A brief analysis of key points and early production characteristics of shale gas exploration and development in China

Xu Chunhua, Zhong Yunhao, Wang Chuansheng, Ke Lin, Qiu Weidong, Zhao Qian

(1. East China Mineral Exploration and Development Bureau, Nanjing 210007, Jiangsu, China; 2. Xinjiang Branch, CNPC Logging, Karamay 834000, Xinjiang, China; 3. The Unconventional Oil-Gas Headquarters of Sinopec East China Oil & Gas Company, Taizhou 225300, Jiangsu, China)

Abstract: The shale gas industry has been burgeoning in China in recent years. The Shale gas reservoirs originated from marine strata of the Lower Palaeozoic, Upper Yangtze Region, are rich in productivity. The breakthrough has also been achieved in strata of Jurassic continental facies of Sichuan Basin, and typical Triassic continental Yanchang strata of Ordos Basin. In addition, promising findings have been achieved in the Jurassic continental formations in northwest China, and in Upper Palaeozoic transitional facies in Middle Yangzi areas of South China, and the faulted basin of eastern China formed in Paleogene continental strata. It is concluded that the high quality shale gas resource zone has eight key indicators related to geochemical and sedimentary characteristics. An image discrimination method was established based on 8 indicators, namely, pressure coefficient, TOC, thermal maturity (Ro), porosity, total gas content, saturation of gas content, brittle mineral content, and black shale thickness, which can help quickly identify the shale gas productivity of underground reservoirs and evaluate whether the gas production potential can reach the industrial flow (under the horizontal well). This paper recognized that the organic matter in the organic nano pores has the mechanism of a relay into gas to generate natural gas, and further recognized that the organic pores increase at first and then decrease with maturity of organic matter (Ro), identified the Ro value of 2.60%-2.80% as the favorable pore development zone and the best gas generation window, which is also the best window for shale gas exploration. Matter phase transformation can provide effective power for shale gas discharge, and the Ro value of organic pores with optimal maturity window of shale gas exploration is 1.35%-3.00%. It is recognized that about 40%-60% of the total amount of petroleum generated from source rock is trapped in the source rock, which provides a rich material basis for the pyrolysis of gas in the later stage. The ″revolution″ of shale oil and gas exploration and development is a technological revolution alongside the breakthrough of drilling engineering technology and oil production technology. Multi-stage fracturing in horizontal well section which can increase the drainage area of gas from reservoir is the key to increase productivity. All these extend the traditional petroleum geology theory, and result in an expansion of the oil and gas exploration field potential. Based on the analysis on some shale gas production areas and China′s economic development, the paper makes a research on the early stage of the shale gas and believes that China now is still in the early stage of developing. Although China has rapidly acquired commercial development of some blocks in the marine strata, many parts of the region are yet to be accurately assessed. It is still in the initial stage of development and it will take time to be verified before it can achieve great commercial development.

Key words: shale gas reservoir; identification and evaluation; exploration feature; technical barrier; key index; industrial analysis

0 Introduction

Shale gas refers to the unconventional natural gas in the shale, where interlayer is rich in organic matter, mainly composing of methane which exists primarily in adsorption or free-state. Shale gas reservoir has the characteristics of low porosity, ultra-low permeability, high mud content and large continuous extension. Shale has a large number of nano-level pores and micro-fractures, in which the fluid is dispersed in the planar distribution of almost the entire shale layer system with low abundance. The huge volume results in a great amount of oil and gas reserves. Previously, the knowledge of the micron level characteristics of effective pores in the reservoir was based on kerosene method and mercury injection method. However, the application of argonion polishing, nano reconstruction and higher times of field emission scanning electron microscope technology has revealed the gas storage performance of nano pores(Zou et al., 2011; Wang, 2013; Guo, 2014; Wang, 2014; Zhang, 2016; Du et al., 2020; Huang et al., 2020; Sun et al., 2020). This paper recognizes that the organic matter in the organic nano pores has the mechanism of ″continuous gas formation″ to form natural gas, and further thinks that the maturity of organic matter (Ro) increases at first and then decreases. It also identifies that theRovalue of 2.60%-2.80% as the favorable pore development zone and the best gas generation window, which is also the best window for shale gas exploration. Material phase transformation can provide effective power for shale gas discharge, and theRovalue of organic pores with optimal maturity window of shale gas exploration is 1.35%-3.00%. It is recognized that about 40%-60% of the total amount of petroleum generated from source rock is trapped in the source rock, which provides a rich material basis for the pyrolysis of gas in the later stage. Meanwhile, the ″revolution″ of shale oil and gas exploration and development is a technological revolution alongside the breakthrough of drilling engineering and oil production technology. All these make the traditional oil geology theory extended and promoted, and make the field of oil and gas exploration greatly expanded.

