Effects of Different Storage Treatments on Physicochemical Indexes of Green Plums

Dongdi XIE Jun YUE Cuiyang LI Ruhan HUANG

Abstract [Objectives] This study was conducted to discuss the change laws and relationships of the physiological indexes in green plums treated with nisin or 1-MCP in the cold storage process.

[Methods]Different storage methods on the physiological and quality indexes of green plums were investigated through two kinds of different treatment methods (treatment 1: 1-MCP+cold storage, treatment 2: nisin+cold storage), with rotten fruit rate, weight loss rate, yellow ripeness index, hardness, Vc content, titratable acid, soluble solids and peroxidase (POD) activity as the evaluation indexes.

[Results] The storage method of treating green plums with 1-MCP combined with cold storage could delay the quality decline of green plums after harvest, while the effect of nisin treatment was slightly inferior. 1-MCP treatment followed by cold storage could more effectively delay the senescence of green plums, delay the decrease of fruit hardness and soluble solid content to the greatest extent, and maintain the titratable acid and Vc contents at relatively good levels. It further reduced weight loss rate and rotten fruit rate, postponed the time of the peak of POD enzyme activity, and reduced the loss of nutrients in the fruit, thereby maintaining good commercial properties of the fruit.

[Conclusions]This study plays an important role in the post-harvest storage, preservation and transportation, as well as the development of the green plum industry.

Key words Green plum; Cold storage; 1-MCP; Nisin; Physicochemical indexes

Received: April 27, 2021 Accepted: June 28, 2021

Supported by Scientific Research and Technology Development Project of Hezhou City, Guangxi (HKG 1541005).

Dongdi XIE (1968-), female, P. R. China, professor, devoted to research about storage and processing of fruit and vegetables.

*Corresponding author.

Green plums (Armenia camume Sieb.) are the fruit of fruit trees in Cerasus of Rosaceae. They are neutral in nature, sweet, sour or slightly bitter in taste. They are green when they are immature or about to be ripe, and thus get the name. Green plums are bluish-yellow when mature, and mature mainly from mid-to-late April to early June[1]. In Chinas traditional medicine, green plums are processed to dark plums, and they are officially included in the list of "both food and medicine" by the Ministry of Health[2]. Modern medical research has found that green plums also have antibacterial, anti-tumor, antiviral, and metabolic regulation effects. However, green plums are a kind of "high-acid and low-sugar" fruit, which is not suitable for raw consumption and belongs to fruits of the processing type. Since the harvest period of green plums is concentrated in the hot and rainy seasons, the harvested fruit breathes vigorously, and the storage time is extremely short. They can only be stored for about 5 d at room temperature, and are susceptible to mechanical damage and bacterial infection, causing the phenomena such as dehydration, softening and browning. High rotten rate and serious yellowing result in the decline of fruit quality, which brings great difficulties to the post-harvest processing, storage and transportation of the green plum industry. Therefore, doing a good job in post-harvest storage and transportation and preservation will play an important role in promoting the development of the green plum industry.

Temperature is an important factor affecting the metabolic process, quality and storage life of fruits and vegetables. Low-temperature cold storage is one of the most effective methods to control the quality of fruit and vegetables and extend the shelf life of fruit and vegetables[3]. 1-Methylcyclopropene (1-MCP) is an ethylene receptor blocker. When used in the preservation of fruit and vegetables, it can maintain fruit hardness, inhibit respiration, slow down the reduction of titratable acid, soluble solids and vitamin C, and maintain the aroma content of fruit[4]. Nisin can effectively inhibit many Gram-positive bacteria that cause food spoilage[5], and can significantly extend the storage life of fruit, reduce the rates of rot and weight loss, and slow down the loss of fruit contents[6]. However, there is no research report on using nisin and 1-MCP in combination with cold storage to treat green plums. In this study, we discussed the changes and relationships of physiological indexes in the cold storage process of green plums treated with nisin or 1-MCP, so as to explore a new storage method for green plums and provide more options for the preservation of green plums.

Materials and Methods

Materials

Green plums: Fresh green plums, which were free of pests, consistent in size and color, were purchased from Hezhou Hudieling Fruit Farm.

