木质纤维素生物质厌氧发酵沼渣热化学转化利用研究进展

张德俐,王 芳,易维明,李志合,李永军,柳善建

·农业生物环境与能源工程·

木质纤维素生物质厌氧发酵沼渣热化学转化利用研究进展

张德俐,王 芳※,易维明,李志合,李永军,柳善建

(1. 山东理工大学农业工程与食品科学学院,淄博 255000; 2. 山东省清洁能源工程技术研究中心,淄博 255000)

厌氧发酵技术可以将木质纤维素生物质转化为沼气,并伴随副产物沼渣产生。随着大型沼气工程的发展,大量沼渣排放已成为厌氧发酵技术推广应用的主要限制因素之一,亟须对沼渣进行快速有效处理。其中,沼渣的热化学转化利用符合大型沼气工程发展趋势,是当前的研究热点之一。首先分析木质纤维素沼渣的原料特性与热化学转化潜力;再对沼渣成型燃料、热解以及水热炭化等领域的研究现状进行分析,着重对沼渣衍生产物特性、热化学转化过程中存在的问题以及与厌氧发酵结合的潜在优势等方面进行讨论;最后,对沼渣热化学转化的发展趋势进行了展望。木质纤维素生物质厌氧发酵与沼渣热化学转化结合的应用模式研究对大型沼气工程推广应用具有一定的科学意义。

生物质;厌氧发酵;热解;沼渣;燃烧;水热炭化

0 引 言

生物质资源的开发利用是实现循环农业和低碳经济的重要途径,更是达成碳中和目标的重要助力,因此,中国大力发展生物质综合利用技术[1]。其中,通过厌氧发酵技术,可以对生物质废弃物进行有效的资源化利用[2-3]。随着中国“十三五”期间沼气工程转型升级战略实施,大规模沼气工程得到了快速发展,出现了一批日产1万m³以上生物天然气的大型沼气工程[4]。以秸秆为代表的纤维素类生物质具有甲烷产量高、含硫量低、价格低廉、资源丰富、便于储存等优势,能够满足大型沼气工程对原料供应的需求,是未来厌氧发酵技术产业化发展的方 向[5]。然而,随着沼气工程迅速发展,伴随产生大量沼渣的处置问题已成为厌氧发酵技术推广应用的主要限制因素之一[6]。

由于富含植物生长所需的营养元素并含有大量小分子腐殖质,现阶段沼渣最主要的利用方式为土地施肥与土壤改良[7]。但是,随着厌氧发酵残余物总量的提升,沼渣供给与农用土地消纳能力的时空矛盾凸显:一方面残余物连续产出,而土地施肥、土壤改良等属于间歇式需求。一旦进入肥料需求淡季,沼渣、沼液等储存会占用大量空间并存在潜在环境污染。研究表明,沼渣、沼液储存期间会释放N2O、CO2、CH4、NH3等温室气体与有害气体[8-9],而且,CH4的析出也降低了生物质能的利用效率[10];另一方面,如若大型沼气工程周边没有足够的土地对其进行消纳,高含水率沼渣的远途运输将会耗费大量的人力和物力资源[11]。

此外,沼渣施肥对周边环境以及农作物产品的潜在危害也不能忽视,包括氮磷富集、重金属沉积、病原体附着等问题[12-14]。尤其随着人们对食品安全及环境保护等方面的逐渐重视,许多国家与地区提高了土地施肥或土壤改良的准入标准,这也在一定程度上限制了沼渣作为有机肥料与土壤改良剂的应用[15]。因此,在大型沼气工程的发展背景下,亟需一种新的技术手段对厌氧发酵过程伴随产生的沼渣进行快速有效的处理,缓解沼渣处置问题。

其中,沼渣的热化学转化利用符合大型沼气工程的发展趋势,可能实现木质纤维素沼渣的无害化处理与资源化利用,已成为当前的研究热点之一。以沼渣为纽带,可以将厌氧发酵技术与热化学转化技术有机结合。因此,本文将基于国内外木质纤维素生物质厌氧发酵沼渣热化学转化技术的最新研究成果,对沼渣热化学转化的研究情况进行归纳。分析木质纤维素沼渣的热转化潜力,分别对沼渣成型燃料、沼渣热解以及沼渣水热炭化等领域的研究现状进行综述,分析沼渣热化学转化过程中存在的问题及其与厌氧发酵技术相结合的潜在优势,并展望沼渣热化学转化技术的发展趋势。该项研究对于以木质纤维素生物质为主要原料的沼气工程推广应用具有一定的科学指导意义。

1 木质纤维素沼渣原料特性

厌氧发酵产甲烷的过程实际上是微生物物质代谢和能量转换的过程[16]。由于纤维素的结晶性与木质素的存在,甲烷细菌无法对木质纤维素生物质进行有效降解,降低了生物质的整体转化效率[17]。由表1[18-22]所示,木质纤维素生物质在厌氧发酵后,原料中仅有23.2%~45.8%的能量流入到沼气,其物质和能量利用效率较低。相比较,厌氧发酵后沼渣的质量产率较高,在70%~90%左 右[18-19,23],碳元素和能量所占比例也较高,在60%左右。同时,沼渣本身碳元素含量与热值也比较可观,一般约在35%~50%和14~22 MJ/kg之间[18-27]。可见,木质纤维素沼渣中仍保留着发酵前原生物质中的大部分能量,有必要对沼渣进行合理的利用。

在木质纤维素生物质发酵沼渣中,纤维组分的含量也非常可观。由表2[24-28]可见,秸秆类沼渣中纤维组分含量在67.55%~84.80%之间,牛粪沼渣中纤维组分含量也达到了52.67%。与发酵前的原料相比,沼渣中纤维素与半纤维素相对含量降低明显,木质素与灰分含量则有明显增加。但是,从纤维组分含量来看,沼渣仍具有较大的热化学转化潜力。

表1 木质纤维素生物质厌氧发酵能量与沼渣碳元素分布

表2 木质纤维素生物质及其发酵沼渣纤维组分含量

2 沼渣的热化学转化研究现状

根据国内外厌氧发酵沼渣热化学转换技术的文献调研,相关研究内容主要集中在沼渣成型燃料燃烧、沼渣热解和沼渣水热炭化3个领域,如图1所示。

图1 木质纤维素生物质沼渣热转化技术路线

2.1 成型燃料燃烧技术

生物质成型燃料是指干燥粉碎后的生物质在成型设备中被加工成一定形状、一定密度的固体燃料[29]。研究表明,沼渣的成型性能明显优于其发酵前原材料[30-31]。在不添加粘结剂的条件下,木质纤维素发酵沼渣即可实现颗粒化成型,且表现出良好的机械耐久性[30]。杨世关等[31]将厌氧发酵过程作为一种秸秆类生物质制备成型燃料的预处理手段,相比于玉米秸秆原料,发酵沼渣制备的成型燃料松弛密度提高了12.86%,同时,也降低了成型过程中设备的磨损损耗。闫芳等[32]对比研究了玉米秸秆及其沼渣与褐煤的混合成型特性,结果表明,在相同制备条件下,沼渣型煤的抗压强度最高是玉米秸秆型煤的3倍。王雅君等[33]研究表明,仅以沼渣与生物炭掺混部分水即可直接成型,并表现出良好的抗跌落强度和疏水性。沼渣成型性能提升的主要原因是沼渣中木质素相对含量的增加。木质素作为一种天然黏结剂,能够增强成型过程中的固体架桥作用,提高机械强度[34]。此外,木质素相对含量的增加也使得秸秆类沼渣的成型燃料热值有所提高,其低位热值能够达到15.8 MJ/kg(9.2%含水率),接近松木成型颗粒的热值[30]。Li等[35]在沼渣与褐煤混合成型研究中表明,沼渣掺混比例为20%时可制备高品质的成型燃料,热值能够达到20.2 MJ/kg。

在燃烧污染气体排放特性方面,发酵沼渣也与其发酵原料有所不同。表3列出了几种沼渣以及典型生物质成型燃料燃烧的气体排放水平[30,36-38],并对比了国内相关的排放标准。其中,GB 13271-2014为锅炉大气污染物排放标准,NB/T 34006-2011为国内小于50 kW的生物质炉具燃烧排放的行业标准[39]。与原料相比,沼渣基成型燃料燃烧过程中SO2的排放非常少,几乎检测不到[30]。这是由于在发酵过程中会伴随部分H2S的析出,降低了沼渣中S元素含量。但是,沼渣燃烧过程中NOx排放量明显升高,是玉米秸秆等典型生物质成型燃料的3~4倍,超出了新建锅炉以及小型生物质炉具的标准要求。这是由于发酵过程中需要补充N源调控发酵底物的C/N比,导致沼渣中N元素含量升高。因此,沼渣基成型燃料的气体排放指标中应重点检测与关注NOx的排放水平。此外,沼渣燃烧的烟尘排放值也较高,但通过增设静电除尘装置可使其浓度降低到40~43 mg/m³[30],满足标准要求。

表3 几种沼渣与典型生物质成型燃料燃烧的排放水平

注:①为经过静电除尘装置处理后的烟尘浓度。

Note:①is the dust concentration after treatment by electrostatic filter.

