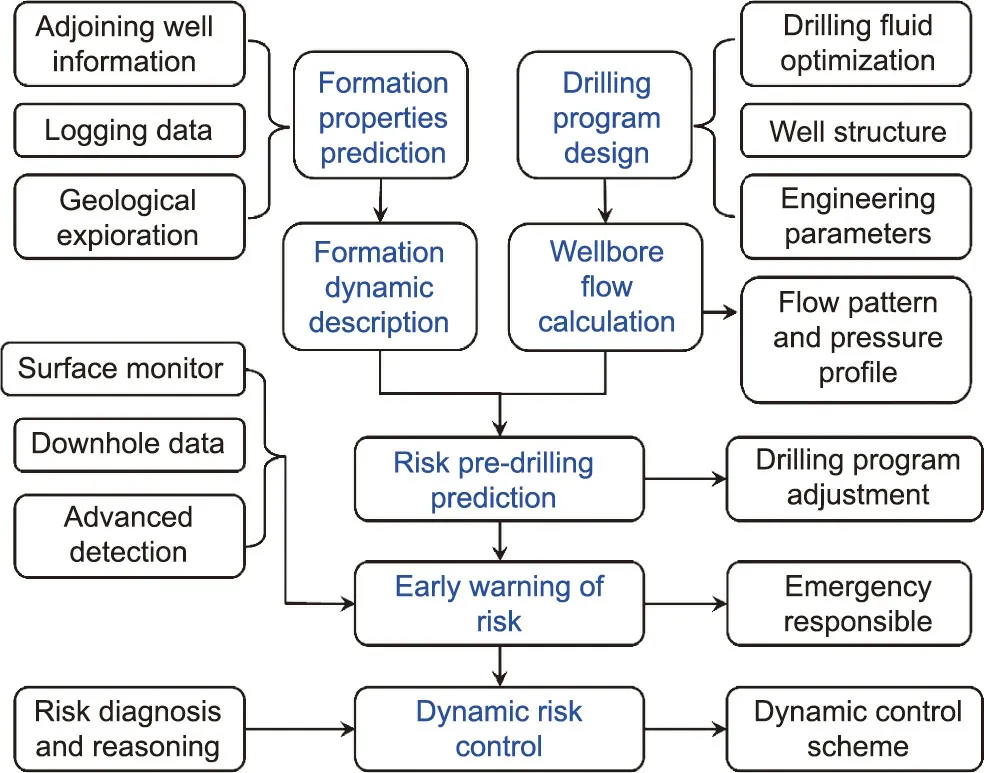

Intelligent management of drilling risk involves achieving accurate characterization of formation properties, dynamic prediction of wellbore flow behavior, early warning, efficient control of dril-ling risk based on various data resources(e.g.,geological detection,logging,and MWD),and AI algorithms(e.g.,digital twin,computer vision, and intelligent control) (Fig. 5).

Table 5 Intelligent design of a well trajectory.

Table 6 Real-time evaluation and optimization of a well trajectory.

Table 7 Intelligent decision-making and control of wellbore trajectory.

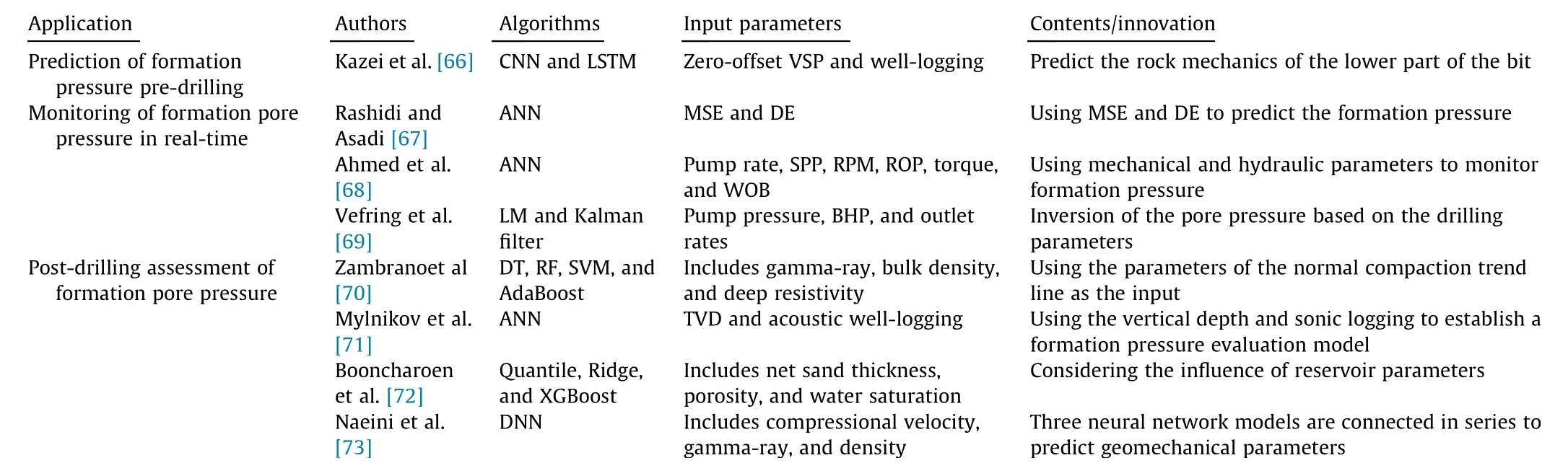

2.3.1. Intelligent characterization of formation properties

Formation properties mainly include formation pressure,stress,and permeability,which are critical to improving the ROP,avoiding risks, and stabilizing borehole walls. To improve the reliability of the formation characterization, some innovative fusion of data and neural network optimization methods have been developed(Table 8 [66-73]).

2.3.2. Intelligent description of wellbore flow behavior

Fig. 5. Application scenarios for AI in drilling risk control.

