Significance of compaction time delay on compaction and strength characteristics of sulfate resistant cement-treated expansive soil

P. Sriram Karthick Raja, T. Thyagaraj

Department of Civil Engineering, Indian Institute of Technology Madras, Chennai, 600 036, India

Keywords:Compaction time delay Ettringite Sulfate resistant cement (SRC)Mercury intrusive porosimetry (MIP)Sulfate

ABSTRACT The addition of cement for stabilization of expansive soils is one of the most commonly used methods.As with every calcium-based stabilizer, the time delay between the physical mixing of the stabilizer and compaction plays an important role in achieving the desired results after stabilization. However, a clear insight on the determination of optimum time delay for achieving the maximum desired compaction properties of cement-stabilized soils is yet to be established.Furthermore,the recent studies highlighted the use of sulfate to mitigate the negative effect of compaction time delay. The only drawback with the use of sulfate along with calcium-based stabilizers is the formation of ettringite, which deteriorates the stabilized soil matrix. In view of this, the present study is aimed at using the sulfate resistant cement(SRC)as a stabilizer along with the controlled addition of sulfate solutions to mitigate the negative effect of compaction time delay in stabilizing the expansive soil.To bring out the above effects,three periods of time delays (0 h, 6 h and 24 h) and three sulfate concentrations of 5000 parts per million (ppm),10,000 ppm and 20,000 ppm were adopted. The experimental results showed that the delay in compaction resulted in the formation of clogs and reduction of strength of SRC-stabilized expansive soil.Upon sulfate addition to SRC-stabilized expansive soil,the formation clogs was not curtailed and resulted in the formation of ettringite clusters.These formations were captured with the help of scanning electron microscope (SEM) images and validated with electron dispersive X-ray spectroscopy (EDAX) analysis.Further,an attempt is also made to explain the mechanism of density and strength reduction with the aid of physico-chemical properties and mercury intrusion porosimetry (MIP) studies.

1. Introduction

Expansive clays, such as black cotton soils, are found in abundance in the Indian subcontinent. About 20% of the Indian subcontinent is covered by these soils. The main problem with these soils is their susceptibility to a reduction in strength and high volume change behavior in response to the changes in water content during wet-dry seasons.This behavior makes them unsuitable for the construction of road and rail embankments (Chen, 1988;Nelson and Miller, 1992; Pettry and Little, 2002; Ikeagwuani and Nwonu, 2019). However, with rapid growth in industrialization and an increase in the land value,the sites covered with expansive soils cannot be avoided for the infrastructural development projects. Hence, there arises a need for effective low-cost and sustainable methods of stabilization to improve the engineering properties of the expansive soils. Stabilization of expansive soils is carried out with methods such as moisture control method, prewetting method, addition of chemical stabilizers, use of cohesive non-swelling layer and in the more recent times the use of green chemical stabilization such as resins,polymers,sulfonated oils and lignosulfonates(Chen,1988;Little,1999;Cokca,2001;Sivapullaiah et al., 2004; Murthy and Praveen, 2008; Alazigha et al., 2016;Soltani et al., 2017, 2021; Raja and Thyagaraj, 2019). Of the above techniques used for stabilizing the expansive soils, the calciumbased stabilizers have been successfully applied in the field for improving the strength and controlling the volume change behavior of expansive soils both economically and efficiently.Of the various calcium-based stabilizers available for stabilization, lime and cement stabilizations are the most effective methods for stabilizing the expansive soils (Jones and Holtz, 1973; Nelson and Miller, 1992; Puppala et al., 2007; Jia et al., 2019; Kumar and Thyagaraj, 2020).

In recent years,the use of calcium-based stabilizers such as lime and cement for controlling the swell potential of expansive soils was brought under scrutiny in the presence of sulfate in natural expansive soils (Mitchell, 1986; Hunter, 1988; Dermatas, 1995;Rajasekaran,2005;Little et al.,2010;Seif,2015;Raja and Thyagaraj,2020a).Numerous studies have been undertaken to understand the sulfate effects on expansive soils stabilized with calcium-based stabilizers. Based on these studies, it can be concluded that the main problem with sulfate contamination of stabilized soils is caused by the formation of swelling minerals such as ettringite and thaumasite (Ogawa and Roy, 1982a,b,c; Mitchell, 1986; Hunter,1988; Dermatas, 1995; Rajasekaran, 2005; Little et al., 2010; Raja and Thyagaraj, 2019). Moreover, the use of cement as a stabilizer poses intrinsic environmental, health and safety problems to the ecosystem. For example, the manufacturing process of cement consumes about 2% of global energy and poses adverse effects by the generation of greenhouse gases and cancerous particulate matter (Albino et al., 2013; Alazigha et al., 2016). Furthermore, it was found that the use of low calcium-based stabilizers such as Type V cement has emerged as one of the most viable and reliable alternatives for stabilization of high-sulfate bearing expansive soils(Cordon,1961; Puppala et al., 2004).