Main instruments and reagents

Reagents: 1-Methylcyclopropene (1-MCP) (produced by Shanghai Xianda Biotechnology Co., Ltd.); nisin (produced by Zhejiang Xinyinxiang Biological Engineering Co., Ltd.); catechol (AR); guaiacol (AR); 2,6-dichlorophenol indophenol (AR); ascorbic acid (AR).

Instruments: HH-S constant temperature water bath (Jiangsu Guosheng Experimental Instrument Factory); CP214 electronic balance (Guangzhou Shenhua Biotechnology Co., Ltd.); VIS-723 visible light spectrophotometer (Unico Instrument Co., Ltd.); centrifuge (Jintan Medical Instrument Factory, Jiangsu Province); GY-1 fruit hardness tester.

Treatment methods

Treatment 1: 1-MCP+cold storage, that is, 1.2 μg of 1-MCP was wrapped with a layer of paper towel, moistened with distilled water, and sealed in fresh-keeping bags together with the fruit which had been soaked with clean water and air-dried. After standing for 12 h, the fruit was stored a cold storage.

Treatment 2: Nisin+cold storeage, that is, the fruit was soaked in a nisin solution with a concentration of 0.2 g/L for 5 min and then air dried, and put into fresh-keeping bags and stored in a cold storage.

The fruit was soaked in clean water, dried and then stored under cold temperature as the control (CK). The cold storage temperatures of the control group and the experimental groups were both (6±1) ℃. The storage time was 24 d, and the experiment was done in three replicates. Samples were taken every 4 d for the determination of the rotten fruit rate, weight loss rate, yellow ripeness index, hardness, Vc content, titratable acid, soluble solids, and peroxidase (POD) activity. In order to determine whether the cold temperature (CK) has an effect on the storage of green plums, a treatment of clean water soaking at room temperature (CK room temperature) was also set up, and only the rotten fruit rate was observed.

Index measurement methods

The calculation of rotten fruit rate was as follows: Rotten fruit rate (%) = Number of rotten fruit/Total number of fruit. The weight loss rate was determined by the weighing method. The hardness was measured by a hand-held portable hardness tester. The yellow ripeness index was determined with reference to the method of Xie et al.[7]. According to the yellow area on the surface of the fruit, the fruit was divided into: grade 0 (full green, bright green), grade 1 (yellow area<20%), grade 2 (yellow area accounted for 21%-40%), grade 3 (yellow area accounted for 41%-50%), grade 4 (yellow area accounted for 51%-60%), and grade 5 (yellow area accounted for 61%-100%. The calculation formula was Yellow ripeness index = ∑ (Yellow ripeness grade × Number of fruit of this grade)/Highest grade of yellow ripeness × Total number of investigated fruit). The soluble solid content was determined by a portable handheld refractometer. For the Vc content, the 2,6-dichlorophenol indophenol titration method[8] was adopted to measure the Vc content in the fruit flesh. The determination of peroxidase (POD) activity referred to the literature [8]. For the determination of titratable acid, the sodium hydroxide titration method was used to determine the titratable acid content[9].

