Feature Extraction Approach for Defect lnspection in Eddy Current Pulsed Thermography

Pei-Pei Zhu | Li-Bing Bai| Yu-Hua Cheng

Abstract—The eddy current pulsed thermography (ECPT) technique is a research focus in the non-destructive testing (NDT) area for defect inspection.Defect feature extraction for defect information analysis in ECPT is limited by image contrast,heat diffusion,background interference,etc.In this paper,a defect feature extraction approach in ECPT has been proposed to improve the quality of defect features,which is based on image partition,local sparse component evaluation,and feature fusion.This method can extract complete defect features by enhancing the defect area and removing background interference,such as noises and heating coil.Two typical steel specimens are utilized to testify the validity of the proposed approach.Compared with other three common feature extraction algorithms in ECPT,the proposed method can reserve more complete defect features and suppress more background interference.

Index Terms—Eddy current thermography,feature extraction,machine learning,non-destructive testing (NDT).

1.lntroduction

The non-destructive testing (NDT) technique is widely used in examining,testing,or evaluating the absence or presence of continuities or discontinuities of materials without influencing usefulness and the service of systems[1],[2].Eddy current pulsed thermography (ECPT) based on electromagnetic induction and infrared thermography,is a research focus in the NDT area and has been widely utilized for defect inspection with high efficiency in metal,carbon fiber material,etc.[3],[4].In ECPT,the eddy current induced by the alternating current is transformed to the Joule heat in the testing material and the infrared camera records its surface temperature distribution[5],[6].The infrared camera records the heating and the cooling phases of the testing material in the form of images.The existence of defects will disturb the eddy current and form a nonuniform temperature distribution in the material.Defect information,which is included in the infrared thermal images,can be extracted by feature extraction methods.

Many researchers have worked on defect feature extraction in ECPT for defect inspection[7]-[9].As two widely used methods in the transform domain,the Fourier transform (FT)[10]and wavelet analysis[11]have been researched in ECPT for feature extraction.In [12],FT has been used in the improvement of blister detection based on ECPT.The result shows that the phase images from FT can improve the detectability of the blister defect.In [13],the wavelet transform has selected a specific frame to maximize the contrast of thermal variation and defect the pattern from complex structure samples.As statistical methods,the principal component analysis (PCA) and independent component analysis (ICA) are the most widely used approaches in ECPT for defect feature extraction[14],[15].PCA has been utilized to extract the significant defect features[16]and evaluate the defect depth in [17].ICA has been used to construct the automatic defect identification system in [18].Chenget al.[19]have integrated PCA and ICA to identify the impact damage in carbon fiber reinforced plastic samples.Baiet al.[20]have discussed the mathematical and physical meanings of PCA and ICA in ECPT.In the conclusion of [20],the author indicated that ICA can present the abnormal patterns more concentrated than PCA in ECPT image enhancement.However,these feature extraction methods separate the extracted features into different components and require artificial operations for feature selection.These limitations decrease the integrity of defect features and the accuracy of the defect analysis.In [21],the usefulness of sparse decomposition in feature extraction in ECPT has been researched and one unsupervised sparse pattern diagnostic method has been proposed.The proposed method based on the sparse decomposition can extract the defect feature in one image and achieve superior enhancement.However,this method loses so much defect information,which brings a big challenge for the further analysis.In order to improve the accuracy of defect feature extraction,Zhuet al.[22]have proposed a method based on the local sparseness and image fusion to improve the integrity of defect features in the feature image.According to the experimental results,this method still has problems in enhancing defect features,which is not significant in the heating phase.

In this paper,a novel defect feature extraction approach including image partition,local sparse component evaluation,and image fusion is proposed to improve the integrity of defect features and suppress background interference.In this approach,the recorded images are partitioned into two parts according the end of the heating time.The local sparse component has been evaluated to extract more defect information for further quantitative analysis.Moreover,feature fusion is utilized to integrate extracted the local sparse components to construct one feature image.Compared with ICA,the sparse decomposition algorithm,and the local sparse and low rank decomposition (LSLD) method in [22],the proposed approach can reserve more significant defect features,which is helpful for further processing.

The rest paper is organized as follows:Section 2 presents details of the developed model.Section 3 introduces the experimental setup and data collection.Section 4 shows the experimental results and discussion.Section 5 concludes the work.