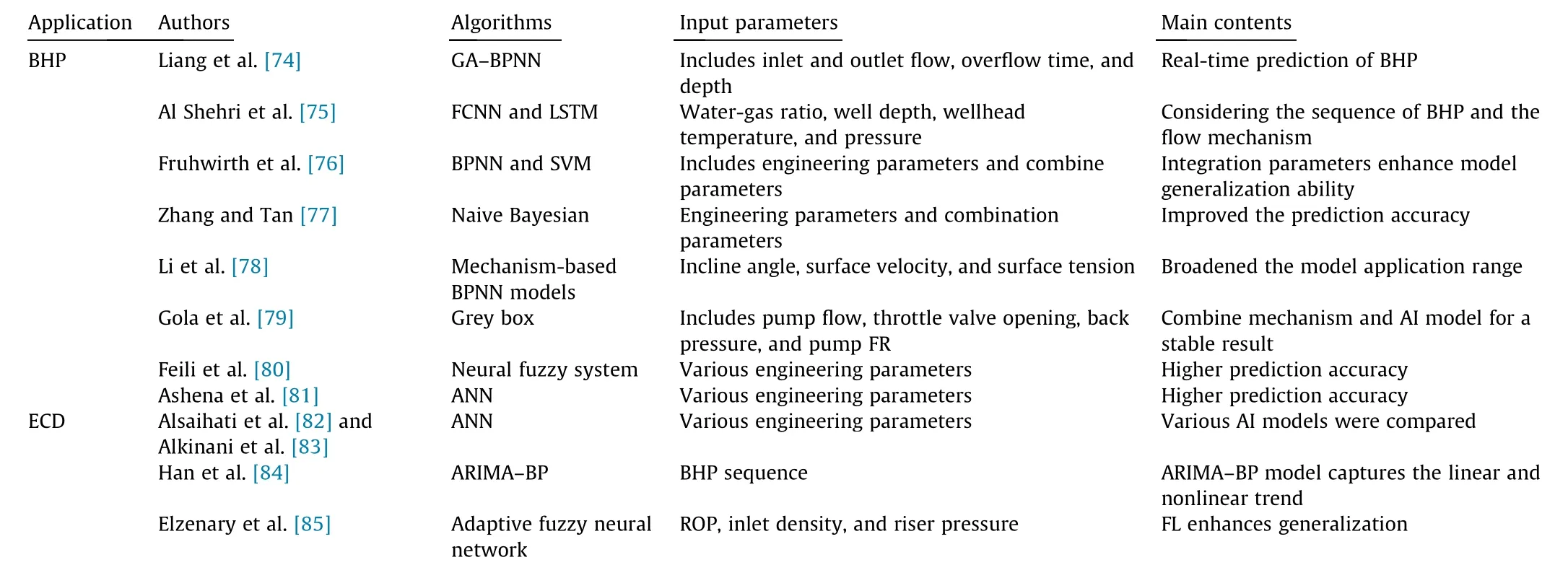

Generally, a wellbore flow description involves the wellbore pressure,flow pattern,circulating pressure loss,cutting concentration, and ECD, based on real-time surface monitoring data and intelligent algorithms (Table 9 [74-85]). The wellbore structure,geothermal gradient,formation pressure,and intruding fluids complicate wellbore flow characterization.MPD or underbalanced drilling processes are the main fields for the intelligent prediction of the bottom-hole pressure and the ECD.The introduction of intelligent algorithms has significantly improved the accuracy and efficiency of downhole pressure prediction and cuttings concentration prediction,overcoming the limitations of traditional empirical models,and replacing the function of downhole sensors.

The direct combination of intelligent algorithms and wellbore flow data is a primary form of intelligent modeling.In recent years,scholars have explored new modeling approaches, such as data fusion, hybrid algorithms, and a combination of data and mechanisms, as shown in Table 9.

