土壤农用地膜微生物降解研究进展

丁豪杰,苏奇倩,李 林,李晓锋,徐其静,Rensing Christopher,刘 雪*

土壤农用地膜微生物降解研究进展

丁豪杰1,2,苏奇倩1,2,李 林1,2,李晓锋1,2,徐其静1,2,Rensing Christopher1,3,刘 雪1,2*

(1.西南林业大学环境修复与健康研究院,云南 昆明 650224;2.西南林业大学生态与环境学院,云南 昆明 650224;3.福建农林大学资源与环境学院,福建 福州 350002)

地膜可保持土壤湿度,调节土壤温度及限制杂草生长从而促进农作物增产,在现代农业生产中具有不可或缺的作用.然而,地膜主要成分聚乙烯(PE)性质稳定,难以降解,极易在农田土壤中残留并积累.此外,地膜在生产过程中添加邻苯二甲酸酯类(PAEs)作为塑化剂,该类有机物极易在土壤和水体环境中积累和迁移,且生物毒性大,对生态环境、粮食安全和人体健康构成极大威胁.聚乙烯和邻苯二甲酸酯复合污染是土壤有机污染治理的重点和难点.因此,农用地膜污染土壤修复是环境科学研究的重要课题,亦是作物生产安全和人类健康的重要保障.微生物降解的生物修复较物理化学技术具有效率高、无二次污染、成本低、环境扰动小等优点,具有广泛应用前景.由此,本文综述农用地膜使用和土壤残留现状及其生物降解的研究进展,以期为地膜污染农田土壤的生物修复提供基础信息和技术参考.

农用地膜;聚乙烯;邻苯二甲酸酯;微生物;生物降解;生物修复

20世纪50年代,日本与欧美等发达国家首次将农用地膜技术应用于农业生产领域[1].由于农用地膜可保持土壤湿度,调节土壤温度及限制杂草生长等优点[2-3],在世界范围内得到推广并广泛使用.中国作为农业大国,引进技术至今,农用地膜已经成为继化肥和农药之后的第三大生产材料[4].

由于聚乙烯(PE)质量轻、制造工艺简单、可塑性强和价格低等优点,市场需求占比较大,约为43%[5].PE又可分为线性低密度聚乙烯(LLDPE)、低密度聚乙烯(LDPE)和高密度聚乙烯(HDPE).LLDPE和LDPE多用于薄膜产品,其中约半数的薄膜产品应用于农业土壤覆盖.邻苯二甲酸酯类(PAEs)是一类广泛使用的改性添加剂,用于增加塑料制品的强度和可塑性,也可用作农药载体、化妆品、润滑剂等产品的生产原料[6].

根据国家统计局的有效数据,截至2018年,我国地膜覆盖面积达1776万hm2,地膜使用量达140万t[7].研究显示,若覆膜率在1%~15%范围内的县域其地膜覆盖率均提高5%,粮食总产量将增加约433万t[8].我国地膜用量在农业农用地膜总量中的占比极高,地膜的广泛应用已使我国粮食作物增产20%~ 35%,经济作物增产20%~60%,对保障粮食供给具有重要作用[9],亦带来极大经济效益,例如,2017年铺设地膜产生的农业产值高达58059.8亿元[10].然而,由于技术和民众认知上的局限性,地膜回收困难,大量地膜残留在农田土壤中,造成严重的“白色污染”[11].同时,农用地膜的主要成分是PE和PAEs,PE性质稳定,难以自然降解,PE对农田土壤理化性质及作物生长有诸多不良影响(阻碍根系生长、影响土壤中水分运移等)[12];而PAEs残留在农田土壤环境中,对农作物食品安全和人体健康造成极大威胁[13].

修复农业土壤中的残膜污染具有重大的环境、经济和社会意义.相较于传统的化学和物理方法,微生物修复技术具有操作简单、经济实用和无二次污染等优点[14].因此,本文重点关注微生物降解技术,阐述其对地膜的降解方式、过程机理及影响因素,旨在为农田土壤有机污染修复提供基础信息和技术参考.

1 土壤农用地膜污染现状与研究进展

1.1 残膜对土壤理化性质的影响

自我国引进地膜覆盖技术以来,地膜用量及覆盖面积年增长率达8%,1991~2011年间,地膜使用强度增加3~10倍[15].然而,约25%~33%投入使用的地膜残留在土壤中[1],地膜主要成分为高分子聚合物,在土壤中难以降解[16],对土壤生态环境[17]、农作物食品安全和人体健康具有潜在风险[18].残膜显著影响土壤的团聚体、水分和养分运输、土壤渗透性、微生物数量和酶活性、有机质及氮素含量等.

数据显示,我国长期覆盖地膜的农田土壤中,残膜量为71.9~259kg/hm2[15].残膜破坏土壤团聚体,使土壤板结[19].研究显示,覆盖地膜7年后,表层15cm土层中水稳性大团聚体(>0.25mm)占比提高16%~ 28%,土壤容重略有增加,但pH值下降0.19~0.54[20].

由于地膜无法被渗透,残膜阻碍水分和养分的正常运输.残膜量为360kg/hm2,水分下渗速度降低30%[21].Bescansa等[22]使用CT扫描技术发现,残膜阻碍土壤孔隙面积增加.当残膜量为225kg/hm2,土壤容重增加18.2%,土壤孔隙度降低13.8%,土壤含水率降低11.7%,并随残膜量增加持续恶化[23].

土壤饱和导水率是土壤饱和渗透性能的直观反映,残膜导致土壤饱和导水率降低.当残膜量为100kg/hm2,其饱和导水率降低45%,当残膜量达到200kg/hm2,其饱和导水率突降88%[24].此外,白一茹等[25]研究发现,在残膜污染土壤入渗过程分析中,更适合采用Kostiakov模型,且在该模型下入渗湿润锋运移距离与入渗时间呈幂指数增长关系.随残膜量增加,水平方向的水迁移速率和累积过滤量呈显著下降趋势[26].曹俊豪等通过因素效应分析发现,当土壤初始含水率<11%,土壤干容重与湿润锋运移时间呈正相关;反之,呈负相关.当土壤干容重<1.41g/cm3,湿润锋运移时间与残膜量呈正相关关系;反之,两者呈负相关.当残膜量<150kg/hm2,湿润锋运移时间与土壤干容重呈正相关;反之,湿润锋运移时间逐渐趋于稳定[27].

高含量残膜使土壤微生物数量和酶活性降低,影响微生物参与的土壤有机质腐质化过程,导致土壤有机质含量下降[28].棉花田实验显示,残膜含量为600kg/hm2,土壤有机质含量降低16.5%[29].此外,土壤中99%氮素来自有机质,当有机质含量降低时,土壤全氮含量亦随之降低[30].

1.2 农用地残膜回收问题

农用地膜的大规模使用、农民回收意识匮乏以及残膜回收机具技术上的限制,导致残膜回收工作困难.上世纪60年代,农业化较为发达的国家开始研制不同类型的残膜回收机具[31],我国残膜回收机具研发近期处在快速发展阶段.按使用时期机具分为三类:(1)苗期地膜回收机具,(2)秋后残膜回收机具,(3)耕后播前残膜回收机具.

国外发达国家使用厚度为0.012~0.015mm的高强度地膜,拉伸性能好,回收较为方便[32].我国农业地膜普遍较薄,96.7%地膜厚度集中在0.004~ 0.008mm,不利于大型机具回收,使大量地膜残留在土壤中[33].目前,我国主要的残膜回收方式为人工捡拾,效率低,效果欠佳.同时,由于缺乏经济效益,费时费力,难以带动农民积极性.云南省1276份有效调查问卷显示,42.9%农户不进行地膜回收[34];宁夏和内蒙古的调查报告显示,68%农户认为有必要进行地膜回收[35].

1.3 残膜对土壤动植物及人体的影响

地膜主要成分包括PE和PAEs.PE作为一种高分子聚合物,呈化学惰性,但经长时间风化,PE碎片造成土壤板结,使土壤肥力下降,抑制植物根系发育.此外,其对土壤理化性质的破坏,亦会影响种子发育和肥料利用,造成农作物减产[36].PAEs是塑料的一种添加剂,与PE、聚丙烯(PP)、聚氯乙烯(PVC)等分子具有较好相容性,由氢键或范德华力进行连接,各自保留相对独立的化学性质[37].当地膜残留在土壤中,随着时间推移,PAEs类污染物可被释放,对空气[38]、水[39]和土壤[40]环境造成危害;植物通过吸收作用富集土壤中的PAEs,对人类健康造成潜在危害[41].

土壤是PAEs储存和迁移的重要介质,PAEs已成为我国土壤含量最高的半挥发性有机物之一.Niu等[42]分析了15种PAEs在中国农田土壤中的残留情况,对中国31个省份涵盖123个区域内的农田土壤进行采样及检测,结果显示采集的全部土壤样品中均检出PAEs.各地农田土壤中15种PAEs总含量均值达到1088µg/kg,其中新疆、广东和福建省农田土壤中PAEs含量在全国范围内较突出,但其污染的主要来源存在差异.新疆PAEs污染主要原因是塑料地膜的大量使用,广东和福建省塑料地膜使用量相对较低,其污染主要来源为污水灌溉及农药、化肥施用[7,43].