Hence,in the present study,the sulfate resistant type V cement(SRC)was used for stabilization of an expansive soil.The SRC results in immediate hydration of the soil-cement mixture on addition of water which in turn leads to the formation of clogs and aggregation of particles. The formation of clogs and aggregation of particles result in reduction of compaction density and thus the strength development of the stabilized expansive soil with the increase in compaction time delay. This necessitates the immediate compaction of the expansive soil upon the addition of SRC. However, the time delay between the physical mixing of SRC with soil and the compaction of the same is inevitable owing to the technical and logistics reasons such as delays due to power failure, mechanical failure of equipment, and unfavorable weather conditions. This inevitable time delay leads to an unwanted reduction in the strength of the stabilized expansive soils.Arman and Saifan(1967)reported that the effect of compaction time delay directly depends on the final setting time of the cement and they have stressed on the importance of compacting the soil-cement mixture well before the final setting time of the cement.Similarly,a study performed by Christensen (1969) on 11 types of clay soils reported that the maximum dry density of the cement-stabilized soils reduced with the increase in compaction time delay.While a study conducted by Cowell and Irwin(1979)suggested that there was no change in the behavior of the compaction characteristics of soil-cement mixtures concerning compaction time delay. Owing to the contradicting conclusions reported in the literature and the need to mitigate the effect of compaction time delay on soil-cement mixtures, the present study is aimed at understanding the effect of compaction delay time on SRC-stabilized expansive soil through microstructural and mineralogical experiments.

Moreover, a recent study by Raja and Thyagaraj (2020b) stated that the controlled addition of sulfate can mitigate the strength loss incurred due to compaction time delay on lime-stabilized expansive soil. Hence, an attempt is made in this study to mitigate the negative effect of compaction time delay on the SRC-stabilized expansive soil by the addition of a controlled quantity of sulfate solution.Further,the literature showed that the SRC works better in the sulfate environment in comparison to the lime. Hence, the addition of a controlled quantity of sulfate to mitigate the negative effects of compaction time delay can be justified as it may not adversely affect the long-term behavior of the SRC-stabilized expansive soil.

2. Materials

The expansive soil used for the present experimental study was collected at a depth of 2 m from Solgampatti, Tiruchirapalli, Tamil Nadu, India. The field moisture content of the expansive soil after the monsoon season was found to be 18%-21%.The expansive soil was spread under the direct sun for air-drying and sieved through a 4.75 mm sieve for removing any gravel fraction. Then, the expansive soil was pulverized using a jaw crusher and passed through a 425 μm sieve.This soil was transferred into plastic storage bins and was used for the present study. The liquid, plastic and shrinkage limits of expansive soil were found to be 95%, 22% and 7.5%,respectively. The pH value, electrical conductivity and specific gravity of expansive soil were found to be 8.75, 1.06 mS/cm and 2.75, respectively. Based on the unified soil classification system(USCS), the expansive soil is classified as inorganic clay of high compressibility (CH) with 24.5% sand, 22.5% silt and 53% clay. The mini Proctor compaction test on expansive soil yielded the maximum dry unit weight(γdmax)and optimum moisture content(OMC) of 16.81 kN/m3and 19.9%, respectively (after Raja and Thyagaraj, 2020b).