在燃烧灰分特性方面,沼渣基成型燃料的结渣现象较为明显。纤维素类原料经过厌氧发酵后,其灰分相对含量增加,而且,灰分中含有较大比例的碱/碱土金属,可能会在较低温度下发生熔融现象。Chen等[40]分析纤维素类沼渣的灰熔融软化温度为1 180℃,Kratzeisen等[30]分析得到沼渣基成型燃料的灰熔融软化温度在1 090~ 1 110℃之间,都远低于松木燃烧灰分的软化温度 (1 370~1 430℃)。Pedrazzi等[36]研究表明,由于聚团、结渣等原因,无法利用小型燃烧炉对木质纤维素沼渣成型燃料进行超过1 h的稳定燃烧。付成果[41]等研究表明,即使经过水洗处理,秸秆类发酵残渣的燃烧仍处于严重结渣水平。因此,降低沼渣灰分中非水溶性的低熔点组分含量是其进行燃烧应用的关键因素之一。研究表明,将沼渣与木材按照一定比例制备成型燃料或与煤混烧可以降低碱/碱土金属在燃烧过程中的影响,缓解聚团、结渣等现象[36]。此外,通过酸洗或水热等预处理手段也可以有效降低生物质灰分中碱/碱土金属含量,有助于提高其燃烧特性[42-44]。

整体来看,沼渣的成型性能好,具有较高的制备固体燃料的转化潜力。但是,需要在NOx排放与结渣控制等方面作进一步深入研究,以提高沼渣基成型燃料的燃烧特性。

2.2 热解技术

生物质热解是在惰性气氛下使生物质发生热分解生成可冷凝挥发分、固体产物和不可冷凝气体的技术[45]。通常改变热解参数,可以对不同的目标产物(生物油、热解炭和热解气)进行调控。木质纤维素沼渣的热解研究现状如表4所示[25,40,46-61]。

在制取生物油液体燃料方面,沼渣表现出一定的优势。为了提高生物油的品质,杨昌炎等[46]将固态发酵作为一种预处理手段,对发酵后的小麦秸秆进行了快速热解液化试验,结果表明其产出的生物油热值由发酵前的16~17 MJ/kg提升到22~24 MJ/kg,并降低了49%的乙酸含量;Neumann等[47]通过异位催化热解木质纤维素发酵沼渣制备的生物油热值达到了35.2 MJ/kg,黏度与总酸值也都有所降低。Hossain等[48]对沼渣进行催化热解得到的生物油,可以与丁醇以及餐厨废油等进行混合直接应用于柴油机中,最大配比为30%。此外,厌氧发酵过程还可以明显增加热解生物油中酚类化合物的含量,尤其是4-乙烯基苯酚。Wang等[50]利用PY-GC-MS,对厌氧发酵前后的玉米秸秆进行了热解生物油的对比分析,在250℃时,发酵后其酚类化合物含量由42.25%增加到79.32%,4-乙烯基苯酚的含量则由28.6%增加到60.9%。但随着热解温度逐渐升高到500℃,其生物油中酚类化合物的含量不断降低。Liang等[25]对稻杆发酵沼渣的研究也得到了类似的规律,在330℃时,生物油中4-乙烯基苯酚的含量由发酵前的29.33%增加到发酵后的34.93%;而在650℃时,4-乙烯基苯酚的含量则仅从5.76%增加到7.68%。

在厌氧降解过程中,随着纤维素与半纤维素的去除,木质素相对含量增加,有助于生物油中酸类化合物含量的降低与酚类化合物含量的升高,提高生物油燃料品质。同时,经过发酵后,三组分交联结构变得松散,使得更多的木质素结构暴露出来,在相对较低的温度即可降解产生大量4-乙烯基苯酚[25]。可见,经过厌氧发酵后的沼渣在热解转化制取生物油液体燃料和提取酚类化合物等方面具有一定的优势。

在沼渣基热解炭方面,对其吸附特性的研究相对较多,吸附目标包含无机污染物(氨氮、磷)、有色染料(刚果红)、抗生素(四环素)以及重金属(Pb2+、Cu2+、 Ni2+、Cd2+)等[54-57, 62]。由表4可见,许多沼渣基热解炭能够媲美甚至优于商业活性炭的吸附效果。根据文献,沼渣基热解炭优良的吸附特性主要归因于其与吸附质的络合反应或共沉淀作用。Yao等[54]研究认为甜菜发酵沼渣对磷酸盐优异的吸附特性是由其表面存在的纳米方镁石胶质结构导致的;Inyang等[55]研究认为沼渣基热解炭中富含的碳酸盐和磷酸盐能够通过共沉淀反应实现重金属离子的吸附。可见,沼渣基热解炭的吸附特性与其自身的灰分结构、组分等密切相关,有必要加强发酵过程中无机组分的演变规律研究,进一步明确其与吸附行为之间的关联性。

表4 木质纤维素厌氧发酵沼渣热解研究现状

此外,郑杨清等[57]以沼渣基热解炭为前驱体,通过氢氧化钾活化方式制备的活性炭(KOH-CC)对氨氮的最大吸附容量达到120 mg/g。以此为依据,一个500 m3的生物产甲烷示范装置产生沼渣制备的KOH-CC足够用于处理其每天排放的沼液,循环工艺如图2所示[54]。这为沼渣基热解生物炭在沼气工程中的循环利用途径提供了一种新的思路,会更加直观地提高沼气工程的能量、经济以及环境效应。

图2 KOH-CC处理沼液循环工艺示意[57]

沼渣基热解炭在土壤改良方面也展现出一定的优势,包括较高的pH值、表面负电荷、离子交换能力以及营养元素含量等。Monlau等[63]对沼气工程中的沼渣及其热解炭进行了对比分析,结果表明热解炭中营养元素P和K的含量大幅增长,能够部分取代无机肥料的使用;而且其孔隙结构更加发达(49~88 m2/g),具有更好的持水能力,表现出优良的土壤改良性能。但是,由于厌氧发酵底物源头复杂,沼渣基热解炭的施用对生态环境的影响也引起了学者们的关注[64]。Stefaniuk等[65]研究表明,木质纤维素沼渣基热解炭中镉金属含量最高达到 8.8 mg/kg,超标严重,需进行重点防控。Garlapalli等[66-67]研究表明沼渣基热解炭中多环芳烃(PAHs)含量随着热解温度的升高而升高,在800℃制得的沼渣基热解炭中PAHs的含量达到4.7 mg/kg,远高于中国农用污染物控制标准。因此,在关注沼渣基热解炭在土壤改良领域正向效应的同时,也应在重金属与多环芳烃的迁移规律等方面做重点研究,严格评估其潜在的生态风险。

在生物质热解气化领域,纤维素类沼渣的转化也引起了众多学者们的关注,如表4所示。相较于生物质原料,发酵沼渣的挥发分含量较低,导致其热解气低位热值(LHV)与冷气化效率(CGE)相对较低[40,58-60]。研究表明,共气化技术可有效改善沼渣的热解气化性能。Chang等[61]研究表明,沼渣与褐煤共气化,可有效提高其热解气LHV。Yao等[68]将沼渣以20%掺混比例与木屑进行气化,其能量转化效率可达70.8%。此外,Chen等[69]研究表明,适度调控发酵时间等参数也能够有效提高气化产物LHV和CGE。而且,轻度的发酵预处理后,热解气中H2含量增幅达63%,提高了H2/CO摩尔比,这将有利于其作为合成气原料做进一步化工合成。Marchese等[70]的对比研究也表明,相较于生物质原料,发酵沼渣制备的热解气更适合作为费托合成等合成原料。