目前,粮食作物[44]、蔬菜[45]、水果[46]等食物中均已检出PAEs.PAEs也可通过皮肤接触、吸入、饮食等方式进入人体[47].研究显示,母亲、婴儿和胚胎组织中均已检出PAEs[48].作为一类典型的环境激素类物质,PAEs具有抗雄性激素和类雌性激素活性的作用,进入人体后与激素受体结合,在低浓度下导致动物与人体内分泌紊乱,高浓度可产生致畸性、致癌性及致突变性等症状[49-50].对动物的相关研究表明,PAEs通过其代谢物抑制卵巢中雌二醇的产生,导致雌性排卵异常[51].暴露于高浓度PAEs氛围中可影响人类精液质量和睾丸间质细胞发育[52],亦对儿童智力和行为产生影响[53].

1.4 可降解地膜的应用与发展

为解决残膜污染问题,国内外学者以保证农作物产量为前提研发出可降解地膜,可降解性聚乙烯地膜为了加快降解进程,通常在生产过程中加入活性基团.例如,光降解塑料在高分子材料中引入醛基、羰基等活性基团,利用太阳光的紫外线作用产生自由基,使聚合物分子断裂以达到降解的目的[54],其特点在于地膜发挥生产作用后,可在土壤中自行降解为环境低毒或无毒的小分子物质[55],但农用聚乙烯薄膜生产过程中没有加入活性基团,不利于微生物粘附,难以使微生物在聚乙烯表面生长,不利于残膜的微生物降解.

目前,随着相关技术逐渐完善,我国已拥有多种类型的可降解地膜,依据材质可大致分为三类[35]:

(1) 淀粉基聚乙烯(PE)材料,它的价格低廉,但剩余PE碎片仍无法降解.

(2) PE/PP光–氧降解类,相对于传统地膜,它可以自行分解成碎片,但降解后碎片在土壤中长期存在.

(3) 聚乳酸(PLA)、聚丁二酸丁二醇酯(PBS)、聚丙烯酸丁酯(PBA)、聚对苯二甲酸-己二酸丁二醇酯(PBAT)、聚己内酯(PCL)降解聚酯类,可最终降解为CO2和H2O,其中PLA价格较高,PBAT和PBS是当前应用较多的可降解地膜材料.

在烟草[56]、玉米[57]和花生[58]的覆膜实验中发现,可降解地膜的增产效果略低于普通地膜,而在马铃薯[59]实验中,可降解地膜的增产效率更高,可能原因是马铃薯为不耐热植物,随着可降解地膜的降解,土壤温度降低,促进马铃薯生长.同时,可降解地膜与普通地膜都具有增温和保墒效果,但可降解地膜的保水性能略低于普通地膜[60].虽然应用可降解地膜可极大缓解农用地土壤有机污染,但较高的成本是限制其大规模推广使用的最直接因素[61].

2 聚乙烯生物降解研究进展

PE作为地膜的最主要成分,具有以下特点:高分子量、结构复杂、疏水性、缺少微生物可以作用的官能团,故在土壤中难以被大多数微生物降解,但自然界中仍有一部分微生物可使聚乙烯内部结构发生变化,使其分子量降低,最终实现降解[62-63].这种降解方式可极大缓解残膜对土壤环境的压力,故筛选分离功能性聚乙烯降解菌已成为研究的热点.

2.1 聚乙烯降解菌种类

土壤聚乙烯降解微生物包括真菌、细菌和放线菌三大类,目前发现的降解菌主要是真菌和细菌,放线菌报道较少.截至2014年,已报道聚乙烯降解菌包含9个属的真菌和17个属的细菌[64].PE降解微生物对PE的降解特性见表1.

表1 聚乙烯(PE)降解微生物及其特性

由于真菌代谢产物丰富、产生的酶种类丰富和酶活性高等优点,其降解性能高于细菌和放线菌[65].真菌在降解聚乙烯过程中不仅分泌胞外聚合物[66],且产生特异性酶,主要包括细胞内和胞外解聚酶[67].此外,真菌的菌丝结构利于其粘附于聚乙烯表面,形成紧密的生物膜,极大提高降解效率和降解程度.但对于未经过任何处理的PE薄膜,目前尚未发现可在较短时间内对其进行高效降解的细菌、真菌或放线菌[68].现有研究发现,在微生物降解前对PE进行光、热、化学氧化等前处理可显著加速其降解进程[69].其中,光降解是降低农用PE分子量,提高微生物降解速率的有效方法[70].

在聚乙烯微生物降解研究中,大多关注单一菌株对聚乙烯的降解,但是单一菌株在降解PE的过程中产生的中间产物或最终产物积累可能具有更高的潜在毒性,所以混合菌株对PE的降解研究逐渐引起关注.Han等[71]研究发现,栉杆菌(sp.)和链霉菌(sp.)均能独自降解聚乙烯薄膜.但将菌株接种到含有聚乙烯薄膜的溶液中发现,前者以浮游生物的方式在溶液介质中生长,后者则是粘附在薄膜表面,这两种不同的代谢方式为微生物联合降解PE提供新的可能.

2.2 聚乙烯微生物降解机制

理论上,微生物可利用PE作为唯一碳源,但是由于PE具有较高的分子量,很多酶无法以PE为底物进行催化反应.1992年, Pometto等[84]将处理后的淀粉-聚乙烯可降解薄膜、活性与非活性酶和由、、制备的浓缩物一起进行孵育,最终机械性能、分子量和FTIR分析结果表明,PE薄膜能在活性酶的作用下发生降解.

Zhao等[88]使用过氧化氢作为氧化剂和过氧化物酶作为催化剂对酶表面进行改性,通过FTIR、XPS和SEM表征改性后HDPE表面的结构和化学组成,结果显示,酶处理后HDPE表面出现了新的官能团(羰基等)、O/C比增加.紫外可见光谱和接触角测量分析发现,改性后HDPE表面与水的接触角变小,且对水溶性染料的吸附能力增强,表明酶处理可显著增加HDPE表面的亲水性.

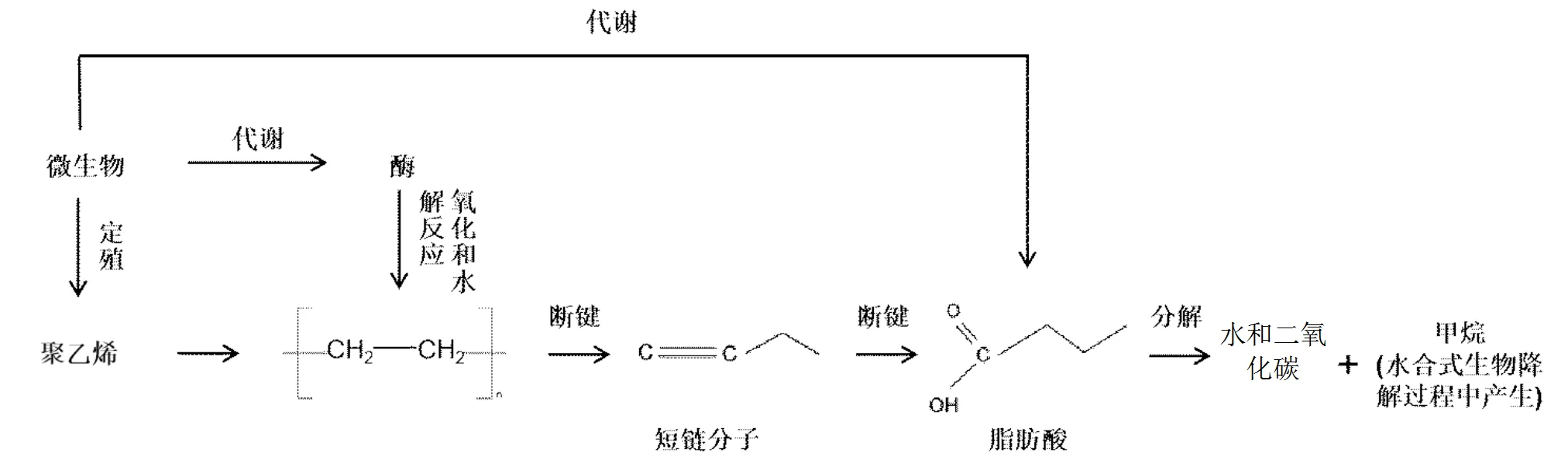

PE微生物降解的生化过程包括分子量的降低和分子的氧化作用.当PE分子量降低后,PE可通过氧化作用将碳氢化合物转化为羧酸分子,再通过β-氧化或三羧酸循环进行代谢降解.PE的分子量降低一般通过光、热、化学氧化处理完成,Santo[89]在研究中发现漆酶可通过增加PE中羧基的数量来使其分子量降低.PE的生物降解过程主要包括两种机制:氧化式生物降解和水合式生物降解[90],两种机制都是先进行化学分解,再进行生物降解,最终实现无机矿化,产生H2O和CO2,此外,水合式生物降解过程中还产生甲烷(图1).