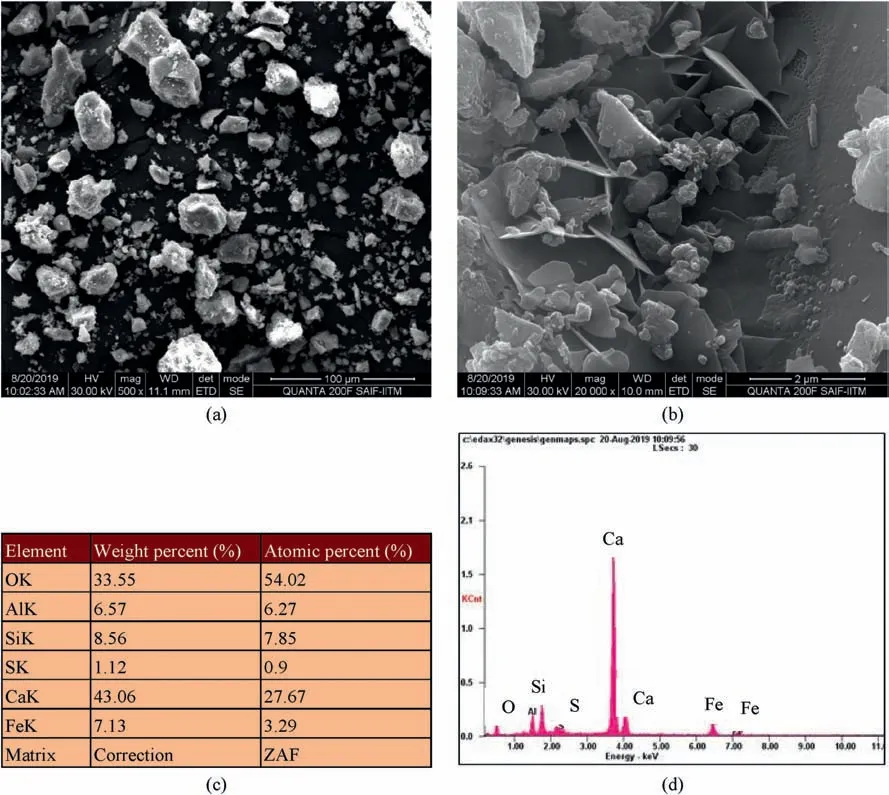

For the present study, the laboratory-grade sodium sulfate(Na2SO4) with a purity of 99% and SRC were used. Owing to its maximum solubility, the sodium sulfate (Na2SO4) was selected for the present study. The scanning electron microscope (SEM) micrographs, elemental composition and electron dispersive X-ray spectroscopy (EDAX) analysis of the SRC are provided in Fig.1.

3. Experimental procedures

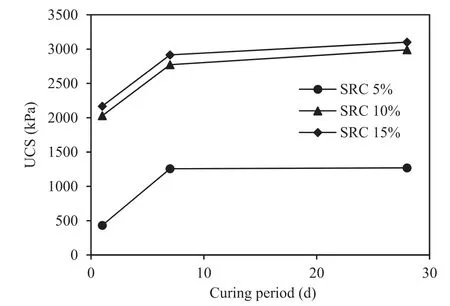

For the present study,three contents of SRC were used based on the optimum cement content value.The optimum cement content was determined based on the unconfined compressive strength(UCS)of the stabilized expansive soil specimens cured for different periods,i.e.1 d,7 d and 28 d(Fig.2).The UCStests were carried out on statically compacted cylindrical specimens with dimensions of 38 mm in diameter and 76 mm in height.The UCS specimens were prepared at their corresponding optimum moisture content by mixing it with distilled water and compacted to their corresponding maximum dry densities(Table 1).The prepared UCS specimens were stored in a moisture-controlled desiccator for curing. After the required period of curing,the specimens were tested at a strain rate of 0.625 mm/min following ASTM D2166/D2166M-16(2016).Based on the UCS tests carried out by Raja and Thyagaraj (2020a) on the expansive soil used in the present study,the SRC contents of 5%,10%and 15% were finalized for the present study as the optimum SRC content was found to be 10%(Fig.2)(Raja and Thyagaraj,2020a).

Calculated quantity of distilled water,in addition to the natural moisture content of the expansive soil, was added to a measured quantity of dry soil-cement mixture and mixed with the help of spatulas.Following this,the mini compaction tests were performed immediately based on the protocol given by Sridharan and Sivapullaiah (2005). Further, to understand the effect of compaction time delay on the SRC-treated expansive soil, the known weight of soil-cement mixtures, prepared as per the aforementioned procedure, was placed in zip lock covers and stored in moisture equilibration storage unit.The above storage arrangement helps in minimizing the evaporation loss during compaction time delay.After the desired period of 6 h and 24 h of compaction time delay, the soil-cement mixtures were taken out and compacted following the protocol given by Sridharan and Sivapullaiah(2005).A maximum time delay of 24 h was chosen as it represents the maximum time delay that can be anticipated in the field due to labor and logistics reasons.

Fig.1. SEM micrographs of SRC at magnifications of (a) 500 times and (b) 20,000 times; (c) Elemental composition of SRC; and (d) EDAX corresponding to (b). ZAF refers to the correction method adopted to find the atomic percent (%) and weight percent (%) from the energy counts.

Fig. 2. Variations of UCS with SRC content of SRC-stabilized expansive soil cured for 1 d, 7 d and 28 d (after Raja and Thyagaraj, 2020a).

To bring about the effect of sulfate contamination on SRCstabilized expansive soil, the soil-cement mixture was mixed with sulfate solutions of 5000 parts per million (ppm) (S5),10,000 ppm (S10), and 20,000 ppm (S20) concentrations individually. The above concentrations of sulfate solutions are chosen based on the study reported by Raja and Thyagaraj (2020b). Specimen preparation was carried out following the procedure mentioned in the previous paragraph for the determination of sulfate effect on compaction characteristics and compaction time delay on the soil-cement mixtures except that the sulfate solutions of desired concentrations were used instead of distilled water.

For determination of pH value and electrical conductivity, a small portion of soil was taken from the compacted soil specimens and oven-dried at 45°C for 24 h. This small portion of soil was pulverized and made to pass through 425 μm sieve for obtaining 30 g of representative soil.Then,75 mL of distilled water was added to 30 g of soil for maintaining the soil-water ratio at 1:2.5 for determination of both pH value and electrical conductivity.All thetests were carried out at a room temperature of(28±2)°C and the average values of three determinations are reported here.

Table 1 Compaction conditions of UCS test specimens adopted for the determination of optimum cement content.