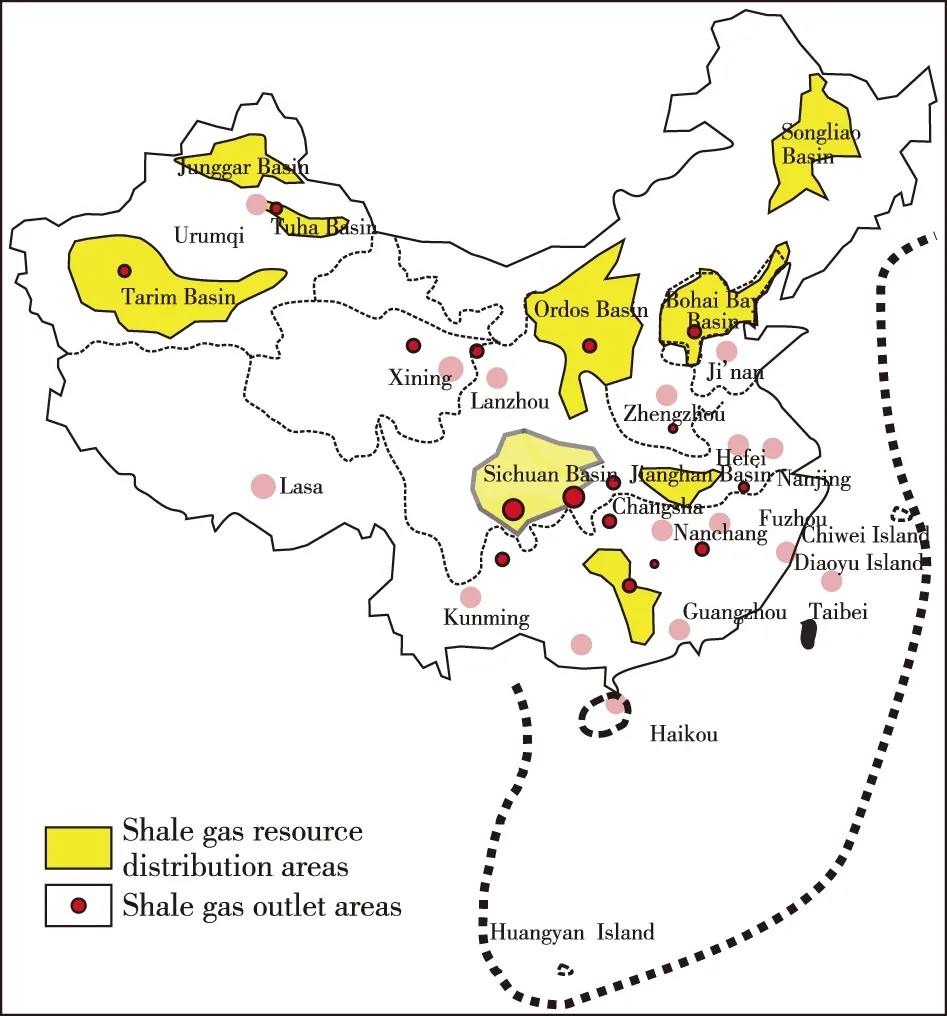

Inspired by American shale gas development and facing with the multiple pressures of environmental protection and energy security, China also kicked off shale gas projects (Fig. 1). It started to promote the development of shale gas in 2011, and launched a series of encouraging fiscal and tax policies, implemented 2 rounds of bidding, and allowed private capital and other diversified investment bodies to participate in the development of shale gas. Since 2011, China has evaluated more than 41 basins with shale gas resources and defined 180 targets. 764.3 billion m3of shale gas has been defined over several years in the Sichuan Basin and the peripheral areas of Silurian Longmaxi Formation of Lower Palaeozoic, which is marine facies strata of the Sichuan Basin. Since 2017, its Ministry of Natural Resources has also launched a grand strategy for shale gas development, pushing forward the application of shale gas in 11 provinces.

Fig. 1 Distribution of shale gas exploration in China (by July, 2019)(The picture is due north and south)

Compared with the United States, China′s shale gas reservoirs are characterized with a few disadvantages, including: deeper burial of the target layer, frequent occurrence of the tectonic movement of the target layer, higher maturity of the source rock, more content of adsorbed gas, and various sedimentary environment, high clay mineral content and high cost per well, complex terrain and high population density, small target block, and less water resource in the production area. These characteristics determine that China′s shale gas has a different material basis from the United States.

State support for shale gas industry mainly focused on fiscal subsidies and tax relief. From 2016 to 2018, it gave 0.3 RMB/m3of shale gas subsidies, which will be reduced to 0.2 RMB/m3from 2019 to 2020, according to related documents. From April 2018 to March 2021, the shale gas resource tax will be reduced by 30%. In 2019, China′s shale gas output reached 15.3 billion m3, in 2020, it reached 20.04 billion m3, and it was expected to produce 30 billion m3of gas in 2021. In 2030, it is predicted to be (80-100) billion m3.

Although shale gas development is supported by the national finance, for enterprises, shale gas construction and production investment is large in scale and takes long time to recover, when confronted with many uncertain factors including a rapid decline in production. A large number of wells needs to be drilled to maintain the stable production of gas field. Moreover, the technology of deepth development has not been fully mastered. The development of shale gas resources with a depth of more than 3,500 m places higher requirements for horizontal well drilling, completion, stimulation and improved technologies and equipment.

At present, more than half of the shale gas resources was buried deeper than 3,500 m in southern Sichuan Province. There is lack of sufficient competition in exploration and development. Mineral rights for favorable areas of shale gas mostly overlap with those of registered conventional oil and gas mineral rights, and the withdrawal mechanism of the later rights is not perfect. It is difficult to give full play to the advantages of shale gas. It is also difficult to increase investment subjects through market competition, and to expand effective investment of shale gas. Shale gas is more expensive to develop than conventional natural gas. The current tax cuts are still not enough to ease the pressure of high initial spending. After deliberation in recent years, its initial upsurge has gradually cooled down to a rational state of participation, with the intervention of enterprises.

1 Enlightenment of shale gas development status in the United States

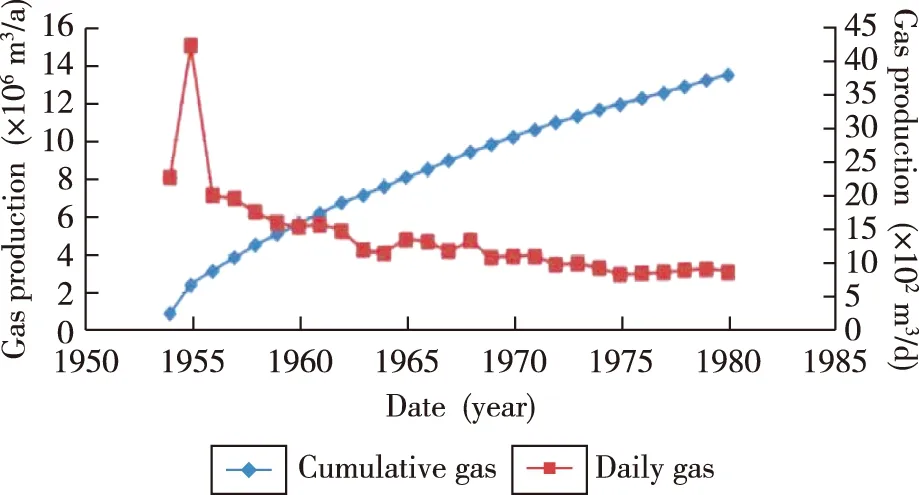

Shale gas exploration in the United States started in the 17th century. However, since the 1980s, the technology has been wrestling with severe difficulties until the beginning of this century that a technological breakthrough was achieved. According to incomplete statistics, more than 1×105shale gas (oil) wells have been drilled in the United States. The successful experience of the United States is worth learning from. According to Chinese scholars (based on Sinopec data), American shale gas presents the following characteristics: ① Diversified exploration and development participators; ② From the characteristics of single well early production, it can be seen that, in general, more than 40% of the wells in the early completion stage have no natural productivity in the early open hole test; All wells require fracturing to produce gas;55% of wells have no industrial production capacity in the initial open air flow; ③ Average fracturing production of vertical wells is about 8,000 m3/d; ④ The average fracturing output of horizontal wells can reach more than 1×105m3/d, and the maximum is 3×105m3/d; ⑤ Although the production cycle of a single well is relatively long, the initial production of shale gas is declining fast before slowing down, as is shown in the production decline curves of Devonian shale gas wells in Kentucky, United States (Fig. 2).

Fig. 2 Production decline curves of shale gas wells in Devonian strata in Kentucky, USA (1954-1980)(after Sinopec data)

A rule can be seen that in the early two years, the daily gas production was almost down by half from the peak, after 5 years it maintained at a higher level and then began to drop by a third and then kept stable for a long time. This also suggests that the shale gas itself is in the form of free-state and adsorbed gas in the reservoir. Early high yields are due to high bottom-hole formation pressure, free gas output is the priority of yielding, so gas-well yields dived (up to 65%) for the first year. In the later stage, due to pressure release, adsorption gas was gradually produced, and the output was relatively low. The annual decline rate also was reduced by about 2-3 percentage. Fracturing production is a major measure to increase and stabilize production. It requires multiple stages, multiple well stages and multiple fracturing to maintain the production capacity of a single well. It is estimated that the producing period of shale gas field can reach 30-50 years.

The production of shale gas blocks in the United States is mainly based on the well factory model. The analysis of the exploitation benefits of the 4 major shale gas blocks shows that the development of shale gas is of great risk. In the first year, it is difficult for a single well to produce more than 1.5×104m3of gas per day, with an average daily output of 7,000 m3per well. The production capacity of other non-main development blocks is relatively low, about 4,000 to 8,000 m3. Late Cretaceous Eagle Ford Formation shale, in Texas of US, rich in shale oil and shale gas, for example, its JX Well was put into production in 2010. At the beginning, it produced about 40 m3of oil and 12,000 m3of gas per day, but the production dropped rapidly. After 9 months, it produced about 3 m3of oil and 2,800 m3of gas per day. Several wells have similar development trends. In general, the average cost of producing shale gas in the US is about 0.9 RMB/m3.

