Extreme Engineering:Polarization in Product Development and Manufacturing

Andrew Kusiak

Department of Industrial and Systems Engineering,The University of Iowa,Iowa City,IA 52242-1527,USA

1.Introduction

Products and solutions are usually developed to meet customer needs at a cost justified by the market.New technologies are likely to be adopted by promising applications involving tolerable risks.Over time,some application domains become saturated with new technologies.This naturally occurring market phenomenon and progress in the technology itself are likely to lead to new developments that normally would not be considered.The industry needs to be prepared to tolerate a higher risk associated with the departure from a routine technology path.Some of these new applications could involve extreme developments in technology that are discussed in this paper.

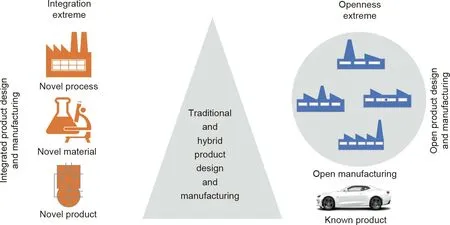

As a discipline,engineering is closely aligned with technology.Two domains of engineering activity,product design and manufacturing,will be used to hypothesize characteristics of the emerging extrema:an integration extreme and an openness extreme(Fig.1).

2.The integration extreme

The integration extreme is illustrated with perovskite solar cells[1].Based on the promise of generating more energy at a cost lower than photovoltaic(PV)solar cells,several corporations are pursuing research and development projects aimed at bringing perovskite solar panels to the market.Despite incomplete evidence of the advantages of perovskite cells over existing solar energy generators,substantial research programs in materials(e.g.,powders),manufacturing processes(e.g.,using powders in additive manufacturing),and the design of solar panels(e.g.,layered structures),have been launched.

3.The openness extreme

An open manufacturing enterprise is a collection of physical assets and services configured for the purpose of producing products.In many instances,physical manufacturing assets will operate in a manufacturing service mode.These developments will gradually shift the focus of competitiveness from the internally developed technology to the acquisition of knowledge and the ability to configure,reconfigure,and optimally operate distributed services and their physical assets.

Both engineering extrema will initially make up a small percentage of all product development and manufacturing activities(Fig.1).Most product development and manufacturing activities will follow the traditional and hybrid(integration and openness extreme)business path.However,it is likely that the middle area in Fig.1 will shrink in time as the two extrema expand.

Fig.1.Two extreme enterprise architectures.

4.Why extreme engineering?

Thus far,progress in engineering,including engineering design and manufacturing,has largely been evolutionary.The future years are likely to bring more dramatic changes to engineering design and manufacturing.The covalence of progress in the development of new materials(e.g.,architected materials that respond to a mechanical force,magnetic field,or another stimuli),manufacturing technology(e.g.,4D printing),artificial intelligence,digitization of the industry,and increasingly dynamic markets has contributed to the emergence of integration and openness extrema in product development and manufacturing[2].

The integration extreme is amenable to the development of disruptive products and technologies.The novelty of these products and technologies will naturally lead to the protection of knowhow.Once in place,capacity expansion of the discovered manufacturing processes will become a prevailing growth mode to meet the market needs.An integrated enterprise is not likely to promote its manufacturing services in the cloud,as its primary focus is to compete on the novelty of products.However,an integrated enterprise could contribute or use services—such as supply and/or distribution—that are available in the cloud.

The openness extreme will be instantiated as an open enterprise comprising services such as product development,manufacturing,and logistics,none of which would need to be owned by the enterprise itself.The openness extreme has its origin in four phenomena:①shortening product use time,②growing variability of product demand,③growing service orientation of enterprises(including service manufacturing),and④proliferation of the concept of shared economy in manufacturing[3].Products with shortened longevity may create pressure on a manufacturing capacity and capability that could not be sustained.A scenario in which the demand for a product may increase n-fold in a short time is likely[4].Meeting such market conditions by means of internal expansion of the manufacturing capability and capacity would be neither feasible nor cost effective.However,a rapid expansion of production capability and capacity based on the concept of shared and service manufacturing is feasible.

Basic characteristics of the integration and openness extrema are summarized in Table 1.