2.Theory and Method

2.1.Two Thermal Phases in ECPT

In the ECPT,eddy currents in the sample are transformed into the Joule heat and the heated sample presents a non-uniform surface temperature distribution if a defect exists.Combined with principles of ECPT,the image sequence recorded by infrared for defect inspection can be separated into two phases:The heating phase and the cooling phase.In the heating phase,the Joule heatQtransferred by the eddy current is proportional to the square of the electric current densityJS.It can be expressed as

whereσis the electric conductivity andEis the electric field intensity.The electric conductivityσis determined by

whereσ0is the conductivity at the reference temperatureT0andαis the temperature coefficient of resistivity.In the heating phase,the thermal conduction can be neglected and the surface temperature is determined by the generated resistive heatQ.Therefore,the surface temperature can indicate the feature of defects immediately when the defect influences the distribution of the induced eddy current in the heating phase.The collected images in the heating phase can be used to extract defect information without considering the influence of heat diffusion.

In the cooling phase,the thermal conduction of a testing sample should take both the heat diffusion and the Joule heating into account.The thermal conduction in the cooling phase can be represented as

whereT=T(x,y,z,t) is the temperature distribution,λis the thermal conductivity of the material,ρis the density,CPis the specific heat,andq(x,y,z,t) is the heat generation function per unit volume.

In the cooling phase,the Joule heat transfers from the high-temperature area to the low-temperature region.Some defect areas,which have not been heated and shown no defect feature in the heating phase,can be revealed by the thermal conduction in the cooling phase.However,the heat diffusion,which mainly happens in the cooling phase,will decrease the thermal contrast between the defect and defect-free areas during the thermal conduction.How to avoid this negative influence for the improvement of defect feature extraction is worth of research.In the previous work,feature extraction methods in ECPT,such as PCA,ICA,the Fourier transform,and LSLD,regard the image sequence as integrity.The heat diffusion decreases the image contrast and impedes accurate defect feature extraction.In this paper,the thermal images have been partitioned into two parts for the improvement of defect feature evaluation according to two different thermal phases.

2.2.lmage Partition and Selection

As shown in (1) and (3),two different thermal phases record the surface temperature distribution of the inspection.Heat diffusion in the cooling phase decreases the thermal contrast in the image sequence.Therefore,in order to analyze defect data accurately,images in two thermal phases will be processed separately in this paper.Denote one recorded image sequence as y={y1y2},where y1means the heating phase and y2is the cooling phase.Firstly,image entropy difference is separately used to select significant images from two thermal phases.Compute entropy difference between two adjacent images in the same thermal phase

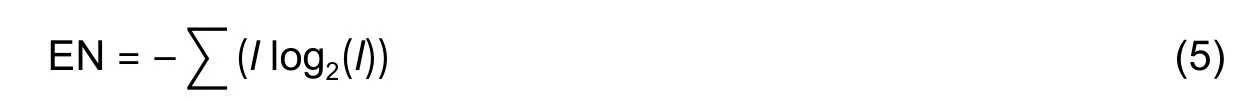

wherep=1 and 2,means theith image’s image entropy in yp,which is defined as

wherelis the probability of the current pixel gray value number in all the number of the pixels.In each thermal phase,sort all the entropy gradientsfrom large to small and then take outFimages with theFlargestfor the future analyzing.

Moreover,initial thermal images in ECPT are polluted by noises.The robust principal components analysis (RPCA) algorithm is utilized to denoise selected images based on the sparsity of the Gaussian noise.The RPCA algorithm can separate one selected imageypinto two components:The low-rank component in thepth thermal phaseLpand the sparse component in thepth thermal phaseSp:

The Gaussian noise in the thermal image is included in the sparse component.Reserve the low-rank component as the input for future processing.Solving (6) is equivalent to optimize the following convex optimization problem:

where ∣∣⋅∣∣∗is the nuclear norm,∣∣⋅∣∣1denotes the sum of the absolute values ofS,andηis a positive parameter.