Results and Analysis

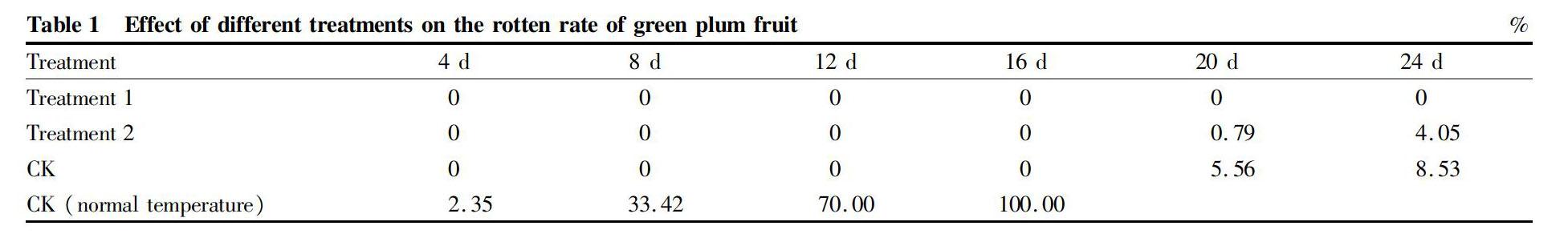

Effects of different treatments on the rotten rate of green plum fruit

The rotten fruit rate was the most direct evaluation of the appearance quality of green plum fruit. Table 1 shows that rotten fruit began to appear on the 4th d of the CK at room temperature, and the rotten fruit rate reached 33.42% on the 8th d, which far exceeded the storage requirement (must be controlled within 5%). Therefore, the CK at room temperature were not studied and analyzed for other indexes. There was no rotten fruit in the control group (CK) and the experimental groups before 20 d, and the CK and treatment 2 showed rotten fruit on the 20th d, while treatment 1 had no rotten fruit during the cold storage period, showing a significant freshness preservation effect. It can be seen that cold storage can significantly inhibit the rot of fruit and vegetables, and the storage method of 1-MCP+cold storage can further delay the maturity and senescence of fruits and vegetables. When stored for 24 d, the rotten fruit rate was 0%, and the fruit still had a certain degree of hardness, and maintained the original fruit flavor, color and quality.

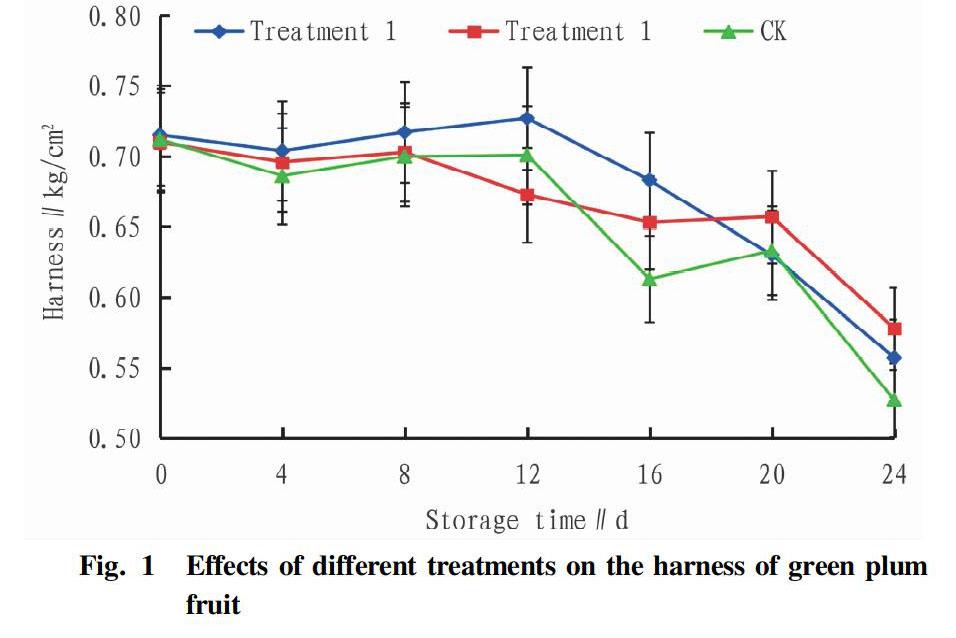

Effects of different treatments on the harness of green plum fruit

Hardness is one of the indexes for judging fruit ripeness, cold storage effect and quality[10]. The decrease of hardness and softening of flesh are important factors that limit the storage of green plums. As the fruit matures, the flesh will gradually soften and the flesh hardness will decrease significantly. It can be seen from Fig. 1 that during the whole cold storage period, the changes in fruit hardness of various treatments showed a decreasing trend to different degrees. The control CK had the largest decrease; and from 0 to 12 d, the experimental groups and the control CK group had no obvious decreases in fruit hardness, but with the extension of the cold storage time, the decrease in the hardness of the green plum fruit increased after 12 d. By the end of storage, the decrease of the CK was 26%, the decrease of treatment 1 was 22.1%, and the decrease of treatment 2 was the smallest, 19.72%. From the change trend of the data, it could be seen that the nisin treatment+cold storage method could reduce the loss of fruit water and delay the decrease of fruit hardness.