研究发现,PE微生物降解过程中的氧化步骤又可细分为以下4种代谢途径:

(1)末端氧化[91]:RCH3→RCH2OH→RCHO→RCOOH.

(2)两端氧化[92]:H3CRCH3→CH3RCOOH→HOH2CRCOO→OHCRCOOH→HOOCRCOOH.

(3)次末端氧化[93]:RCH2CH2CH3→RCH2OC(O)CH3→RCH2OC(O)CH3→RCH2OH+ CH3COOH.

(4)末端过氧化[94]:RCH3→RCH2·OOH→RCO(O) OH→RCHO→RCOOH.

图1 聚乙烯(PE)的微生物降解机制

3 邻苯二甲酸酯生物降解研究进展

PAEs是一种合成的持久性有机污染物,易进入环境并积累,其化学性质稳定,对生物体具有严重危害.目前,PAEs在世界各地土壤[95]、河流[96-97]、湖泊[98]、海洋[99]、湿地[100]、污泥[101]、饮用水[102]、食品[103]和灰尘[104]中均已普遍检出.美国环保局(USEPA)已将PAEs中的邻苯二甲酸二甲酯(DMP)、邻苯二甲酸二乙酯(DEP)、邻苯二甲酸二丙酯(DPP)、邻苯二甲酸二丁酯(DBP)、邻苯二甲酸二辛酯(DOP)和邻苯二甲酸二己酯(DEHP)列为重点控制污染物.中国已将DMP、DEP和DOP列为优先控制污染物[105].

3.1 邻苯二甲酸酯降解菌种类

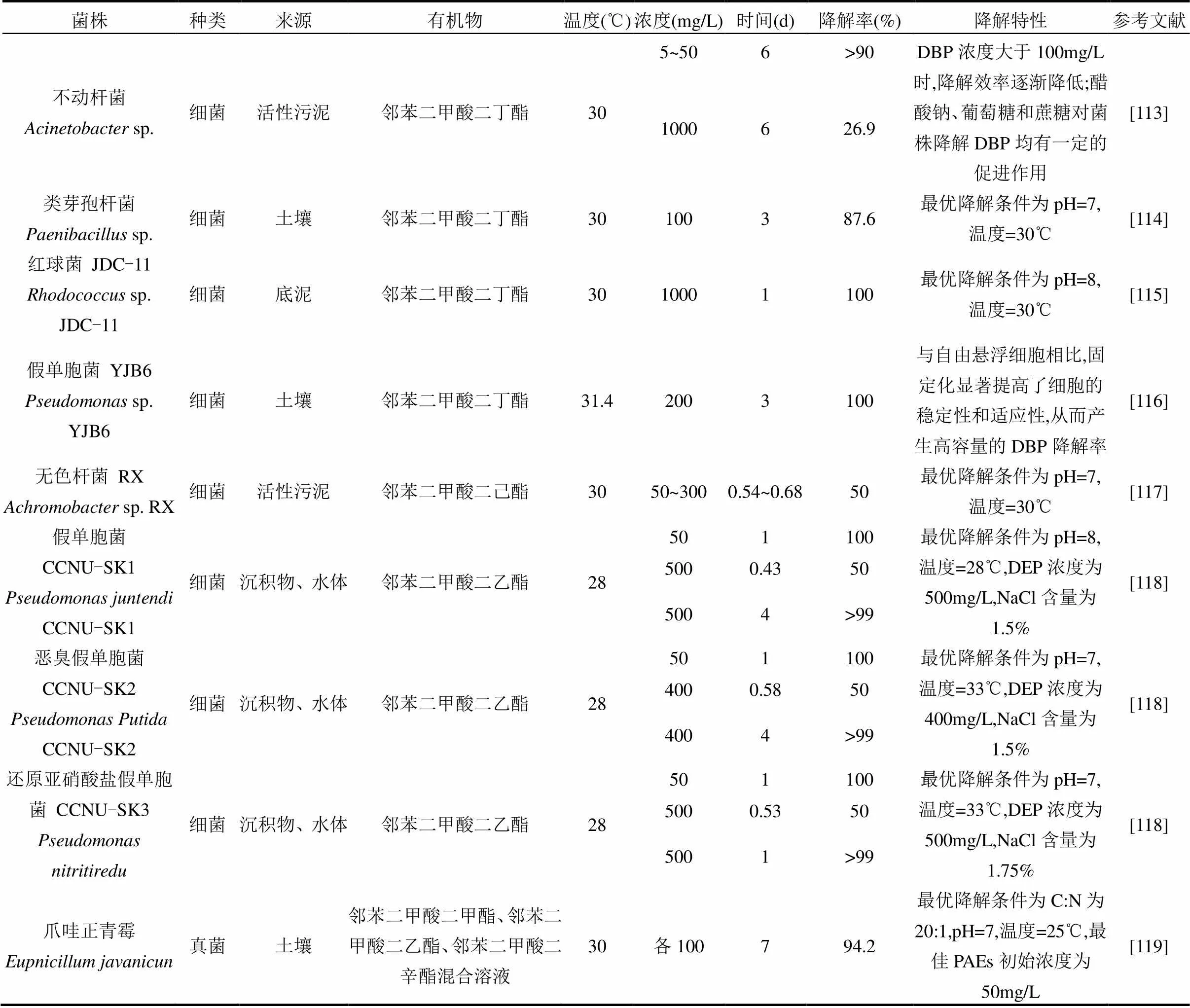

PAEs化学性质稳定,水解和光解速度极慢.因此,微生物降解被认为是环境中邻苯二甲酸酯完全矿化的主要过程.截至2016年,邻苯二甲酸酯降解菌包含36个属,80多种菌株[106],优势属为节细菌属()丛毛单胞菌属()假单胞菌属()红球菌属()和鞘脂单胞菌属().部分PAEs降解微生物的降解效率及特性见表2.

大多数微生物可通过作为唯一碳源的邻苯二甲酸酯进行生长和繁殖,近50%菌株具有降解多种邻苯二甲酸酯的能力.例如,枯草芽孢杆菌()可降解DBP、DEP、DEHP、邻苯二甲酸二丙酯(DPRP)和邻苯二甲酸二戊酯(DPEP)五种PAEs,此类多功能菌株还包括戈登氏菌属(sp.),苍白杆菌属(sp.),贪噬菌属(sp.)等[106].

表2 邻苯二甲酸酯(PAEs)降解微生物及其特性

续表2

3.2 邻苯二甲酸酯微生物联合降解

大多数分离的降解菌难以独立完全降解邻苯二甲酸酯.Vega等[120]发现,节杆菌(sp.)可将DMP转化为邻苯二甲酸单甲酯(MMP),却不能进一步转化为PA.少动鞘氨醇单胞菌()可将MMP降解为PA,但是却不能将DMP转化为MMP.因此,sp.和菌群可实现DMP的完全矿化.Wu等[121]对sp.JDC-2和sp.DFC-32菌群降解DOP发现类似现象.此外,sp. MTCC 4818和sp.[122]都可独立利用BBP作为唯一碳源从而实现降解,但二者的单一菌株均不能完全降解BBP,两种菌株的混合菌群可将BBP完全降解.因此,筛选具有矿化PAEs能力的微生物,构建多菌群复合体系实现PAEs彻底降解具有重要的环境意义和科学研究价值.

3.3 邻苯二甲酸酯微生物降解机制

PAEs是1, 2-苯二羧酸酯类,根据侧链数量和与碱性苯基基团连接的烷基或芳基的不同而形成多种结构.1, 2-苯二甲酸酯类的3种异构形式(邻位、对位和间位)是增塑剂的主要成分.

细菌对邻苯二甲酸酯的降解可分为初始水解和最终降解两个过程.初始水解过程具有两种反应:(1)细菌通过β-氧化、转酯化作用和脱酯化(去甲基化)作用减少侧链长度.β-氧化反应依次脱去一个乙基,使侧链双酯基碳原子>2的PAEs转化为短链的PAEs,目前相关研究较少且尚未在纯菌体系中得到验证[123].随后在单侧酯基上发生转酯化和脱酯化反应,将短链PAEs降解为PA;(2)细菌可通过酯键的水解反应直接将PAEs降解为PA.由于在酶促反应过程中,长链比短链的空间效应更强,使短链更易水解[124].邻苯二甲酸(PA)是PAEs降解的重要中间产物,最终降解过程也是PA的降解.

在不同情况下,细菌对PA的生物降解途径具有显著差异.好氧条件下[125-126],革兰氏阳性菌和革兰氏阴性菌分别在邻苯二甲酸3, 4-双加氧酶和邻苯二甲酸4, 5-双加氧酶的作用下,通过氧化、脱氢和脱羧过程将PA转化成原儿茶酸(PCA),然后PCA开环形成对应的有机酸,再通过转化作用,生成草酰乙酸(OAA)、丙酮酸(PHD)等,经过三羧酸循环最终代谢为H2O和CO2(图2).