在气化副产物方面,沼渣的应用显著降低了气化过程中初级焦油的产生。Chen等[40]研究表明,沼渣气化过程中的焦油含量可低至1.61 g/Nm3,约为常规生物质原料气化焦油产量的1/3。即使经过轻度的厌氧发酵预处理,其焦油含量降幅也能够达到30%~35%[69],这将有利于其简化下游净化过程。而且,沼渣气化的灰渣中P2O5含量(26.96%)明显高于常规生物质气化灰渣中的含量(3.48%~9.76%),其在缓释肥应用方面具有一定潜 力[69]。但是,沼渣气化灰渣的农田应用与热解炭相似,也同样面临着潜在的生态风险。郭祥[71]研究表明,沼渣气化灰渣中铬含量(296.48 mg/kg)远远高于有机肥的农用标准(150 mg/kg),需要进行重点关注。可见,沼渣气化在合成气化工合成、焦油控制和灰渣农用等方面表现出一定的独特优势。但还需要进一步优化设计沼渣气化工艺以提高热解气LHV和CGE等关键指标。

整体来看,木质纤维素沼渣通过热解制取生物油燃料、酚类化合物、碳基吸附剂、土壤改良剂和合成气等方面均呈现出一定的应用潜力。而且,在反应动力学方面,厌氧发酵过程也降低了沼渣的热解活化能,有利于沼渣的热解转化[24,72-74]。但是,有研究表明,由于厌氧发酵工艺的要求,即使经过固液分离的沼渣中含水率依然达到了 70%[75]。沼渣高湿特性导致的干燥能耗在一定程度上制约了其热解转化应用。同时,由于发酵底物多元化,组分极为复杂,相关农药、重金属以及多环芳烃等有害组分在沼渣中具有一定的累积效应,也需要进一步探究沼渣热解过程中这些有害组分的演变规律。

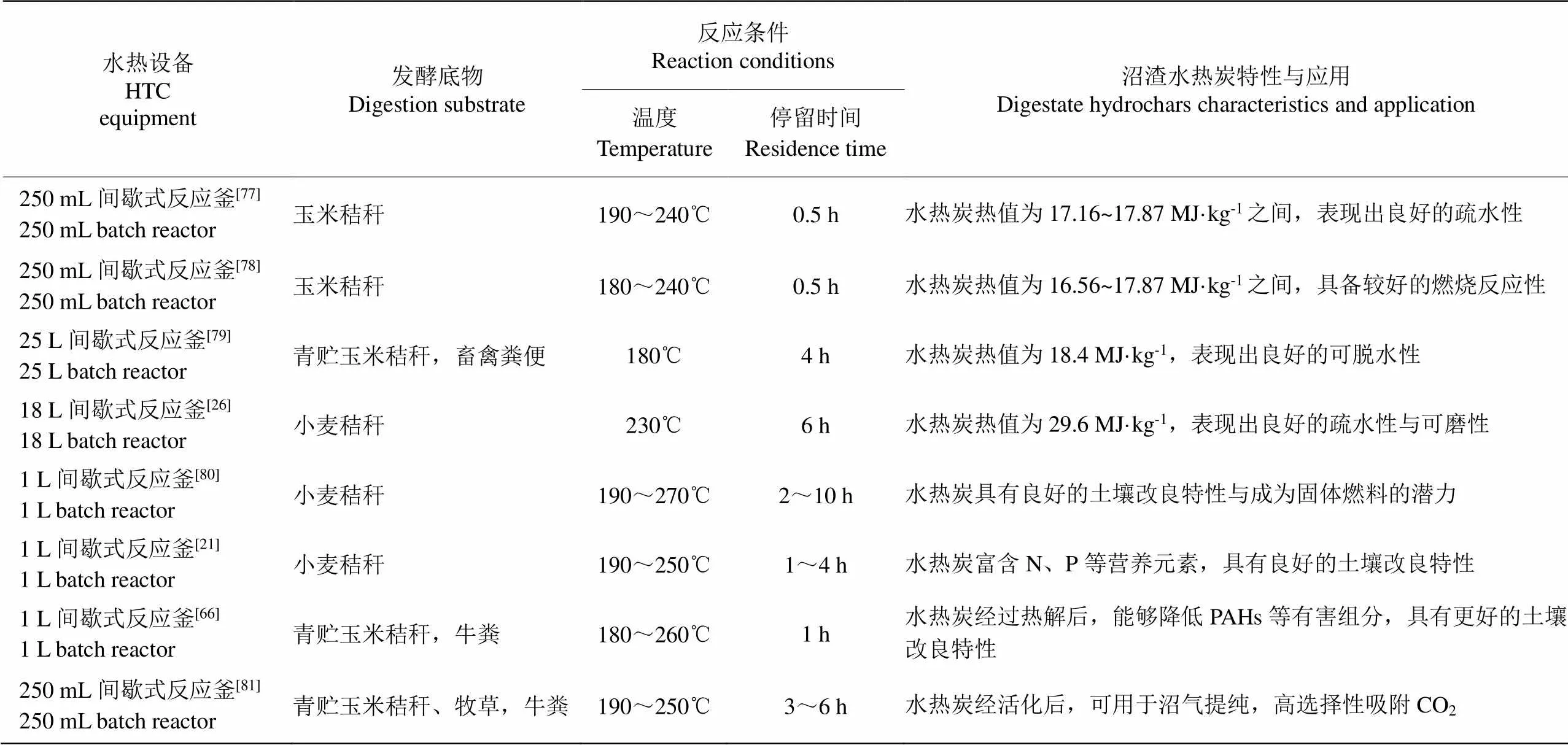

2.3 水热炭化技术

生物质水热炭化(Hydrothermal Carbonization,HTC)技术是指生物质与水在一定的温度(180~250℃)与自生压力(或高于自生压力)下,生成富碳固体产物的过程[76]。同时,还伴随部分有机相转移为水相产物,小部分物质转化为气体。由于HTC过程中水的存在,其非常适合处理高含水率的生物质废弃物,无需在反应前对原料进行干燥处理。而且,水热炭也呈现出较大的应用潜力。因此,木质纤维素发酵沼渣的水热炭化处理是现阶段的研究热点之一,如表5[21,26,66,77-81]所示。

表5 木质纤维素厌氧发酵沼渣水热炭化研究现状

许多学者对不同水热炭化工况下,沼渣基水热炭产率与理化特性的变化规律进行了研究,其关键参数主要包括水热温度、反应时间、初始pH值与液固比等[82]。水热温度无疑是影响HTC行为的最主要因素。根据Arrhenius公式,化学反应速率常数与反应温度和反应时间分别呈正比例指数关系和线性直线关系。水热温度相较于反应时间,对水热炭产率具有更加明显的影响。pH值则主要通过催化作用影响水热反应。但是,由于多数研究中用于调控pH值的柠檬酸在高压高温下会降解为丙酮和乙酸等物质,影响了其催化效果[81]。同时,半纤维素等组分在水热炭化过程中也会产生乙酸等酸性物质,降低了初始pH值对HTC特性的影响[81]。因此有必要加强初始pH值以及反应过程中pH值的变化对沼渣HTC催化机制的研究。此外,液固比不仅能影响水热炭的性质,还与反应的能耗以及水相副产物的排放有直接关系[83]。较高的液固比有利于提高生物质的溶解性,但也导致能耗升高、水相副产物排放增加等问题。因此,需要综合考虑水热炭性能、反应能耗、副产物排放与处置等因素,调节HTC液固比。

现阶段沼渣基水热炭的应用研究主要集中在固体燃料与土壤改良方面。木质纤维素沼渣经过HTC处理后,其燃料品质有显著提升。一方面,HTC降解以脱水和脱羧为主,获得的水热炭热值高于相同温度慢速热解制备的生物炭[78,83]。Oliveira等[79]在180℃下获得的沼渣基水热炭热值即接近于褐煤,Mumme等[80]在270℃的水热温度下得到的水热炭热值甚至达到了35.7 MJ/kg(干燥无灰基);另一方面,HTC对生物质中碱/碱土金属有一定的脱除效果[84]。作者对玉米秸秆发酵沼渣在190~240℃的HTC试验研究表明,K和Na的去除率均超过80%,Ca与Mg的去除率在40%~60%之间[77]。碱/碱土金属的降低能够有利于缓解本文2.1中所述沼渣燃烧过程中潜在的结渣现象[85]。同时,沼渣经过水热炭化处理后,其疏水性、可磨性、脱水性与可流化性等均有明显提 升[26,79,86-87],能够有效降低其作为固体燃料在粉碎、储存以及干燥等阶段中的物质损耗与能量消耗。研究表明,相较于传统的生物质烘焙预处理,水热预处理能够节约30%~50%左右的能耗[88]。此外,作者在玉米秸秆发酵前后的HTC对比研究中发现,厌氧发酵过程相对富集了秸秆中的不溶性灰分,同时,增加了秸秆沼渣在水热转化体系中的水解倾向,从而在一定程度上降低与抑制了HTC在较高水热炭化温度下的脱灰性能与缩合反应[77]。因此,从固体燃料角度看,推荐选择较低的水热温度对秸秆沼渣进行水热炭化处理。