2 Analysis of key points of shale gas and area selection in China

The differences of shale gas exploitation between China and the United States are not only in the resource endowment and technology level, but also the inland ownership, legislation, pipe network, market, population density and environmental protection restrictions caused by the social, mineral and land resource systems. Recently, much efforts and advances have been made in the exploration and development of China′s shale gas, as can be seen in the formations of 4 preliminary areas of Fulin, Changning, Weiyuan, and Zhaotong, but the overall shale gas exploration and development in China is still in its infancy. The development faces both challenges and opportunities: ① Oil and gas rights are not open because of inheritance of historical issues, with 80% of high quality oil and gas mines controlled by a few state-owned big oil companies; ② The great investment risks lead to hesitation of some enterprises with low anti-risk ability in the bidding blocks.

2.1 Key points of shale gas area selection

Since 2011, China has carried out shale gas resource potential assessment on several basins, and set up several large-scale shale gas demonstration zones in Changning, Weiyuan and Fuling blocks, Sichuan Province and etc. After years of research, significant achievements have been made in marine strata of the Lower Paleozoic in Sichuan Basin. The geological reserves of shale gas in marine strata of the Lower Paleozoic Silurian Longmaxi Formation in Sichuan Basin and its surrounding areas have been proved to be 764.3 billion m3. Since 2012, a number of shale gas wells have been drilled in the continental strata of Ordos Basin and Qaidam Basin, and shale gas is also found in the Jurassic continental facies in Northwest China and the Paleogene continental facies in the eastern China faulted basin.

Since 2012, 9 new stratigraphic systems have been developed in the complex structural areas outside the basins of southern China, with 10 prospective areas delineated, and a new area of 6×104km2established. In 2015, China′s shale gas production has reached 4.471 billion m3. Recent breakthroughs in shale gas exploration and development in the Yangtze River economic belt all marked steady progress in the Middle and Upper Yangtze rivers. Fuling shale gas field is currently the world′s largest outside North America, with a cumulative production of more than 10 billion m3from the beginning to May 2017. At present, there are 54 shale gas mining rights in China, covering an area of 1.7×105km2. In China, the mining cost is currently 2-3 RMB/m3.

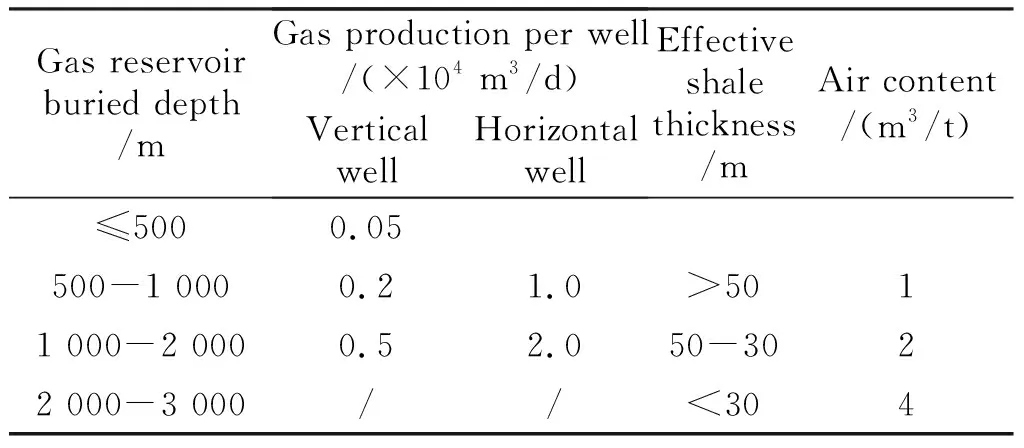

The current typical shale gas productivity construction of China generally shows the following characteristics: ① Formation energy decreases rapidly;② The composition of shale gas production has a trend of from high to low, and then remains stable; ③ Air lift technology is the most appropriate mining method; ④ It is difficult to accurately monitor production dynamic data. Shale gas, whose total organic carbon content is more than 0.5%, has a certain gas-producing potential, but production practice shows that shale gas, whose total organic carbon content is more than 2%, can be of industrial value. Shale has a very low permeability, and only with artificial fracturing can we improve the permeability to obtain industrial airflow. Shale gas content varies greatly from 0.4 to 10 m3/t, generally less than 5 m3/t. Due to the small pore size of shale, macromolecular hydrocarbon saturation content is usually low. In the early stage of shale gas exploration, some knowledge of the feasibility in a specific period were formed. The following factors were considered in the well location design of shale gas: ① The well depth was more than 500 m; ② The thickness of a single layer shall not be less than 30 m; ③ Shale inclination should not be greater than 30 degrees; ④ The well location should not be less than 3 km away from the fault. Chinese scholars set the standard suitable for their domestic conditions, but over recent years the early development practice of local regions prove that the only critical factor is pressure coefficient that determines whether the shale gas formed is preserved or not (Guo, 2014; Wang, 2014; Zhang, 2016). After several years of development, China has got experiences in efficient exploration of shale gas demonstration well layout, which helps to promote the fast development of shale gas exploration and development. Threshold of whether a shale can form an oil and gas reservoir with industrial value, namely, the starting calculation criteria of shale reservoir reserves, includes the lower limit standard of single well production, lower limit standard of gas content, and lower limit standard of total organic carbon content, and lower limit standard of vitrinite reflectance, etc. China′s Ministry of Natural Resources (the former Ministry of Land and Resources) has formulated the lower limit standard of single well gas content according to some current vertical well data (Table 1).

Table 1 Lower limit standards of gas volume and gas content of a single well

Key technical conditions for shale gas development area selection are: ① The thickness of gas-bearing shale formation segment shall be more than 50 m and buried depth more than 1,000-3,500 m; ② TOC mass fraction of marine and land-sea transitional shale should be more than 2.0%, TOC mass fraction of continental shale greater than 1.0% andRogenerally above 1.0%; ③ Brittle mineral content in the target shale formation segment should be more than 40%, and clay mineral content less than 20%; ④ Target shale gas content is greater than 1.5 m3/t; ⑤ The pressure coefficient of the target shale formation segment is more than 1.2; ⑥ The distance between shale gas wells and faults is generally more than a few kilometers, etc. Comparison of domestic and foreign shale gas selection standards is shown in table 2. It can be seen that despite of different points, there are some common factors. (Zhou et al., 2012; Xie et al., 2013; Shen et al., 2016; Wang et al., 2016; Yang et al., 2016; Shu et al., 2020).