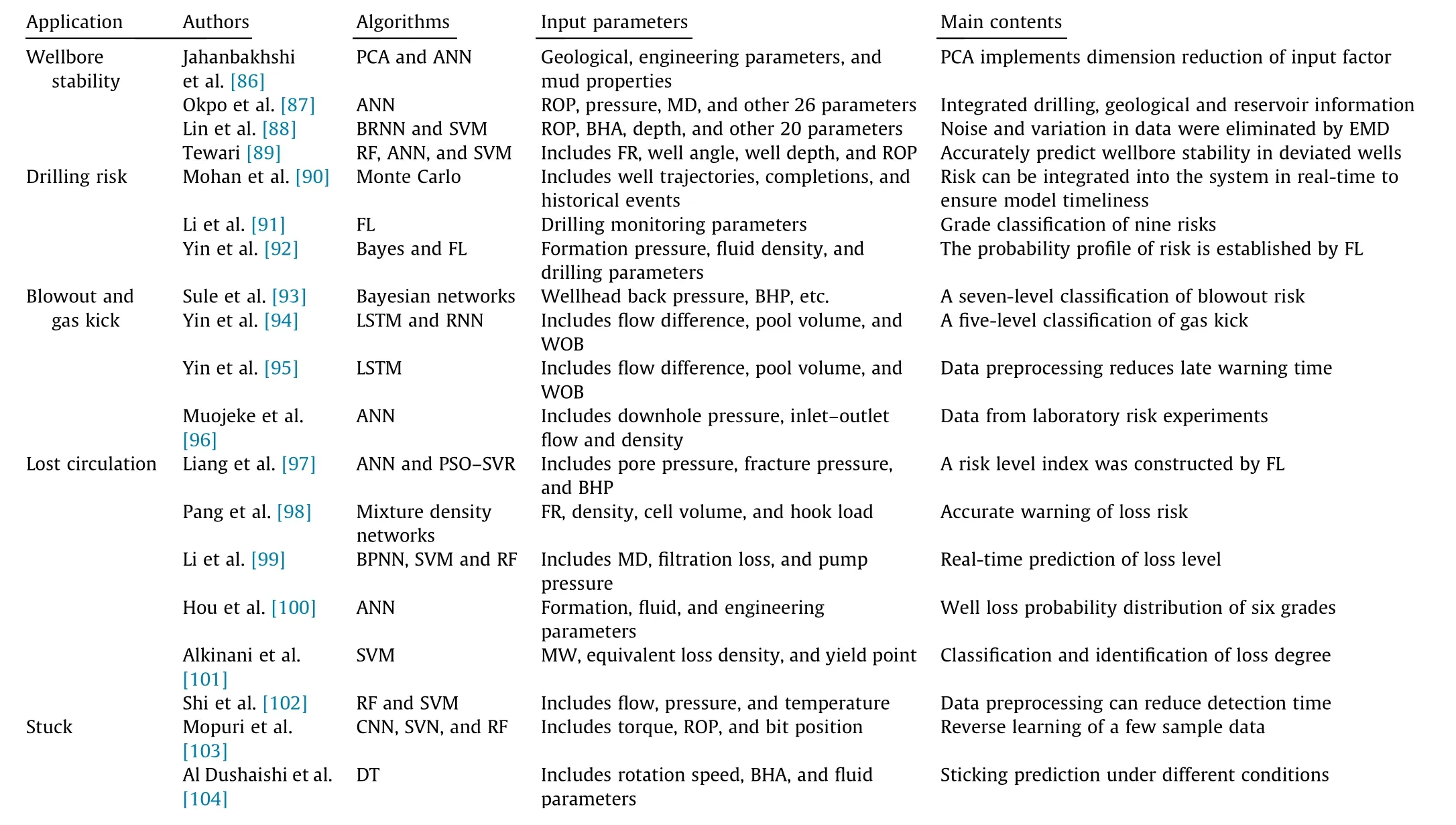

2.3.3. Intelligent prediction and diagnosis of drilling risks

The instability of near-wellbore formation and the imbalance of interaction between the wellbore and formation are the main causes of drilling accidents, such as overflow, well loss, stuck drilling,and well collapse.Advanced prediction and real-time diagnosis are essential for avoiding the occurrence of accidents.However,complex formation properties, such as micro-fractures, high temperature and high pressure in the bottom hole, and the coexistence of kicks and blowouts, are the primary limitations of accurate prediction and identification of drilling accidents. An intelligent algorithm can reflect the comprehensive relationship between multiple factors and drilling risks while exhibiting excellent robustness to the noise of logging data.Conversely,an intelligent algorithm with sensitivity to data fluctuations can diagnose risks in faster. Related research includes pre-drilling risk prediction, risk warning and diagnosis, and risk grade assessment. To the best of the author’s knowledge, existing research mainly focuses on early warning and diagnosis of risks in the drilling process,while research on prediction and risk grade assessment is still in progress (Table 10 [86-104]).

Table 8 Intelligent characterization of formation properties.

Table 9 Intelligent description of wellbore flow behavior.

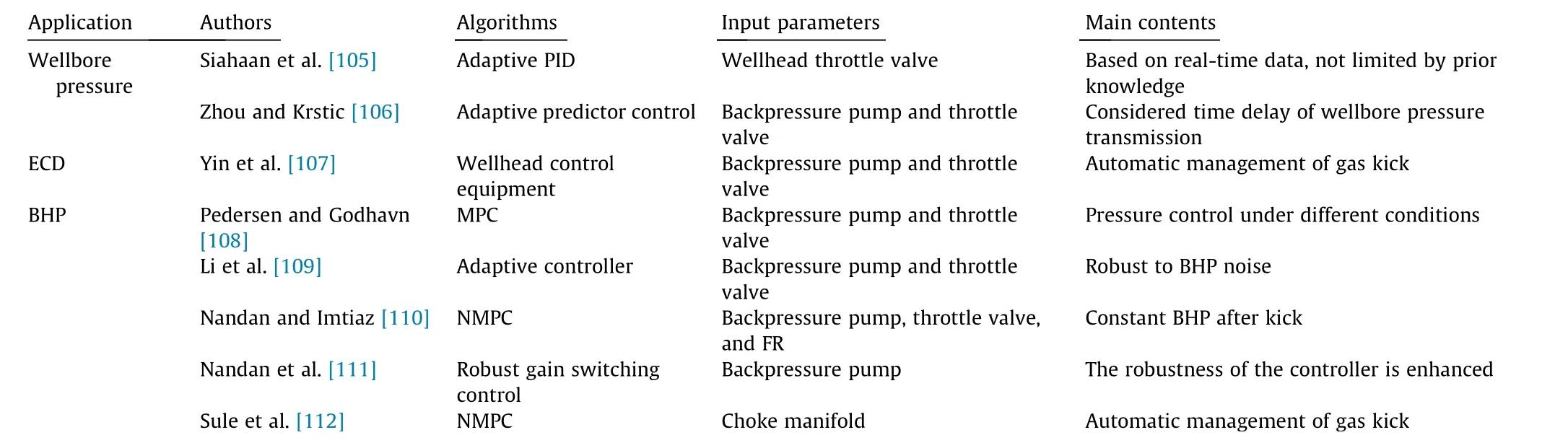

2.3.4. Intelligent management of wellbore stability

Wellbore stability is central to drilling process control.Through the control of wellbore flow to maintain the expected wellbore pressure and cuttings concentration, complex accidents can be eliminated. An intelligent control algorithm can not only regulate wellbore flow through a single parameter, such as throttle valve opening, backpressure pump FR, or mud FR, but also realize the collaborative control of multiple parameters, improve the control efficiency and accuracy,and avoid unnecessary fluctuation of wellbore pressure, which can induce secondary accidents (Table 11[105-112]).

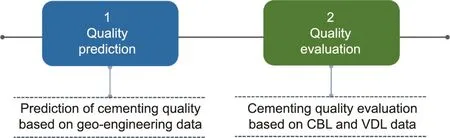

2.4. Intelligent evaluation and optimization of cementing quality

Cementing is an important part of well construction. Because cementing quality assessment is highly dependent on expert knowledge, intelligent cementing is proposed to achieve an accurate assessment and prediction of cementing quality, which includes cementing quality evaluation and prediction (Fig. 6).Cementing quality prediction is primarily based on logging data,and intelligent algorithms are used to correct logging information to evaluate cementing quality. The evaluation is based on a large number of acoustic amplitudes and variable density logging curves,using machine or DL algorithms to train the model to accurately evaluate the cementing quality.

2.4.1. Cementing quality prediction

Deepak Kumar Voleti of Abu Dhabi Company for Onshore Petroleum Operations Limited (trading as ADNOC Onshore) in the United States established different ML algorithms, such as RF and neural networks, based on sound amplitude, variable density logging data, and ultrasound imaging data to make predictions, and eventually adopted an integrated learning method.All the prediction models were combined to output the prediction results of cementing quality with an accuracy rate of 99.4%[113]. Santos and Dahi at the Pennsylvania State University used a Gaussian process regression algorithm for training to generate synthetic logging curves based on CBL and VDL data,which can capture the heterogeneity of cement. This research achieved good results in predicting cement bonding quality[114].