在农田施用方面,与热解炭相似,沼渣基水热炭也具有两面性。一方面,沼渣基水热炭富含N、P等营养元素,具有良好的土壤改良特性。Funke等[21]分析了小麦秸秆发酵沼渣水热炭化过程中N、P等营养元素的分布规律,60%~65%的N元素和77%~80%的P元素留存在水热炭中,其自身含量远高于沼渣中的N、P含量。Mumme等[80]通过分析比表面积与孔隙结构等沼渣基水热炭结构特性,也肯定了其土壤改良潜力。另一方面,水热炭的施用对周边环境也存在着一定的潜在生态风险。Busch 等[89]研究表明水热炭中存在一定的植物性毒素,不利于植物萌芽。Garlapalli等[66]的研究也表明水热炭含有较多的酚类物质和PAHs,直接施用不利于植物的生长。然而,水热炭经过生物处理或者高温热解等方式处理后,都可以有效消除其毒性[59, 89-90]。可见,水热炭的后处理过程是其在农田中安全施用的重要环节之一。

此外,也有学者对沼渣基水热炭作为活性炭前驱体的性能进行了研究。Catalina等[81]通过对秸秆、牧草和牛粪混合发酵沼渣进行水热炭化与KOH高温活化试验,获得的炭材料在CH4/CO2吸附试验中表现出极佳的选择吸附性,对CO2吸附量达到8.8 mol/kg(30℃/1.48 MPa),可以满足沼气中去除CO2的工艺需求。这也为沼渣基水热炭在沼气工程的“就地应用”策略提供了一种新的方式,用于沼气提纯。

整体来看,木质纤维素沼渣的HTC具有一定独特的优势,可忽略热转化前的干燥能耗,能够改善沼渣燃料品质和土壤改良特性,并展现出一定制备功能化炭材料的潜力。因此,有必要进一步加强木质纤维素沼渣HTC转化的相关理论研究,以指导优化厌氧发酵与HTC工艺参数。同时,HTC过程还会产出大量的水相产物,富含有机酸、糠醛等有机组分,也应重视这些副产物的应用研究,包括水相循环利用[91]、生物转化[92]等方式。

3 沼渣热化学转化应用的技术优势

根据上述文献调研,沼渣在燃烧、热解以及水热炭化等领域均表现出一定的应用潜力。针对木质纤维素生物质废弃物,可以很好的以沼渣为纽带将厌氧发酵技术与热化学转化技术进行有机结合。两种技术在能源利用效率、规模化处理以及产物内部循环等方面具有明显的互补优势。

3.1 提高生物质的能量利用效率

对木质纤维素沼渣进行合理的热化学转化利用可以有效提高生物质的能量利用效率,如图3[21,26,93]所示。厌氧发酵结合沼渣热解的整体利用效率较高,达到了85%[93]。然而,在热解转化过程中,沼渣中含有的大量水分显著增加了干燥能耗。Kratzeisen等[30]对两种不同沼渣制备成型燃料的能耗进行了估算,包括机械脱水、干燥与颗粒成型等阶段。其中,干燥阶段能耗所占比例达到了92%左右,两种沼渣基成型燃料的制备能耗与其低位热值的比值分别为0.74与0.78。Monlau等[75]则基于一个运营中的沼气热电联产项目,对沼渣热解的可行性进行了分析。结果显示,耦合沼渣热解工艺后,可以提高该沼气工程42%的产电能力。但是,沼渣(23.8 t/d)的日干燥能耗达到了13 249 kW·h,需要消耗大量的热能,不利于产电能力的进一步提高。相较于燃烧或热解,厌氧发酵结合沼渣HTC的整体能量利用效率相对较低,在65%~72%之间。然而,HTC转化过程中可完全避免前处理过程中的干燥能耗。而且由于水热炭化反应较温和、水热炭脱水性能较好等原因,HTC反应以及后续的水热炭干燥能耗较小,一般占比在水热炭总能量的7%~20%之间[21,94]。此外,Reza等[26]研究表明小麦秸秆厌氧发酵结合沼渣发酵的能量效率比单独HTC处理增加了20%,从能量利用效率来看,相较于原物料,小麦秸秆发酵沼渣更加适合作为水热炭化的原料。

图3 厌氧发酵与热转化技术结合的生物质能利用效率[21,26,93]

高含水率在一定程度上制约了木质纤维素沼渣的燃烧与热解应用。但是,沼渣经过干燥、成型等预处理后,燃烧和热解技术仍然可以实现其能量增益。而HTC技术,由于能够忽略沼渣干燥工艺,在能耗方面具有巨大优势。3.2 厌氧发酵沼渣规模化处理

随着大型沼气工程的发展,沼渣的产量非常巨大。Ravina等[95]研究表明,以牛粪和青贮玉米秸秆为发酵原料,日产14 000 m³左右沼气工程的沼渣日产量达到了80.5 t。传统的农用土地很难对如此巨量的沼渣进行消纳,亟需其他技术手段进行快速有效的处理。其中,燃烧是最简便有效的生物质能产业化应用方式,相关燃烧技术已经非常成熟;在热解方面,固定床、流化床以及下降管等热解工艺的规模化转化技术也已经相对成熟[96-97]。同时,HTC技术也表现出足够的规模化转化潜力[97-98]。

此外,由于木质纤维素生物质分布广泛、能量密度低,使得纤维素原料热化学转化技术产业化过程中的“收、储、运”成本较高,从而导致原本价格低廉的废弃生物质原料成本提高。以生物质热解液化技术为例,生物质收集半径的增加直接制约了热解液化设备的规模,原料供应问题凸显[99-100]。如果以大型沼气工程产生的沼渣为生物质热化学转化原料,则可大幅降低传统秸秆等木质纤维素生物质的收集与运输成本。赵胜雪等[101]研究表明,与常规生物质相比,沼渣成型燃料的生产成本可节省46.4%,销售净利润增加1倍。节省的成本主要来自于生物质原料的收集、运输与粉碎等环节。可见,在原料供应方面与生物质热化学转化技术能够很好地实现互补,有效提高经济效益。

3.3 高温处理降低沼渣的生物毒性

由于沼气工程是对包括玉米秸秆、畜禽粪便等在内的生物质废弃物进行厌氧处理,其产生的沼渣中含有大量的抗生素、农药、细菌、寄生虫和各种病原菌等。如果直接施用于农田中,这些有害物质会污染相关农业产品并对周边环境造成危害[14-15]。热化学转化过程中高温处理可以有效去除沼渣中具有生物毒性的物质[79]。目前,沼渣的利用主要在农业方面,如若能够通过热化学转化技术,在消除有害物质的同时,还能进一步提高其肥料或土壤改良特性,将对现阶段的沼渣利用具有重要的现实意义。

3.4 热化学转化产物具有与厌氧发酵技术结合循环利用的潜力

对沼渣进行合理的热化学转化,其产物具有极大的潜力可重新应用于沼气工程中。温度作为影响厌氧发酵产气特性的主要参数之一,严重制约了沼气工程在中国北方寒冷地区的正常运行[102]。通过对沼渣的热转化处理,其产生的高温烟气可循环应用于发酵罐的保温,以提高沼气工程的稳定性[103];沼渣燃烧灰渣以及热解生物炭对于沼液的净化作用也十分显著,这将有助于沼液的无害化处理[57,104];沼渣热解以及HTC过程中的水相产物也表现出良好的厌氧发酵产甲烷潜力[79,105]。这些沼渣燃烧、热解以及水热转化过程中的产物应用与厌氧发酵技术的结合,减少了生物质能源转化的二次污染,符合现阶段低碳循环的发展趋势,也将会极大地推动沼渣热化学转化技术的发展。

4 结论与展望

如何实现沼渣快速有效的规模化应用是目前推广大型沼气工程运营的关键问题之一。木质纤维素生物质产甲烷技术符合大型沼气工程的发展趋势,其产生的沼渣也具有极高的热化学转化潜力,在成型燃料燃烧、热解以及水热转化等领域均表现出一定的优势。而且,沼渣的热化学转化一旦与大型沼气工程形成有机结合,可显著提高生物质能利用效率,实现厌氧发酵过程中过量沼渣的无害化处理与资源化利用。这种生物质废弃物厌氧发酵与沼渣热化学转化相结合的应用模式将有利于促进中国生物质能源的产业化发展。

但是沼渣热转化应用,还面临着燃烧结渣与NOx排放、重金属和PAHs等有害组分积累以及大量干燥能耗等问题。今后建议在以下几点对沼渣的热化学转化应用进行研究:

1)优化木质纤维素生物质厌氧发酵的相关参数及工艺流程,以有机结合厌氧发酵过程与热化学转化过程。譬如,干发酵工艺可有效降低沼渣中的含水率,将有利于其燃烧或热解应用;不同的沼气发酵工艺及沼渣收集方式对沼渣生物炭特性也有显著影响[105]。针对不同发酵工艺的沼渣,在应用策略上应该有所改变,以提高厌氧发酵与沼渣热化学转化应用的适配性。

2)拓展木质纤维素类沼渣的热化学转化应用途径。建议开展沼渣的水热处理制备液体燃料或提取精细化工产品等相关研究,一方面能够解决热解中的干燥能耗问题,另一方面可以提高热转化产物的附加值。但是,目前沼渣水热液化研究还相对较少。Biller等[106]研究认为由于沼渣水热的生物油产率非常低(25%左右),厌氧发酵与水热液化技术的结合还存在一定问题。因此,需要加强沼渣的水热液化机理与反应过程调控等方面研究,提高沼渣水热处理的液相转化率。

3)对厌氧发酵技术与沼渣热转化技术的结合进行生命周期评估,全面掌握该模式下生物质转化过程中的环境影响,包含燃烧污染气体或HTC水相产物等废弃物的排放、物料和能源的消耗以及对环境可能造成的破坏作用。

4)基于产业化应用,开发新型规模化装置,加大专用设备研发力度。包括专用于木质纤维素沼渣沼液的分离装置,高效便捷的沼渣干燥、成型装置以及沼渣基生物质燃烧锅炉、连续式高温高压反应器等,并重点关注相关技术工业化产业链上下游的发展。同时,加深沼渣热化学转化产物的应用研究,包括将其转化为高品质的清洁能源、提取高附加值的化学品以及制备高性能的生物炭基材料等。

[1] 马隆龙,唐志华,汪丛伟,等. 生物质能研究现状及未来发展策略[J]. 中国科学院院刊,2019,34(4):434-442.

Ma Longlong, Tang Zhihua, Wang Congwei, et al. Research status and future development strategy of biomass energy[J]. Bulletin of Chinese Academy of Sciences, 2019, 34(4): 434-442.(in Chinese with English abstract)

[2] Wang F, Zhang D L, Wu H K, et al. Enhancing biogas production of corn stover by fast pyrolysis pretreatment[J]. Bioresource Technology, 2016, 218:731-736.

[3] Yu Q, Liu R H, Li K, et al. A review of crop straw pretreatment methods for biogas production by anaerobic digestion in China[J]. Renewable and Sustainable Energy Reviews, 2019, 107: 51-58.

[4] 朱颢,胡启春,汤晓玉,等. 我国农作物秸秆资源燃料化利用开发进展[J]. 中国沼气,2017,35(2):115-120.

Zhu Hao, Hu Qichun, Tang Xiaoyu,et al.Current development and progress of fuelization of agricultural straw in China[J].China Biogas, 2017, 35(2): 115-120. (in Chinese with English abstract)

[5] 杨茜,鞠美庭,李维尊. 秸秆厌氧消化产甲烷的研究进展[J]. 农业工程学报,2016,32(14):232-242.

Yang Qian, Ju Meiting, Li Weizun. Review of methane production from straws anaerobic digestion[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2016, 32(14): 232-242. (in Chinese with English abstract)

[6] 葛振,魏源送,刘建伟,等. 沼渣特性及其资源化利用探究[J]. 中国沼气,2014,32(3):74-82.

Ge Zhen, Wei Yuansong, Liu Jianwei, et al. Characteristics of digestate and utilization: An overview[J]. China Biogas, 2014, 32(3): 74-82. (in Chinese with English abstract)

[7] Monlau F, Sambusiti C, Ficara E, et al. New opportunities for agricultural digestate valorization: Current situation and perspectives[J]. Energy Environ. Sci. 2015, 8(9): 2600-2621.

[8] Sambusiti C, Ficara E, Malpei F, et al.Benefit of sodium hydroxide pretreatment of ensiled sorghum forageon the anaerobic reactor stability and methane production[J]. Bioresource technology, 2013, 144: 149-155.

[9] Andreas M A, Alexander S, Hans J H, et al. Impact of uncertainties on greenhouse gas mitigation potential of biogas production from agricultural resources[J]. Renewable Energy, 2012, 37(1): 277-284.

[10] Menardo S, Gioelli F, Balsari P. The methane yield of digestate: Effect of organic loading rate, hydraulic retention time, and plant feeding[J]. Bioresource technology, 2011, 102: 2348-2351.

[11] 吴媛媛,常旭宁,张佳维. 基于LCA方法的秸秆沼气发电和制备生物天然气的环境排放评价[J]. 中国沼气,2020,38(1):59-65.

Wu Yuanyuan, Chang Xuning, Zhang Jiawei, et al. Environmental emission evaluation for straw biogas power generation and bio-natural gas preparation based on LCA method[J]. China Biogas, 2020, 38(1): 59-65. (in Chinese with English abstract)

[12] Insam H, Gómez-Brandón M, Ascher J. Manure-based biogas fermentation residues – Friend or foe of soil fertility?[J]. Soil Biology and Biochemistry, 2015, 84: 1-14.

[13] He L, Zhu Q L, Wang Y W, et al. Irrigating digestate application increases Cd accumulation in pennisetum hybridum[J]. Chemosphere, 2021, 279: 130592.

[14] Natalia M, Romina R, Vanina C, et al. Potential use of a poultry manure digestate as a biofertiliser: Evaluation of soil properties andGrowth[J]. Pedosphere, 2019, 29(1): 60-69.

[15] Rasheed R, Yasar A, Wang Y, et al. Environmental impact and economic sustainability analysis of a novel anaerobic digestion waste-to-energy pilot plant in pakistan. Environmental Science and Pollution Research, 2019, 26(1): 26404-26417.

[16] Czatzkowska M, Harnisz M, Korzeniewska E, et al. Inhibitors of the methane fermentation process with particular emphasis on the microbiological aspect: A review[J]. Energy Science and Engineering, 2020, 8(33): 1880-1897.

[17] Fabbri D, Torri C. Linking pyrolysis and anaerobic digestion (Py-AD) for the conversion of lignocellulosic biomass[J]. Curr Opin Biotechnol, 2016, 38: 167-173.

[18] 牛红志,孔晓英,李连华,等. 厌氧发酵制备生物燃气过程的物质与能量转化效率[J]. 化工学报,2015,66(2):723-729.

Niu Hongzhi, Kong Xiaoying, Li Lianhua, et al. Material and energy conversion efficiency of biogas preparation process by anaerobic fermentation[J]. Journal of Chemical Industry and Engineering, 2015, 66(2): 723-729. (in Chinese with English abstract)

[19] 牛红志,孔晓英,李连华,等. 农业废弃物制备生物燃气过程的物质流分析[C]. 能源草产业发展战略暨学术研讨会论文集.中国草学会能源草类专业委员会,2014,9:194-202.

[20] 甄峰,孙永明,孔晓英,等. 杂交狼尾草厌氧发酵的物质与能量转化率分析[J]. 农业工程学报,2017,(19):236-241.

Zhen Feng, Sun Yongming, Kong Xiaoying, et al. Material and energy conversion efficiency of anaerobic fermentation process offor biogas[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2017, 33(19): 236-241. (in Chinese with English abstract)

[21] Funke A, Mumme J, Koon M, et al. Cascaded production of biogas and hydrochar from wheat straw: Energetic potential and recovery of carbon and plant nutrients[J]. Biomass and Bioenergy, 2013, 58: 229-237.

[22] 武斌. 生物沼气生产利用系统建模分析及可持续性评价[D]. 北京:中国科学院研究生院,2016.

Wu Bin. The Modeling Analysis and Sustainability Assessment of Biogas Production and Utilization System[D]. Beijing: University of Chinese Academy of Sciences, 2016. (in Chinese with English abstract)

[23] Li J, Kong C, Duan Q, et al. Mass flow and energy balance plus economic analysis of a full-scale biogas plant in the rice-wine-pig system[J]. Bioresour Technol, 2015, 193: 62-67.

[24] Zhang D L, Wang F, Yi W M, et al. Comparison study on pyrolysis characteristics and kinetics of corn stover and its digestate by TG-FTIR[J]. BioResources, 2017, 12(4): 8240-8254.

[25] Liang J, Lin Y, Wu S, et al. Enhancing the quality of bio-oil and selectivity of phenols compounds from pyrolysis of anaerobic digested rice straw[J]. Bioresour Technol, 2015, 181: 220-223.