2.2 Stratigraphic sedimentary tectonic model in shale gas deposit

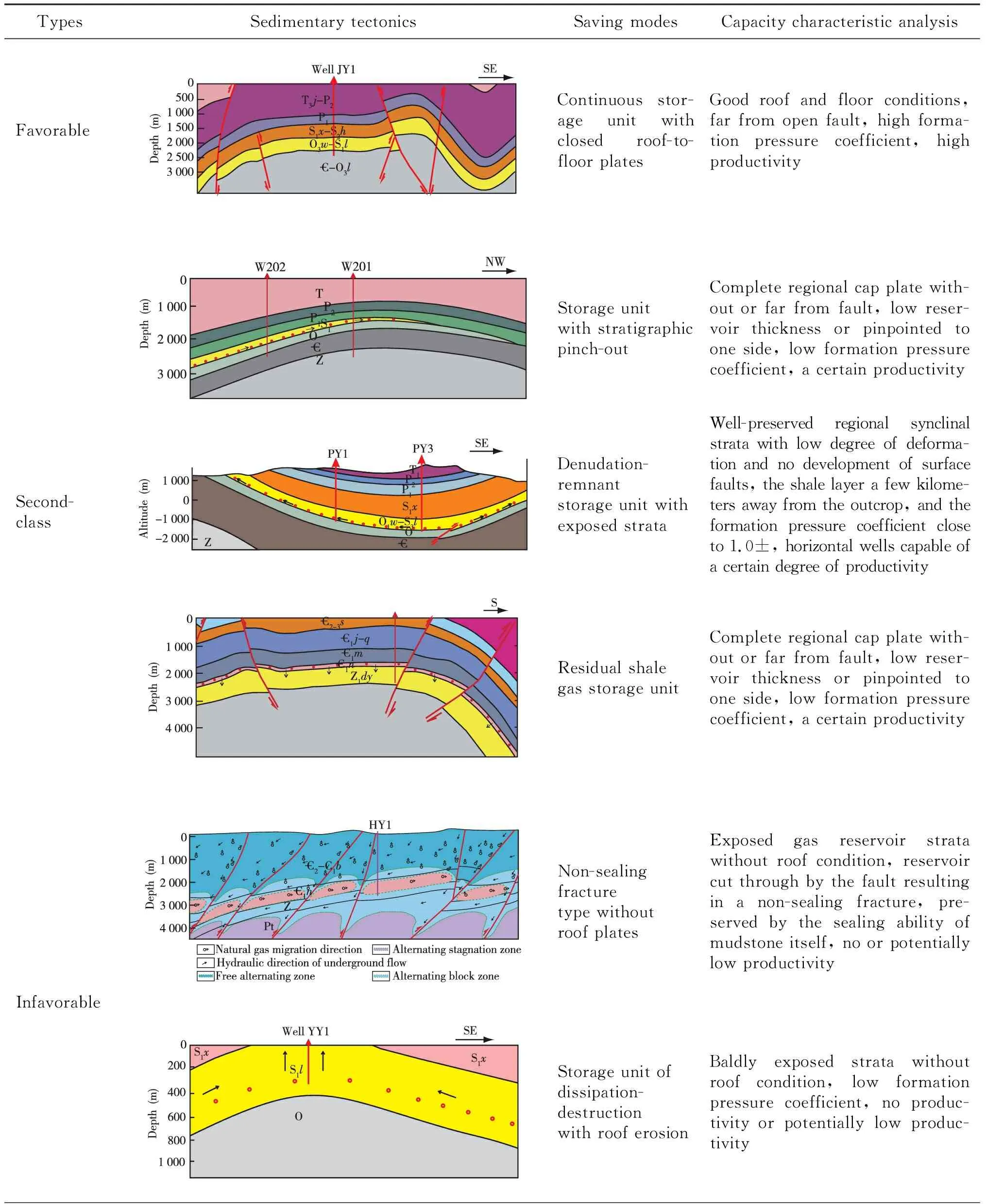

Table 3 summarizes the features of sedimentary structure model and productivity analysis of strata in typical shale gas exploration and development zones in China. As can be seen from the gas accumulation pattern diagram of all types of strata, JY1 Well has closed roof and floor conditions, is far away from open faults, and has a higher formation pressure coefficient, so it has good productivity. Compared to JY1 Well and W201 Well, HY1 Well has thicker shale, higher organic carbon content with similar roof and floor conditions (Hammes et al., 2012). However, located in the basin uplift-developed fault fold zone, HY1 Well is in the improved open environment with poor preservation conditions, resulting in a small proportion of field gas desorption, and more gas loss.

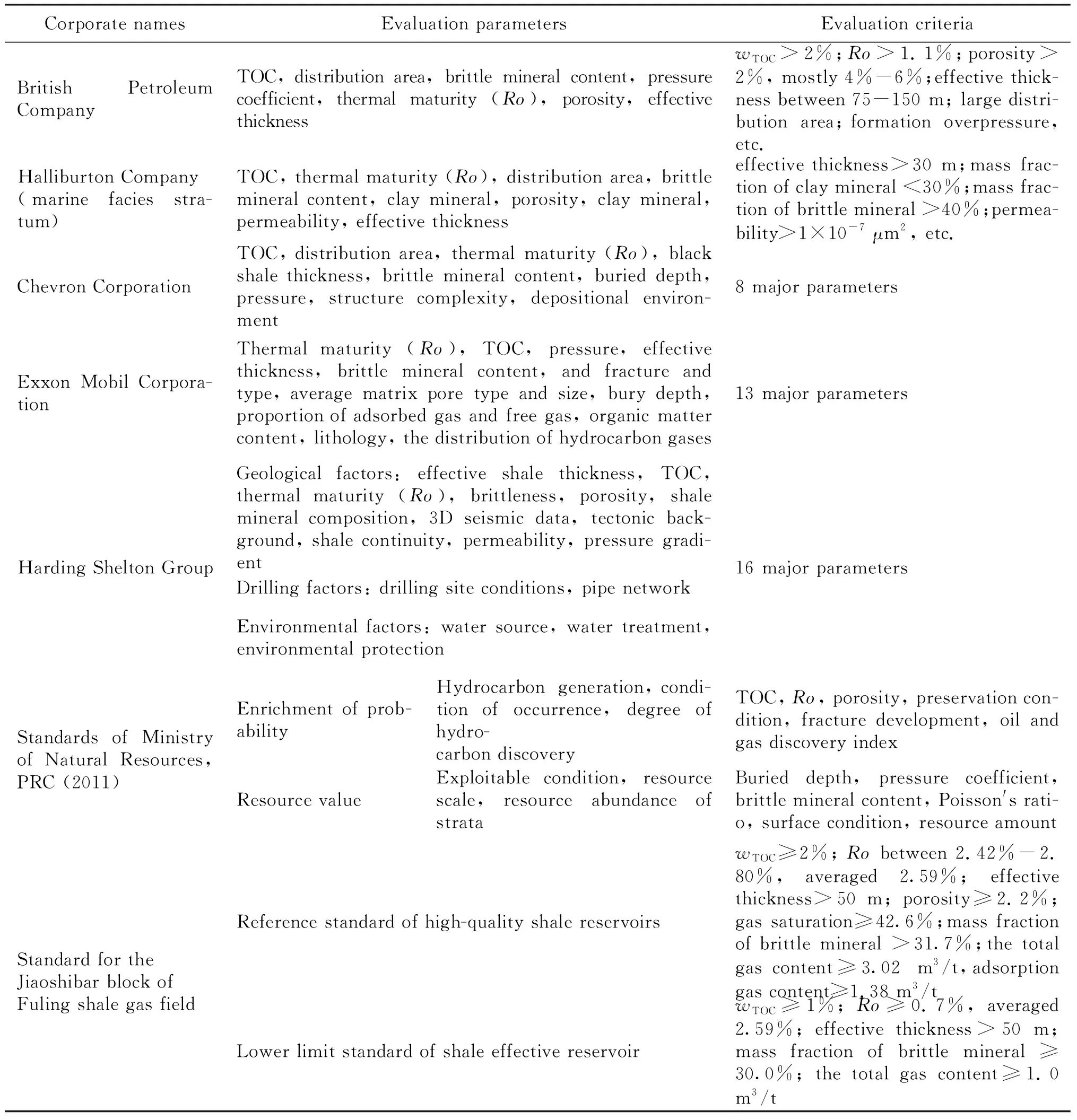

Table 2 Comparison of domestic and overseas shale gas selection standards

Table 3 Features of sedimentary structure model and productivity analysis of strata in typical shale gas exploration and development zones in China