2.4.2. Cementing quality evaluation

Reolon et al.[115]used the MRGC algorithm by identifying patterns in acoustic and ultrasonic logging/graphs and then integrating MRGC into a Bayesian framework through entropy to calculate the probability of obtaining cement cementation phases,the most likely scenarios, and related uncertainties. This method can interpret and analyze cementing quality in real time. Viggen et al. [116] proposed the use of a CNN for logging data interpretation; inputted 11 types of logging data, conducted training, andfinally outputted six types of cementing quality with an accuracy rate of 86.7%. Viggen et al. [117] studied ML methods to automatically evaluate cementing quality and compared the self-extracting feature CNN with feature engineering to extract features artificially. The results showed that the classifier using feature engineering performed better, with accuracies of 88.9% for HI, 86.7%for CNN, and 51.6% for BQ.

Table 10 Intelligent prediction and diagnosis of drilling risk.

Table 11 Intelligent control of drilling process.

Fig. 6. Intelligent evaluation and optimization of cementing.

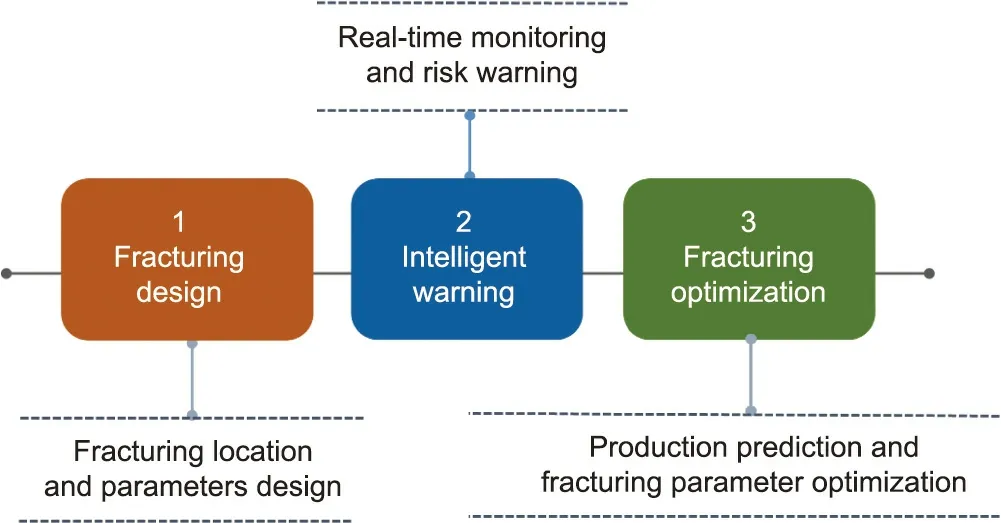

2.5. Intelligent design and optimization of fracturing process

Intelligent fracturing involves the use of AI and big data technology to solve nonlinear, multiparameter, and multiobjective problems in the fracturing process. Intelligent fracturing consists of three application scenarios: intelligent design of the fracturing process, intelligent monitoring of the fracturing process, and fracturing optimization for production (Fig. 7).

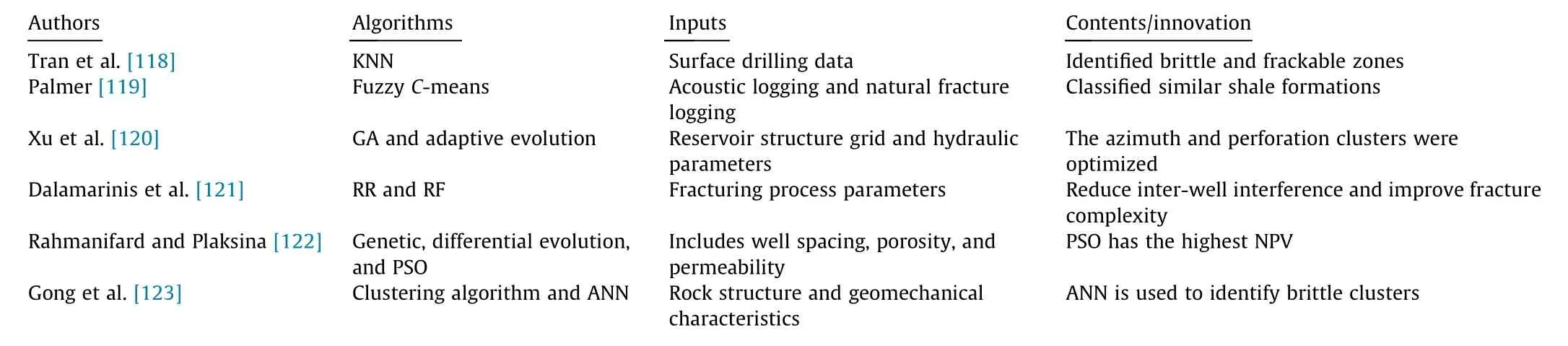

2.5.1. Intelligent design of the fracturing process

Fig. 7. Intelligent design and optimization of fracturing.

The fracturing design of a horizontal well includes fracturing location and fracture parameter design. The optimization design of horizontal fracturing has evolved through several methods and technologies,from simple analytical to complex numerical models from being data-driven to,now,being intelligence-driven.With big data(e.g.,logging,MWD,and rock mechanics data)and intelligent algorithms (e.g., clustering, regression, and optimization algorithms), perforation fracturing optimization can be achieved(Table 12 [118-123]). Currently, the accuracy is approximately 70%-80%, which greatly improves the prediction accuracy of the productivity of fractured horizontal wells, compared with traditional methods. However, owing to the limitations of data quality and quantity, there are few examples of field applications of relevant research.