[26] Reza M T, Werner M, Pohl M, et al. Evaluation of integrated anaerobic digestion and hydrothermal carbonization for bioenergy production[J]. J Vis Exp, 2014, 88, e51734.

[27] Reza M T, Borrego A, Wirth B. Optical texture of hydrochar from maize silage and maize silage digestate[J]. International Journal of Coal Geology, 2014, 134/135: 74-79.

[28] 刘丽雪,陈海涛,韩永俊. 沼渣物理特性及沼渣纤维化学成分测定与分析[J]. 农业工程学报,2010,26(7):277-280.

Liu Lixue, Chen Haitao, Han Yongjun. Determination and analysis of physical characteristics and fiber chemical composition of biogas residue[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2010, 26(7): 277-280. (in Chinese with English abstract)

[29] 蔡红珍,刘建彪,程卫东,等.立式柱塞冲压生物质成型机设计与试验[J].农业机械学报,2020,51(S2):435-441.

Cai Hongzhen, Liu Jianbiao, Cheng Weidong, et al. Design and experiment on vertical ram compression molding machine[J]. Transactions of the Chinese Society for Agricultural Machinery, 2020, 51(S2): 435-441. (in Chinese with English abstract)

[30] Kratzeisen M, Starcevic N, Martinov M, et al. Applicability of biogas digestate as solid fuel[J]. Fuel, 2010, 89(9): 2544-2548.

[31] 杨世关,肖婷,李继红,等. 秸秆厌氧发酵改性制备成型燃料试验[J]. 农业工程学报,2013,29(17):182-187.

Yang Shiguan, Xiao Ting, Li Jihong, et al. Densified biomass fuels production from crop straw pretreated by anaerobic fermentation[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2013, 29(17): 182-187. (in Chinese with English abstract)

[32] 闫芳. 玉米秸秆厌氧发酵及其沼渣与褐煤共制备生物质型煤研究[D].北京:中国石油大学(北京),2017.

Yan Fang. Preparation of Bio-briquette by Lignite and Digestate after Anaerobic Digestion of Corn Straw[D]. Beijing: China University of Petroleum (Beijing), 2017. (in Chinese with English abstract)

[33] 王雅君. 玉米秸秆低温热解规律与生物炭成型特性的研究[D]. 杨凌: 西北农林科技大学,2019.

Wang Yajun. Study on the Low Temperature Pyrolysis Mechanism of Corn Stalk and Densification Characteristic of Biochar[D]. Yangling: Northwest A&F University, 2019. (in Chinese with English abstract)

[34] Kaliyan N, Morey RV. Natural binders and solid bridge type binding mechanisms in briquettes and pellets made from corn stover and switchgrass[J]. Bioresour Technology, 2010, 101(3): 1082-1090.

[35] Li Y Q, Yan F, Li T, et al. High-solid anaerobic digestion of corn straw for methane production and pretreatment of bio-briquette[J]. Bioresour Technol, 2018, 250: 741-749.

[36] Pedrazzi S, Allesina G, Belló T, et al. Digestate as bio-fuel in domestic furnaces[J]. Fuel Processing Technology ,2015, 130: 172-178.

[37] 郭飞强,董玉平,董磊,等. 生物质成型燃料三次配风锅炉的设计及低NOx排放效果[J]. 农业工程学报,2012,28(14):42-46.

Guo Feiqiang, Dong Yuping, Dong Lei, et al. Design and low NOxemission effect of biomass briquette boiler with third air distribution type[J]. Transactions of the Chinese Society of Agricultural Engineering, 2012, 28(14): 42-46. (in Chinese with English abstract)

[38] 李亚猛,周雪花,胡建军,等. 生物质颗粒直燃炉灶设计与试验[J]. 农业机械学报,2017,48(10):280-285.

Li Yameng, Zhou Xuehua, Hu Jianjun, et al. Design and test of direct-fired stove using biomass pellet fuel[J]. Transactions of the Chinese Society for Agricultural Machinery, 2017, 48(10): 280-285. (in Chinese with English abstract)

[39] 张政清,张毅,高振强,等. 国内外中小型生物质燃烧设备排放标准比较研究[J]. 山东理工大学学报(自然科学版),2017,31(5):12-17.

Zhang Zhengqing, Zhang Yi, Gao Zhenqiang, et al. A comparative study on domestic and foreign emissionstandards[J]. Journal of Shandong University of Technology(Natural Science Edition), 2017, 31(5): 12-17. (in Chinese with English abstract)

[40] Chen G Y, Guo X, Cheng Z J, et al. Air gasification of biogas-derived digestate in a downdraft fixed bed gasifier[J]. Waste Manage, 2017, 69: 162-169.

[41] 付成果,田宜水,李十中,等. 水洗预处理对甜高粱茎秆酵渣燃料性能改善试验研究[J].太阳能学报,2017,38(1):78-84.

Fu Chengguo, Tian Yishui, Li Shizhong, et al. experimental study of fuel performance improvement on fermented residue of sweet sorghum stalk by water-washing pretreatmen[J]. Acta Energiae Solaris Sinica, 2017, 38(1): 78-84. (in Chinese with English abstract)

[42] Chen W H , Lin B J, Lin Y Y, et al. Progress in biomass torrefaction: Principles, applications and challenges[J]. Progress in Energy and Combustion Science, 2021, 82: 100887.

[43] Quang V B, Øyvind S. Upgrading biomass fuels via wet torrefaction: A review and comparison with dry torrefaction[J]. Renewable and Sustainable Energy Reviews, 2016, 54: 665-677.

[44] Cen K , Zhuang X , Gan Z , et al. Effect of the combined pretreatment of leaching and torrefaction on the production of bio-aromatics from rice straw via the shape selective catalytic fast pyrolysis[J]. Energy Reports, 2021, 7: 732-739.

[45] Wang S R, Dai G X, Yang H P, et al. Lignocellulosic biomass pyrolysis mechanism: A state-of-the-art review[J], Progress in Energy and Combustion Science, 2017, 62: 33-86.

[46] 杨昌炎,姚建中,林伟刚,等. 秸秆蒸汽汽爆、固态发酵处理结合快速热解制液体燃料[J]. 现代化工,2006(S1):126-130.

Yang Changyan, Yao Jianzhong, Lin Weigang, et al. A combination process of straw steam-explosion and solid-state fermentation with fast pyrolysis for producing liquid fuels[J]. Modern Chemical Industry, 2006(S1): 126-130. (in Chinese with English abstract)

[47] Neumann J, Meyer J, Ouadi M, et al.The conversion of anaerobic digestion waste into biofuels via a novel thermo-catalytic reforming process[J]. Waste Manage, 2016, 47(Part A): 141-148.

[48] Hossain A K, Serrano C, Brammer J B, et al. Combustion of fuel blends containing digestate pyrolysis oil in a multi-cylinder compression ignition engine[J]. Fuel, 2016, 171: 18-28.

[49] Liang S, Han Y, Wei L, et al. Production and characterization of bio-oil and bio-char from pyrolysis of potato peel wastes[J]. Biomass Conversion and Biorefinery, 2014, 5(3): 237-246.

[50] Wang T, Ye X, Yin J, et al. Effects of biopretreatment on pyrolysis behaviors of corn stalk by methanogen[J]. Bioresour Technol, 2014, 164: 416-419.

[51] Monlau F, Francavilla M, Sambusiti C, et al. Toward a functional integration of anaerobic digestion and pyrolysis for a sustainable resource management. Comparison between solid-digestate and its derived pyrochar as soil amendment[J]. Applied Energy, 2016, 169: 652-662.

[52] Inyang M, Gao B, Pullammanappallil P, et al. Biochar from anaerobically digested sugarcane bagasse[J]. Bioresour Technol, 2010, 101(22): 8868-8872.

[53] Stefaniuk M, Oleszczuk P. Characterization of biochars produced from residues from biogas production[J]. Journal of Analytical and Applied Pyrolysis, 2015, 115: 157-165.

[54] Yao Y, Gao B, Inyang M, et al. Biochar derived from anaerobically digested sugar beet tailings: characterization and phosphate removal potential[J]. Bioresour Technol, 2011, 102(10): 6273-6278.

[55] Inyang M, Gao B, Yao Y, et al. Removal of heavy metals from aqueous solution by biochars derived from anaerobically digested biomass[J]. Bioresour Technol, 2012, 110: 50-56.

[56] Fu D, Chen Z, Xia D, et al. A novel solid digestate-derived biochar-Cu NP composite activating H2O2system for simultaneous adsorption and degradation of tetracycline[J]. Environ Pollut, 2017, 221: 301-310.