2.3.Local Sparse Component Evaluation Based on Partitioned lmage Selection

Images in the different thermal phases have been partitioned into two parts to be selected and denoised.After the preprocessing procedure,local sparse component decomposition[22]is developed to separate thermal features of defects from the background area under different scales for the selected image.Combined with the previous research result[23],this problem can be denoted as

wheredenotes the local thermal feature ofLpin theith scale,(⋅) is a block reshape operator and extracts a block from the image matrix,and r ank(⋅) denotes the rank of matrix.Specifically,when two scales are used(S=2) and setm1=1 andn1=1,(8) can be rewritten as

where SVT(·) is the soft-threshold operator[24],WiandViare intermediate variables,andβis the alternating direction method of multipliers (ADMM) parameter which only influences the convergence rate.

2.4.Local Sparse Components Fusion

In this procedure,Fimages selected from two thermal phases are processed by the local sparse component evaluation algorithm to evaluate their local sparse components.A new image fusion criterion is defined in this paper to integrate different local sparse components into a complete feature image.Define a thresholdτ.In order to suppress background interference,the pixels of the evaluated local sparse components are processed by the thresholdτas follows:

where FL is the final feature image of the recorded thermal image sequence.Fig.1shows the whole procedure of the proposed method.

3.Experimental Dataset

Fig.2shows the experimental schematic diagram of the ECPT technique in this paper.The experimental setup mainly includes five functional units.The induction heater,which produces a highfrequency alternating current,is utilized for coil excitation.The sample is heated by a rectangular coil applying directional excitation.The infrared camera records the surface heat distribution of the sample.Shown inFig.3,the experimental data of the first steel sample (Sample 1) with a slot defect is recorded in the digital form by the infrared camera(the frame rate is 383 Hz)[20],[24].The second steel sample (Sample 2) includes a hole defect.The infrared camera with the 50-Hz sampling rate records its surface temperature values into the thermal image sequence.For Sample 1,200 thermal images have been collected for defect feature analysis.For Sample 2,305 thermal images have been used to testify the proposed method.Fig.4shows some temperature variation curves of several positions in the samples.

Fig.1.Proposed algorithm diagram.

Fig.2.Experimental schematic diagram.

Fig.3.Experimental samples:(a) Sample 1 and (b) Sample 2.

Fig.4.Temperature variation curves of several pixels (arrows) in thermal images (vertical dashed in the figure is the end of heating time):(a) thermal image of Sample 1,(b) temperature curve of Sample 1,(c) thermal image of Sample 2,and(d) temperature curve of Sample 2.

4.Results and Discussion

In this paper,a defect feature extraction method,which mainly includes partitioned image selection,local sparse component evaluation,and component fusion,has been proposed to improve defect inspection accuracy.Two samples,which represent two typical surface defect types,have been utilized to testify the proposed method.In the first sample,the ends of the slot are heated by the induced eddy current in the heating phase and the sides of the slot show significant thermal contrast in the cooling phase.In the second sample,the partial hole defect presents prominent thermal contrast in the heating phase and other defect areas are enhanced in the cooling phase by the thermal conduction.That is to say,the main defect features are usually highlighted in two different thermal phases.Therefore,according to the end of the heating time,thermal images are divided into two parts to concentrate on different thermal distribution features in different thermal phases.Select a segment of image data from each thermal phase.Image entropy,which can measure the richness of information,is used to selectF(F=4) significant thermal images from the segment of image data in each thermal phase.Fig.5shows the image entropy difference of two samples.Four images with the top 4 largest entropy differences in the heating phase have been selected for the local sparse component evaluation (as shown by the arrows in the figure).In the same way,four images in the cooling phase,whose entropy differences are the top 4 largest,have been selected and extracted their local sparse components.

