Study on Physicochemical Properties and Surface Properties of Biochar from Different Materials

Xue YANG Huihe LI

Abstract [Objectives] This study was conducted to explore the differences in physicochemical properties and surface properties of biochar from different sources.

[Methods]Four kinds of materials including rice husk and corn straw were prepared at 450 ℃ by the limited-oxygen program temperature control method into biochar, and the differences in physicochemical properties and surface properties of the biochar from different sources were studied.

[Results] All four kinds of biochar were alkaline (pH=8.7-10.0). Corn straw biochar had the highest organic carbon content (653.6 g/kg), while rice husk biochar had the lowest organic carbon content (486.1 g/kg). Corn straw biochar had the highest nitrogen content (2.7%), while rice husk biochar had the lowest nitrogen content (0.75%). Corn straw biochar had the highest total phosphorus content (5.64 g/kg), while rice husk biochar had the lowest total phosphorus content (1.1 g/kg). Rice straw biochar had the highest total potassium content (53.1 g/kg), while rice husk biochar had the lowest total potassium content (10.6 g/kg). The four types of biochar were all porous, but their pore structure sizes and shapes were different to certain degrees. The order of the specific surface areas of the four types of biochar was rice stalk biochar>corn stalk biochar>wheat stalk biochar>rice husk biochar; the order of the pore volumes was rice stalk biochar>corn stalk biochar>wheat stalk biochar Charcoal>rice husk biochar; and the pore sizes ranked as wheat stalk biochar>corn stalk biochar>rice husk biochar>rice stalk biochar. The biochar from different sources ranked according to the comprehensive evaluation of all indicators as corn straw biochar>wheat straw biochar>rice straw biochar>rice husk biochar.

[Conclusions]This study provides reference data for the preparation process of biochar from industrial and agricultural wastes and its application and promotion.

Key words Biochar; Physicochemical properties; Morphological structure; Specific surface area; Pore volume; Pore size

Received: April 23, 2021 Accepted: June 20, 2021

Supported by General Project of Chongqing Technology Innovation and Application Demonstration (Social Peoples Livelihood) (cstc2018jscx-msybX0215); Science and Technology Planning Project of Kaizhou District, Chongqing City (KZKJ-2020-J-10).

Xue YANG (1994-), female, P. R. China, major: food science and engineering.

*Corresponding author. Huihe LI (1977-), male, P. R. China, professor, PhD, devoted to research about plant nutrition and quality, plant nutrition and environmental ecology. E-mail: lihuihe@163.com.

Biochar is a kind of stable, highly-aromatized and carbon-rich solid matter (such as crop waste, wood, plant tissue, animal bones, etc.) produced by pyrolysis (usually≤700 ℃) under complete or partially anoxic conditions[1-4]. Biochar contains stable carbon elements, mainly composed of aromatic hydrocarbons and elemental carbon or carbon with a graphite-like structure, and has good chemical stability and resistance to biological decomposition[5]. The technology of biochar preparation is relatively mature, and has a wide range of raw material sources which are produced abundantly. The raw material sources mainly include organic wastes such as sludge and garbage generated in urban life and industry, and agricultural and forestry wastes such as husks, straws, wood chips, and branches. Therefore, biochar has a stable structure, low price and low pollution, and has certain advantages compared with other materials[6-7]. Biochar has a unique structure and physical and chemical properties, and has attracted attention for its rich material sources and wide application value. Therefore, the use of agricultural and forestry wastes and organic wastes generated in industry and urban life as carbonization raw materials to produce biochar is an important means of effective resource utilization[8]. The properties of biochar are mainly affected by pyrolysis conditions, raw materials and methods. The proportions of hemicellulose, cellulose and lignin contained in different materials are different, and the tissue structure of different crops is also different, making the pore structure and size of the biochar made quite different[9].