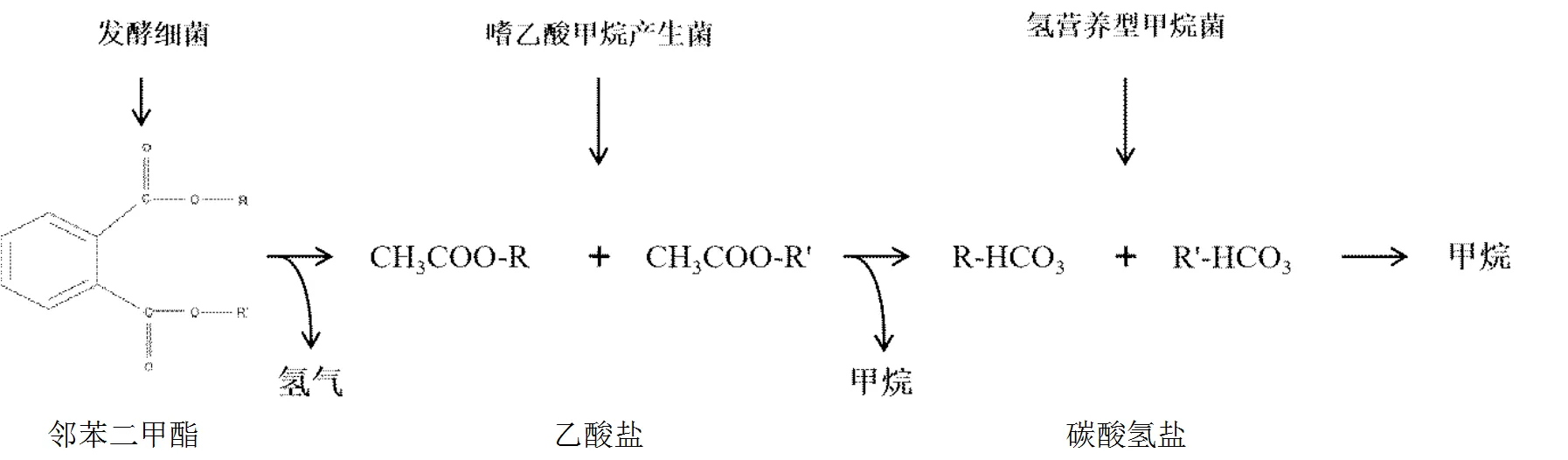

但在厌氧条件下,PAEs的生物降解机制研究较少.Kleerebezem等[127]研究了产甲烷菌与细菌的混合菌群在厌氧环境下通过发酵细菌()、嗜乙酸甲烷产生菌()和氢营养型甲烷菌()作用将PAEs转化并产生甲烷(图3).

图2 好氧条件下革兰氏阳性菌和革兰氏阴性菌对邻苯二甲酸酯(PAEs)的降解机制

图3 厌氧条件下产甲烷菌与细菌的混合菌群对邻苯二甲酸酯(PAEs)的降解机制

目前关于PAEs真菌降解途径的报道较少. Sivamurthy等[128]发现,白绢病菌()可将对苯二甲酸二甲酯(DMTP)转化为对苯二甲酸(TPA),TPA是该过程的最终代谢产物.Ganji等[129]报道,可将DMTP完全降解,转化成对苯二甲酸单甲酯(MMTP)、PCA和TPA,再通过PCA开环反应,最终完全降解为H2O和CO2.

4 结语

4.1 残膜危害

由于我国农业生产过程中对于农用地膜具有很大的依赖性,加之回收意识匮乏和回收技术发展的欠缺,导致大量薄膜残留在农田土壤中.残膜中的PE在自然环境中难以降解,累积在农田土壤中可显著影响土壤中的水分运移、酶活性、有机质及氮素含量等;而残膜中的PAEs生物毒性大,极易在土壤和水环境中迁移,对农田土壤生态环境造成严重威胁.因此,如何处理农用地膜已引起广泛关注.

4.2 微生物降解技术

微生物降解的生物处理技术较物理、化学技术具有效率高、无二次污染、成本低、环境扰动小等优点,具有广泛的应用前景.但现阶段农用地膜的微生物降解理论无法完全应用于工业化技术处理过程,使得微生物降解技术发展受到限制.同时,农用地膜的微生物降解受环境、微生物及降解底物性质影响,其中降解环境可人为控制,降解微生物性质的筛选及降解物质性质的改变尤为重要.

4.3 展望

现阶段对于农用聚烯烃地膜微生物降解理论研究及微生物修复技术实际应用仍显不足,可加强以下几方面的研究:

加强对PE微生物降解机制、过程、影响因素等的理论研究.力求发现可对PE进行高效降解的微生物菌种材料,同时仍需针对混合菌株对PE的降解机理进行探索,以提高残膜微生物降解效率.

结合PE、PAEs现有的微生物降解理论研究成果,开展实际农田土壤环境下的降解研究,探索及解决土壤环境条件下微生物的存活问题以及复杂土壤环境下的降解过程及机制,为微生物降解技术的发展提供理论依据.

应加快地膜的微生物降解理论成果向微生物降解技术的工业化转化,对解决农田土壤地膜残留这一棘手问题做出技术支持,保证农田土壤环境的生态健康与种植安全.

[1] 邹小阳,牛文全,刘晶晶,等.残膜对土壤和作物的潜在风险研究进展 [J]. 灌溉排水学报, 2017,36(7):47-54.

Zou X Y, Niu W Q, Liu J J, et al. Potential risks of plastic film residuals on soils and crops: a review [J]. Journal of Irrigation and Drainage, 2017,36(7):47-54.

[2] Kader M A, Senge M, Mojid M A,et al. Recent advances in mulching materials and methods for modifying soil environment [J]. Soil and Tillage Research, 2017,168:155-166.

[3] Martín-Closas L, Costa J, Pelacho A M. Agronomic effects of biodegradable films on crop and field environment [M]. Pozzuoli: Soil Degradable Bioplastics for a Sustainable Modern Agriculture, 2017,67-104.

[4] 崔晓红.地膜覆盖在农业生产中的应用探讨 [J]. 现代农业科技, 2013,49(16):192-195.

Cui X H. Discussion on the application of mulch in agricultural production [J]. Modern Agricultural Science and Technology, 2013, 49(16):192-195.

[5] Geyer R, Jambeck J R, Law K L. Production, use, and fate of all plastics ever made [J]. Science Advances, 2017,3(7):doi:10.1126/ sciadv.1700782.

[6] 孙若男.食品和塑料橡胶中酞酸酯的GC-EI/MS及GC-MS/MS分析方法研究 [D]. 厦门:厦门大学, 2008.

Sun R N. Study of phthalic acid esters in food and plastics rubber by GC-EI/MS and GC-MS/MS [D]. Xiamen: Xiamen University, 2008.

[7] 国家统计局农村社会经济调查司.中国农村统计年鉴2019 [M]. 北京:中国统计出版社, 2019.

Rural Society Investigation Department of National Statistical Bureau. China rural statistical yearbook 2019 [M]. Beijing: China Statistics Press, 2019.

[8] 王秀芬,陈百明,毕继业.基于县域的地膜覆盖粮食增产潜力分析 [J]. 农业工程学报, 2005,21(11):154-157.

Wang X F, Chen B M, Bi J Y. Analysis of potential of grain yield increase under film-mulching condition on a county scale [J]. Transactions of the Chinese Society of Agricultural Engineering, 2005,21(11):154-157.

[9] 张 丹,胡万里,刘宏斌,等.华北地区地膜残留及典型覆膜作物残膜系数 [J]. 农业工程学报, 2016,32(3):1-5.

Zhang D, Hu W L, Liu H B, et al. Characteristics of residual mulching film and residual coefficient of typical crops in North China [J]. Transactions of the Chinese Society of Agricultural Engineering, 2016,32(3):1-5.

[10] 雍 婕,程 益,周海燕.地膜降解途径及机理研究进展 [J]. 应用生态学报, 2021,32(2):729-736.

Yong J, Cheng Y, Zhou H Y. Advances in researches of the mulch degradation and its mechanism [J]. Chinese Journal of Applied Ecology, 2021,32(2):729-736.

[11] Liu E K, He W Q, Yan C R. 'White revolution' to 'white pollution'- Agricultural plastic film mulch in China [J]. Environmental Research Letters, 2014,9(9),doi:10.1088/1748-9326/9/9/091001.

[12] 王 亮,林 涛,严昌荣,等.不同残膜量和灌溉定额对棉花养分和水分利用的影响 [J]. 植物营养与肥料学报, 2018,24(1):122-133.

Wang L, Lin T, Yan C R, et al. Effects of different film residue and irrigation quota on nutrient and water use efficiency of cotton under drip irrigation [J]. Journal of Plant Nutrition and Fertilizer, 2018, 24(1):122-133.

[13] 曹 龙,张朝升,陈秋丽,等.邻苯二甲酸酯的环境污染和生态行为及毒理效应研究进展 [J]. 生态毒理学报, 2018,13(2):34-46.