In terms of fruit preservation, 1-MCP, as an ethylene receptor inhibitor, can effectively slow down the senescence and softening of fruits. Fig. 1 shows that in the early stage of fruit hardness decrease, the effect of the 1-MCP treatment was obvious, that is, the hardness of green plums treated with 1-MCP was the highest within the storage time of 0-12 d, but in the late storage period (12-24 d), the hardness of the nisin group, on the contrary, was higher than the 1-MCP group, indicating that the inhibitory effect of 1-MCP on the decrease of hardness was mainly reflected in the early storage period.

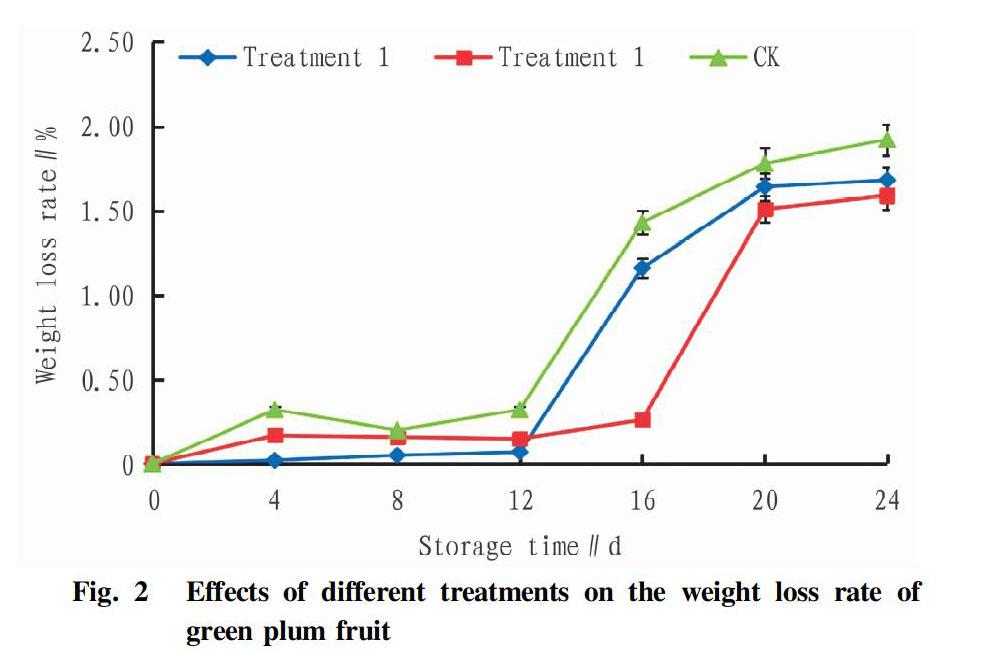

Effects of different treatments on the weight loss rate of green plum fruit

After harvesting of fruit and vegetables, transpiration and respiration will cause tissue cells to lose water and shrink within a certain period of time, which in turn causes loss of quality of fruit and vegetables and makes them lose their freshness. The weight loss rate can be used to measure the quality of green plums after harvest.

It can be seen from Fig. 2 that on the 24th d, the weight loss rates of treatment treatment 2 and CK were 1.68%, 1.59%, and 1.92%, respectively. The weight loss rates of the control group and the experimental groups were not high, and the differences were not obvious. It could be seen that cold storage, nisin, 1-MCP treatment all could inhibit the respiration of green plums, and reduce the respiration consumption of fruit and vegetables, thereby reducing the rate of weight loss. The metabolic activity of the fruit after harvesting leads to an increase in weight loss rate. After comprehensive comparison, it could be seen that the nisin+cold storage treatment could significantly reduce the weight loss rate of green plums during storage.

Effects of different treatments on the yellow ripeness index of green plum fruit

It can be seen from Fig. 3 that with the extension of time, the yellow ripeness index of the control group and the experimental groups all showed an upward trend, with similar rising amplitudes, and the yellow ripeness index of the CK was always higher than those of the experimental groups. The yellow ripeness indexes of the control group and the experimental groups changed little within 8 d of cold storage, and increased significantly on the 12th d, with an average increase of 16.32%; and at the end of storage, that is, on the 24th d, the yellow ripeness indexes of treatment treatment and CK were 68.13%, 80.19%, and 90.62%, respectively. It could be seen that treatment 1 could delay fruit ripening to a certain extent and maintain its fresh food quality.