Biochar has a rich pore structure, a huge specific surface area, is alkaline, and has long-term stability and strong adsorption capacity[10-11]. It has become a new material for increasing carbon sequestration and repairing the soil environment. Biochar has been involved in carbon sequestration and emission reduction, pollution remediation, improvement of the recycling rate of agricultural and forestry waste, water purification, heavy metal pollution remediation, soil water retention improvement, etc., thus having very important application value[4,10,12-17]. In the application of energy security, biochar is the only renewable carbon source on the earth, which can replace other fuels, and has the advantages of high combustion efficiency and high calorific value, and can be used as a clean energy. In the application of agricultural environment and food security, biochar can improve soil production performance, improve soil fertility and water holding capacity and adjust pH value, can adsorb inorganic nitrogen and pollutants, and has effective restoration and mitigation effects in terms of soil acidification, heavy metal pollution, pesticide residues, agricultural greenhouse gas emissions, etc. In the application of environmental protection, biochar is a kind of adsorbent with better performance, which can purify sewage and waste gas, adsorb heavy metals, and adsorb polycyclic aromatic hydrocarbons such as organic pollutants. In the application of carbon sequestration and emission reduction, plants absorb CO2 through photosynthesis, and plant stems are thermochemically converted into biochar and returned to the field. The whole process achieves zero carbon emission, which can effectively alleviate the global greenhouse effect[18-19]. At present, there are many researches on the production process of biochar from different sources. Even if the carbonization process parameters are the same, there are certain differences in the biochar made from different source materials, which affects the field and scope of its application[20]. Therefore, in this study, with four raw materials of rice straw, wheat straw, rice husks, and corn straw as experimental materials, the differences in the physicochemical properties and surface properties of biochar from different sources were explored, providing reference data for the preparation process of biochar from industrial and agricultural wastes and its application and promotion.

Materials and Methods

Experimental materials

In Yongchuan District, rice straw, wheat straw, rice husk and corn straw were collected.

Preparation of biochar

The biochar was prepared by the oxygen-limited program temperature control method. The raw materials of the four types of biochar were rice straw, wheat straw, rice husk, and corn straw. After removing surface adhesions with clean water, they were dried. After grinding the dried raw materials, they were sieved with a 2 mm sieve, and put into stainless steel tanks, respectively, followed by compacting and covering. Next, they were put in a muffle furnace for cracking at 450 ℃. After reaching 450 ℃, carbonization was continued for 3 h. After the muffle furnace was cooled to room temperature, the biochar was taken out, and the biochar was ground and sieved with a 100-mesh sieve to obtain rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar[1].

Analytical methods

The pH value of biochar was measured with the pH meter method (NY 525-2012); the organic carbon content was determined by the potassium dichromate heating oxidation method (NY 525-2012); the nitrogen content was determined by the Kjeldahl method (NY 525-2012) ); the total phosphorus content was determined by molybdenum antimony anti-spectrophotometry (NY 525-2012); the total potassium content was determined by flame atomic absorption spectrophotometry (NY 525-2012); the specific surface area, pore volume, and pore size of biochar were measured by specific surface area and pore size distribution instrument (GB/T 19587-2004); and SEM was used to observe the morphology and structure of biochar[6].

Results and Analysis

Comparison of physicochemical properties of biochar from different sources

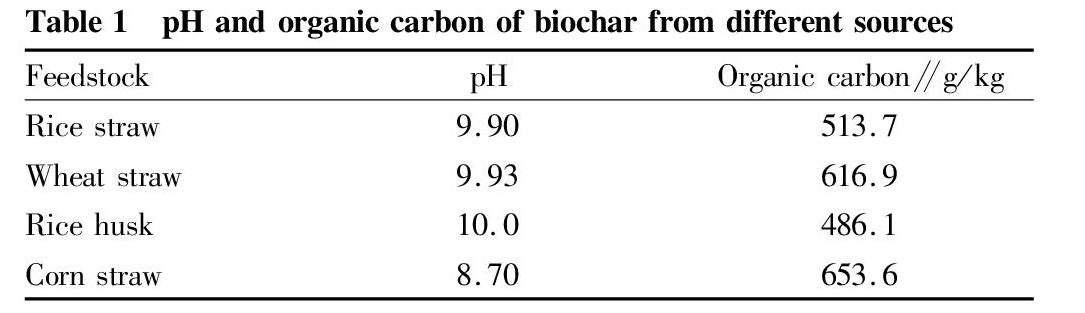

pH

After biochar is added to the soil, the pH value of the soil changes, causing a series of problems such as soil nitrogen mineralization, waste material precipitation, and greenhouse gas emissions. Therefore, as a soil amendment, the pH value of biochar itself is a factor that cannot be ignored[12]. In this study, biochar was alkaline. It can be seen from Table 1 that the pH values of rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar were 9.90, 9.93, 10.0 and 8.70, respectively. The pH values of biochar from different sources ranked as rice husk biochar>wheat straw biochar>rice straw biochar>corn straw biochar. There were certain differences in the properties of different raw materials, resulting in certain differences in the pH value of the biochar made.