Cao L, Zhang C S, Chen Q L, et al. Progress in the study of environmental pollution and ecological behavior and toxicological effects of phthalate ester [J]. Asian Journal of Ecotoxicology, 2018, 13(2):34-46.

[14] Yang L, Chen S, Hu M, et al. Biodegradation of carbofuran bystrain HQ-C-01and its application for bioremediation of contaminated soils [J]. Biology and Fertility of Soils, 2011,47(8): 917-923.

[15] 严昌荣,刘恩科,舒 帆,等.我国地膜覆盖和残留污染特点与防控技术 [J]. 农业资源与环境学报, 2014,31(2):95-102.

Yan C R, Liu E K, Shu F, et al. Review of agricultural plastic mulching and its residual pollution and prevention measures in China [J]. Journal of Agricultural Resources and Environment, 2014,31(2): 95-102.

[16] Briassoulis D, Babou E, Hiskakis M, et al. Analysis of long-term degradation behaviour of polyethylene mulching films with pro-oxidants under real cultivation and soil burial conditions [J]. Environmental Science and Pollution Research, 2015,22(4):2584- 2598.

[17] 高维常,蔡 凯,曾陨涛,等.农用地膜残留对土壤氮素运移及烤烟根系生长的影响 [J/OL]. http://kns.cnki.net/kcms/detail/32.1119.P. 20190924.1033.006.html, 2019-09-24.

Gao W C, Cai K, Zeng Y T, et al. Impacts of mulching plastic film residue on migration of soil nitrogen and growth of flue-cured tobacco roots [J/OL]. http://kns.cnki.net/kcms/detail/32.1119.P.20190924.1033. 006.html, 2019-09-24.

[18] Reddy M S, Yamaguchi T, Okuda T, et al. Feasibility study of the separation of chlorinated films from plastic packaging wastes [J]. Waste Management, 2009,30(4):597-601.

[19] Chen Y, Wu C, Zhang H, et al. Empirical estimation of pollution load and contamination levels of phthalate esters in agricultural soils from plastic film mulching in China [J]. Environmental Earth Sciences, 2013,70(1):239-247.

[20] Wang L, Li X G, Lv J, et al. Continuous plastic-film mulching increases soil aggregation but decreases soil pH in semiarid areas of China [J]. Soil and Tillage Research, 2017,167:46-53.

[21] 何 晶.不同分子量的聚乙烯粉末对土壤环境及作物生长的影响研究 [D]. 绵阳:西南科技大学, 2011.

He J. Comparative study on effects of different molecular weight polyethylene powder to soil environment and crop development [D]. Mianyang: Southwest University of Science and Technology, 2011.

[22] Bescansa P, Imaz M J, Virto I, et al. Soil water retention as affected by tillage and residue management in semiarid Spain [J]. Soil and Tillage Research, 2006,87(1):19-27.

[23] 尉海东,伦志磊,郭 峰.残留农膜对土壤性状的影响 [J]. 生态环境学报, 2008,17(5):1853-1856.

Wei H D, Lun Z L, Guo F. Effects of mulch film residues on soil properties [J]. Ecology and Environment, 2008,17(5):1853-1856.

[24] 王志超,李仙岳,史海滨,等.农膜残留对土壤水动力参数及土壤结构的影响 [J]. 农业机械学报, 2015,46(5):101-106.

Wang Z C, Li X Y, Shi H B, et al. Effects of residual plastic film on soil hydrodynamic parameters and soil structure [J]. Transactions of The Chinese Society of Agricultural Machinery, 2015,46(5):101-106.

[25] 白一茹,张 兴,王幼奇,等.不同残膜含量对淡灰钙土水分入渗过程的影响 [J]. 农业资源与环境学报, 2019,36(2):227-235.

Bai Y R, Zhang X, Wang Y Q, et al. Study on influence of different agricultural residue film amounts on soil infiltration process of light sierozem [J]. Journal of Agricultural Resources and Environment, 2019,36(2):227-235.

[26] 王志超,李仙岳,史海滨,等.农膜残留对砂壤土和砂土水分入渗和蒸发的影响 [J]. 农业机械学报, 2017,48(1):198-205.

Wang Z C, Li X Y, Shi H B, et al. Effects of residual plastic film on infiltration and evaporation for sandy loam and sandy soil [J]. Transactions of The Chinese Society of Agricultural Machinery, 2017,48(1):198-205.

[27] 曹俊豪,李援农,谷晓博,等.土壤残膜对水分入渗过程的影响 [J]. 中国农村水利水电, 2020,62(1):26-30.

Cao J H, Li Y N, Gu X B, et al. The effect of residual plastic film soil on water infiltration process [J]. China Rural Water and Hydropower, 2020,62(1):26-30.

[28] 焦晓光,高崇升,隋跃宇,等.不同有机质含量农田土壤微生物生态特征 [J]. 中国农业科学, 2011,44(18):3759-3767.

Jiao X G, Gao C S, Sui Y Y, et al. Research on soil microbial ecology under different soil organic matter levels in farmland [J]. Scientia Agricultura Sinica, 2011,44(18):3759-3767.

[29] 董合干.地膜残留对棉花产量影响的极限研究 [D]. 石河子:石河子大学, 2013.

Dong H G. The limit effect of film residue on cotton yield [D]. Shihezi: Shihezi University, 2013.

[30] 杨丽霞,陈少锋,安娟娟,等.陕北黄土丘陵区不同植被类型群落多样性与土壤有机质、全氮关系研究 [J]. 草地学报, 2014,22(2):291- 298.

Yang L X, Chen S F, An J J, et al. Relationships among community diversity and soil organic matter, total nitrogen under different types in the gully region of loess region [J]. Actaagrestia Sinica, 2014,22(2): 291-298.

[31] 杨松梅.随动式棉田残膜回收机设计及关键技术研究 [D]. 长春:吉林大学, 2020.

Yang S M. Design and key technology research of passive cotton field residual plastic film recycling machine [D]. Changchun: Jilin University, 2020.

[32] 赵 岩,陈学庚,温浩军,等.农田残膜污染治理技术研究现状与展望 [J]. 农业机械学报, 2017,48(6):1-14.

Zhao Y, Chen X G, Wen H J, et al. Research status and prospect of control technology for residual plastic film pollution in farmland [J]. Transactions of The Chinese Society of Agricultural Machinery, 2017,48(6):1-14.

[33] 张 丹,王洪媛,胡万里,等.地膜厚度对作物产量与土壤环境的影响 [J]. 农业环境科学学报, 2017,36(2):293-301.

Zhang D, Wang H Y, Hu W L, et alEffect of film thickness on crop yield and soil environment [J]. Journal of Agro-Environment Science, 2017,36(2):293-301.

[34] 朱彩霞,杨林伟,李永前.农用地膜污染的多层影响因素及防治策略实证研究—以云南省为例 [J]. 生态经济, 2019,35(9):206-211.

Zhu C X, Yang L W, Li Y Q. Empirical study on multi-layer influencing factors and control strategies of agricultural membrane pollution: taking Yunnan Province as an Example [J]. Ecological Economy, 2019,35(9):206-211.

[35] 李佳璇,闫龙成,王 宁.农用地膜的污染与新型地膜 [J]. 内蒙古石油化工, 2019,45(7):52-54.

Li J X, Yan L C, Wang N. Pollution of agricultural mulch and degradable plastic film [J]. Inner Mongolia Petrochemical Industry, 2019,45(7):52-54.

[36] 姜益娟,郑德明,朱朝阳.残膜对棉花生长发育及产量的影响 [J]. 农业环境保护, 2001,20(3):177-179.

Jiang Y J, Zheng D M, Zhu C Y. Effects of remnant plastic film in soil on growth and yield cotton [J]. Journal of Agro-Environment Science, 2001,20(3):177-179.

[37] 谷成刚,相雷雷,任文杰,等.土壤中酞酸酯多界面迁移转化与效应研究进展 [J]. 浙江大学学报(农业与生命科学版), 2017,43(6):700- 712.

Gu C G, Xiang L L, Ren W J, et al. Multi-interfacial migration/ transformation and effects of phthalic acid esters in soils: a review [J]. Journal of Zhejiang University (Agriculture & Life Sciences), 2017, 43(6):700-712.

[38] Tran T M, Kannan K. Occurrence of phthalate diesters in particulate and vapor phases in indoor air and implications for human exposure in Albany, New York, USA [J]. Archives of Environmental Contamination and Toxicology, 2015,68(3):489-499.

[39] Net S, Sempéré R, Delmont A, et al. Occurrence, Fate, behavior and ecotoxicological state of phthalates in different environmental matrices [J]. Environmental Science and Technology, 2015,49(7):4019-4035.

[40] Selvaraj K K, Sundaramoorthy G, Ravichandran P K, et al. Phthalate esters in water and sediments of the Kaveri River, India: environmental levels and ecotoxicological evaluations [J]. Environmental Geochemistry and Health, 2015,37(1):83-96.