Table 3 (continued)

With Pengshui blocks as the productivity research object, it is shown that: ① After the fracturing measures, early production was centered on free gas production. Gas production would quickly rise to the peak in a short period of time,then its production rate gradually declined, when the flow pressure dropped to roughly the desorption pressure, gas production was mainly adsorbed gas output, and remained a relatively long period of stable production. The stable gas production remained about 30%-50% of the peak output. When some wells have poor reservoir or poor fracture performance, the output could be stabilized at about a quarter of the peak volume. This is similar to the production regularity of the North American shale gas of quickly reaching gas production peak and then rapidly diminishing; ② Part of the well core field desorption experiment analysis shows that, in general, adsorption gas enrichment is the main characteristic of shale gas reservoir, but this adsorption state is relative. With the decrease of formation pressure, the occurrence state of shale gas gradually changes from absorpted status to free state. In combination with the experimental results and actual production volume, the pressure coefficient of the shale gas well generally decreased by 40%-50% in the months to come, but the rate of failure in the later stage obviously slowed down; ③ The well production characteristics analysis showed that in many cases the production did not follow the conventional gas well production curve: There was a short rise at the beginning, and then a big jump, with stability affected by technological measures.

The decline in shale gas production is usually faster than conventional gas production. Using Arps curve method to analyze data of conventional gas reservoir production requires that formation pressure is stable and production time is long enough. Generally, the production calculation results could not reliably reflect recoverable reserves because of the short production time of data section, low formation energy and unstable gas production. It can only be used as a reference. Therefore, in order to predict the trend of gas reservoir development, it is necessary to explore more effective calculating theoretical model suitable for shale gas in this area.

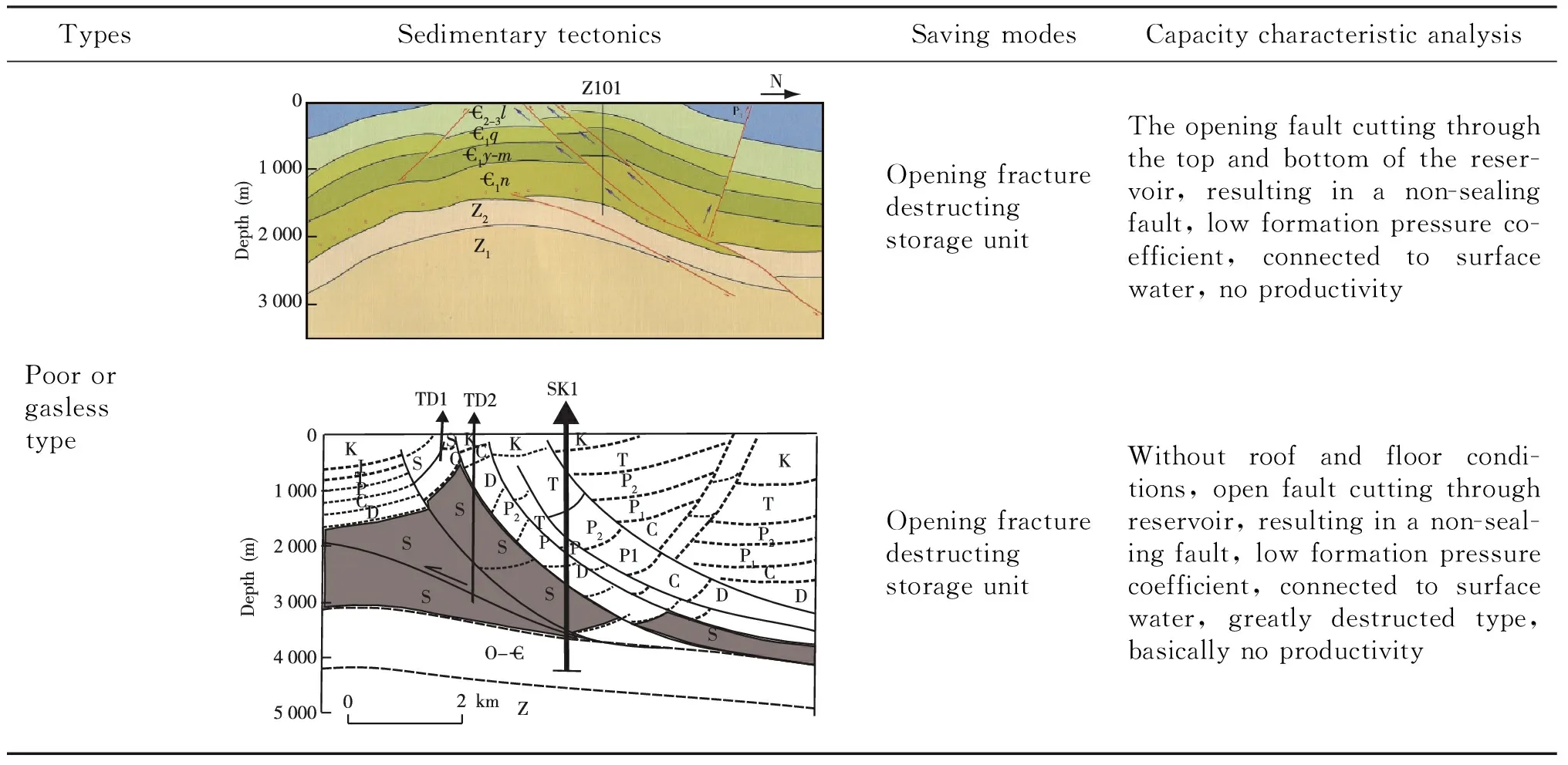

The Paleozoic strata in Sichuan Basin and its surrounding areas are typical of long mine life and large scale. The characteristics of block production capacity with good development effect of marine shale gas are analyzed and the favorable factors for high yield are summarized as follows (Guo, 2014): ① Good congenital conditions, such as rich organic shale formation, great thickness, wide distribution of rich organic matter mudstone or shale development (commonly 50 to 160 m thick), superior shale gas occurrence conditions (stable shale roof and floor, weak late tectonic movement), good preservation condition; ② High organic matter abundance, good organic matter type and general TOC of 1.0%-3.0%; ③ Slightly higher degree of evolution, which is in favor of the pyrolysis of the gas peak segment. The main production layer of the 5 peaks is the Longmaxi Formation, which is generally between 2.0%-3.6%; ④ Good physical properties and high adsorption capacity. The porosity of shale samples in the Wufeng-Longmaxi Formation averaged 2.95%-10.14%, which is generally larger than the porosity of other shale formations in China; ⑤ High formation pressure coefficient (about 1.0-1.5), which is favorable for long-term stable production. For example, in the Longmaxi Formation of southeastern Sichuan basin, the shale gas generation and distribution as well as the preservation condition is good with high pressure coefficient. For example, Jiaoshiba area, west of Qiyueshan fault zone, has high formation pressure coefficient (>1.5) of shale gas section and better storage condition. However, Fuling area, east of Qiyueshan fault zone, has low pressure coefficient (<1) in shale gas interval and relatively poor preservation conditions. The high formation pressure coefficient of shale gas well is conducive to the continuous and stable high production of shale gas formation (Fig. 3).