5.Open product development and manufacturing

Over the past decades,industry has been perfecting the design-for-manufacturing approach.The goal of this approach is to design products and components for manufacturing accordingto their specifications without design changes.Design-for-manufacturing(or dedicated manufacturing)principles have become widely practiced in industry.Tools have been developed in support of design-for-X beyond discrete manufacturing and assembly processes.

Table 1 Characteristics of the integration and openness extrema.

Many future products are likely to be designed for manufacturing processes not known at the design phase.In open manufacturing,such design practice will be driven by

(1)Growing market dynamics that may not tolerate the usual development time needed to build or expand the existing manufacturing facility;and

(2)Separability of the physical and cloud assets of manufacturing;

and will be supported by

(3)Experience with the design-for-manufacturing procedures and tools;and

(4)The concept of shared manufacturing resources.

Some designs will be created by design-as-a-service enterprises.Design for manufacturing-as-a-service is an instance of design for open manufacturing.At least three existing industrial practices support the evidence that industry has been moving toward the manufacturing configuration model hypothesized in this paper.These are:①contract manufacturing(e.g.,Foxconn manufacturing Apple products);②subcontracting;and③outsourcing services.

In an enterprise of the future,some of these services may be owned and operated by the enterprise itself,while others may constitute independent business entities and be spatially distributed across the globe.

6.Examples of domains of extreme engineering

For reasons ranging from the limits of current technologies to the changing markets and climate conditions,the concept of extreme engineering is likely to enter every domain of engineering activity,including:

(1)Civil engineering,as extreme weather patterns impact the design of buildings and structures;

(2)Computer engineering,as neural networks have progressed in their scale and capability to model the complex phenomena reflected in their names,such as extreme,deep,and broad neural networks;

(3)Environmental engineering,as the water level of rivers and the operations of hydropower and wastewater processing plants are impacted by the changing rainfall patterns;

(4)Energy,as the operations of electrical equipment,energy generators,and the pick demand for electricity are impacted by extreme weather conditions;

(5)Electronics,as the historical adherence to Moore’s law pressures the semiconductor industry to explore new technologies,including quantum computing;

(6)Manufacturing processes,as high-precision components for medical,industrial,and consumer products call for scales and tolerances not seen in the past.High-precision material technologies have been reviewed in Zhang et al.[5].Fang et al.[6]summarized the progress in close-to-atomic-scale manufacturing.The status of the extreme-ultraviolet light source for high-volume manufacturing has been reviewed by Fujimoto et al.[7].Unexpected changes in the product mix and volume due to natural disasters and pandemics such as coronavirus disease 2019(COVID-19)need to be factored in product design and manufacturing requirements;

(7)Transportation,as aviation,personal vehicles,and public transport all react to extreme weather conditions and pandemics.

7.Conclusion

Science is in search of solutions for problems that have not been addressed.One could hypothesize that the ideas with the highest impact emerge outside the mainstream domains of research,from gene editing in biology and medicine to the discovery of new planets.The concept of generative adversarial networks can be considered as an extreme development in data science.Recent applications of generative adversarial networks were presented in Kusiak[8].These developments support the emergence of extreme science as a discipline of future research.

Analogous extreme developments can be observed in engineering.This paper has focused on two engineering extrema:an integration extreme and an openness extreme.The integration extreme was illustrated with the product development and manufacturing case involving a novel material,product,and manufacturing process.The integration extreme is at the core of innovation.

An open enterprise was selected as an example of the openness extreme.Such an enterprise would be a collection of services,including service manufacturing.In both extrema,the original business entity would not need to own any product development assets;rather,all would be configured from open services.The original business entity would own a product,and its focus would be on the developmant of new ideas(e.g.,products),rather than usual product development and manufacturing activities.Examples of extrema in several engineering disciplines were provided.These examples offer evidence that extreme engineering deserves attention of the research and practice community.

- Engineering的其它文章

- Process Intensification in Pneumatically Agitated Slurry Reactors

- New Standards Release Sets Stage for 5G Future

- Fundamentals and Processes of Fluid Pressure Forming Technology for Complex Thin-Walled Components

- Extreme Learning Machine-Based Thermal Model for Lithium-Ion Batteries of Electric Vehicles under External Short Circuit

- Progress in Research and Development of Molten Chloride Salt Technology for Next Generation Concentrated Solar Power Plants

- Evaluation Method and Mitigation Strategies for Shrinkage Cracking of Modern Concrete