[41] Luo Y, Liu L, Qiao W, et al. Facile crystal-structure-controlled synthesis of iron oxides for adsorbents and anode materials of lithium batteries [J]. Materials Chemistry and Physics, 2016,170:239-245.

[42] Niu L, Xu Y, Xu C, et al. Status of phthalate esters contamination in agricultural soils across china and associated health risks [J]. Environmental Pollution, 2014,195:16-23.

[43] 杜 欢.邻苯二甲酸酯降解菌的筛选、降解特性及其在土壤修复中的应用研究 [D]. 广州:暨南大学, 2016.

Du H. Isolation and characterization of phthalate-degrading bacteria and its application in soil remediation [D]. Guangzhou: Jinan University, 2016.

[44] 饶潇潇,王建超,周震峰.花生对土壤中邻苯二甲酸酯的吸收累积特征 [J]. 环境科学学报, 2017,37(4):1531-1538.

Rao X X, Wang J C, Zhou Z F. Characteristics of uptake and accumulation of phthalic acid esters in soil by peanut () [J]. Acta Scientiae Circumstantiae, 2017,37(4):1531-1538.

[45] 杨 彦,于云江,李定龙,等.太湖流域(苏南地区)农业活动区人群PAEs健康风险评估 [J]. 中国环境科学, 2013,33(6):1097-1105.

Yang Y, Yu Y J, Li D L, et al. PAEs health risk assessment of agriculture area in Taihu Lake Basin (Southern Jiangsu Province) [J]. China Environmental Science, 2013,33(6):1097-1105.

[46] Shi M, Sun Y, Wang Z, et al. Plastic film mulching increased the accumulation and human health risks of phthalate esters in wheat grains [J]. Environmental Pollution, 2019,250:1-7.

[47] 柳春红,张明明,赖玉婷,等.邻苯二甲酸酯暴露的大鼠尿液生物标志物研究 [J]. 中国环境科学, 2015,35(9):2868-2873.

Liu C H, Zhang M M, Lai Y T, et al. Urine biomarker of exposure to phthalate in rat [J]. China Environmental Science, 2015,35(9):2868- 2873.

[48] Magdouli S, Daghrir R, Brar S K, et al. Di 2-ethylhexylphtalate in the aquatic and terrestrial environment: a critical review [J]. Journal of Environmental Management, 2013,127:36-49.

[49] 解 玮,蒋颂辉,屈卫东,等.DEHP、DBP内分泌干扰活性的实验研究 [J]. 中国环境科学, 2004,(1):46-49.

Xie W, Jiang S H, Qu W D, et al. Experimental studies on the endocrine disrupting activity of DEHP and DBP [J]. China Environmental Science, 2004,(1):46-49.

[50] Hauser R, Calafat A M. Phthalates and human health [J]. Occupational and Environmental Medicine, 2005,62(11):806-818.

[51] 穆希岩,李成龙,黄 瑛,等.两种邻苯二甲酸酯类污染物对斑马鱼胚胎发育的影响 [J]. 中国环境科学, 2017,37(9):3566-3575.

Mu X Y, Li C L, Huang Y, et al. Effects of two phthalate esters on zebrafish embryos [J]. China Environmental Science, 2017,37(9): 3566-3575.

[52] Jurewicz J, Hanke W. Exposure to phthalates: reproductive outcome and children health. A review of epidemiological studies [J]. International Journal of Occupational Medicine and Environmental Health, 2011,24(2):115-141.

[53] Cho S C, Bhang S Y, Hong Y C, et al. Relationship between environmental phthalate exposure and the intelligence of school-age children [J]. Environmental Health Perspectives, 2010,118(7):1027- 1032.

[54] Shimao M. Biodegradation of plastics [J]. Current Opinion in Biotechnology, 2001,12(3):242-247.

[55] 胡琼恩,李 婷,马丕明,等.生物可降解地膜的研究进展 [J]. 塑料包装, 2017,27(3):34-41.

Hu Q E, Li T, Ma P M, et al.Progress in the research of biodegradable mulching film [J]. Plastic Packaging, 2017,27(3):34-41.

[56] 樊 俊,谭 军,邓建强,等.不同地膜的降解性能及对烟株生长和土壤环境的影响 [J]. 中国烟草科学, 2019,40(4):22-28,36.

Fan J, Tan J, Deng J Q, et alDegradation property of degradable films and their effects on flue-cured tobacco development and soil ecological environment [J]. Chinese Tobacco Science, 2019,40(4): 22-28,36.

[57] 张俊华,谢 茵,李翠微.不同可降解地膜对土壤温度及玉米产量的影响 [J]. 农业科技通讯, 2020,(10):44-48.

Zhang J H, Xie Y, Li C W. Effects of different biodegradable plastic film on soil temperature and maize yield [J]. Bulletin of Agricultural Science and Technology, 2020,(10):44-48.

[58] 林萌萌,孙 涛,尹继乾,等.不同生物降解地膜对花生光合特性和产量的影响 [J]. 中国农学通报, 2015,31(27):190-197.

Lin M M, Sun T, Yin J Q, et al.Effects of different biodegradable films mulching on the photosynthetic characteristics and yield of peanut [J]. Chinese Agricultural Science Bulletin, 2015,31(27):190- 197.

[59] 刘姝彤,张宝时,金胜利,等.不同全生物可降解地膜降解特征及其对马铃薯产量的影响 [J]. 中国农技推广, 2019,35(12):65-68.

Liu S T, Zhang B S, Jin S L, et alDegradation characteristics of different biodegradable plastic film and its effect on potato yield [J]. China Agricultural Technology Extension, 2019,35(12):65-68.

[60] 张相松,王献杰,房晓燕,等.可降解地膜农田适用性评价 [J]. 安徽农业科学, 2019,47(22):79-82.

Zhang X S, Wang X J, Fang X Y, et alApplicability evaluation of degradable mulching films in farmlands [J]. Journal of Anhui Agricultural Sciences, 2019,47(22):79-82.

[61] 赵彩霞,何文清,刘 爽,等.新疆地区全生物降解膜降解特征及其对棉花产量的影响 [J]. 农业环境科学学报, 2011,30(8):1616-1621.

Zhao C X, He W Q, Liu S, et alDegradation of biodegradable plastic mulch film and its effect on the yield of cotton in Xinjiang region, China [J]. Journal of Agro-Environment Science, 2011,30(8):1616- 1621.

[62] 王佳蕾,霍毅欣,杨 宇.聚乙烯塑料的微生物降解 [J]. 微生物学通报, 2020,47(10):3329-3341.

Wang J L, Huo Y X, Yang Y. Microbial degradation of polyethylene [J]. Microbiology China, 2020,47(10):3329-3341.

[63] 孙 璇,俞安琪,王学松,等.富里酸在聚苯乙烯微塑料上的吸附行为 [J/OL]. 中国环境科学: 1-13. https://doi.org/10.19674/j.cnki. issn1000-6923.20210721.007.

Sun X, Yu A Q, Wang X S, et al. Adsorption behaviors of fulvic acid onto polystyrene microplastics [J/OL]. China Environmental Science: 1-13. https://doi.org/10.19674/j.cnki.issn1000-6923.20210721.007.

[64] Restrepo-Flórez J-M, Bassi A, et al. Microbial degradation and deterioration of polyethylene-A review [J]. International Biodeterioration and Biodegradation, 2014,88:83-90.

[65] 尚博菲.土壤真菌多样性研究及塑料降解真菌菌株的筛选 [D]. 长春:吉林大学, 2013.

Shang B F. The research of soil fungal diversity and screening of degradable plastic fungal strains [D]. Changchun: Jilin University, 2013.

[66] Volke-Sepúlveda T, Saucedo-Castaeda G, Gutiérrez-Rojas M, et al. Thermally treated low density polyethylene biodegradation byand[J]. Journal of Applied Polymer Science, 2010,83(2):305-314.

[67] Shah A A, Hasan F, Hameed A, et al. Biological degradation of plastics: a comprehensive review [J]. Biotechnology Advances, 2008,26(3): 246-265.

[68] 胡逸晨.细菌sp. 4-7降解聚乙烯 [D]. 武汉:华中农业大学, 2015.

Hu Y C. Degradation of polyethylene bysp. 4-7 [D]. Wuhan: Huazhong Agricultural University, 2015.

[69] Gilan (Orr) I, Hadar Y, Sivan A. Colonization, biofilm formation and biodegradation of polyethylene by a strain of[J]. Applied Microbiology and Biotechnology, 2004,65(1):97-104.

[70] 李凤珍.合成聚合物的微生物降解 [J]. 微生物学杂志, 1988, (3):69-77.

Li F Z. Microbiological degradation of synthetic polymers [J]. Journal of Microbiology, 1988,(3):69-77.

[71] Han Y N, Wei M, Han F, et al. Greater biofilm formation and increased biodegradation of polyethylene film by a microbial consortium ofsp. andsp. [J]. Microorganisms, 2020, 8(12):1979.