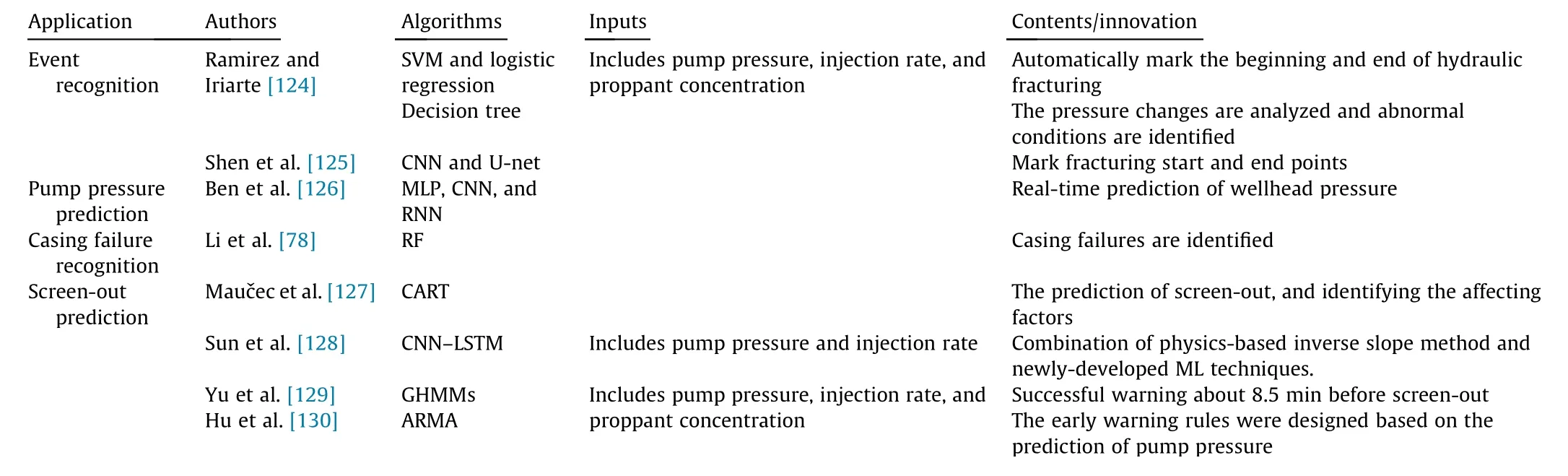

2.5.2. Intelligent monitoring of the fracturing process

Real-time monitoring is an important aspect of the fracturing process. The intelligent algorithms are gradually replacing traditional manual feature selection and anomaly monitoring, and the performance of intelligent algorithms in abnormal signal identification has greatly improved compared with traditional methods.The intelligent monitoring of the fracturing process consists of two aspects:fracturing condition identification and intelligent risk warning (Table 13 [78,124-130]).

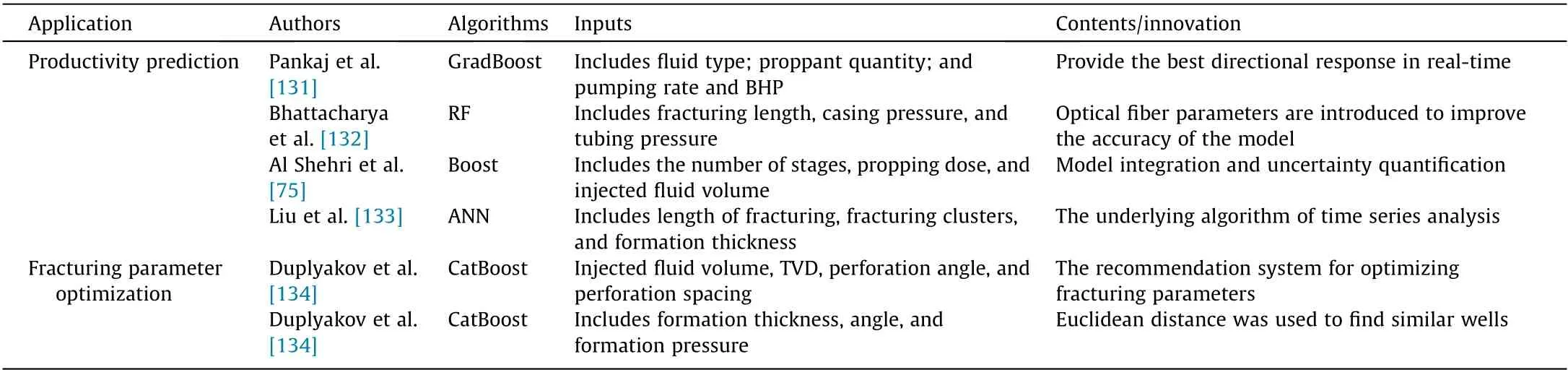

2.5.3. Productivity prediction and fracturing optimization

Staged fracturing is necessary for efficient exploitation of unconventional oil and gas resources. The productivity prediction of fractured horizontal wells is of great significance for the evaluation of production schemes and completion optimization.With the extensive use of hydraulic fracturing technology and development of AI, the effective application of ML methods in parameter optimization design has become a trend that is expected to grow in the future.Intelligent algorithms,such as support vector machines,decision trees, neural networks, and their variants, are already being used to construct productivity prediction models (Table 14[75,131-134]).