Dongdi XIE et al. Effects of Different Storage Treatments on Physicochemical Indexes of Green Plums

Effects of different treatments on the soluble solid content of green plum fruit

The content of soluble solids (TSS) in fruit and vegetables reflects the degree of the fruits turning from sour to sweet during the ripening process. Soluble solids mainly contain sugar, and can be used to describe the process of ripening and senescence of fruit and vegetables.

It can be seen from Fig. 4 that the control CK and the experimental groups showed similar change trends, all of which were in the form of falling, then rising and finally falling. The soluble solid content decreased from 0 to 8 d, increased from 8 to 16 d, and then decreased after 16 d. Among them, CK had the smallest change range, and treatment 1 had the largest change range. The three groups of treatment treatment 2 and CK all reached the highest points of soluble solid content on the 16th d, which were 9.1%, 8.5% and 7.3%, respectively, indicating that the three treatments of cold storage, nisin and 1-MCP had certain effects on maintaining the soluble solid content of green plums during storage.

The respiratory consumption of green plums led to a decrease in the soluble solid content, and the increase in the soluble solid content was presumed to be due to the relatively strong catabolism in the fruit during the initial storage period, that is, the protein and other macromolecular substances contained in the fruit were hydrolyzed into small molecular nutrients, leading to an increase in the content of soluble solids[11].

Effects of different treatments on the content of vitamin C (Vc) in green plum fruit

Vc is an unstable vitamin and is easily oxidized and decomposed during storage. The content of Vc is closely related to the nutritional quality of green plums. The change in Vc content is an important indicator of the quality of green plums under different storage conditions[12].

It can be seen from Fig. 5 that the Vc content in green plums showed a downward trend with the extension of the storage period. Before the 12th d, the Vc content of the CK was always higher than that of the experimental groups. At the end of the storage period, i.e., on the 24th d, Vc was oxidized and decomposed. Specifically, the Vc content of the CK decreased to 1.65 mg/100 g, and the Vc contents of treatment 2 and treatment 1 were 3.07 and 3.16 mg/100 g, respectively. It indicated that proper treatment of green plums with nisin or 1-MCP before cold storage could reduce the postharvest loss of Vc in green plums.

Effects of different treatments on the titratable acids of green plum fruit

To maintain the taste and flavor of the green plum fruit, it is necessary to maintain a suitable acid content in the fruit. It can be seen from Fig. 6 that during the whole storage period, the titratable acids of the experimental groups and the control group increased first and then decreased. The peak appeared on the 16th d, and the titratable acid content was the highest in treatment 1 (4.7 g/100 g), followed by treatment 2 (4.16 g/100 g), and the lowest in the CK (3.85 g/100 g). At the end of storage, the total decreases of titratable acid content in treatment treatment 2 and CK were 0.44, 0.7 and 0.68 g/100 g, respectively. Treatment 1 had the smallest change range, treatment 2 and CK had similar changes, and the differences were not obvious. It could be seen that nisin and cold storage were not the best way to maintain the titratable acid content of the fruit during the storage period, while the total decrease of titratable acid content in treatment 1 was the least, and the loss was not large, indicating that the 1-MCP+cold storage treatment was more suitable for green plum cold storage preservation, which could well control the loss of titratable acids.

Effects of different treatments on peroxidase (POD) activity of green plum fruit

The senescence of plant organs is related to the continuous production of free radicals in plants and the continuous reduction of free radical scavengers. POD is a common oxidoreductase in fruit and vegetables, and it is also an important free radical scavenger in plants[13].

It can be seen from Fig. 7 that during the whole storage process, the change trends of POD activity of various treatments were similar. They all decreased in the first 4 d, then increased to a peak and decreased again. The POD activity peaked in the control CK and treatment 2 on the 12th d, and on the 20th d in treatment and the peaks were 5.1 5.40, and 5.24 U/kg·FW, respectively.