Fig. 3 Relationship between productivity and pressure coefficient of marine shale gas well in Sichuan Basin

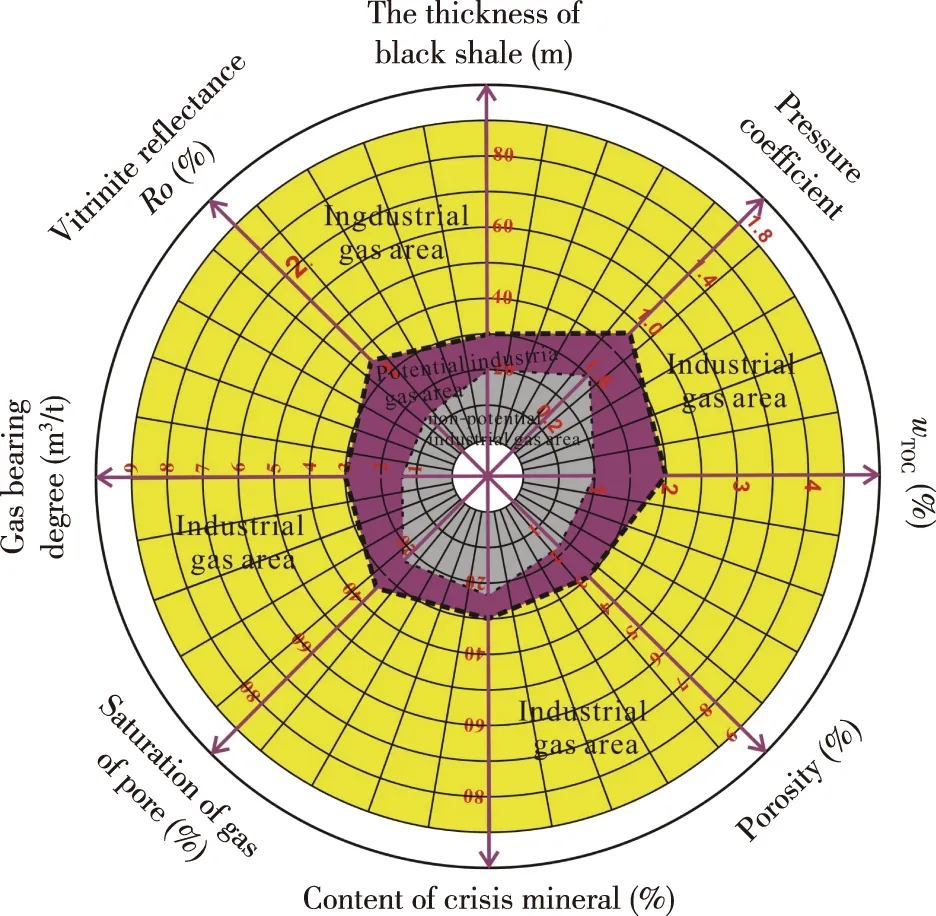

Fig. 4 Diagram of 8 key reservoir indictors in high-quality shale gas area(after Xu et al., 2020)

Fig. 5 Initial productivity diagram of typical wells in shale gas production areas, China

2.3 Key points of high-quality shale gas reservoirs

The gas-bearing property of shale is determined by sedimentary conditions and tectonic preservation conditions. Only when the conditions of hydrocarbon generation, deposition and preservation are satisfied together, can the shale form hydrocarbon source rock reservoirs and reach development value.

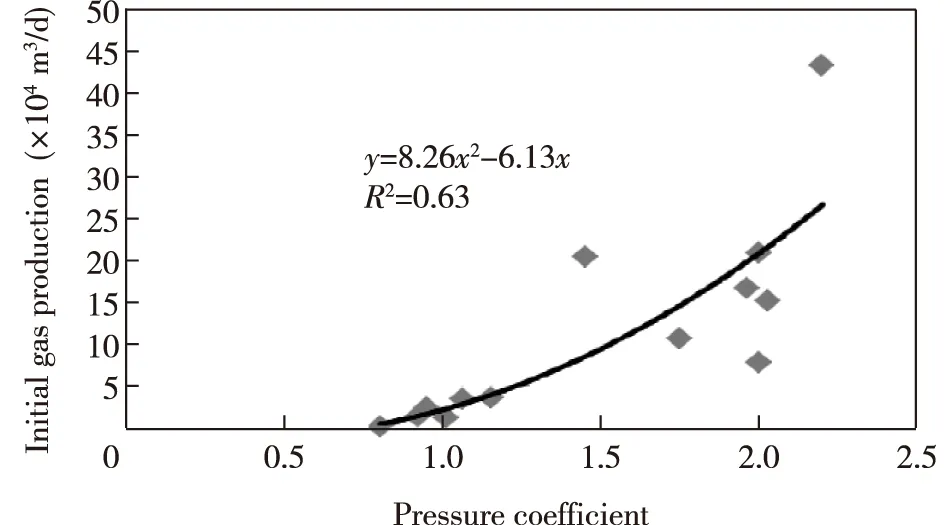

Based on the analysis and comparison of reservoir characteristics of China′s current shale gas production areas, the author summarized 8 key points. As shown in Figure 4, yellow area is the reservoir index of high-quality shale gas, orange area is the sub-optimal reservoir indexes, and gray area is the non-shale gas reservoir indexes.

As seen from the figure, the reservoir sedimentary condition and tectonic preservation condition determine the gas-bearing property of shale. Only when hydrocarbon generation, sedimentation, preservation and other conditions are satisfied together, can mud shale form hydrocarbon source gas reservoir, and reach the development value.

3 The status quo of development and characteristics of shale gas area selection in China

China′s shale gas is widely distributed in the country, and the conditions for shale gas occurrence are superior. Over 10 years of exploration and development from 2011, China has set up 5 shale gas demonstration areas,that is, Weiyuan, Fushun-Changning, Fuling, Zhaotong and Yanchang. Shale gas exploration in the Lower Paleozoic marine strata of Sichuan Basin has made significant achievement. Since 2012, shale gas flow has successively been made in continental strata of the Ordos Basin and Qaidamu Basin by multiple well drilling. In the Jurassic continental, northwest of China, Palaeogene continental faulted basin of the eastern China, discoveries have also been made. With the pushing pace of exploration and development of Upper Yangtze progressing steadily, recent breakthroughs have been made in the Middle Yangtze. The test of EYY1 Well in Yichang, Hubei Province shows that a single well can produce 123,800 m3of high-yielding flow per day, which is expected to become a new industrial gas field. At the same time, shale gas reservoirs in the Sinian Doushantuo Formation about 600 Ma ago is believed to be the world′s oldest strata.

However, it still faces the challenges of short exploration time, deeper burial of shale gas reservoirs, more complicated geology and more difficult engineering construction. For example, the deepest shale gas well in China is ZU201-H1 in Chongqing, with a depth of 6,038 m. As a result of the above contradictions, the single well development cost is relatively high.

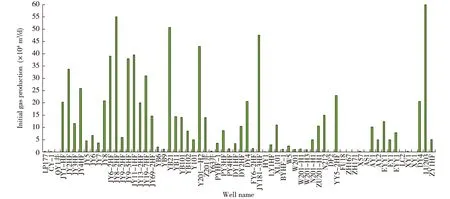

By the end of 2020, China had drilled over 1,000 shale gas (oil) wells. Shale gas is distributed in marine, marine-continental and continental strata. Progress has been made in 3 facies of shale gas and 9 series of strata. Here is the initial productivity diagram of typical wells in China′s shale gas production areas (Fig. 5).