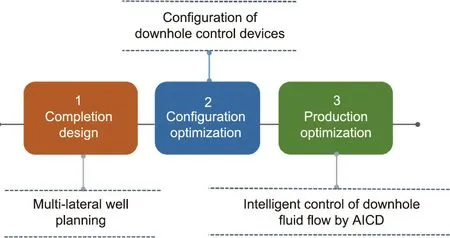

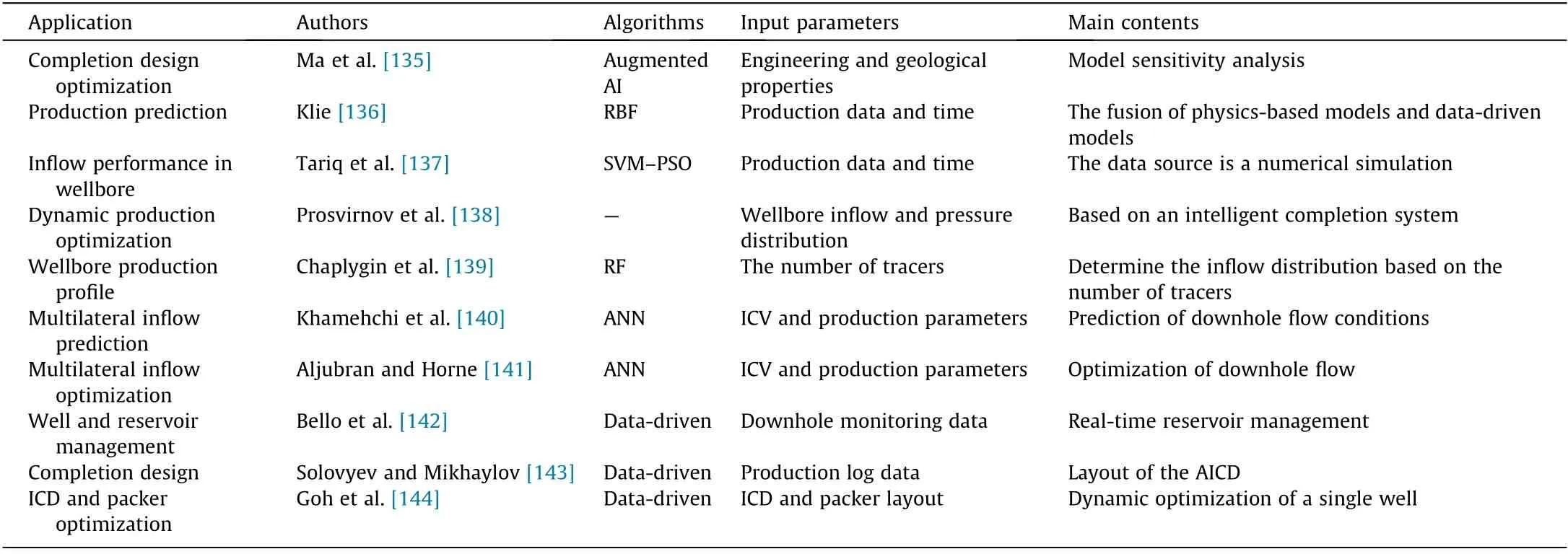

2.6. Intelligent design and optimization of completion

Intelligent completion is primarily composed of downhole automation, remote sensing, and control systems. The intelligent completion analyzed here is an advanced method for maximizingproduction and recovery using the methods shown in Fig. 8. The data sources for completion are composed of static and dynamic data. Static data include the reservoir properties and multilateral well structure,while dynamic data include surface monitoring production data and downhole sensing information.Regarding intelligent algorithms, sequential regression algorithms are usually combined with numerical simulations to predict future production dynamics,and optimization algorithms and hydraulic control lines are used to optimize and control the operating state of downhole fluid control equipment, such as inflow control valves (Table 15[135-144]).

Table 12 Intelligent design of hydraulic fracturing.

Table 13 Intelligent warning and identification of fracturing event.

Table 14 Productivity prediction and fracturing parameter optimization.

Fig. 8. Intelligent design and optimization of completion.

2.7. Overall optimization and intelligent decision-making of the drilling process

Fig. 9. Overall optimization of the drilling process.

Table 15 Intelligent completion design and optimization.

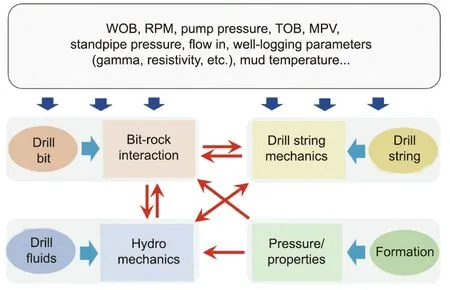

A drilling system is extremely complicated because it is composed of several tightly related downhole subsystems, such as geo-steering, rock-breaking, hydraulic, and drill-string systems,the majority of measurements are only available at the ground,and very sparse data from downholes are accessible (Fig. 9). The goal of drilling is to form a hole with high efficiency and quality while maintaining low risks and costs.Therefore,drilling optimization involves multiple objectives and subsystems, for which a model integrating the coupled subsystems is needed. The overall optimization and intelligent decision-making of the drilling process is an important scenario in which AI is applied in the realm of drilling and completion. It is expected to ensure drilling safety,shorten drilling periods, and save drilling costs.

To achieve this goal,a mathematical model integrating the subsystems by combining physics-based and data-driven methods and analyzing the coupling mechanism of the subsystems is required.The integrated model should be dynamic and serve as the foundation for drilling optimization.The model should be constrained by the controllable operational parameters on the ground as well as drilling risks. The latter implies that the operational parameters must not cause accidents, such as kick-off and stuck pipes. The multi-objective optimization algorithms and intelligent decisionmaking strategies must be implemented with specific goals,including optimizing the drilling rate, MSE, and drilling costs.The algorithms must be fast and efficient to meet the demands of real-time operation. Finally, a framework integrating all the models and algorithms must be developed to perform the overall optimization and intelligent decision making while drilling.