To evaluate the UCS of the SRC-stabilized soil for bringing out the effect of compaction time delay, cylindrical soil specimens having diameter of 38 mm and height of 76 mm were prepared by static compaction of soil-cement mixtures in three layers of equal thickness.These soil specimens were mixed at their corresponding optimum moisture contents and compacted to their maximum dry unit weights. For specimens compacted with a compaction time delay,the soil-cement mixture was thoroughly mixed with the help of spatula by the addition of a calculated quantity of distilled water.The soil-cement mixtures thus prepared were placed in zip lock bags and kept in moisture-controlled desiccators during the compaction time delay period. After the desired duration of compaction time delay (6 h and 24 h), the soil-cement mixtures were compacted statically to achieve corresponding maximum dry unit weights.The specimens were immediately tested for their UCS values. The above-mentioned protocol was adopted for the preparation of specimens mixed with sulfate solutions as well. The results presented in the present study were the average of three identical specimens tested for each individual condition.

For analyzing the micro-structural properties of the specimens,the mercury intrusion porosimetry(MIP)technique was employed.A part of the specimens, cut out from the UCS test specimens, were used for carrying out the MIP)micro-structural studies using Pascal mercury porosimeters (140 and 440 series). The specimens thus obtained by cutting were stored in vacuum desiccators before drying them using the freeze-drying technique.The freeze-drier used in this research was Lark Penguin Classic.A freezing temperature of-60°C was maintained in the freeze-drier.The maximum intrusive pressure of 360 MPa was applied for the MIP analysis.The specimens used for MIP analysis were also adopted for the SEM and EDAX analysis using Thermo Scientific Quanta 200. The SEM specimens were sputter coated with 100 Å thin layer of gold palladium for 60 s using a sputter coater,Polaron E5100 at 10-3Torrvacuum.

4. Results and discussion

4.1. Compaction behavior of SRC-stabilized soil

4.1.1. Mixed with distilled water

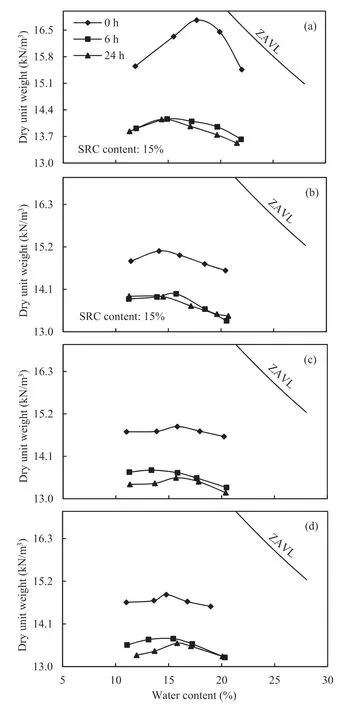

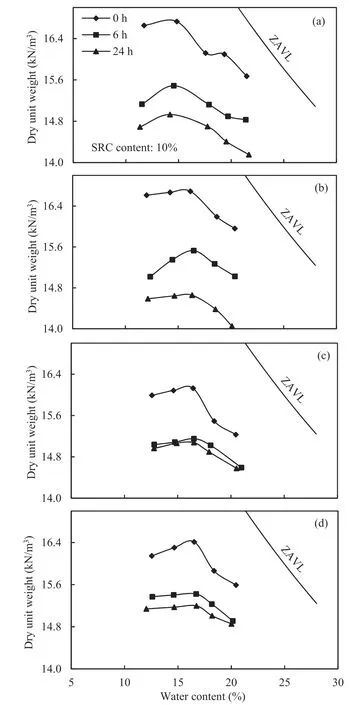

Figs. 3-5 bring out the effect of compaction time delay on the compaction behavior of soil-cement mixtures mixed with distilled water and sulfatesolutions of varying concentration at SRC content of 5%,10%and 15%,respectively.From Fig.3,it can be observed that for an SRC addition of 5%,γdmaxof the soil-cement mixture mixed with distilled water reduced from 16.45 kN/m3to 15.04 kN/m3for a compaction time delay of 24 h. This reduction in γdmaxof the soilcement mixture is mainly attributed to the formation of clogs due to the hydration reaction of cement. The clogs formed during the initial compaction delay period increase the resistance of the soil-SRC mixture against the compactive effort, due to which the γdmaxof the soil-SRC mixture reduces with compaction time delay.A similar reduction in γdmaxwith compaction time delay was observed at other SRC contents of 10%and 15%as well(Figs.4 and 5). Similar results were obtained by Raja and Thyagaraj (2019,2020b)for expansive soil treated with lime.However,the variation in OMC of the soil-cement mixtures was negligible with compaction time delay.