Organic carbon

Biochar is rich in organic carbon. Adding biochar to the soil can increase soil fertility, thereby increasing crop yields. It can also be added to the soil as a carbon sequestrant, thereby increasing terrestrial carbon sequestration and reducing greenhouse gas emissions. It can be seen from Table 1 that the organic carbon contents of rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar were 513.7, 616.9, 486.1, and 653.6, respectively. Comparing the organic carbon contents of biochar from different sources, the order was corn straw biochar>wheat straw biochar>rice straw biochar>rice husk biochar. Green plants have a carbon fixation function and have a high organic carbon content.

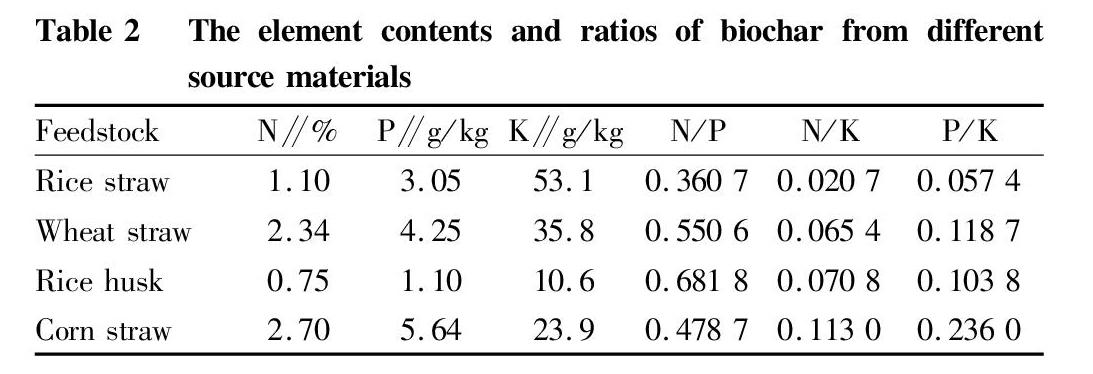

Total nitrogen

The nitrogen in biochar mainly exists in the form of ammonium salts, nitrates and heterocyclic compounds. Nitrogen is an essential element in plant growth. Nitrogen is the main element of proteins, and is an essential element for chloroplasts, vitamins, enzymes, alkaloids, and plant hormones. As a land amendment, biochar can increase nitrogen nutrient reserves. It can be seen from Table 2 that the nitrogen contents of rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar were 1.10, 2.34, 0.75 and 2.70, respectively. Comparing the nitrogen contents of the biochar from different sources, the order was corn straw biochar>wheat straw biochar>rice straw biochar>rice husk biochar.

Total phosphorous

Biochar can increase the phosphorus in the soil as a land amendment. Phosphorus can improve the normal metabolism, growth and development of plants, and the cold and drought resistance of plants. It can be seen from Table 2 that the total phosphorus contents of rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar were 3.05, 4.25, 1.10 and 5.64, respectively. When comparing the total phosphorus contents of the biochar from different sources, the values ranked as corn straw biochar>wheat straw biochar>rice straw biochar>rice husk biochar.

Total potassium

Biochar contains a lot of potassium. As a land amendment, it can increase the potassium in the soil. Potassium plays an important role in plant growth. From Table 2, the total potassium contents of rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar were 53.1, 35.8, 10.6, and 23.9, respectively. Comparing the total potassium contents of the biochar from different sources, the order was rice straw biochar>wheat straw biochar>corn straw biochar>rice husk biochar.

Element ratios

The ratios of nitrogen to phosphorus in rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar were 0.360 7, 0.550 6, 0.681 8 and 0.478 7, respectively. The order of the ratio of nitrogen to phosphorus in the biochar from different sources was: rice husk biochar>wheat straw biochar>corn straw biochar>rice straw biochar. The ratios of nitrogen to potassium in rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar were 0.020 7, 0.065 4, 0.070 8 and 0.113 0, respectively. The ratios of nitrogen to phosphorus in the biochar from different sources ranked as rice husk biochar>wheat straw biochar>corn straw biochar>rice straw biochar. The ratios of phosphorus to potassium of rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar were 0.057 4, 0.118 7, 0.103 8, and 0.236 0, respectively. Comparing the phosphorus-to-potassium ratios of biochar from different sources, the values ranked as corn straw biochar>wheat straw biochar>rice husk biochar>rice straw biochar (Table 2).