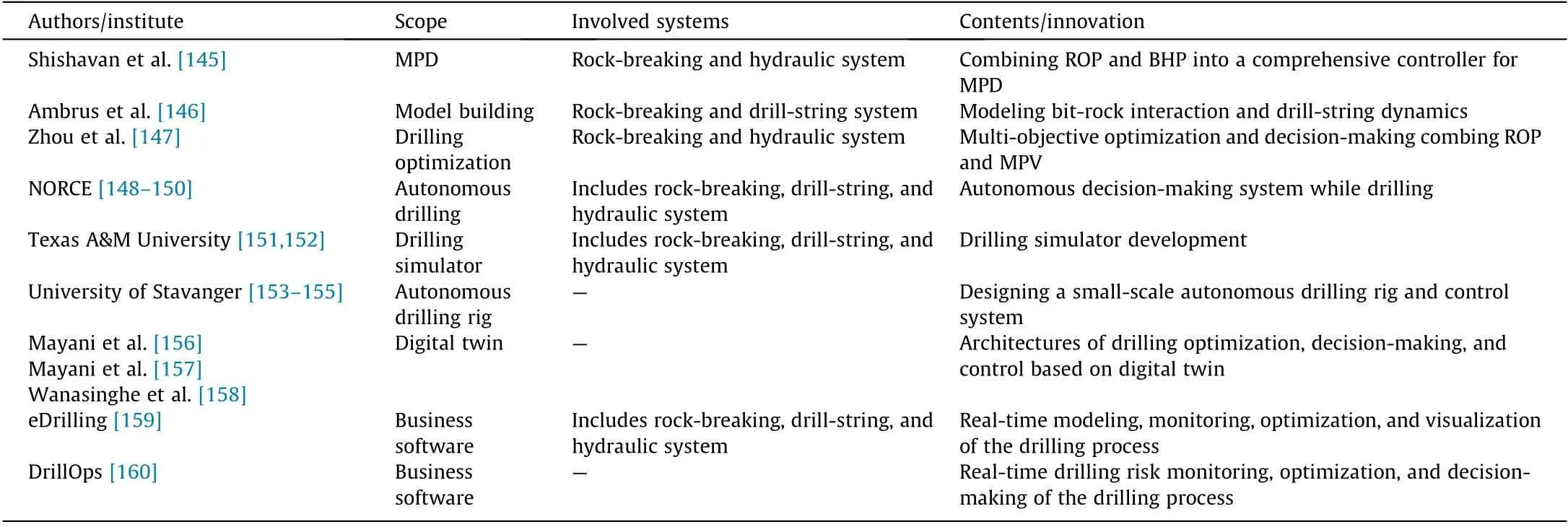

Integrating all the subsystems of the drilling process to perform optimally is crucial for intelligent or autonomous drilling.Although many studies have been conducted on model construction, framework design,and system development,as shown in Table 16[145-160], research on overall optimization and intelligent decisionmaking during drilling is still in the early stages.

2.8. Overview of the research status

Intelligent drilling and completion are now developing rapidly,and the integration of AI with drilling and completion engineering is deepening. Many studies have ranked particular models as best by comparing the performance of ML, DL, and optimization methods in specific scenarios,and have even established hybrid models to meet the needs of precision, efficiency, and systematic reasoning. The fusion of physics-based and data-driven models has become a popular approach, which overcomes the limitations of the mechanism model, improves the stability of the data model,and reduce the interference of data noise. Common methods include reconstructing the neural network topology with mechanism knowledge, constructing loss functions under mechanism constraints,and sharing and complementation of input data.In the complex drilling process with multisystem coupling, the single-objective optimization method has obvious limitations and cannot achieve global optimization. According to the scenarios of drilling and completion, the coupling of multiple process models is realized with an optimization algorithm to realize multiobjective optimization of the drilling process and global optimization.

3. Prospects and challenges of intelligent drilling and completion

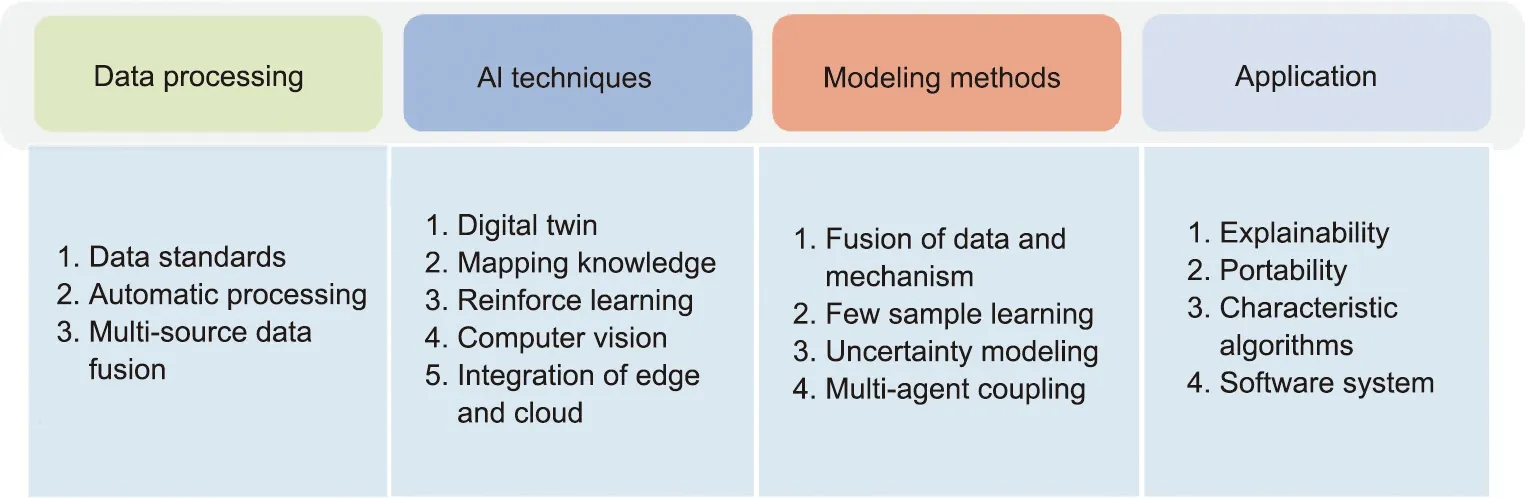

Despite the rapid development of intelligent drilling and completion,challenges remain to be addressed.Future work on intelligent drilling and completion should focus on data processing,intelligent methods, modeling methods, and application requirements (Fig. 10).

3.1. Standards and methods for data processing

Drilling and completion data are multisource and multiscale,and include micrometer-level formation pore structures and kilometer-level geologic mechanisms, as well as dynamic data from real-time monitoring and static data of formations and reservoirs.The data types are varied,and include numerical values,text,and pictures.The dynamic integration of this information is a necessary for the development of intelligent drilling and completion.Monitoring information in complex environments, such as downholes and formations, has considerable noise, anomalies, and vacancy values. Automated data governance methods and processes are critical for data-driven modeling and optimization, and data processing standards drive the application of data processing methods.

3.2. Intelligent algorithms and techniques

While computer vision can be used to process image information, it is also an important technology for digital twin visualization. Digital twin visualization, with its hypothetical capabilities,will effectively improve risk warnings and intelligent decisionmaking. The knowledge graph also connects different business scenarios, enhancing overall control over drilling and completion business networks. The edge-cloud integrated computing method will further release the potential of computing power forlarge-scale model operations and simulations, including digital twins.

Table 16 Overall optimization and intelligent decision-making of drilling process.

Fig. 10. Prospects of intelligent drilling and completion.