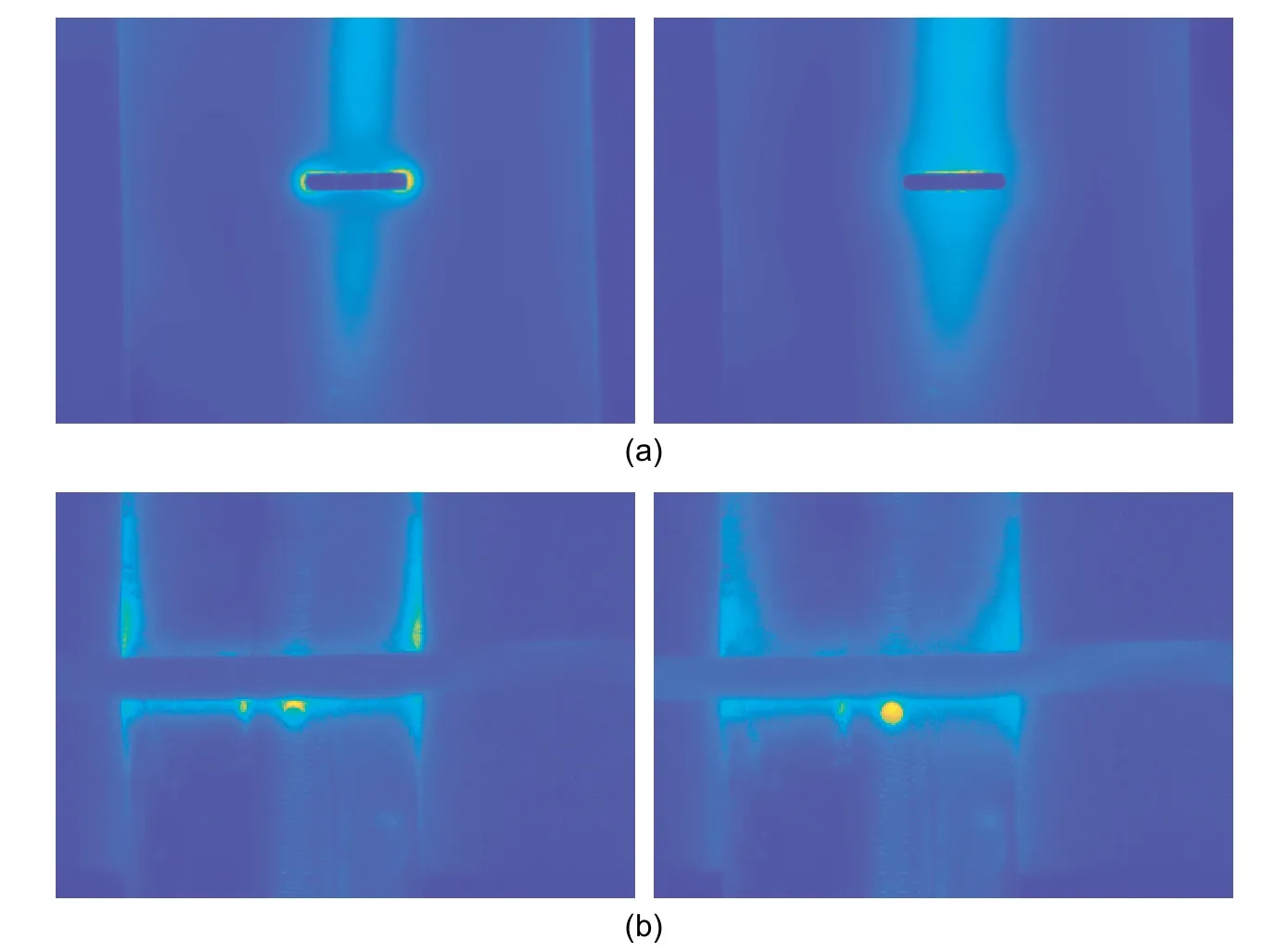

Fig.6presents RPCA’s results of some selected images of two samples for denoising before the local sparse component evaluation.It can be seen that the low-rank components reserve the principal information of the images in different thermal phases.Two ends of the slot in Sample 1,which have significant thermal contrast in the heating phase,are reserved in the component.The significant thermal information of two sides of the slot are also reserved in the component in the cooling phase.In the second sample,the thermal features of the hole,which are highlighted in different thermal phases,are separately extracted from images.Then,save the low-rank components and put them into the local sparse component evaluation algorithm.

Fig.5.Entropy difference of images of two samples:(a) entropy difference of images in the heating (left) and cooling(right) phases for Sample 1,and (b) entropy difference of images in the heating (left) and cooling (right) phases for Sample 2.

Fig.6.RPCA results of Sample 1 and Sample 2:(a) the low-rank component of one image to Sample 1,left: In the heating phase and right:In the cooling phase and (b) the low-rank component of one image to Sample 2,left:In the heating phase and right:In the cooling phase.