[57] 郑杨清,郁强强,王海涛,等. 沼渣制备生物炭吸附沼液中氨氮[J]. 化工学报,2014,65(5):1856-1861.

Zheng Yangqing, Yu Qiangqiang, Wang Haitao, et al. Preparation of biochars from biogas residue and adsorption of ammonia-nitrogen in biogas slurry[J]. Journal of Chemical Industry and Engineering, 2014, 65(5): 1856-1861. (in Chinese with English abstract)

[58] Antoniou N, Monlau F, Sambusiti C, et al. Contribution to circular economy options of mixed agricultural wastes management: Coupling anaerobic digestion with gasification for enhanced energy and material recovery[J]. Journal of Cleaner Production, 2019, 209: 505-514.

[59] Freda C, Nanna F, Villone A, et al. Air gasification of digestate and its co-gasification with residual biomass in a pilot scale rotary kiln[J]. International Journal of Energy and Environmental Engineering, 2019, 10(3): 335-346.

[60] Guo X, Zhang Y, Guo Q, et al. Evaluation on energetic and economic benefits of the coupling anaerobic digestion and gasification from agricultural wastes[J]. Renewable Energy, 2021, 176: 494-503.

[61] Chang S, Zhang Z, Cao L, et al. Co-gasification of digestate and lignite in a downdraft fixed bed gasifier: Effect of temperature[J]. Energy Conversion and Management, 2020, 213: 112798.

[62] Namasivayam C, Kavitha D. Removal of Congo Red from water by adsorption onto activated carbon prepared from coir pith, an agricultural solid waste[J]. Dyes and Pigments, 2002, 54(1): 47-58.

[63] Monlau F, Francavilla M, Sambusiti C, et al. Toward a functional integration of anaerobic digestion and pyrolysis for a sustainable resource management. Comparison between solid-digestate and its derived pyrochar as soil amendment[J]. Applied Energy, 2016, 169: 652-662.

[64] Righi S, Bandini V, Marazza D, et al. Life Cycle Assessment of high ligno-cellulosic biomass pyrolysis coupledwith anaerobic digestion[J]. Bioresour Technol, 2016, 212: 245-253.

[65] Stefaniuk M, Oleszczuk P, Bartminski, P. Chemical and ecotoxicological evaluation of biochar produced from residues of biogas production[J]. J Hazard Mater, 2016, 318: 417-424.

[66] Garlapalli R K, Wirth B, Reza M T. Pyrolysis of hydrochar from digestate: Effect of hydrothermal carbonization and pyrolysis temperatures on pyrochar formation[J]. Bioresour Technol, 2016, 220: 168-174.

[67] Fernandez M, Puig M, Lopez D, et al. Life cycle assessment of swine and dairy manure: Pyrolysisand combustion processes[J]. Bioresour Technol, 2015, 182: 184-192.

[68] Yao Z, Li W, Kan X, et al. Anaerobic digestion and gasification hybrid system for potential energy recovery from yard waste and woody biomass[J]. Energy, 2017, 124: 133-145.

[69] Chen G Y, Guo X, Liu F, et al. Gasification of lignocellulosic biomass pretreated by anaerobic digestion (AD) process: An experimental study[J]. Fuel, 2019, 247: 324-333.

[70] Marchese M, Chesta S, Santarelli M, et al. Techno-economic feasibility of a biomass-to-X plant: Fischer-Tropsch wax synthesis from digestate gasification[J]. Energy, 2021, 228: 120581.

[71] 郭祥. 生物质厌氧发酵耦合热解气化试验研究与机理分析[D]. 天津:天津大学,2019.

Guo Xiang. Experimental Study and Mechanism Analysis on Integration of Anaerobic Fermentation and Pyrolytic Gasification from Biomass[D]. Tianjin: Tianjin University, 2019. (in Chinese with English abstract)

[72] Li X W, Mei Q Q, Dai X H, et al. Effect of anaerobic digestion on sequential pyrolysis kinetics of organic solid wastes using thermogravimetric analysis and distributed activation energy model[J]. Bioresour Technol, 2017, 227: 297-307.

[73] 王芳,张德俐,高子翔,等. 玉米秸秆及其发酵沼渣热解动力学研究[J]. 农业机械学报,2018,49(1):296-304.

Wang Fang, Zhang Deli, Gao Zixiang, et al. Kinetics of Pyrolysis of Corn Stover and Its Fermentation Residue[J]. Transactions of the Chinese Society for Agricultural Machinery, 2018, 49(1): 296-304. (in Chinese with English abstract)

[74] Chang S, Zhang Z, Cao L, et al. Interaction and kinetics study of the co-gasification of high-solid anaerobic digestate and lignite[J]. Molecules, 2020, 25(3): 459.

[75] Monlau F, Sambusiti C, Antoniou N, et al. A new concept for enhancing energy recovery from agricultural residues by coupling anaerobic digestion and pyrolysis process[J]. Applied Energy, 2015, 148: 32-38.

[76] Azzaz A A , Khiari B , Jellali S , et al. Hydrochars production, characterization and application for wastewater treatment: A review[J]. Renewable and Sustainable Energy Reviews, 2020, 127: 109882.

[77] Zhang D, Wang F, Shen X, et al. Comparison study on fuel properties of hydrochars produced from corn stalk and corn stalk digestate[J]. Energy, 2018, 165(15): 527-536.

[78] Zhang D, Wang F, Zhang A, et al. Effect of pretreatment on chemical characteristic and thermal degradation behavior of corn stalk digestate: Comparison of dry and wet torrefaction[J]. Bioresour Technol, 2019, 275: 239-246.

[79] Oliveira I, Blohse D, Ramke H G. Hydrothermal carbonization of agricultural residues[J]. Bioresour Technol, 2013, 142: 138-146.

[80] Mumme J, Eckervogt L, Pielert J, et al. Hydrothermal carbonization of anaerobically digested maize silage[J]. Bioresour Technol, 2011, 102(19): 9255-9260.

[81] Catalina R C, Bernardo M, Ribeiro R, et al. Evaluation of hydrothermal carbonization as a preliminary step for the production of functional materials from biogas digestate[J]. Journal of Analytical and Applied Pyrolysis, 2017, 124: 461-474.

[82] Volpe M, Goldfarb J, Fiori L. Hydrothermal carbonization of Opuntia ficus-indica cladodes: Role of process parameters on hydrochar properties[J]. Bioresour Technol, 2018, 247: 310-318.

[83] Libra J A, Ro K S, Kammann C, et al. Hydrothermal carbonization of biomass residuals: A comparative review of the chemistry, processes and applications of wet and dry pyrolysis[J]. Biofuels 2011, 2: 71-106.

[84] Zhang S, Su Y, Ding K, et al. Impacts and release characteristics of K and Mg contained in rice husk during torrefaction process[J]. Energy, 2019, 186(1): 115888.

[85] 霍丽丽,赵立欣,郝彦辉,等. 国内外生物质成型燃料质量标准现状[J]. 农业工程学报,2020,36(9):245-254.

Huo Lili, Zhao Lixin, Hao Yanhui, et al. Quality standard system of densified biomass fuels at home and abroad[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2020, 36(9): 245-254. (in Chinese with English abstract)

[86] Zhuang X, Zhan H, Song Y, et al. Structure-reactivity relationships of biowaste-derived hydrochar on subsequent pyrolysis and gasification performance[J]. Energy Conversion and Management, 2019, 199: 112014.

[87] Aguado R , Cuevas M , L Pérez-Villarejo, et al. Upgrading almond-tree pruning as a biofuel via wet torrefaction[J]. Renewable Energy, 2020, 145: 2091-2100.

[88] Benavente V, Calabuig E, Fullana A. Upgrading of moist agro-industrial wastes by hydrothermal carbonization[J]. J Anal Appl Pyrolysis, 2015, 113: 89-98.

[89] Busch D, Stark A , Kammann C I, et al. Genotoxic and phytotoxic risk assessment of fresh and treated hydrochar from hydrothermal carbonization compared to biochar from pyrolysis[J]. Ecotoxicology & Environmental Safety, 2013, 97: 59-66.

[90] 吴艳姣,李伟,吴琼,等. 水热炭的制备、性质及应用[J]. 化学进展,2016,28(1):121-130.

Wu Yanjiao, Li Wei, Wu Qiong, et al. Preparation, properties and applications of hydrochar[J]. Progress in Chemistry, 2016, 28(1): 121-130. (in Chinese with English abstract)

[91] Ghaziaskar A, McRae G, Mackintosh A, et al. Catalyzed Hydrothermal Carbonization with Process Liquid Recycling[J]. Energy Fuels, 2019, 33: 1167-1174.