[72] 胡亚楠,贺 旭,亚森·沙力,等.大蜡螟和黄粉虫肠道菌中聚乙烯地膜降解细菌的筛选及其降解性能 [J]. 微生物通报, 2020,47(12): 4029-4041.

Hu Y N, He X, Yasen-Shali, et alScreening of polyethylene film-degrading bacteria from gut microbiota ofand[J]. Microbiology China, 2020,47(12):4029- 4041.

[73] Esmaeili A, Pourbabaee A A, Alikhani H A, et al. Biodegradation of low-density polyethylene (LDPE) by mixed culture ofandin Soil [J]. PLOS ONE, 2013, 8(9),doi:10.1371/journal.pone.0071720.

[74] Tribedi P, Sil A K. Low-density polyethylene degradation bysp. AKS2biofilm [J]. Environmental Science and Pollution Research, 2013,20(6):4146-4153.

[75] Hadad D, Geresh S, Sivan A. Biodegradation of polyethylene by the thermophilic bacterium[J]. Journal of Applied Microbiology, 2005,98(5):1093-1100.

[76] Sivan A, Szanto M, Pavlov V. Biofilm development of the polyethylene-degrading bacterium[J]. Applied Microbiology and Biotechnology, 2006,72(2):346-352.

[77] Kaneeda T, Yokomizo S, Miwa A, et al. Biochemical machining-biochemical removal process of plastic [J]. Precision Engineering, 1997,21(1):57-63.

[78] Nowak B, Pajak J, Drozd-Bratkowicz M, et al. Microorganisms participating in the biodegradation of modified polyethylene films in different soils under laboratory conditions [J]. International Biodeterioration and Biodegradation, 2011,65(6):757-767.

[79] Yamada-Onodera K, Mukumoto H, Katsuyaya Y, et al. Degradation of polyethylene by a fungus,YK [J]. Polymer Degradation and Stability, 2001,72(2):323-327.

[80] Orhan Y, Büyükgüngör H. Enhancement of biodegradability of disposable polyethylene in controlled biological soil [J]. International Biodeterioration and Biodegradation, 2000,45(1/2):49-55.

[81] Zahrh S, Abbas S S, Mahsa M-T, et al. Biodegradation of low-density polyethylene (LDPE) by isolated fungi in solid waste medium [J]. Waste Management, 2010,30(3):396-401.

[82] Mathur G, Mathur A, Prasad R. Colonization and degradation of thermally oxidized high-density polyethylene by(ITCC No. 6052) isolated from plastic waste dumpsite [J]. Bioremediation Journal, 2011,15(2):69-76.

[83] 李 夏,顾文杰,杨少海,等.一株地膜降解真菌的筛选及其降解性能分析 [J]. 微生物学报, 2019,59(1):56-67.

Li X, Gu W J, Yang S H, et al. Screening of a plastic mulch film degrading fungus [J]. Acta Microbiologica Sinica, 2019,59(1):56-67.

[84] Pometto A L, Lee B T, Johnson K E. Production of an extracellular polyethylene-degrading enzyme(s) byspecies [J]. Applied and Environmental Microbiology, 1992,58(2):731.

[85] 冯 静.白浅灰链霉菌对聚乙烯降解效果研究及降解酶的基因克隆 [D]. 成都:四川师范大学, 2016.

Feng J. The study on the degradation of polyethylene byand degradation enzyme gene cloning [D]. Chengdu: Sichuan Normal University, 2016.

[86] 何 红,刘 沛,罗贝旭,等.一株降解淀粉填充聚乙烯放线菌的筛选以及诱变选育 [J]. 四川师范大学学报(自然科学版), 2016,39(3): 408-413.

He H, Liu P, Luo B X, et al. Isolation and complex mutagenesis of an actinomycetes with degraded starch/polyethylene powder [J]. Journal of Sichuan Normal University (Natural Science), 2016,39(3):408-413.

[87] 钟 越.ZEL-1的聚乙烯降解特性及其基于转录组测序的降解关键基因和代谢通路研究 [D]. 成都:四川师范大学, 2017.

Zhong Y. Study on polyethylene degradation characteristics ofZEL-1and its key genes and metabolic pathways of polyethylene degradation based on RNA-seq [D]. Chengdu: Sichuan Normal University, 2017.

[88] Zhao J C, Guo Z A, Ma X Y, et al. Novel surface modification of high-density polyethylene films by using enzymatic catalysis [J]. Journal of Applied Polymer Science, 2004,91(6):3673–3678.

[89] Santo M, Weitsman R, Sivan A. The role of the copper-binding enzyme–laccase–in the biodegradation of polyethylene by the actinomycete Rhodococcus ruber [J]. International Biodeterioration & Biodegradation, 2013,84:204-210.

[90] 罗贝旭.聚乙烯降解菌的筛选, 鉴定和降解特性的研究 [D]. 成都:四川师范大学, 2013.

Luo B X. Screening and identification of strains degrading polyethylene (PE) and researches on degradation characteristics of LBX-2strian [D]. Chengdu: Sichuan Normal University, 2013.

[91] Weiland M, David C, Daro A. Biodegradation of thermally oxidized polyethylene [J]. Polymer Degradation and Stability, 1995,48(2):275- 289.

[92] Roy P K, Hakkarainen M, Varma I K, et al. Degradable polyethylene: fantasy or reality [J]. Environment Science and Technology, 2011, 45(10):4217-4227.

[93] Maeng J H, Sakai Y, Tani Y, et al. Isolation and characterization of a novel oxygenase that catalyzes the first step of n-alkane oxidation insp. strain M-1 [J]. Journal of Bacteriology, 1996, 178(13):3695-3700.

[94] Scheller U, Zimmer T, Krgel E, et al.Characterization of the n-alkane and fatty acid hydroxylating cytochrome P450 forms 52A3 and 52A4 [J]. Archives of Biochemistry and Biophysics, 1996,328(2):245-254.

[95] 张小红,王亚娟,陶 红,等.宁夏土壤中PAEs污染特征及健康风险评价 [J]. 中国环境科学, 2020,40(9):3930-3941.

Zhang X H, Wang Y J, Tao H, et al. Study on pollution characteristics and health risk assessment of phthalates in soil of Ningxia [J]. China Environmental Science, 2020,40(9):3930-3941.

[96] Zheng X, Yan Z, Liu P, et al. Derivation of aquatic life criteria for four phthalate esters and their ecological risk assessment in Liao River [J]. Chemosphere, 2019,220:802-810.

[97] 沙玉娟,夏星辉,肖翔群.黄河中下游水体中邻苯二甲酸酯的分布特征 [J]. 中国环境科学, 2006,(1):120-124.

Sha Y J, Xia X H, Xiao X Q. Distribution characters of phthalic acid ester in the waters middle and lower reaches of the Yellow River [J]. China Environmental Science, 2006,(1):120-124.

[98] He Y, Wang Q, He W, et al. The occurrence, composition and partitioning of phthalate esters (PAEs) in the water-suspended particulate matter (SPM) system of Lake Chaohu, China [J]. Science of the Total Environment, 2019,661:285-293.

[99] Paluselli A, Kim S K. Horizontal and vertical distribution of phthalates acid ester (PAEs) in seawater and sediment of East China Sea and Korean South Sea: Traces of plastic debris? [J]. Marine pollution bulletin, 2020,151,doi:10.1016/j.marpolbul.2019.110831.

[100] Li T, Fan Y, Cun D, et al. Treatment performance and microbial response to dibutyl phthalate contaminated wastewater in vertical flow constructed wetland mesocosms [J]. Chemosphere, 2019,246,doi:10. 1016/j.chemosphere.2019.125635.

[101] Net S, Delmont A, Sempéré R, et al. Reliable quantification of phthalates in environmental matrices (air, water, sludge, sediment and soil): a review [J]. Science of the Total Environment, 2015,515-516: 162-180.

[102] 丁梦雨,康启越,张释义,等.全国23个城市水源水中邻苯二甲酸酯代谢物浓度调查 [J]. 中国环境科学, 2019,39(10):4205-4211.

Ding M Y, Kang Q Y, Zhang S Y, et al. National survey of phthalate metabolites in drinking source water of 23 cities in China [J]. China Environmental Science, 2019,39(10):4205-4211.

[103] Thomas W. Methods for the determination of phthalates in food [J]. Outcome of A Survey, 2009,doi:10.2787/1406.

[104] 邹德坤,王夫美,焦 姣,等.夏季学生宿舍室内降尘中PAEs污染特征和暴露评价 [J]. 中国环境科学, 2013,33(11):2075-2080.

Zou D K, Wang F M, Jiao J, et al. Pollution characteristics of PAEs derived from indoor settled dust of dormitory and exposure assessment in summer [J]. China Environmental Science, 2013,33(11):2075- 2080.

[105] 聂湘平,吴志辉,李凯彬,等.不同暴露方式下酞酸酯在黄斑篮子鱼体中的富集 [J]. 中国环境科学, 2007,(4):467-471.

Nie X P, Wu Z H, Li K B, et alEffects of different exposure ways upon the bioaccumulation of phathalate esters in[J]. China Environmental Science, 2007,(4):467-471.