Comparison and analysis on the performance of biochar from different sources

Specific surface area

As shown in Fig. 1, the specific surface areas of rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar were 224.249, 2.274, 1.611 and 2.995 m2/g, respectively. Comparing the specific surface areas of the biochar from different sources, the order was rice straw biochar>corn straw biochar>wheat straw biochar>rice husk biochar. Because of different types of material sources, the number of pores of biochar changed, so the specific surface area of biochar had a certain difference[21].

Pore volume

The pore volumes of rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar were 0.114, 0.008 19, 0.002 90, and 0.011 4 cm3/g, respectively. Comparing the pore volumes of the biochar from different source materials, the order of the pore volumes was: rice straw biochar>corn straw biochar>wheat straw biochar>rice husk biochar (Fig. 2).

Pore diameter

The pore diameters of rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar were 2.656, 21.982, 8.617 and 13.743 nm, respectively. The pore diameters of the biochar from different sources ranked as wheat straw biochar>corn straw biochar>rice husk biochar>rice straw biochar (Fig. 3).

Xue YANG et al. Study on Physicochemical Properties and Surface Properties of Biochar from Different Materials

SEM

It can be seen from Fig. 4 that under the same pyrolysis temperature, the rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar had obvious pore structures on the surface, and were different in the number and size of the pores to certain degrees. The pore structures of rice straw biochar were regular and neatly arranged; the pore structures of wheat straw biochar were irregular and the pores were large; there were pores between rice husk biochar particles, and the pore structures were disorder; and the pores of corn straw biochar were small, but many small microporous structures could be observed.

The photographs from left to right were rice straw biochar, wheat straw biochar, rice husk biochar, corn straw biochar, respectively.

Fig. 4 SEM photographs of biochar from different material sources

Evaluation of biochar from different sources

The evaluation detection method is a method in which the evaluator classifies and ranks one or more samples based on one or more indicators. The biochar was assigned the values 1, 2, 3, and 4 from small to large. It can be seen from Table 3 that the total values of rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar were 24, 31, 21 and 34, respectively, and the order of the total values was corn straw biochar>wheat straw biochar>rice straw biochar>rice husk biochar.

Conclusions and Discussion

The biochar from different sources was all alkaline in pH value, and the order of pH values was: rice husk biochar>wheat straw biochar>rice straw biochar>corn straw biochar; and the organic carbon contents of the biochar from different sources were different, and ranked as corn straw biochar>wheat straw biochar>rice straw biochar>rice husk biochar.

The order of the nitrogen contents of the biochar from different sources was: corn straw biochar>wheat straw biochar>rice straw biochar>rice husk biochar; the order of total phosphorus contents was: corn straw biochar>wheat straw biochar>rice straw biochar>rice husk biochar; and the order of total potassium contents was: rice straw biochar>wheat straw biochar>corn straw biochar>rice husk biochar.

The biochar from different sources all showed a porous structure, but their pore structure sizes and shapes were different to certain degrees. The order of the specific surface areas of the biochar from different sources was: rice straw biochar>corn straw biochar>wheat straw biochar>rice husk biochar; the order of pore volumes was rice straw biochar>corn straw Straw biochar>wheat straw biochar>rice husk biochar; and pore diameter ranked as wheat straw biochar>corn straw biochar>rice husk biochar>rice straw biochar.

The rice straw biochar, wheat straw biochar, rice husk biochar, and corn straw biochar all had obvious pore structures on the surface, but were different in pore number and diameter. The biochar from different sources ranked according to the comprehensive evaluation of all indicators as corn straw biochar>wheat straw biochar>rice straw biochar>rice husk biochar.

References

[1] FU L, XU XY, FU GQ, et al. Characteristic analysis of five biochars[J]. Journal of Arid Land Resources and Environment, 2019(9): 202-208. (in Chinese)

[2] WANG HY, WANG XC, ZHANG YJ, et al. Comparison of biochars characteristics from biomass residues produced through slow pyrolysis[J]. Journal of Northeast Agricultural University, 2016, 47(5): 83-90. (in Chinese)

[3] LI L, LIU Y, LU YC, et al. Review on environmental effects and applications of biochar[J]. Environmental Chemistry, 2011, 30(8): 1411-1421. (in Chinese)

[4] HE XM, FENG DZ, AO FL, et al. Research on the characteristic and application of bio-carbon[J]. Fuel & Chemical Processes, 2015, 46(4): 1-3, 7. (in Chinese)