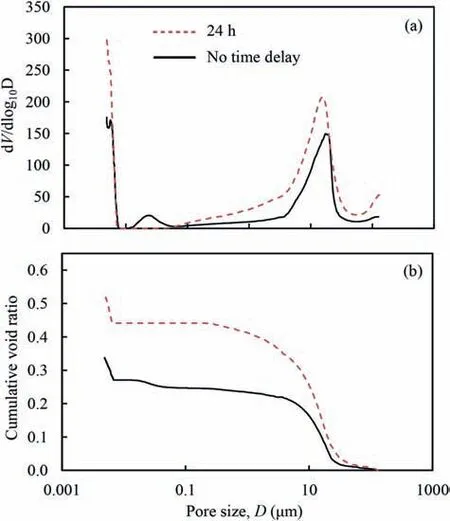

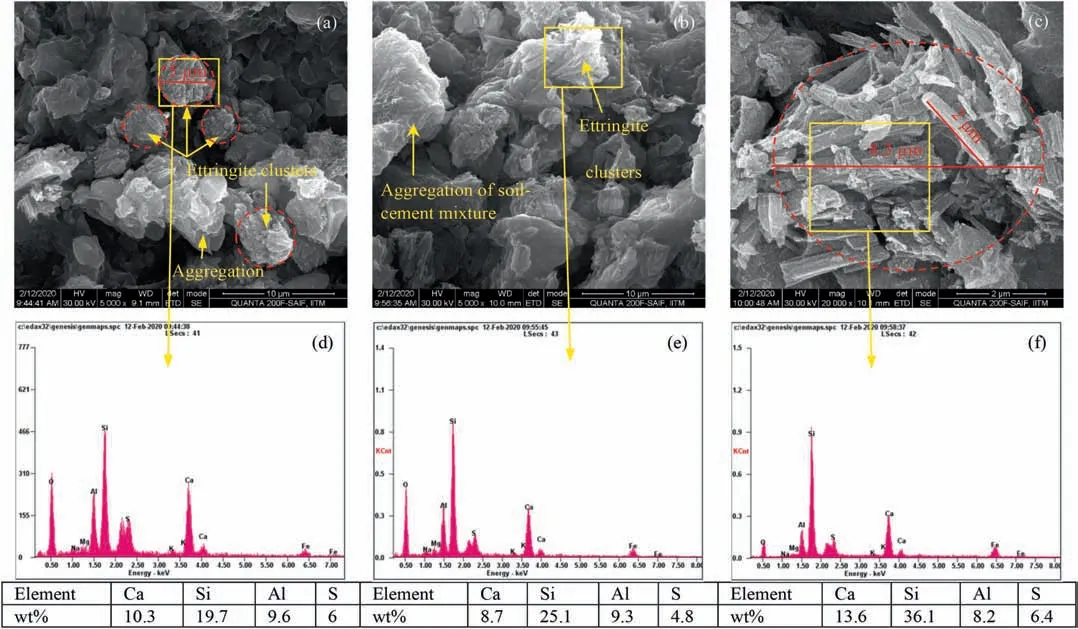

Based on the test results presented in Figs. 3a, 4a and 5a, the reduction in γdmaxfor a compaction time delay of 24 h for SRC contents of 5%,10%and 15%was calculated as 8.5%,10.8%,and 15.6%,respectively(Table 2).The percentage reduction in γdmaxincreased with increase in the SRC content.This is attributed to the increase in aggregation and clog formation due to the hydration of SRC cement.This formation of clogs and aggregation of particles can be visualized in the SEM micrographs provided in Fig. 6a-c. Their corresponding EDAX analysis along with their element concentrations is provided in Fig.6d-f.Fig.7a and b compares the pore size density(PSD)functions and corresponding cumulative void ratio curves of 10%SRC-stabilized expansive soil compacted immediately and after 24 h of compaction time delay,respectively.From Fig.7a and b,it is evident that the PSD function of both curves is bimodal. The soil compacted immediately is characterized by micropore peak size of 0.2 μm and macropore peak size of 19.75 μm.With the compaction time delay of 24 h,the macropore peak slightly shifted towards the left with macropore peak size of 16.86 μm (Fig. 7a). However, the density of macropores increased with compaction time delay of 24 h (Fig. 7a). This is evidenced in the cumulative void ratio curve presented in Fig. 7b. From Fig. 7b, it can be observed that the cumulative void ratio of SRC-stabilized expansive soil compacted immediately,and after 24 h of compaction time delay,it was found to be 0.33 and 0.527, respectively. From the above study, it can be concluded that with increase in compaction time delay, the pore structure of the SRC-stabilized soil changed to a great extent.These changes in the pore structure are due to the formation of clogs and aggregation of the particles as discussed earlier.

Fig. 3. Comparison of compaction curves of 5% SRC-stabilized expansive soil mixed with(a)distilled water,(b)5000 ppm(S5), (c)10,000 ppm(S10), and(d) 20,000 ppm(S20) sulfate solutions and compacted at different periods of compaction time delay.ZAVL represents zero air voids line.