[106] 韩永和,何睿文,李 超,等.邻苯二甲酸酯降解细菌的多样性、降解机理及环境应用 [J]. 生态毒理学报, 2016,11(2):37-49.

Han Y H, He R W, Li C, et al. Phthalic acid esters-degrading bacteria: biodiversity, degradation mechanisms and environmental applications [J]. Asian Journal of Ecotoxicology, 2016,11(2):37-49.

[107] 温志丹,高大文,李 喆,等.邻苯二甲酸酯降解菌的分离鉴定及降解特性 [J]. 哈尔滨工业大学学报, 2013,45(12):38-42.

Wen Z D, Gao D W, Li Z, et alIsolation and identification of phthalate-degrading bacteria and their characteristics [J]. Journal of Harbin Institute of Technology, 2013,45(12):38-42.

[108] 梁浩花,王亚娟,陶 红,等.一株同时降解3种邻苯二甲酸酯降解菌的筛选鉴定及降解特性 [J]. 环境化学, 2019,38(12):2808-2818.

Liang H H, Wang Y J, Tao H, et al.Isolation, identification and degradation characteristics of a three phthalates degrading bacterium [J]. Environmental Chemistry, 2019,38(12):2808-2818.

[109] Chao W L, Cheng C Y. Effect of introduced phthalate-degrading bacteria on the diversity of indigenous bacterial communities during di-(2-ethylhexyl) phthalate (DEHP) degradation in a soil microcosm [J]. Chemosphere, 2007,67(3):482-488.

[110] 李建龙,邵向丽,刘书亮,等.邻苯二甲酸二丁酯降解菌株的筛选鉴定及其降解特性研究 [J]. 现代食品科技, 2014,30(10):108-144.

Li J L, Shao X L, Liu S L, et al.Isolation and identification of dibutyl phthalate-degrading strain and its degradation characteristics [J]. Modern Food Science and Technology, 2014,30(10):108-144.

[111] Chao W L, Lin C M, Shiung I I, et al. Degradation of di-butyl- phthalate by soil bacteria [J]. Chemosphere, 2006,63(8):1377-1383.

[112] Chen J, Li X, Li J, et al. Degradation of environmental endocrine disruptor di-2-ethylhexyl phthalate by a newly discovered bacterium,sp. strain CQ0110Y [J]. Applied Microbiology and Biotechnology, 2007,74(3):676-682.

[113] 李容榛,李 成,赵 暹,等.一株高效邻苯二甲酸二丁酯降解菌的筛选、鉴定及其降解特性研究 [J]. 环境化学, 2019,38(10):2274-2282.

Li R Z, Li C, Zhao X, et alIsolation and identification of a highly efficient DBP degrading bacteria and its degradation characteristics [J]. Environmental Chemistry, 2019,38(10):2274-2282.

[114] 金 雷,陈 瑜,严忠雍,等.邻苯二甲酸二丁酯高效降解菌H-2的分离鉴定及其降解特性 [J]. 食品科学, 2014,35(15):202-206.

Jin L, Chen Y, Yan Z Y, et al. Isolation and identification of a di-n-butyl phthalate (DBP) -degrading strain H-2 and its degradation characteristics [J]. Food Science, 2014,35(15):202-206.

[115] 金德才,梁任星,王洋洋,等.一株DBP高效降解菌的筛选及其降解特性 [J]. 中南大学学报(自然科学版), 2010,41(1):8-14.

Jin D C, Liang R X, Wang Y Y, et al.Isolation and characterization of a highly efficient DBP-degrading bacterium [J]. Journal of Central South University (Science and Technology), 2010,41(1):8-14.

[116] Feng N X, Feng Y X, Liang Q F, et al. Complete biodegradation of di-n-butyl phthalate (DBP) by a novelsp. YJB6 [J]. Science of The Total Environment, 2020,doi:10.1016/j.scitotenv. 2020.143208.

[117] Wang P, Gao J, Zhao Y, et al. Biodegradability of di-(2-ethylhexyl) phthalate by a newly isolated bacteriumsp. RX [J]. Science of The Total Environment, 2021,775,doi:10.1016/j.scitotenv, 2020.142476.

[118] Khadka S, Nshimiyimana J B, Zou P, et al. Biodegradation kinetics of diethyl phthalate by three newly isolated strains of[J]. Scientific African, 2020,8,doi:10.1016/j.sciaf.2020.e00380.

[119] 韩 蕊,王冬莹,芮 洋,等.一株降解邻苯二甲酸酯真菌的筛选及其降解特性研究 [J]. 环境科学学报, 2013,33(11):2941-2946.

Han R, Wang D Y, Rui Y, et al. Biodegradation of PAEs by a newly isolated fungusF9. [J]. Acta Scientiae Circumstantiae, 2013,33(11):2941-2946.

[120] Vega D, Bastide J. Dimethylphthalate hydrolysis by specific microbial esterase [J]. Chemosphere, 2003,51(8):663-668.

[121] Wu X, Liang R, Dai Q, et al. Complete degradation of di-n-octyl phthalate by biochemical cooperation betweensp. strain JDC-2 andsp. strain JDC-32 isolated from activated sludge [J]. Journal of Hazardous Materials, 2010,176(1-3):262-268.

[122] Chatterjee S, Dutta T K. Metabolic cooperation ofsp. strain MTCC 4818 andsp. strain WY in the utilization of butyl benzyl phthalate: effect of a novel co-culture in the degradation of a mixture of phthalates [J]. Microbiology, 2008,154(11):3338-3346.

[123] Okamoto Y, Toda C, Ueda K, et al. Transesterification in the microbial degradation of phthalate esters [J]. Journal of Health Science, 2011,57(3):293-299.

[124] Ren L, Lin Z, Liu H, et al. Bacteria-mediated phthalic acid esters degradation and related molecular mechanisms [J]. Applied Microbiology and Biotechnology, 2018,102(3),doi:10.1007/s00253- 017-8687-5.

[125] Eaton R W. Plasmid-encoded phthalate catabolic pathway in12B [J]. Journal of Bacteriology, 2001,183(12): 3689-3703.

[126] Chang H K, Zylstra G J. Novel organization of the genes for phthalate degradation fromDBO1 [J]. Journal of Bacteriology, 1998,180(24):6529-6537.

[127] Kleerebezem R, Pol W H, Lettinga G. Anaerobic degradation of phthalate isomers by methanogenic consortia [J]. Applied and Environmental Microbiology, 1999,65(3):1152-1160.

[128] Sivamurthy K, Swamy B M, Pujar B G. Transformation of dimethylterephthalate by the fungus[J]. Fems Microbiology Letters, 1991,79(1):37-40.

[129] Ganji S H, Karigar C S, Pujar B G. Metabolism of dimethylterephthalate by[J]. Biodegradation, 1995, 6(1):61.

Progresses in microbial degradation of agricultural soil mulches.

DING Hao-jie1,2, SU Qi-qian1,2, LI Lin1,2, LI Xiao-feng1,2, XU Qi-jing1,2, RENSING Christopher1,3, LIU Xue1,2*

(1.Institute of Environment Remediation and Health, Southwest Forestry University, Kunming 650224, China;2.Institute of Ecology and Environment, Southwest Forestry University, Kunming 650224, China;3.Institute of Resources and Environment, Fujian Agriculture & Forestry University, Fuzhou 350002, China)., 2021,41(9):4231~4244

Plastic film mulching can increase crop yields by maintaining soil moisture, regulating soil temperature and limiting weed growth, thus plays an indispensable role in modern agricultural production. However, its predominant component polyethylene (PE) is stable and resistant to degradation thus being accumulated in farmland soils. In addition, phthalates (PAEs) are added as plasticizers during plastic film production, which are readily being accumulated and transported in soil and water environment, together with the high biotoxicity, posing great threats to the environment, plant, animal and human. The multi-contamination of PE and PAEs is one of the most difficult form in soil organic pollution remediation. Therefore, how to remediate plastic film mulching soils attracts increasing attention in scientific researches and plays an important role in ensuring crop production safety and human health. Compared to physical and chemical methods, bioremediation using microbial degradation shows advantages in high efficiency, no secondary pollution risk, lower cost, and less environmental disturbance. As such, the present status of agricultural film mulching application and residue in soils, and the research progress of biodegradation were reviewed in order to provide basic information and technical supports for bioremediation of organic film pollutants in farmland soils.

plastic film mulching;polyethylene;phthalic acid ester;microorganism;biodegradation;bioremediation

X53,X171,X172

X

1000-6923(2021)09-4231-14

丁豪杰(1997-),男,河南信阳人,硕士研究生,主要从事有机物污染土壤生物修复研究.

2021–01–28

国家自然科学基金项目(41867066;41907129);云南省自然科学基金项目(2019FB032);云南省教育厅科学研究基金项目(2020Y0391; 2020J0406;2021Y234);云南省高端外国专家项目(YNQR-GDWG- 2018-017)

* 责任作者, 副研究员,liuxue20088002@126.com