[5] CHEN WF, ZHANG WM, MENG J. Biochar and agro-ecological environment: Review and prospect[J]. Journal of Agro-Environment Science, 2014, 33(5): 821-828. (in Chinese)

[6] CHEN ZL, YUAN ZH, HUANG L, et al. Pyrolysis materials, characteristics of biochar and its application on remediation of heavy metal contaminated soil: A review [J]. Ecology and Environment Sciences, 2016, 25(11): 1879-1884. (in Chinese)

[7] WANG N, WEI Y. The physical and chemical properties of different biochar and their adsorption of heavy metals[J]. Land Development and Engineering Research, 2020, 5(3): 50-55. (in Chinese)

[8] WANG TT, WANG XL, REN ZS, et al. Microscopic morphology and surface features of biochars derived from different raw materials[J]. Environmental Science & Technology, 2017, 40(1): 42-48. (in Chinese)

[9] HAUNG ZQ, ZHANG NW, LIU X. Preparation and characterization of physical and chemical structures of rice husk-derived biochar[J]. Guangzhou Chemical Industry, 2018, 46(12): 40-43. (in Chinese)

[10] HUANG ZQ, ZHAO KX, ZHANG NW, et al. Review on the properties and environmental effects of biochar[J]. Guangzhou Chemical Industry, 2020, 48(19): 22-26. (in Chinese)

[11] GUO XH, KANG K, YU XN, et al. Study on physicochemical properties of magnetic modified biochar derived from pyrolysis of pomelo peel and apricot kernel shell[J]. Transactions of the Chinese Society of Agricultural Engineering, 2018, 34(B11): 164-171. (in Chinese)

[12] SUN T, ZHU XP, LI DP, et al. Comparison of biochars characteristics from different raw materials[J]. Journal of Agricultural Resources and Environment, 2017, 34(6): 543-549. (in Chinese)

[13] XU DQ. Preparation biochar of corn stover and structural characteristics analysis[J]. Guihaia, 2018, 38(9): 1125-1135. (in Chinese)

[14] KONG SF, YAO XC, ZHANG JY, et al. Review of characteristics of biochar and research progress of its applications[J]. Ecology and Environment Sciences, 2015, 24(4): 716-723. (in Chinese)

[15] HUANG YD, DU YQ, CHEN YJ, et al. Physicochemical properties of biochars originated from different agricultural wastes and their impact on the yield of Brassica campestris L.[J]. Ecology and Environment Sciences, 2018, 27(2): 356-363. (in Chinese)

[16] YANG Z, CHEN J, CHUAI Y. Preparation, characterization and adsorption properties of reed biochar [J]. Jiangsu Agricultural Sciences, 2016(11): 464-467. (in Chinese)

[17] JIAN MF, GAO KF, YU HP. Effects of different pyrolysis temperatures on the preparation and characteristics of bio-char from rice straw[J]. Acta Scientiae Circumstantiae, 2016, 36(5): 1757-1765. (in Chinese)

[18] HUO LL, YAO ZL, ZHAO LX, et al. Physical and chemical properties and product quality evaluation of biochar from typical agricultural residues[J]. Transactions of the Chinese Society of Agricultural Engineering, 2019, 35(16): 249-257. (in Chinese)

[19] MENG J, CHEN WF. Biochar in China: Status quo of research and trend of industrial development[J]. Journal of Shenyang Agricultural University: Social Science Edition), 2013, 15(1): 1-5. (in Chinese)

[20] MAO MY, ZHAO ZY, WANG SL, et al. Biochar yield and physicochemical properties of five halophyte species[J]. Arid Zone Research, 2019, 36(6): 1494-1501. (in Chinese)

[21] YUAN S, ZHAO LX, MENG HB, et al. The main types of biochar and their properties and expectative researches[J]. Journal of Plant Nutrition and Fertilizer, 2016, 22(5): 1402-1417. (in Chinese)

- 农业生物技术(英文版)的其它文章

- Effects of Pruning Methods on the Growth and Development of New Shoots and Fruit Yield and Quality of Walnut

- Selection of Grape Varieties Suitable for Double Cropping a Year in Northern Greenhouse

- Effects of Uniconazole on Photosynthetic Characteristics of Dahlia pinnata Cav. under Drought Stress

- Community Structure and Value Evaluation of Local Brassicaceae Potherbs in Shiyan City

- Home Planting Techniques of Green and Healthy Rape Sprouts

- Research Progress of Polygonatum Germplasm Resources in China