Fig. 5. Comparison of compaction curves of 15% SRC-stabilized expansive soil mixed with(a)distilled water,(b)5000 ppm (S5),(c)10,000 ppm(S10), and(d) 20,000 ppm(S20) sulfate solutions and compacted at different periods of compaction time delay.

Fig. 4. Comparison of compaction curves of 10% SRC-stabilized expansive soil mixed with(a) distilled water,(b) 5000 ppm(S5),(c)10,000 ppm(S10), and (d)20,000 ppm(S20) sulfate solutions and compacted at different periods of compaction time delay.

The above change in the pore structure increased the porosity of the compacted soil and thus reduces the compaction and strengthparameters of the stabilized soil.The significant reduction in γdmaxof the SRC-stabilized soil impacts the engineering properties of the SRC-stabilized expansive soils significantly. Hence, there arises a need for mitigating this reduction in γdmaxthat occurs due to compaction time delay. With a view of mitigating the negative effect of compaction time delay, the addition of sulfate to the SRCstabilized expansive soil and its effects are discussed in the following sections.

Table 2 Summary of percentage reduction in γdmax for SRC-stabilized expansive soil mixed with different mixing liquids.

Fig.6. SEM micrographs of 15%SRC-stabilized soil mixed with distilled water and compacted immediately at magnification of(a)1000 times,(b)5000 times,and(c)10,000 times;(d) EDAX corresponding to micrograph presented in (a); (e) EDAX corresponding to micrograph presented in (b); and (f) EDAX corresponding to micrograph presented in (c).

Fig.7. Comparison of(a)PSD function and(b)cumulative void ratio curves of 10%SRCstabilized expansive soil mixed with distilled water and compacted immediately(0 h)and 24 h of time delay.

4.1.2. Mixed with sulfate solutions

For a SRC content of 5%,γdmaxof the soil mixed with 20,000 ppm sulfate solution decreased from 15.48 kN/m3to 14.69 kN/m3for a compaction time delay of 24 h (Fig. 3d). This reduction in density with compaction time delay of the soil-SRC mixture upon the addition of sulfate is surprising,as the previous studies by Le Roux(1969), Le Roux and Toubeau (1987), and Raja and Thyagaraj(2020b) suggested that the addition of sulfate retards the pozzolanic reactions in lime-treated soils. Thereby, it reduces the formation of clogs and results in higher compaction densities. In contrast, the present study shows that the addition of sulfate solution to the SRC-stabilized expansive soil reduced γdmaxirrespective of the compaction time delay and sulfate concentration.This reduction in γdmaxvalue upon sulfate addition is attributed to the formation of ettringite along with the hydration of cement.

Fig.8. SEM micrographs of 15%SRC stabilized soil mixed with 20,000 ppm sulfate solution and compacted after 24 h of time delay at magnification of(a)5000 times,(b)5000 times at different location, and (c) 20,000 times; (d) EDAX corresponding to micrograph presented in (a); (e) EDAX corresponding to micrograph presented in (b); and (f) EDAX corresponding to micrograph presented in (c).

Fig.9. Comparison of(a)PSD function and(b)cumulative void ratio curves of 10%SRCstabilized expansive soil mixed with distilled water and sulfate solution of 20,000 ppm and compacted immediately (0 h).

This hydration of cement along with ettringite formation can be visualized in the SEM images shown in Fig. 8a-c. The presence of ettringite is confirmed through the EDAX analysis shown in Fig.8d-f.Fig.9a and b compares respectively the PSD functions and corresponding cumulative void ratio curves of 10% SRC-stabilized expansive soil mixed with distilled water and 20,000 ppm sulfate solution and compacted without any time delay. Both the curves represent a bimodal distribution, with micropore and macropore peaks at 0.2 μm and 19.75 μm for specimens mixed with distilled water.For specimen mixed with sulfate solution,the micropore and macropore peaks are found at 0.009 μm and 9.565 μm,respectively.Upon mixing with sulfate solution,there is an increase in the peak intensity of the micropore volume and the macropore size reduced to a great extent. This reduction in the macropores size can be attributed to the formation of ettringite in the sulfate mixed specimen.These ettringite crystals are generally 2-3 μm in length as visualized in the SEM micrographs provided in Fig. 8a-c.Furthermore, from the micrographs presented in Fig. 8a and c, it can be observed that these crystals are found in clusters with each cluster approximated to be spherical with a diameter of about 5-9 μm. Now, these spherical ettringite clusters formed get rearranged within the void pores during the compaction of the specimens, and thus resulted in the reduction in macropore size of the SRC-stabilized soil mixed with sulfate solution. Even though the ettringite crystals formed occupy the void pores and reduce the macropore size,the increase in micropores or intra-aggregate voids due to the ettringite formation increased to a greater extent.Further, the density of macropores also increased slightly in soil mixed with sulfate solution and compacted (Fig. 9a). Due to these reasons, the overall porosity of the SRC-stabilized soil mixed with sulfate solution increased in comparison to the soil mixed with distilled water (Fig. 9b). This leads to the reduced density and strength of the SRC-stabilized expansive soil mixed with sulfate solution as discussed in the previous paragraphs.