3.3. Intelligent modeling

Appropriate modeling methods can improve data utilization and enhance model performance.Intelligent models incorporating prior knowledge (e.g., physical laws and expert knowledge) can guarantee accuracy and efficiency, and simultaneously improve stability and portability. Modeling methods based on the fusion of prior knowledge and big data are regarded as an important driving force in promoting the application of AI.Despite the volume of drilling and completion data, there are many few-sample scenarios, such as complex downhole conditions, that are difficult to monitor and have few reliable data about drilling accidents. Fewsample modeling can provide excellent model performance with limited data. Uncertainty analysis of the few-sample problems is helpful in understanding the nature of the problem. The coupling of agents representing physical processes to achieve accurate characterization and global optimization of drilling and completion processes will become an essential requirement for intelligent drilling and completion.

3.4. Intelligent application requirements

Interpretability and transferability of intelligent algorithms are two critical problems in the application of AI.In combination with real drilling and completion scenarios, interpretable and transferable methods for intelligent models should be explored to form unique models suitable for specific drilling and completion scenarios.Furthermore,the development of reliable intelligent models in business software can accelerate the development of intelligent models.

4. Conclusions

Intelligent drilling and completion is regarded as a transformative technology and has become a hot spot or hub for development in the oil and gas industry,significantly improving DE and reducing drilling costs.In this review,seven intelligent scenarios or application areas of AI techniques in drilling and completion engineering are proposed, and the status of research in each of the scenarios comprehensively reviewed. By combining the characteristics of drilling and completion engineering and AI, key future research areas of intelligent drilling and completion are proposed.

In the future,efforts should be focused on promoting the development of intelligent drilling and completion in the following areas: ①exploring automated data management methods and standards; ②strengthening the research in intelligent methods,such as digital twins,computer vision,knowledge graphs,and reinforcement learning;③developing new modeling methods,such as the combination of data and mechanisms, few-sample learning,uncertainty modeling, and multi-agent coupling; and ④building intelligent models that are interpretable and transferable. This study has provided a systemic review of intelligent drilling and completion, and is expected to spark research and establishment of intelligent algorithms.

Acknowledgment

The authors gratefully acknowledge the support of the National Key Research and Development Project of China(2019YFA0708300), National Science Fund for Distinguished Young Scholars of China(52125401),and National Natural Science Foundation of China (L1924060).

Compliance with ethics guidelines

Gensheng Li, Xianzhi Song, Shouceng Tian, and Zhaopeng Zhu declare that they have no conflict of interest or financial conflicts to disclose.

Nomenclature

Abbreviations

5G The fifth generation mobile communication technology

AdaBoost Adaptive boosting

ABC Artificial bee colony

AC Acoustic time difference

ACO Ant colony optimization

ADNOC Abu Dhabi National Oil Company

AHP Analytic hierarchy process

AI Artificial intelligence

AICD Autonomous inflow control device

ANFIS Adaptive neuro-fuzzy inference system

ANN Artificial neural network

ARIMA Auto regressive integrated moving average

ARMA Auto-regressive and moving average model

ATC Analytical target cascading

BHA Bottom hole assembly

BHP Bottom hole pressure

BPNN Back propagation neural network

BQ Bond quality

BRNN Bayesian regularization neural network

BTS Brazilian tensile strength

CAI Cerchar abrasivity index

CART Classification and regression tree

CBL Cement bond logging

CNN Convolutional neural networks

COA Cuckoo optimization algorithm

DE Drilling efficiency

DL Deep learning

DNN Deep neural networks

DS Differential search

DT Decision tree

ECD Equivalent circulating density

ELM Extreme learning machine

EMD Empirical mode decomposition

FCNN Fully convolutional neural network

FD Formation drillability

FL Fuzzy logic

FNN Functional neural network

FR Flow rate

FSCARET Automated feature selection from ‘‘caret”

FSQGA Fibonacci sequence based quantum genetic algorithm

GA Genetic algorithm

GBM Gradient boosting machine

GHMMs Gaussian hidden markov models

GR Gamma ray

GradBoost Gradient boosting

HI Hydraulic isolation

HS Harmony search

ICD Inflow control device

ICV Interval control valve

IGA Improved genetic algorithm

IoT Internet of Things

IPSO Improved particle swarm optimization

KNN K-nearest neighbor

LDA Linear discriminant analysis

LM Levenberg-Marquardt

LMR Linear multivariate regression

LR Logistic regression

LSTM Long short-term memory neural network

LWD Logging while drilling

MCM Minimum curvature method

MD Mud density

MedAE Median absolute error

ML Machine learning

MLP Multi-layer perceptron

MOC Multi-objective cellular

MOGA Multi-objective genetic algorithm

MPC Model predictive control

MPD Managed pressure drilling

MPV Mud pit volume

MRGC Multi-resolution graph-based clustering

MSE Mechanical specific energy

MW Mud weight

MWD Measurement while drilling

MVRA Multivariate regression analysis

NPV Net present value

PCA Principal component analysis

PID Proportional integral differential

PSO Particle swarm optimization

QDA Quadratic driscriminant analysis

RBF Radial basis function

RBFNN Radial basis function neural network

RF Random forest

RNN Recurrent neural network

ROA Rain optimization algorithm

ROP Rate of penetration

RPM Revolutions per minute

RR Ridge regression

RSS Rotary steerable system

SPP Stand pipe pressure

SVM Support vector machine

SVR Support-vector regression

SWOB Specific weight on bit

TOB Torque on bit

TVD True vertical depth

UCS Unconfined compressive strength

VDL Variable density log

VSP Vertical seismic profile

WOB Weight on bit

XGBoost Extreme gradient boosting

- Engineering的其它文章

- Erratum to ‘‘Targeted Genotyping of a Whole-Gene Repertoire by an Ultrahigh-Multiplex and Flexible HD-Marker Approach”[Engineering 13(2022) 186-196]

- China’s Rural Transformation and Policies: Past Experience and Future Directions

- Treating Chronic Diseases by Regulating the Gut Microbiota

- State of Science:Why Does Rework Occur in Construction?What Are Its Consequences? And What Can be Done to Mitigate Its Occurrence?

- Tailoring Anti-Impact Properties of Ultra-High Performance Concrete by Incorporating Functionalized Carbon Nanotubes

- An Intelligent IEQ Monitoring and Feedback System: Development and Applications