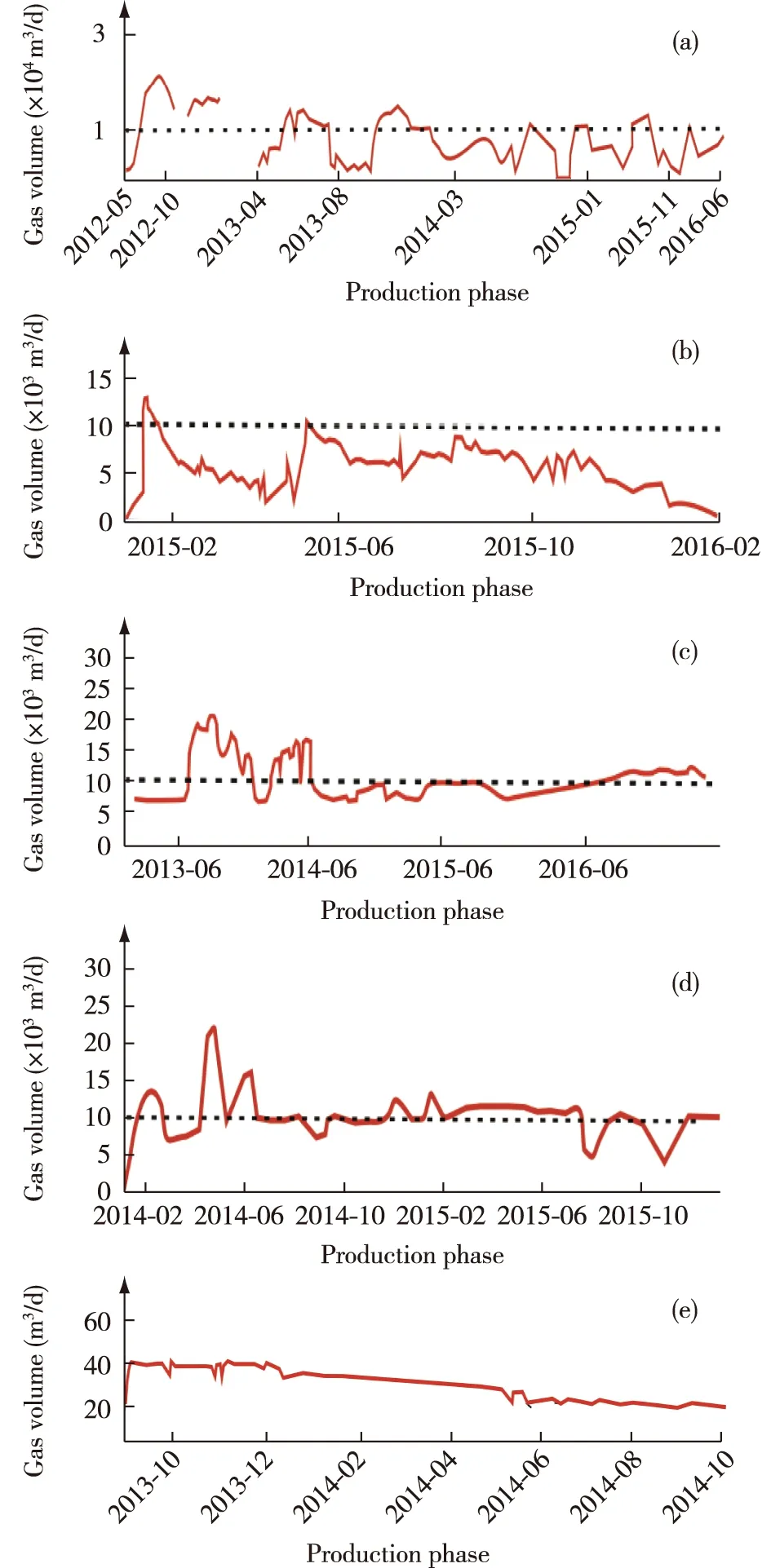

Fig. 6 The producing curves of some typical production wells in shale gas demonstration area(a) Shale gas capacity curve of Well PY1HF in the Longmaxi Formation; (b) Shale gas capacity curve of Well PY2HF in the Longmaxi Formation; (c) Shale gas capacity curve of Well PY3HF in the Longmaxi Formation; (d) Shale gas capacity curve of Well PY4HF in the Longmaxi Formation; (e) Shale gas capacity curve of Well JY2HF in the Wufeng-Longmaxi Formation

The experience of shale gas exploration shows that the 7 main controlling factors for the enrichment and high yield of marine shale gas in southern China are: ① Deep-water continental shelf as a favorable facies belt for the development of high-quality shale; ② Structural preservation condition as the key factor affecting shale gas enrichment; ③ Relatively stable structural region and good roof and floor conditions as the key to high production; ④ Formation pressure coefficient as a direct evaluation index of shale gas preservation conditions; ⑤ Good reservoir physical pro-perty as an important prerequisite for high production; ⑥ Technology as the guarantee of high production; ⑦ Horizontal well trajectory and fracturing technology as important factors affecting post-pressure production.

At present, the Sichuan-Chongqing shale gas demonstration area is primarily based on the ″factory″ production mode, with each platform drilling 4-8 wells, controlling about 5 km2of reservoir area, and the daily output of horizontal wells is in the range of ten thousand to tens of thousands m3. The factory production mode of batch drilling, not only improves drilling efficiency, but also reduces drilling and production costs at the same time, which greatly reduces the well site area and ground pollution, and accordingly the cost of land use. In some areas, researchers (Zhou et al., 2012; Xie et al., 2013; Wang et al., 2016) are also probing the way that horizontal wells are laid out in shale gas development.

3.1 Analysis of productivity characteristics of shale gas mining areas

China′s shale gas has its own characteristics. Considering shale reservoir foliation development in Sichuan Basin, local development of natural fractures, and a certain angle between the natural fracture strike and the current maximum horizontal principal stress direction, shale reservoir has the prerequisite of large-scale artificial fracturing to form a complex fracture network. It is also consistent with the fracturing technology of ″large fluid volume, large sand volume and large displacement″ of shale reservoir. Relying on technological breakthrough and management innovation, gas regions in southwest China present a set of shale gas benefit development modes in shale gas development. For instance, in Changning block, the target location is optimized to lock the high-quality layer. Rotation-guided technology is adopted to maintain the integrity and smoothness of the wellbore for rapid drilling. Factory fracturing mode is carried out with low viscosity slippery water and high strength, low density proppant and fast drilling or soluble bridge plug. Effective management mechanism also provides a strong guarantee for the effective development of shale gas. Technological breakthroughs in sweet spot area, target location optimization, optimal and fast drilling, large-scale volume fracturing, and factory operation have increased the output of shale gas in a single well and realized the technological leap of shale gas from invalid resources to effective development of a single well. The productivity curves of typical production wells in the shale gas demonstration areas is shown in figure 6.

Shale gas well productivity showed that (Fig. 6): ① Gas production would quickly rise to the peak in a short period of time, and then its production rate gradually declined. The stable gas production remained about 30%-50% of the peak output; ② In combination with the experimental results and actual production volume, the pressure coefficient of the shale gas well generally decreased by 40%-50% in the months to come, but the rate of failure in the later stage obviously slowed down; ③ The production decline is usually faster than conventional gas production. Using Arps curve to analyze data of conventional gas reservoir production requires that formation pressure is stable and production time is long enough. Generally, in calculating the shale gas well production, the calculation results could not reliably reflect recoverable reserves because of the short production time of data section, low formation energy and unstable gas production.