However, variation in γdmaxof soil mixed with distilled water and soil mixed with sulfate solution is not significant.The reduction in density upon sulfate addition is presented in Table 3. From Table 3, it can be seen that the average reduction in density uponsulfate addition is around 3.6%with a coefficient of variation of 1%.This reduction in γdmaxwith respect to specimens mixed with distilled water is due to the formation of ettringite clusters in the specimens mixed with sulfate solutions. This can be visualized in the SEM micrographs provided in Fig. 8a-c. This ettringite cluster formation makes the soil-cement mixture more resistant against compactive effort,thus increasing the porosity.This along with the aggregation of particles and hydration of cement results in a higher reduction in γdmaxof the soil-cement mixtures mixed with sulfate solution.However,the optimum moisture content is not influenced significantly with increases in the compaction delay time and sulfate concentration.

Table 3 Comparison of percentage reduction in γdmax for SRC-stabilized expansive soil mixed with distilled water and sulfate solutions.

Fig. 10. Variation in pH value and electrical conductivity of SRC-stabilized soil with concentration of sulfate solutions for compaction time delay of 0 h (immediately compacted).

There are two main reasons for the ineffectiveness of the sulfate solution in mitigating the negative effect of compaction delay time.The main reason for sulfate to control the pozzolanic reactions in stabilized soil is due to its ability to reduce the pH value of the stabilized soil mixture.However,in the present study,Fig.10 shows the variation of pH value and electrical conductivity of soil-cement mixtures with concentration of sulfate solutions for compaction time delay of 0 h. From Fig.10, it is clear that the sulfate addition considered in this study (5000-20,000 ppm) to 10% and 15% SRCstabilized soils and compacted immediately could not reduce the pH value to a value below 10. The pH value of 10% SRC-stabilized soil mixed with sulfate solution of 20,000 ppm reduced to 9.66 even at higher water content after a time delay of 24 h (Raja and Thyagaraj, 2020a). The above reduction in pH value is not significant enough to completely stop the hydration and pozzolanic reactions occurring in the soil-cement mixtures, as the reactive compounds like calcium and silica are readily available for the pozzolanic reactions at the reduced pH value of 9.66 (Boardman et al., 2001). Hence, in the present study, it can be safely concluded that the pH value reduction brought about by the addition of a limited quantity of sulfate solutions is not significant enough to retard the hydration and pozzolanic reactions.However,the electrical conductivity of the soil-cement mixtures compacted with compaction time delay of 0 hand 24 h increased upon sulfate addition. The other reason for the failure of sulfate addition in mitigating the negative effect of compaction time delay is due to the formation of ettringite.

4.2. UCS of SRC-stabilized soil

4.2.1. Mixed with distilled water

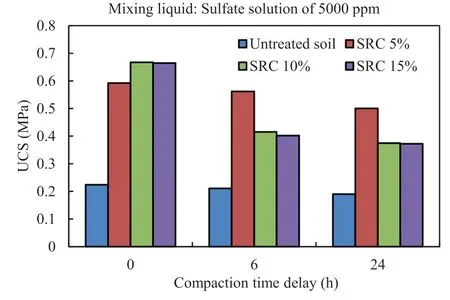

Fig.11 plots the variation of UCS with SRC content at different compaction time delays of the soil-cement mixtures mixed with distilled water. From Fig. 11, it can be observed that the UCS decreased with increase in compaction time delay. The strength decrease for a compaction time delay of 24 h was from 0.63 MPa to 0.56 MPa for specimens admixed with 5% SRC content. In soil specimens mixed with SRC contents of 10% and 15%, the rate of reduction in strength is higher in the initial 6 h of time delay. The UCS reduced from 0.67 MPa to 0.42 MPa for a compaction time delay of 6 h in specimens added with 10% SRC content, while the strength reduction after the initial delay of 6 h was from 0.42 MPa to 0.38 MPa for a compaction time delay of 24 h.This reduction in strength is mainly attributed to the aggregation of soil-cement mixtures and the formation of clogs due to the hydration of cement and the pozzolanic reactions occurring during the compaction delay period. These aggregated particles result in less dense packing of the soil-cement mixture during compaction and thus reduce the strength of the stabilized soil.

4.2.2. Mixed with sulfate solutions

Fig.11. Variation of UCS with compaction time delay of SRC-stabilized expansive soil using distilled water as mixing liquid.

Fig.12. Variation of UCS with compaction time delay of SRC-stabilized expansive soil using 5000 ppm sulfate solution as mixing liquid.

Fig.13. Variation of UCS with compaction time delay of SRC-stabilized expansive soil using 10,000 ppm sulfate solution as mixing liquid.

Fig.14. Variation of UCS with compaction time delay of SRC-stabilized expansive soil using 20,000 ppm sulfate solution as mixing liquid.