[92] Wang F, Yi W M, Zhang D L, et al. Anaerobic co-digestion of corn stover and wastewater from hydrothermal carbonation[J]. Bioresource Technology, 2020, 315: 123788.

[93] Li Y, Zhang R, He Y, et al. Anaerobic co-digestion of chicken manure and corn stover in batch and Continuously Stirred Tank Reactor (CSTR) [J]. Bioresour Technol, 2014, 156: 342-347.

[94] He C, Tang C Y, Li C H, et al. Wet torrefaction of biomass for high quality solid fuel production: A review[J]. Renewable and Sustainable Energy Reviews, 2018, 91: 259-271.

[95] Ravina M, Genon G. Global and local emissions of a biogas plant considering the production of biomethane as an alternative end-use solution[J]. Journal of Cleaner Production, 2015, 102: 115-126.

[96] Li Z H, Li N, Yi W M, et al. Design and operation of a down-tube reactor demonstration plant for biomass fast pyrolysis[J]. Fuel Processing Technology, 2017, 161: 182-192.

[97] Fu P, Yi W M, Li Z H, et al. Comparative study on fast pyrolysis of agricultural straw residues based on heat carrier circulation heating[J]. Bioresour Technol, 2019, 271: 136-142.

[98] Zhang Z M, Yang J T, Qian J Q, et al. Biowaste hydrothermal carbonization for hydrochar valorization: Skeleton structure, conversion pathways and clean biofuel applications[J]. Bioresour Technol, 2021, 324: 124686.

[99] 朱锡锋,朱建萍. 生物质热解液化技术经济分析[J]. 能源工程,2004,6:32-34.

Zhu Xifeng, Zhu Jianping. Economical analysis on the technology of biomass pyrolysis[J]. Energy Engineering, 2004, 6: 32-34. (in Chinese with English abstract)

[100]魏庭玉. 木质纤维素类生物质转化为液体燃料的能源-环境-经济综合评价[D]. 杭州:浙江大学,2020.

Wei Tingyu. Integrated Energy-environment-economy Assessment of Biofuel from Lignocellulose[D]. Hangzhou: Zhejiang University, 2020. (in Chinese with English abstract)

[101]赵胜雪,赵越,康可新,等. 秸秆气固燃料二元联产的可行性与经济性研究[J]. 太阳能学报,2020,41(1):186-191.

Zhao Shengxue, Zhao Yue, Kang Kexin, et al. Dualistic co-production of strawgas-solid fuel: focus on feasibilityand economy[J]. Acta Energiae Solaris Sinica, 2020, 41(1): 186-191. (in Chinese with English abstract)

[102]寇巍,张欢,孙玉辉,等. 寒冷地区沼气工程增温保温能量效益分析[J]. 太阳能学报,2015,36(3):708-713.

Kou Wei, Zhang Huan, Sun Yuhui, et al. Energy efficiency analysis of insulation and warming for biogas engineering in coldarea[J]. Acta Energiae Solaris Sinica, 2015, 36(3): 708-713. (in Chinese with English abstract)

[103]浦绍瑞,钱红亮,马春燕,等. 畜禽粪便高温发酵与秸秆热化学处理工艺的耦合[J]. 化工学报,2015,66(6): 2220-2226.

Pu Shaorui, Qian Hongliang, Ma Chunyan, et al. Coupling between thermophilic fermentation of livestock manure and thermochemical treatment of straw[J].Journal of Chemical Industry and Engineering, 2015, 66(6): 2220-2226.

[104]李刚,崔燕平,李玲,等. 生物质灰渣特性及其对沼液净化的试验研究[J]. 河南农业大学学报,2016,50(3): 331-335.

Li Gang, Cui Yanping, Li Ling, et al. Characteristics of biomass ash and its application in digested slurry purification[J]. Journal of Henan Agricultural University, 2016, 50(3): 331-335. (in Chinese with English abstract)

[105]Hubner T, Mumme J. Integration of pyrolysis and anaerobic digestion-use of aqueous liquor from digestate pyrolysis for biogas production[J]. Bioresour Technol, 2015, 183: 86-92.

[106]Biller P, Lawson D, Madsen R B, et al. Assessment of agricultural crops and natural vegetation in Scotland for energy production by anaerobic digestion and hydrothermal liquefaction[J]. Biomass Conversion and Biorefinery, 2016, 7(4): 467-477.

Thermochemical conversion and utilization of digestates from anaerobic digestion of lignocellulosic biomass

Zhang Deli, Wang Fang※, Yi Weiming, Li Zhihe, Li Yongjun, Liu Shanjian

(1.255000; 2255000)

Anaerobic digestion can be widely used to convert the lignocellulosic biomass into biogas, particularly with the by-product digestates. A large amount of digestate discharge has been one of the most limiting factors for the promotion and application of anaerobic digestion, with the development of large-scale biogas engineering in recent years. It is highly urgent to rapidly and effectively treat the digestate. Alternatively, the thermochemical conversion can be selected to realize the harmless treatment and resource utilization of lignocellulosic digestates. The digestates still retain most of the carbon elements and energy in the original material before digestion. The content of lignocellulosic is also very considerable for a large potential of thermochemical conversion. Therefore, this review aims to focus on the digestates forming fuel, pyrolysis, and hydrothermal carbonization. The forming performance of digestates was better than that before digestion, but the NOx emission and slagging phenomenon during the combustion were outstanding to be monitored and controlled. In pyrolysis, the lignocellulosic digestates presented the application potential in the preparation of liquid fuels, phenolic compounds, carbon-based adsorbents, soil amendments, and syngas synthesis. Specifically, the digestate derived bio-oil behaved a much higher calorific value while a lower acid content, where the relative content of 4-vinylphenol reached 60.9%. The pore structure of the biochar was also developed to contain more nutrients, such as P and K. The gaseous product presented a more suitable H2to CO molar ratio with less tar. However, the conversion application in the combustion and pyrolysis was confined to the drying energy consumption caused by the high water content of digestates. In comparison, the drying energy consumption was ignored before hydrothermal carbonization. At the same time, hydrothermal carbonization was used to improve the quality of digestates fuel, including the removal of alkali and alkaline earth metals, the higher calorific value, as well as the improved hydrophobicity, grindability, and fluidizability. Another potential was to prepare the functionalized carbon materials for soil improvement. But, there were still some challenges to the disposal of water phase products after hydrothermal carbonization. In addition, the potential ecological hazards of biochar and hydrochar derived from digestates for farmland application also needed to be paid enough attention, including heavy metals, and polycyclic aromatic hydrocarbons. Overall, the anaerobic digestion and thermochemical conversion presented complementary advantages in energy utilization efficiency, large-scale treatment, and the removal of biotoxicity. Additionally, the thermochemical conversion products of digestates also showed great potential for recycling in anaerobic digestion processes. For instance, the high-temperature flue gas produced by combustion can be recycled to the insulation of the biogas engineering, while the ash residue and biochar can be used to purify the biogas slurry, and the water-phase by-products also have a certain methane production potential. Consequently, a combination of lignocellulosic biomass anaerobic digestion and digestates thermochemical conversion can greatly contribute to the promotion and application of large-scale biogas engineering.

biomass; anaerobic digestion; pyrolysis; digestate; combustion; hydrothermal carbonization

10.11975/j.issn.1002-6819.2021.21.026

TK6

A

1002-6819(2021)-21-0225-12

张德俐,王芳,易维明,等.木质纤维素生物质厌氧发酵沼渣热化学转化利用研究进展[J]. 农业工程学报,2021,37(21):225-236.doi:10.11975/j.issn.1002-6819.2021.21.026 http://www.tcsae.org

Zhang Deli, Wang Fang, Yi Weiming, et al. Thermochemicalconversion and utilization of digestates from anaerobic digestion of lignocellulosic biomass[J]. Transactions of the Chinese Society of Agricultural Engineering (Transactions of the CSAE), 2021, 37(21): 225-236. (in Chinese with English abstract) doi:10.11975/j.issn.1002-6819.2021.21.026 http://www.tcsae.org

2021-06-21

2021-10-17

国家重点研发计划项目(2019YFD1100602);国家自然科学基金(51536009);山东省自然科学基金(ZR2019BEE049)

张德俐,博士,讲师,研究方向为生物质能源与材料。Email:zhangdeli@sdut.edu.cn。

王芳,博士,讲师,研究方向为生物质能生物化学与热化学转化技术。Email:wangfang1987711@126.com