3.2 Analysis of favorable productivity characteristics of shale gas producing layers

In addition to the above favorable characteristics of reservoir geology, there are some optimal development engineering technology matching: ① A good match between gas well horizontal section roadway location and extension direction and production layer, the horizontal section displacement extension azimuth nearly parallel to the direction of the minimum principal stress, which is conducive to improve the fracturing transformation effect; ② When the roadway spacing of multi-branch horizontal wells is between 400-500 m, the interference between wells is small and the recovery ratio is high; ③ When the extension length of horizontal roadway is between 1,400 m and 1,800 m, the total cumulative gas production of a single well is the largest (Xie et al., 2013). The above several favorable conditions,such as the progress of gas extraction engineering technology, are also technical guarantees for the high and stable production of Paleozoic marine shale gas in Sichuan Basin.

However, due to the extremely low permeability of shale gas, it takes a long time to reach the quasi-stable flow and fracturing is often carried out, which makes the seepage extremely complex. Conventional Arps decline is suitable for stable production of oil and gas reservoirs, so there is a large error in shale gas productivity analysis. The seepage process in multi-stage fracturing horizontal well shale gas reservoir can be divided into 5 parts: unstable linear flow, bilinear flow, matrix linear flow without considering fracture, unstable linear flow from matrix to fracture, and boundary flow (Yang et al., 2017). The uniqueness of shale gas reservoir determines the complex diversity of influencing factors of shale gas reservoir productivity. The Backward & Ilk method has a better effect on shale gas production capacity dynamic analysis. Due to many problems and uncertainties in production capacity dynamic analysis, the prediction effect is not ideal. Because fractures are usually filled with calcite, fracturing is usually required before production can occur. At present, the existing dynamic analysis methods for the production and recoverable reserves of the prediction of the deviation is the main reason: ① Uncertainty of the adsorption of gas volume; ② The unique seepage mechanism of shale gas reservoir determines that it has a rapid decline in early production and long development time. Currently, the available dynamic data are very limited.

China′s continental shale gas development test zones are mainly distributed in Ordos Basin in northern China. Generally, the output of the gas-producing vertical wells is several thousand cubic meters per day, and the maximum output of horizontal wells is about 2×104m3/d.

The correspondence between the horizontal segment length and the output of shale gas wells in Sichuan Basin showed that the optimal matching could be achieved between the horizontal segment length of about 1,500 m and the economic output, otherwise the cost-benefit would decline (Zhou et al., 2012; Xie et al., 2013).

4 Preliminary analysis of economic benefits of shale gas industry

Compared with the United States who has drilled more than 1×105shale gas wells and focused on development for over nearly 40 years, China has only developed for about 10 years. It may be too early to predict the future from the limited pool of only about 1,000 shale gas wells drilled. Progress is stumbling. Although large state-owned oil and petrochemical enterprises have made some breakthroughs in the development of some shale gas blocks, they are still far from commercial value development on the whole. At present, the production cycle has been shortened, the cost of a single well reduced, and the mining and fracturing technology mastered. However, problems, such as gas gathering and transportation network failing to keep up with the development stage have led to many difficulties in rapid promotion.

An overall analysis of the present typical shale gas production areas in China showed the economic benefit can be roughly classified into 4 categories: ① Type Ⅰregion is mostly marine strata, where initial gas production of a well can generally reach hundreds of thousands of cubic meters per day. The wells of this kind have significant economic benefits, and the investment can be recovered in 3-5 years, being the most optimistic of mining prospect, such as JY6-2HF Well. Since its production, it has produced gas of 300 million m3; ② Type Ⅱregion is also mostly the marine strata where initial daily gas production of a well can generally reach tens of thousands of cubic meters. The wells of this kind of production area have good economic benefits and the investment can be recovered in 5-10 years. Mining prospect can be optimistic. For example, the daily output of shale gas wells in Nanchuan District of Chongqing in Sichuan Basin can reach (1-2)×105m3. Weiyuan and Changning demonstration areas also have gas wells where daily output can reach tens of thousands of cubic meters. Wells of such high production with an annual output value of tens of millions RMB only account for a minority of total wells, taking over 5 years to recover its investment. These high-yielding wells of considerable economic benefit are mainly distributed in the marine strata of the Upper Yangtze region; ③ Type Ⅲ class region reservoir is relatively poor, located in relatively thin marine strata or marine and continental stratigraphic area. Initial daily gas production of a single well can peak at tens of thousands of cubic meters, but only thousands of cubic meters in stable time. Wells of this kind need over 10 years in getting back investment. The long-term economic benefit depends on technical development observation. Taking the wells with better production conditions in Pengshui shale gas area as an example, although the initial horizontal well can produce tens of thousands of cubic meters per day, the discontinuity of drainage and production interrupted by well shut-in, pump inspection, well workover and tank filling leads to the failure of the multiple wells to produce at full capacity all years round, and the average annual production cycle is also usually to be less than 200 days; ④ Type Ⅳ region reservoir is typically continental strata area, where vertical wells are generally difficult to meet the industrial standards. Initial daily gas production of horizontal wells keep stable only at thousands of cubic meters per day, difficult to surpass 5 000 m3/d, leading to pessimistic investment prospects. It is doubtful that these wells will pay for themselves in 20 years.

At present, China encourages a variety of investment bodies to get involved in the shale gas field, but the technical threshold for exploiting shale gas is relatively high, and there is still a market monopoly in gas pipe network collection and transportation.

Moreover, many companies of the industry cannot make profit from the market because companies such as PetroChina and Sinopec own the advantageous royalty interest and supporting technologies. Therefore their original driving force has been cooling down.

The shale gas areas that have been developed in China are mainly located in the mountainous terrain. In addition to learning from the advanced technology and successful experience of foreign countries, researchers should also aim at the characteristics of mountainous landforms and ecological environment, and try to develop large displacement wells and cluster horizontal wells, thus to efficiently develop a new model of wells, and actively carry out related research and field tests. The key to achieve industrialization development is whether the cost is reduced through technological improvement.

5 Conclusions and recommendations

(1) Sichuan Province and Chongqing City have been the main gas-producing areas since China′s shale gas industry thrived. Many wells that are so called shale gas wells are not shale gas at all. They may be gas producing from other unconventional reservoirs such as tightly mixed layers, argillaceous sandstones, and limestone strata. With the new academic concept of shale, professional energy companies attempt to seek more fiscal subsidies, while the gas-rush from the unconventional energy companies further complicates the situation of the marketable push for shale gas.

(2) The unique characteristics of shale gas in China determine that there are differences in the material basis of shale gas industry at home and abroad. Although there are several sets of strata in China which have the potential for shale gas exploration, and even some reserves in the demonstration areas (Jiaoshibar) are of more abundance than conventional oil and gas, the author believes that the development of oil and gas in thin sandstone or non-mud shale with the same cost of investment and technology could be more productive, more economic and less risky than the development of some deep shale gas.

(3) Considering the current production of shale gas area, the innate superiority of marine strata in China is obvious, although the continental shale gas only obtains low-yielding gas flow in some wells in some regions. Whether it can reach the commercial value still takes time to be verified.