Table 4 Variation of parameter E50 of SRC-stabilized soil specimens mixed with distilled water and sulfate solutions and compacted at compaction time delay.

Figs. 12-14 plot the variations of UCS with SRC content at different compaction time delays of the soil-cement mixtures mixed with sulfate solutions of 5000 ppm, 10,000 ppm and 20,000 ppm, respectively. It is evident from Figs. 12-14 that the strength reduction is slightly higher in the soil specimens admixed with 10% and 15% SRC contents and mixed with 5000 ppm,10,000 ppm and 20,000 ppm sulfate solutions (from 0.67 to 0.37 MPa) for a compaction time delay of 24 h, while the soilcement mixtures admixed with SRC content of 5% and mixed with 5000 ppm sulfate solution exhibited a lower reduction in strength (from 0.59 to 0.5 MPa) (Fig.12). The higher reduction in strength is due to the rapid formation of ettringite clusters in the stabilized soil admixed with 10,000 ppm sulfate solution or still higher concentration. The ettringite clusters formed further reduces the density of compacted soils. Thereby the strength development in the soil-cement mixtures admixed with sulfate solutions of 10,000 ppm or higher concentration is lower. This formation of ettringite clusters in conjunction with the aggregation of the soilcement mixtures can be visualized in the SEM images presented in Fig. 8a and b. Therefore, from Figs.12-14, it can be concluded that the addition of sulfate above 5000 ppm adversely affects the strength development in SRC-stabilized soils.

4.2.3. Parameter E50of SRC-stabilized soil

E50parameter represents the secant modulus of the soil.Table 4 presents the parameter E50of SRC-stabilized soil specimens mixed with distilled water and sulfate solutions and compacted at different compaction time delays. It may be noted here that E50is defined as the 50% secant stiffness modulus obtained from the nonlinear stress-strain curve of primary loading curve (Surarak et al., 2012). From Table 4, it is clear that the E50value increased from 16.1 MPa to 19.1 MPa for an increase in SRC content from 5%to 15% for specimens mixed with distilled water and compacted without any compaction delay. From this it can be concluded that the variation in stiffness is directly proportional to the cement content. However, with the increase in concentration of sulfate solutions at a given SRC content and compaction time delay, the stiffness of the SRC-stabilized specimens decreased marginally.For example, an increase in sulfate concentration from 5000 ppm to 20,000 ppm resulted in a decrease in E50value from 19.1 MPa to 18.7 MPa for specimens stabilized with 15% SRC content. In contrast,the decrease in stiffness with compaction time delay was large at any given SRC content and mixing liquid (distilled water/sulfate solution).

5. Conclusions

The following conclusions are drawn from the present experimental study:

(1) The maximum dry density of SRC-stabilized expansive soil reduced with increase in the compaction time delay. This reduction in maximum dry density is attributed to the formation of clogs and aggregation of particles that occur during the compaction time delay. The clogs and aggregated particles resisted against the compactive effort, leading to the reduced dry density of the compacted soils.

(2) The concentration of sulfate solutions considered in the present study (5000-20,000 ppm) to mitigate the negative effect of compaction time delay was not successful as the reduction in pH value brought about by the sulfate addition was not significant enough to control the aggregation and pozzolanic reactions occurring in the SRC-stabilized soil.Further, the addition of sulfate solutions resulted in the immediate formation of ettringite in the SRC-stabilized soil which was confirmed through the microstructural and EDAX elemental analysis. MIP analysis also confirms that the addition of sulfate increased the porosity and led to the deterioration of the SRC-stabilized soil, resulting in the reductions in strength and compaction density.

(3) The strength reduction due to compaction time delay was proportional to the reduction in compaction dry density of the SRC-stabilized soil. This reduction in strength is the manifestation of the reduced dry densities which occurred during the delayed compaction.This is due to the formation of clogs prior to the compaction in stabilized soil mixed with distilled water. In case of stabilized soil mixed with sulfate solutions, it is due to the formation of clogs and ettringite crystals.

(4) Based on the present experimental study,it can be concluded that the addition of sulfate further deteriorates the compaction and strength characteristics of the SRCstabilized soil.

Declaration of competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Journal of Rock Mechanics and Geotechnical Engineering2021年5期

Journal of Rock Mechanics and Geotechnical Engineering2021年5期

- Journal of Rock Mechanics and Geotechnical Engineering的其它文章

- Surface characteristics analysis of fractures induced by supercritical CO2 and water through three-dimensional scanning and scanning electron micrography

- Prediction of fracture and dilatancy in granite using acoustic emission signal cloud

- Hysteresis in the ultrasonic parameters of saturated sandstone during freezing and thawing and correlations with unfrozen water content

- Coupled Eulerian-Lagrangian simulation of a modified direct shear apparatus for the measurement of residual shear strengths

- A novel true triaxial test system for microwave-induced fracturing of hard rocks

- Hydromechanical behavior of unsaturated expansive clay under repetitive loading