In order to present the procedure of the whole method,Fig.7shows the procedure of the proposed local sparse component evaluation based on partitioned images of Sample 1.FromFig.7,it can be seen that the defect profile of Sample 1 is highlighted in the fused local sparse component.The background information,including heating coil and the lift-off effect,is restrained in the defect feature component.The ends of the slot defect are extracted from the images in the heating phase and the sides of the slot presented in the cooling phase are enhanced in the fused feature image.

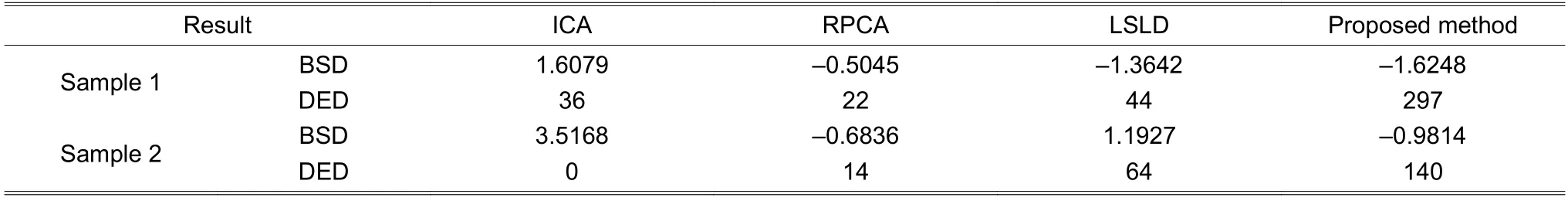

Compared with other three feature extraction methods in ECPT,the developed method shows better performance in the integrity of the defect feature and background suppression,as shown inFig.8.In ICA,the independent component which the algorithm has enhanced the defect area,cannot extract complete defect information and suppress the background well.Though the sparse decomposition implemented by RPCA can suppress background well,the most defect features are lost and cannot be used to further processing.The LSLD method proposed in [22] does not consider the thermal phases in the local sparse component evaluation and the defect features in the cooling phase had been missed.In the developed method in this paper,image partition in the thermal phase has been added in the local sparse component evaluation and the image fusion criterion has been improved.The experimental results show that the proposed method can extract the most complete defect features and suppress the background well compared with other three methods in ECPT.

Fig.7.Processing procedure of Sample 1.

Fig.8.Result comparison of four algorithms.

In [22],the authors have proposed two indicators to measure the degree of background suppressing(BSD) and defect enhancing degree (DED).BSD is calculated by the entropy of the background area.Less BSD means better background suppressing.DED is equal to the number of pixels,which highlights the defect area.In order to measure the performance of the proposed method,BSD and DED have been calculated for two samples in four algorithms,shown inTable 1.The thresholdτin DED is set as 20 in two samples.Compared with ICA,RPCA,and LSLD,feature images extracted by the proposed method has the smallest BSD value and the largest DED value in two samples.This result indicates that the proposed method in this paper has superior performance in background suppressing and defect enhancing.

Table 1:BSD and DED of two samples under different algorithms

5.Conclusions

In this paper,a feature extraction method based on image partition,local sparse component evaluation,and image fusion has been proposed to enhance defect features and suppress background interference in ECPT.This developed method optimizes the LSLD method in the authors’ previous work in [22].Compared with other three feature extraction algorithms:ICA,RPCA,and LSLD,the proposed method can reserve more defect features and suppress the influence of background interference preferably.

Future work will focus on developing this proposed method to detect the multi-defects and analyze quantitative defect information.

Disclosures

The authors declare no conflicts of interest.

Journal of Electronic Science and Technology2021年4期

Journal of Electronic Science and Technology2021年4期

- Journal of Electronic Science and Technology的其它文章

- lmpact of Fiber Dispersion on Performance of Entanglement-Based Dispersive Optics Quantum Key Distribution

- Effect of lmpeller Solidity on the Generating Performance for Solar Power Generation

- Effects of Material and Dimension on TCF,Frequency,and Q of Radial Contour Mode AlN-on-Si MEMS Resonators

- Large-Capacity and High-Speed lnstruction Cache Based on Divide-by-2 Memory Banks

- Effect of Wall Thicknesses on Broadband Design of Ka-Band TE21-Mode Coupler

- Device-Free Through-the-Wall Activity Recognition Using Bi-Directional Long Short-Term Memory and WiFi Channel State lnformation