The 1-MCP+cold storage treatment could delay the peak of POD activity of green plum fruit. It could be seen that the 1-MCP+cold storage treatment could inhibit POD activity to a certain extent and prolong the storage period of the fruit

Conclusions

From the results of study, the soluble solid content, Vc content, and titratable acid could well reflect the nutritional quality of green plums. During the whole storage process, these three indexes generally showed a downward trend. The weight loss rate, yellow ripeness index and rotten fruit rate of the control CK were higher than those of the experimental groups, while the weight loss rate, rotten fruit rate and yellow ripeness index of the 1-MCP treatment were the lowest; and both nisin and 1-MCP treatments could delay the appearance of the peak of enzyme activity and reduce the loss of soluble solids to certain extents, and maintain the titratable acid and Vc contents at relatively good levels. After comparison, the storage method of cold storage after proper treatment with nisin or 1-MCP had an important effect on delaying the senescence of green plums, and the fresh-keeping effect of the 1-MCP treatment was better than that of the nisin treatment.

References

[1] XIA DZ. Study on the effect and mechanism of effective parts of green plum in preventing and treating hyperuricemia and gout[D]. Hangzhou: Zhejiang University, 2010. (in Chinese)

[2] XU YJ, XIAO GS, CHEN WD, et al. Research progress of green plums[J]. Science and Technology of Food Industry, 2005(1): 185-187. (in Chinese)

[3] HUA ZZ, LI YF, LIU BL. Principles and equipment of food freezing and refrigeration[M]. Beijing: China Machine Press, 1999. (in Chinese)

[4] LIANG YZ, LI LL, CHEN CK, et al. Combined effects of ozone, 1-MCP and ethylene absorbent on the quality of tomato preservation [J]. Science and Technology of Food Industry, 2018, 39(11): 275-280, 286. (in Chinese)

[5] PAN EL. Application and prospection of microorganism as natural preservation[J]. Journal of Nanping Teachers College, 200 20(2): 68-70. (in Chinese)

[6] XIE DD, QIN LD, SONG MB, et al. Effects of nisin on corm rot and storage quality of postharvest water chestnut (Eieocharis tuberose Sehult) [J]. Guangxi Agricultural Sciences, 2019, 50(2): 378-384. (in Chinese)

[7] XIE DD, MA ZW, WEI XP. Study on the preservation technology of papaya during the shelf life[J]. Storage and Process, 2018, 18(3): 28-35. (in Chinese)

[8] LI HS. Principles and techniques of plant physiological biochemical experiment[M]. Beijing: Higher Education Press, 2001: 164-248. (in Chinese)

[9] CHEM A. Official analytical chemists[J]. Analytical Chemistry, 1999, 59(19): 1133A-1133A.

[10] MA X, ZHU X, ZHAO YT, et al. Studies on the effect of tissue structure at different maturity on wooly breakdoun of apricot fruits[J]. Food and Fermentation Industries, 2015, 41(8): 203-207. (in Chinese)

[11] SITU MQ, FAN MH, TANG M, et al. Influence of ozone gas with cold storage on storage effect of post-harvest Chinese flowering cabbage[J]. Food Research and Development, 2018, 39(1): 167-171. (in Chinese)

[12] TANG HY. Studies on diseases species of major flower plants in Shanghai and root rot of Gerbera jamesonii[D]. Chengdu: Sichuan Agricultural University, 2007. (in Chinese)

[13] WANG YG, XI F, LU SM, et al. Effects of modified atmosphere packaging and ethylene absorbent treatments on green preservation and physiology in green mume[J]. Food Science, 2002(9): 102-105. (in Chinese)

- 农业生物技术(英文版)的其它文章

- Effect of Nitrogen and Density Interaction on Yield Formation of Late Japonica Rice Under Different Transplanting Dates

- Comparative Test of New Late Indica Hybrid Rice Combinations with Good Quality

- Effects of Hydrogen on Storage Decay and Antioxidant System of Strawberry

- Quality Analysis of Five Edible Wild Vegetables in Chongqing

- Grading Method of Kiwifruit Based on Surface Defect Recognition

- Diurnal Variation of Photosynthetic Physiological Characteristics of Kadsura coccinea (Lem.) A. C. Smith